OWNER’S Manual

1303248701 Rev F 0616

06/2010

Thank you for buying a Hayward pool heat pump.

The Hayward pool heat pump is a self-contained unit designed specifically for pool heating. Each component has been selected with care to achieve a high-quality product in an

the effort to exceed all industry standards.

All Hayward pool heat pumps have an electronic board with a service analyzer, a titanium heat exchanger tube warranted for 10 years against corrosion, and a UV-resistant plastic cabinet that eliminates all maintenance for life. All components are of superior quality, which presents you with an effective, state-of-the-art technology heat pump.

Compared to other types of pool heaters, such as gas or oil-fired, the Hayward pool heat pump has a lower heating capacity on a BTU/hr basis. Therefore, it needs to operate for a longer time to accomplish the desired results. Occasionally, it may be necessary to run the heat pump for up to 24 hours per day. However, this should not be of concern to the owner because the heater is designed to operate continuously. What’s more, despite continuous operation, it will still heat the pool far more economically than other types of heaters.

As with all pool heaters, you are advised to use a pool cover at night and when the pool is not in use. The pool cover should be used if night temperatures are 15°F less than desired pool temperature. This will keep evaporation, the greatest source of heat loss, to a minimum, thus greatly reducing the overall pool heating costs. During warmer weather, the pool cover may not be required.

Please read carefully

Record your model’s information

Please complete and mail in the ownership registration card provided with this guide. The return address is displayed on the front of your registration card. Simply mail it as you would a postcard. The card helps us notify you about any new information about your heater.

Whenever you call to request service for your heater, you must know your complete model and serial numbers. You can find this information on the plate located at the base of your heater. Please also record the purchase date of your device and your dealer’s name, address, and telephone number.

Model Number ____________________________________________________

Serial Number _____________________________________________________

Purchase Date ____________________________________________________

Dealer Name ______________________________________________________

Dealer Address ____________________________________________________

Dealer Phone _____________________________________________________

Keep this book and the sales slip together in a safe place for future reference.

Service can be obtained by calling these phone numbers.

CANADA: 1 888 238-7665

USA: 1 908 355-7995

General Safety Instructions

We care for our customers

We have provided important safety messages in this manual and on your heater. Always read and obey all safety messages.

![]() IMPORTANT

IMPORTANT

The IMPORTANT sign calls attention to a note that provides important information or information essential to the completion of a task.

![]() CAUTION

CAUTION

The CAUTION sign denotes a hazard. It calls attention to an operating procedure, practice, or the like, which, if not correctly performed or adhered to, could result in material damage, particularly to the product, up to the destruction of part or all of the product.

![]() WARNING

WARNING

The WARNING sign denotes a hazard. It calls attention to a procedure, practice, or the like, which, if not correctly performed or adhered to, could result in personal injury or injury to a third party. These signs are rare but are extremely important.

![]() CAUTION All electrical connections must be done by a qualified electrician and according to the local electrical codes. Always disconnect the unit’s main power whenever the access panel is open or removed. Always install the machine outdoors (unless otherwise approved by the manufacturer), while respecting the minimal clearances needed for proper operation and heating.

CAUTION All electrical connections must be done by a qualified electrician and according to the local electrical codes. Always disconnect the unit’s main power whenever the access panel is open or removed. Always install the machine outdoors (unless otherwise approved by the manufacturer), while respecting the minimal clearances needed for proper operation and heating.

![]() CAUTION

CAUTION

Proper pool chemistry is vital to the life of your heater. Pay particular attention to the total alkalinity and TDS. It is highly recommended that you have your pool chemistry checked often by an independent pool store.

Installation Instructions

ATTENTION!!! CONSUMER KIT LOCATED BEHIND FRONT PANEL

Location

The placement of the pool heater is very important in keeping installation costs to a minimum while providing for maximum efficiency of operation, as well as allowing adequate access for service and maintenance.

The pool heat pump is designed for outdoor installation and should not be installed in a fully enclosed area, such as a shed, garage, etc. Recirculation of cold discharged air back into the evaporator coil will greatly reduce unit heating capacity and efficiency.

