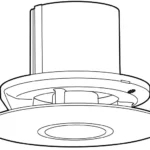

Xpelair VX100 Range Bathroom Fan

overview

installing the fan

These appliances are intended for connection to fixed wiring. Check that the electrical rating shown on each fan matches the mains supply. THESE APPLIANCES ARE DOUBLE INSULATED AND DO NOT REQUIRE AN EARTH CONNECTION. All installations must be supervised by a qualified electrician. Installations and wiring must conform to current IEE Regulations (UK),local or appropriate regulations (other countries). This appliance is not intended for use by persons (including children and the infirm) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless th ey have been given supervision or instruction concerning use of the appliance by a person responsibl e for their safety. Children should be supervised to ensure that they do not play with the appliance. If you have any queri es before installing these products or after they have been installed, call the XpelairTechnical Hotline +44 (0) 344 879 3588. Our engineers are there to help you during normal office hours (UK only)

Description

Xpelair fans have the following features:

- Universal mounting kit allows window/ wall panel/ ventilation shaft/ ceiling mounting

- Single speed extraction

VXl00

- Operate the fan using an on/off switch (not supplied).

VXl00P

- Operate the fan using integral pull

- Built-in timer automatically operates fan for a preset delay of up to 30 minut

what the installer will need

- A means for disconnection in all poles must be incorporated in the fixed wiring in accordance with the wiringrules.

- If metal switch boxes are used, earthing regulations must be

- Suitably rated 2-core cable (VXl 00, VXl00P).

- Suitably rated 3-core cable (VXl 001).

- 3mm electrician’s screwdriver and 1 or 2 Pozdriv screwdrivers.

- A wall or ceiling on/off switch with built-in indicator light (VXl 00, VXl 001).

- To prevent a possible hazardous situation from water ingress, a condensation trap (Xpelair n XCTl00) must be fitted as close as possible to the fan in all situations where any section of the duct work is positioned higher than the fan itself.

If wall mounting the fan, you will also need

- Masonry drill, hammer & chisel (or core drill equipment if available).

- Mortar to make good the hole if

If window mounting the fan

- You will need a window pane between 3mm and 6mm thick (preferably 4mm).

- Do not install in glass 3mm thick if the window pane area is more than 2sq.m.

- If installing in sealed double glazing, a specially manu factur ed unit should be obtained from the glazing manufacturer. You will also require a special kit, Xpelair ref. DXDG.

- If installing in sash windows, you should mount the fan in the upper window. Secure the upper sash in the closed position and fit stops just below the level of the fan, to prevent damaging it when the sash is raised.

- If installing in a panel which is between 9mm and 46mm thick, you will need a special kit, Xpelair ref. DXDG. Do not install these fans in a panel which is more than 46mm thick.

If ceiling mounting the fan

You will need to use the appropriate ancillaries for termination. These items are available from Xpelair.

- WTl 0 – Termination ducting

- CFWG100 – Soffit board termination grille (white or brown).

- FD100 / 3 and FD100 / 6 – Flexible ducting.

Where to locate the fan

- Locate it as high as possible.

- At least 110mm from the edges of the mounting surface to the centre of the hole.

- As far away as possible from and opposite tothe main source of air replacement to ensure airflow across the room (e.g. opposite the internal doorway).

- Near the source of steam or odours.

- Not where ambient temperatures are likely

- If installed in a kitchen fans must not be

- If installing in a room containing a fuelburning device which has a non-balanced flue, it is the installer’s responsibility to ensure that there is enough replacement air to prevent fumes being drawn down the flue when the fan is operating up to maximum extract. Refer to Building Regulations for specific requirements.

- Exhaust air must not be discharged into a flue used for exhausting of fumes fromappliances supplied with energy other than electric. Requirements of all authorities concerned must be observed for exhaust air discharge and intake flow rates.

- When intended for use in possiblechemical corrosive atmospheres, consult out Technical Service Department. (For overseas markets contact your local Xpelair distributor).

