Medium Strength Threadlocker BLUE

PRODUCT DESCRIPTION

PERMATEX〉 Medium Strength Threadlocker BLUE is a medium strength anaerobic threadlocking material, which cures between engaged threads to form a unitized assembly that resists virtually all leakage, shock and vibration. The product is a single component, anaerobic liquid that cures when confined in the absence of air between close fitting metal surfaces. Ideal for all 1/4 inch to 3/4 inch diameter nut and bolt assemblies. Excellent chemical resistance with a temperature resistance range of -175°C to +150°C (-65°F to +300°F). Easily removable with hand tools for servicing requirements. OEM Specified. NSF White Book registered.

PRODUCT BENEFITS

Improved Reliability

- Eliminates vibration issues

- Seals against leakage

- Prevents rusting of threads

- Cures without cracking or shrinking

Easy Application

- No mixing

- No curing outside of joint

- Thixotropic: resists dripping from threads during assembly

- No torque compensation required during assembly

TYPICAL APPLICATIONS

Prevents loosening and leakage of threaded fasteners. Particularly suitable for applications such as:

- Belt tensioner bolts

- Pulley bolts

- Cup and core plugs

- Fan hub bolts

- Visor mount bolts

- Starter mounting bolts

- Alternator Mounting Bolts

- Intake Manifold Bolts

- Valve Cover Bolts

- Vacuum Adjustment Screws

- Oil Pan Bolts

- Axle Cover Screws

- Drive Shaft Bolts

- Disc Brake Caliper Bolts

- Gearshift Knobs

DIRECTIONS FOR USE

For assembly

- Clean all threads (Bolt and Hole) with a cleaning solvent such as PermatexâBrake and Parts Cleaner and allow to dry.

- Determine if the threads to be bonded are Active or Inactive Metals (Ref: Cure Speed Substrate on the second page). If material is an Inactive Metal, spray all threads with Permatexâ Surface Prep and allow 30 seconds to dry . Priming is not required if the material is an Active Metal. If unknown, it is always best to use the primer.

- Shake the product thoroughly before use.

- To prevent the product from clogging in the nozzle, do not allow the tip to touch metal surfaces during

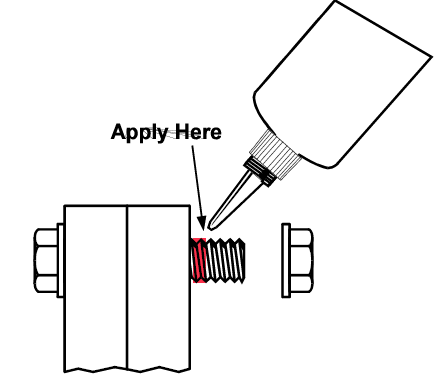

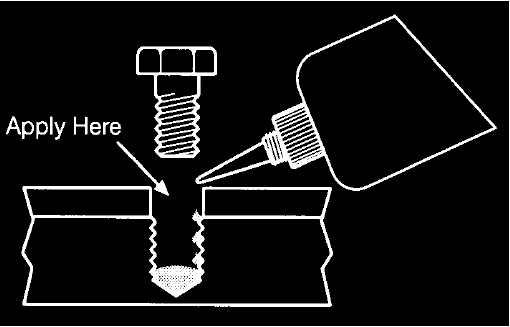

- For Thru Holes, apply several drops of product onto the bolt at the nut engagement

- Assemble and tighten as When tightening to established torque values, torque compensation is not required.

For Cleanup

- Residual liquid films and/or fillets outside the joint are readily soluble in Permatex Brake and Parts

- Cured product can be removed with a combination of soaking in Permatex Gasket Remover and mechanical abrasion such as a wire

For Disassembly

- Remove with standard hand

- In the rare instance where hand tools do not work, because of excessive engagement length, apply localized heat to nut or bolt to approximately 232°C (450°F). Disassemble while hot.

For Reassembly

- Remove loose product from nut and

- Apply primer to all threads, regardless of metal

- Assemble and tighten as usual.