The unit should be located as close as practical to the existing pool pump and filter to minimize water piping. However, do not forget to provide a 24”clearance at the very least

all-around your heat pump. The use of 90-degree bends and short radius elbows in the water piping should be kept to a minimum.

Mount the unit on a sturdy base, preferably a concrete slab or a set of blocks. The base should be completely isolated from the building foundation wall to prevent the possibility of sound or vibration transmission into the building. The size of the base should not be less than 36” x 36” (92 cm x 92 cm).

![]() IMPORTANT

IMPORTANT

Air is pulled through the evaporator coil and discharged through the top grille. A minimum clearance of 72 inches should be allowed above the unit for unrestricted air discharge. The unit must not be installed under a porch. Any side of the unit should be located at least 24 inches from a wall or from any other obstruction for unrestricted air intake and service access.

Water piping

The piping sequence is as follows: pool > pool pump > filter > heater > check valve > chemical feeder > pool. Automated chlorine distribution systems, if used, must be placed downstream of the heater to minimize harm to the pool equipment. Use rigid PVC piping if possible (SCH40 or SCH80). All joints should be glued with PVC glue. When the piping installation is complete, operate the pool pump and check the system for leaks. Then, check the filter pressure gauge to verify that there isn’t any indication of excessive pump head pressure.

You can also make the connections using a high-pressure flexible hose, but make sure the hose can withstand high pressure. The installation of a heat pump bypass is not necessary unless the water flow exceeds 75 GPM.

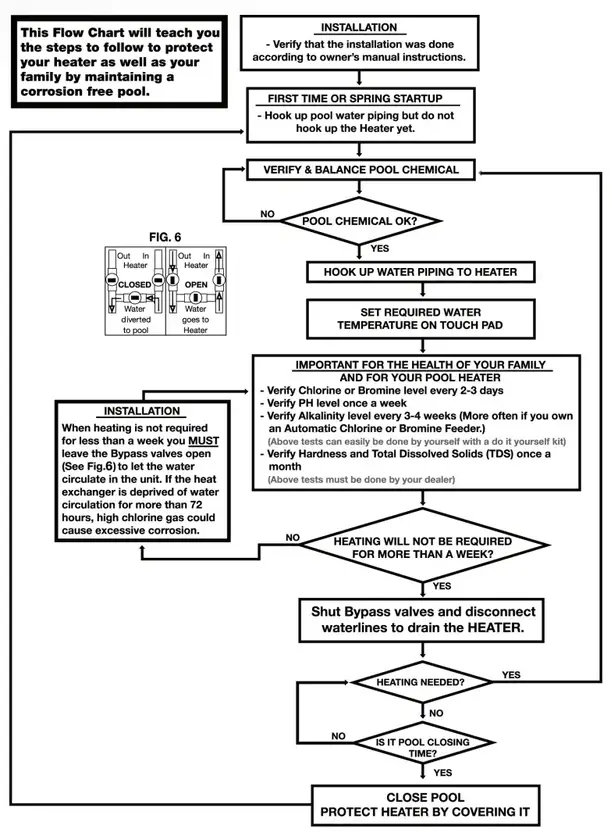

Note: Certain installations have valves that isolate the heat pump from the water circuit. If the heat exchanger is deprived of water circulation for several days, high chlorine gas could cause excessive corrosion. If the disconnect switch is turned off, be sure that the pool water is allowed to circulate through the unit, or is drained out of it.

Electrical

![]() CAUTION

CAUTION

The wiring of your pool heat pump should be performed by a qualified electrician in accordance with local requirements.

Suitable electrical supply line: See rating plate on the heat pump units for electrical specifications. A junction box is not needed at the heat pump; connections are made inside the heat pump’s electrical compartment. Minimum wire size to be selected per NEC SEC.440.33 based on unit MCU.

An electrical disconnect switch that will interrupt all power to the unit is required. This switch MUST be installed within line of sight of the heat pump.

Check the heat pump data label for required maximum breaker size.