Installing the isolating switch and cables

- Check that the electrical rating shown inside the back plate matches your mains supply.

- Check there are no buried pipes or cables e. g. electricity, gas, water behind the switch location (in the wall or above the ceiling). If in doubt, seek professional advise.

- Isolate the mains supply.

- Lay in the cable from the isolating switch to the fan location via the on/off switch (if required).

- Lay in the cable from the isolating switch to the point of connection to the mains supply.

- Install the isolating switch and on/off switch (if required).

- Make all connections within the isolating switch and the on/off switch (if required).

Note: on/off switch must be situated so that it cannot be touched by persons making use of the bath or shower.

WARNING : DO NOT MAKE ANY CONNECTIONS TO THE ELECTRICAL SUPPLY AT THIS STAGE.

Connection to the supply can be made by a flexible 2-core cable complete with 3 pin plug for insertion into an approved 10 amp GPO or directly wired through an approved 10A wall-mounted surface switch with at least 3mm clearance between contacts.These models are permanently connected to the supply and operation is controlled by a remote switch. They should be directly wired to the supply through an approved 10amp wall mounted surface switch with at least 3mm clearance between contacts.

Preparing the hole

If working above ground floor level, appropriate safety precautions must be observed. WARNING: EYE PROTECTION MUST BE WORN DURING ALL DRILLING AND CHISELLING OPERATIONS.

If installing in a wall

- Check there are no buried pipes or cables in the wall or obstructions on the outside e. g. electricity, gas, water. If in doubt, seek professional advise.

- Mark on the wall the centre of the duct hole.

- Use this centre to mark a circle to suit the wall duct (115mm diameter).If core drill equipment is available: 4a.Use as directed by core drill manufacturer. If core drill equipment is not available:

- Drill a centre hole right through the wall.

- Cut the hole. Do not cut right through the wall. (The recommended method is to drill a series of holes, close together, around the edge of the cutting line and remove the brick between the holes with a chisel).

- Go outside and cut a hole in the outer wall, repeating the process described above.

- Cut ducting to the correct length if required. The wall tube supplied is telescopic and can extend to 300mm maximum.

- Fit the ducting. Ensure that the duct slopes down away from the fan to allow drainage of any incoming rain water to the outside.

- Make good the hole. Allow the mortar to set before continuing the fan installation.

If installing in a window or panel

- Cut a hole, 125mm in diameter or if installing in a window, obtain a ready cut pane.

- The centre of the hole should be at least 110mm away from the edge of the panel or pane of glass.

If installing in a ventilation shaft

- Check there are no buried pipes or cables in the ventilation shaft. If in doubt, seek professional advise.

- Cut a hole 110mm in diameter, in the side of the shaft.

- If the shaft has cavity wall, use the wall tube to bridge the cavity.

- Fit ducting and condensation trap if necessary, positioning condensation trap as near to the fan as possible.

If installing in a ceiling

- Check there are no buried pipes or cables in the ceiling/joists etc. If in doubt, seek professional advise.

- Cut a hole 115mm diameter.

Preparing the fan for installation

Remove the front cover by pressing the release catches located on the sides of the unit with a 3mm screwdriver, whilst pulling the front cover forward L

If installing in a window or panel less than 16mm thick, the fan spigot needs to be cut back to the visible step 20mm away from the rear of the back plate.

- Remove the impeller by pulling it forward.

- Cut the spigot back to the step using a junior hacksaw, ensure that the motor shaft is not marked by the hacksaw.

- Remove any burrs from the edge of the spigot.

- the impeller by locating it onto the shaft and pushing it on fully.

Mount the fan in the hole

If working above ground level, appropriate safety precautions must be observed.

If installing in a wall, ceiling or vent

- Hold the backplate so that the terminal block faces you in the top left hand corner and the lip points towards the hole.

- Carefully insert the lip into the wall duct/ceiling or vent shaft.

- Adjust the position of the back plate until it is level.