TYPICAL CURING PERFORMANCE

Cure speed vs. substrate

The rate of cure will depend on the material used. PERMATEX® Medium Strength Thread locker BLUE will react faster and stronger with Active Metals. However, Inactive Metals will require the use of a primer (Surface Prep) to obtain maximum strength and cure speed at room temperature.

| Active Metals | Inactive Metals |

| Soft Steel Iron | Bright Platings |

| Copper | Anodized Surfaces |

| Brass | Titanium |

| Manganese | Zinc |

| Bronze | Pure Aluminum |

| Nickel | Stainless Steel |

| Aluminum Alloy | Cadmium |

Cure speed vs. temperature

The rate of cure will depend on the ambient temperature. Full cure is attainable in 24 hours at room temperature, 22°C (72°F), or 1 hour at 93°C (200°F).

Cure speed vs. primer

To shorten cure time or if an inactive surface is present, applying a primer (Surface Prep) to the surface will improve cure speed. A 3/8-16 steel nut and bolt assembly will fixture in 5 minutes using a primer, while fixturing will occur in 20 minutes without a primer. Full cure in 24 hours for both procedures.

TYPICAL ENVIRONMENTAL RESISTANCE

Temperature Resistance

Product temperature range from -175°C to +150°C (-65°F to +300°F). The Breakaway and Prevailing Torque values decrease as temperature increases, however the assembly remains effective against vibration and leakage.

Chemical / Solvent Resistance

The product retains effective properties in contact with automotive fluids, such as motor oil, gasoline, brake fluids, transmission fluids, alcohol and antifreeze solutions.

GENERAL INFORMATION

This product is not recommended for use in pure oxygen and/or oxygen rich systems and should not be selected as a sealant for chlorine or other strong oxidizing materials. For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

This product is not normally recommended for use on plastics (particularly thermoplastic materials where stress cracking of the plastic could result). It is recommended to confirm compatibility of the product with such substrates.

ORDERING INFORMATION

| Part Number | Container Size |

| 24206 | 2.5 ml bottle |

| 24200 | 6 ml bottle |

| 24240 | 36 ml bottle |

| 24283 | 90 ml bottle |

| 09178 | 1 mil pouch, display box |

OEM Interchange

| Manufacture | OEM Specifications Numbers | |

| BMW | 07-58-9-056-031 | 0121874 |

| Chrysler (Mopar) | 4318031 | |

| Fiat | 976173410

639197110 |

639147100 |

| Ford | EOAZ-19554-AA | WSK-M2G351-A5 |

| GM | 12345382

1700.09985283 |

9985283 |

| Isuzu | 1-8844-9032-0

9-8893-2601-0 |

1-8844-9033-0

9-8893-2605-0 |

| Maxiun | 15060003 | |

| Mazda | 105177743 | |

| Mercedes Benz | A00398931710011 A00398931710004 | A00398931710002 A00398931710005 |

| Opel | L0010184 | L0020184 |

| Saab | 7990963 | 7496268 |

| Scania | 814283 | |

| Toyota | 00001-01003 | |

| Valmet | 78723013 | |

| Volvo | 591255

8701007 |

1161054 |

| VW/Audi | AMV197500 | |

STORAGE

Products shall be ideally stored in a cool, dry location in unopened containers at a temperature between 8° to 28°C (46° to 82°F) unless otherwise labeled. Optimal storage is at the lower half of this temperature range. To prevent contamination of unused product, do not return any material to its original container.

NOTE: The data contained herein are furnished for information only and are believed to be reliable. We cannot assume responsibility for the results obtained by others over whose methods we have no control. Permatex, Inc. specifically disclaims all warranties expressed or implied, including warranties of merchantability or fitness for a particular purpose, arising from sale or use of Permatex, Inc. products and disclaims any liability for consequential or incidental damages of any kind, including lost profits. This product may be covered by one or more United States or foreign patents or patent applications.