![]() WARNING

WARNING

The unit main power must always be disconnected before opening the access panel.

Bonding

![]() CAUTION

CAUTION

Because all metals have different electrical potentials, all metal and electrical components of the pool system must be bonded together. This includes the metal framework of the pool, the light, the pump, the filter (if made out of metal), the heater, any automatic chlorine generator, and any other metal or electrical equipment. On some older pools, this substructure bond wire may not exist. In these cases, an electrode rod must be driven into the ground near the equipment. All electric and metal components must then be bonded to each other, and then to the rod.

Bonding and Plumbing step-by-step instructions

- A check valve must be installed between the heater and any automatic chlorine distribution system (if used).

- Any kind of automatic chlorine distribution system must be installed after or downstream of the heat pump.

- The filter must be placed before or upstream from the heat pump.

- Bypasses must be installed on any system where water flow at the heat pump is to be in excess of 75GPM.

Bonding and Plumbing diagram

Installation in Combination with Solar or Gas Heaters

If you are installing a heat pump in combination with any other type of heating device, please call the Hayward Service Department at (908) 355-7995. We will advise you of installation practices that will help keep your warranty valid. Other pool heaters, such as gas-fired or solar-powered devices must be in- stalled in a parallel circuit and operated independently (only one at a time) for your warranty to stay valid.

NOTICE – Because of the intense heat that can be generated by gas and solar units, isolating it with a shut-off valve and a check valve when gas or solar heater is in operation protects the heat pump. Failure to follow the instructions may result in property damage.

Notes:

- Isolate the heat pump from the hot water flow of heating devices such as gas or solar heater.

- Install bypass loop for heat pump unit.

Using an External Controller

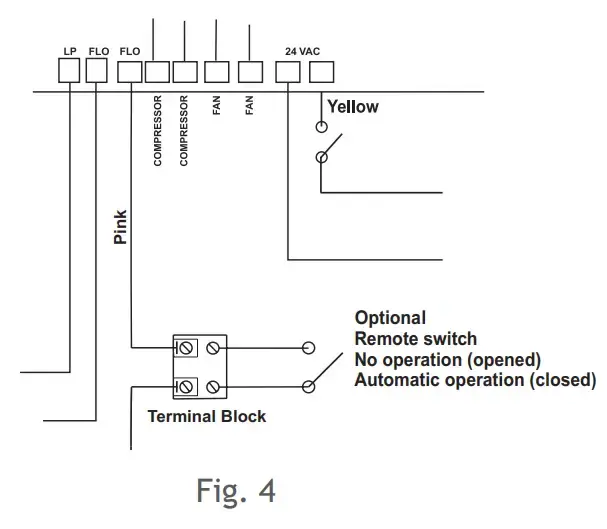

To control the board using an external switch, follow these steps:

- Disconnect the unit’s main power.

- Remove the front by removing screws on the bottom of each side and allowing the front to slide down and out.

- Remove the jumper on the terminal block. Reinstall screws without tightening for the next step.

- Run two terminal wires from the terminal block to the normally open switch being used for external control. Route wires as necessary inside the unit and from the unit to the external switch housing to prevent damage and to comply with local codes. Tighten screws on terminal block to capture the wire leads.

- Replace front.

- Turn main power back onto the unit.

- Set to SPA or POOL mode and to the desired temperature.

- You can now remotely control the operation of the unit by the remote switch (open = heater operation disabled, closed = normal automatic operation).

Therefore, a board set to OFF in POOL mode and to 104 degrees in SPA mode can be controlled with an external switch to heat up to 104 degrees.

Electrical Connections

![]() WARNING

WARNING

The installation of the pool heater should be performed by a certified electrician. To connect the electricity, you must unscrew the five screws of the front panel, then slide the electric cable through the knockout located on the left or the right side of the base, and then insert it in the control box. The electrical diagram is located on the lid of the control box as well as in this manual.

Power requirements

240 V, 1 PH, 60 Hz

Look at the nameplate located on the heat pump to know the required amperage. Please refer to your local electrical code for additional wiring requirements.