- Mark on the wall/ceiling or vent shaft the

- Remove the back plate from the ducting.

- Drill screw holes in these positions if necessary, and wall plugs if necessary.Mount the back plate C

- Push the ribbed gasket (RG100) onto the lip of the back plate 1

- If installing in a ceiling or vent, push the larger diameter piece of the telescopic wall tube onto the ribbed gasket. Cut the tube to the required length if necessary.

- If wiring the fan from behind, removeknockout. Feed the mains cable through the cable entry hole in the back plate to the terminals D.

- If wiring from above, leave the cable free to be into labyrinth.

- Insert the lip of the back plate into the wall duct/ceiling or vent shaft as before.

- Fasten the back plate to the wall/ceiling or vent shaft using appropriate fasteners. If using screws, do not overtighten the screws.

Mount the back draught shutter

- Peel the backing from the foam strip supplied and attach it around the outside of the lip on the back draught shutter.

- Go outside. Holding open the top and bottom vanes, insert the lip into the wall duct.

- Making sure that the back draught shutter is level, mark the positions of the two holes in the top right hand and bottom left hand corners.

- Remove the back draught from the wall duct.

- Drill screw holes in these positions, and the remaining wall plugs.

- Holding open the top and bottom vanes, the back draught shutter and fasten it to the wall using the pointed and self-tapping screws. Do not over tighten screws.

- Make sure that the vanes open and shut freely.

If installing in window or panel

- 1. If installing in a window or panel no morethan 9mm thick, the white rubber gasket around the edge of the hole. If installing in a panel or sealed double glazing more than 9mm thick, a DXDG double glazing kit is required. Follow the instructions supplied with the special kit.

Attach the back draught shutter to the spacer F

- Holding the top and bottom vanes, insert theback draught shutter 2 into the spacer 3 so that the holes in the top right and bottom left hand corners match those on the spacer.

- Insert two of the fat-ended self-tappingscrews provided and fasten the back draught shutter to the spacer.

Mount the fan in the window G

- Someone else must hold the back draught shutter and spacer in position outside, with the spacer against the glass.

- Make sure that the two raised holes in the spacer are horizontal and are positioned within the hole.

- From inside, hold the back plate so that the terminal block faces you in the top left hand corner and the lip points towards that hole.

- Align the holes in the back plate with those in the spacer.

- Insert two of the ended self-tapping screws provided in the holes, and fasten the back plate to the spacer. Do not overtighten the screws.

Wire the electrical connections

- Wire the fan as shown in H check the fan model to diagram, feeding the cable between the two raised pegs, if wiring from above, and through labyrinth to terminal block.

- Switch the mains electrical supply and remove fuses

- Connect the cable from the isolating switch to the electrical supply wiring.

VX100T only I

To adjust the over-run period turn the control(T) clockwise to increase and anti-clockwise to decrease.

All fans

If wiring from above cut out the cable entry slot marked on top of the front cover. Fit the front cover by aligning it square to the duct and pushing it onto the duct until therelease catches snap into the slots on the front cover.

Using the fan

Operate the fan using the switch.Repeat to switch o .

VX100P only

Operate the fan by pulling and releasing thecord. Repeat to switch o .

VX100T only

Operate the fan using the switch. Whenthe switch is turned o , the fan continues to operate for the adjustable time delay.

Cleaning (recommended once a month)

A QUALIFIED ELECTRICIAN MUST CARRY OUT ALL CLEANING.

- Before cleaning, isolate the fan completely from the mains supply.

- Remove the front cover by pressing the release catches located on the sides at the unit with a 3mm screwdriver, whilst pulling the front cover forward L

- To clean the front cover, either wipe it with a damp, lint free cloth or wash it in warm soapy water. Thoroughly dry the front cover and

- Do not immerse the fan in water or other liquids to clean any other parts of the fan.

- Never use strong solvents to clean the fan.

- Apart from cleaning, no other maintenance is required.