Wiring Diagram

Service Analyzer Control

The control panel is factory set to display the temperature in Fahrenheit degrees.

Operation

Master switch must be in the “ON” position (rocker switch up) before the heater control will operate.

To increase the temperature

Push the SET key until you see POL or SPA. The programmed temperature will be displayed. Press the UP▲ arrow to increase the temperature setting one degree at a time.

To lower the temperature

Proceed as explained above using the down arrow▼

To select the pool or spa mode

The unit can keep two temperature settings in memory: one for pool mode (max: 95°F/35°C), and the other for spa mode (max: 104°F/40°C). To have access to either program, press the SET key until you see P_S and by pressing one of the arrow keys, you can switch to POL or SPA. Once the heating mode has been programmed, it will be displayed for five seconds, and will then return to the actual pool water temperature. The lights on the right side of the display indicate the chosen heating mode.

To display the temperature in °F or in °C

Press the SET key until you see F_C and by pressing one of the arrow keys, you can switch to °F or °C. Once the temperature unit has been programmed, it will be displayed for five seconds, and will then return to the actual pool water temperature in the mode that you have chosen.

Caring for your Pool Heater

How to protect your pool heater

Initial Startup

![]() IMPORTANT

IMPORTANT

Before starting the pool heater for the first time, it is important to verify that the breaker and Master switch (see the front of the unit) is in the ON position. Also, make sure that the water circulates freely and that the pool pump is activated. Then, you will need to set the water temperature you desire. The fan will immediately start. The compressor will start after a 3 to 4-minute delay. When the compressor is running, the HEATING/CHAUFFAGE indicator located on the right (see “Service Analyzer Control,” p. 13) should be lit. At initial startup, it is normal for the unit to run 24 hours a day. It is also normal to see water dripping from the holes at the base of the unit. This is just condensation.

Meaning of Display Codes

Service Analyzer Codes

Most problems will be detected by the service analyzer and a code will be displayed on the digital display of your heater.

Display Meaning of codes

| OFF | The desired programmed temperature point is lower than 60°F (15°C). |

| LP & LP3 | Shortage of refrigerant gas in the unit or faulty low-pressure control. The digital display will show LP3 after 3 LP faults and shut down your pool heater. The pool pump will also be stopped for protection if the unit’s internal time clock feature is used. If LP or LP3 occurs you should call for service. |

| HP & HP3 | Low water flows to the unit or faulty high-pressure control. Check water flow. Backwash filter and/or heater. The unit will show HP3 after 3 HP faults. This will stop your heater for protection. |

| Po | Water temperature probe connected to WS on the electronic board may be disconnected. If it is not, the probe may be open or defective. |

| Pc | Water temperature probe is short-circuited or may be defective. |

| FLo | Possible causes:

– The filter is in the backwash position. |

| dPo | Suction temperature probe connected to DS on the electronic board may be disconnected. If it is not, the probe may be open or defective. |

| dPc | Suction temperature probe is short-circuited or may be defective. |

| FS | Unit currently in defrosting cycle (the fan works but the compressor is stopped). This is normal operation when outside temperatures are cold. |

Troubleshooting

The pool heater is not running.

| Heat pump control set to OFF. | |

| Desired water temperature is reached. | |

| Main breaker is tripped. | |

| The heater is displaying “flo” and it will not start. | |

| Pool pump is not running. | |

| Filter is dirty, restricting the water flow. | |

| The fan is running, but the compressor is not. | |

| The heat pump is in protection mode. | |

| The unit is on defrost cycle. | |

| There is no display and the fan is not running, but the compressor is running. | |

| There is water around the unit. | |

| While your pool heater is in the heating mode, a large quantity of warm and humid air passes over the evaporator and causes condensation. It is normal to see condensation dripping under the heater. | |

| The heater is running but desired water temperature cannot be reached. | |

| Evaporator is dirty. | |

| Restricted water flow. | |

Note: If your pool heater does not operate for reasons other than those mentioned above, please contact Consumer Assistance Center (see “Introduction”, p. 3) to obtain the proper authorization for the warranty to apply.

Requesting Assistance or Service

![]() IMPORTANT

IMPORTANT

All services will be handled by an Authorized Service Center. Warranty may be voided if service is not done by an Authorized Service Representative. Do not return the heater to your dealer as they do not provide service.

Before calling for assistance or service, please check the “Troubleshooting” (pp. 18-19) and “Warranty” (pp. 22-23) sections or call your dealer. It may save you the cost of a service call. If you still need help, follow the instructions below.

Service can be obtained by calling one of these phone numbers.

CANADA: 1 888 238-7665

USA: 1 908 355-7995

When asking for help, please provide a detailed description of the problem, your heater’s complete model and serial number, and the purchase date (see p. 3). This information will help us respond properly to your request.

Keep a copy of the sales receipt showing the date of purchase. Proof of the purchase will assure you of warranty service.

Maintenance

Dirt can accumulate on the evaporator. You can easily remove it by using a non-pressured water spray without damaging the small aluminum fins. The cleaning of the plastic cabinet can be done with the help of a brush and soap.

Winterizing

First, you must turn the breaker off. The unit must be drained of all its water. You will need to disconnect the IN and OUT water connections. Then the unit must be tilted or blown out with air until all water is out.

The next step is to reconnect your IN and OUT water connections that will have previously been drained.

It is recommended to cover the heat pump to prevent snow from getting inside. A protective winter cover is also offered by your retailer.

Hayward®Heat Pump Pool Heater Limited Warranty

The Hayward heat pump pool heater is warranted by the manufacturer to be free of defects in materials and workmanship for a period of two (2) years for parts and (1) one year for labor. In the state of Florida, warranty labor is covered for (2) years. This warranty is applicable to the original location and owner only and is not transferable. The compressor component has a five (5) to year limited warranty with parts and labor warranted the first two (2) years and parts only warranted in years three (3), four (4), and five (5). The titanium tube component of the heat exchanger has a ten (10) year warranty. Hayward will not void this warranty due to improper pool chemistry. This warranty is valid only if the product is installed according to the Hayward specifications.

This warranty does not include refrigerants or other expendable materials, or services such as inspection, maintenance, or unnecessary service calls due to erroneous operational reports, external valve position, or electrical service. It also does not include the repair of damage due to negligence, accident, freezing, installation in corrosive environments or

atmospheres, conditions beyond the normal intended use of the unit, or acts of God. This warranty is void if the product is repaired or altered in any way by any persons or agencies other than those authorized by Hayward, and is in lieu of all other warranties, expressed or implied, written or oral. There are no implied warranties of merchantability

or fitness for a particular purpose that apply to this product. This warranty applies to the continental USA, Hawaii, Alaska, and Canada.

At its option, Hayward will replace or repair any Hayward part that proves defective if such parts are returned to our factory, freight collected, within the warranty period. It is agreed that such replacement or repair is the exclusive remedy available from Hayward. Unless authorized by Hayward and performed by a factory-authorized service center, Hayward is not liable for any labor involved in the removal of defective parts or the installation of replacement parts. Hayward is not liable for damages of any sort whatsoever, including incidental and consequential damages. Parts returned and services performed under terms of this warranty must be approved by Hayward. All parts returned under terms of this warranty will be repaired or replaced and returned transportation charges prepaid, by best and most economical means.

International Warranty

The Hayward heat pump pool heater is warranted by the manufacturer to be free of defects in materials and workmanship for a period of one (1) year. The compressor is warranted for two (2) years, and the titanium tube component of the heat exchanger has a ten (10) year warranty.

The above coverage begins from the date of purchase, or sixty days after the product manufacture date, and applies only if the product is installed according to the Hayward specifications. This warranty does not include the repair of damage due to negligence, accident, freezing, installation in corrosive environments or atmospheres, conditions beyond the normal intended use of the unit, or acts of God. There are no implied warranties of merchantability or fitness for a particular purpose that apply to this product.

These warranties apply to units shipped after October 1, 2008

Hayward Industries, Inc.

620 Division Street

Elizabeth, NJ 07207