MASTER Kerosene Radiant Heater MH-80-OFR

MASTER Kerosene Radiant Heater MH-80-OFR

MODEL NUMBERS: MH-80-OFR / MH-125-OFR-A

CONSUMER: READ AND SAVE THESE INSTRUCTIONS

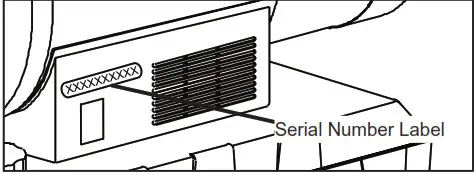

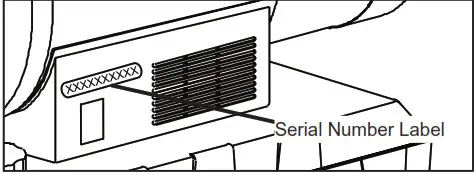

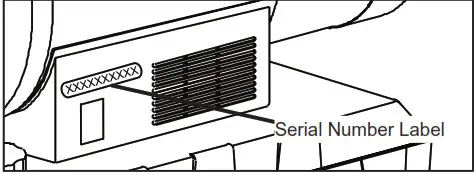

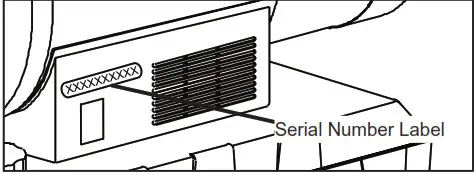

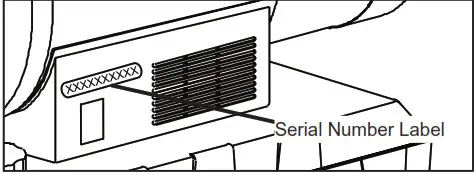

Locating Your Serial Number

Your serial number can be found on a blue label on the left side cover. It will begin with the letter “S” followed by 9 digits. For Example S160901126. Have your Serial Number ready before calling customer service at 800-641-6996.

DANGER

DANGER

GENERAL HAZARD WARNING:

READ AND UNDERSTAND ALL OF THE INSTRUCTIONS IN THIS MANUAL BEFORE ASSEMBLING, STARTING, OR SERVICING

THE HEATER. Be sure to comply with the instructions and warnings provided with this heater failure to comply can result in fire or explosion that can cause property loss, bodily injury, or loss of life. Only persons who can follow and understand these instructions should operate or service this heater. If you need heater info; such as an operating manual, labels, etcetera, contact Pinnacle Climate Technologies at 800-641-6996.

DANGER

DANGER

NOT FOR USE IN RESIDENTIAL LIVING AREAS OR IN ENCLOSED SPACES WITHOUT ADEQUATE VENTILATION. THIS HEATER IS SUITABLE FOR OUTDOOR USE, AND INDOOR USE ONLY IN WELL-VENTILATED AREAS.

NOT FOR USE IN RESIDENTIAL LIVING AREAS OR IN ENCLOSED SPACES WITHOUT ADEQUATE VENTILATION. THIS HEATER IS SUITABLE FOR OUTDOOR USE, AND INDOOR USE ONLY IN WELL-VENTILATED AREAS.

INDOOR USE IS PERMITTED ONLY FOR: THE TEMPORARY HEATING OF ADEQUATELY VENTILATED BUILDINGS OR STRUCTURES UNDER CONSTRUCTION, ALTERATION, OR REPAIR.

This is an unvented portable heater that uses air (Oxygen) from within the area in which it is used. Failure to provide adequate combustion and ventilation air will result in asphyxiation, carbon monoxide poisoning, bodily injury or death. Refer to “Ventilation” on Page 7.

NEVER LEAVE HEATER UNATTENDED WHILE BURNING OR WHILE CONNECTED TO A POWER SOURCE

SAFETY INFORMATION

WARNING

WARNING

FIRE, BURN, INHALATION, AND EXPLOSION HAZARD. Keep combustibles such as; building materials, paper, or cardboard a safe distance away from the heater as recommended by these instructions.

Never use the heater in spaces that contain products such as; gasoline, solvents, paint thinners, dust particles, volatile or airborne combustibles or any unknown chemicals. This is an unvented portable heater. It uses air (Oxygen) from the area in which it is used. Adequate combustion and ventilation air must be provided. Refer to “Ventilation” on page 7. Bulk fuel storage should be a minimum of 25 feet from the heater.

WARNING

WARNING

DO NOT OPERATE THIS HEATER UNTIL YOU HAVE READ AND THOROUGHLY UNDERSTAND THESE SAFETY AND OPERATING INSTRUCTIONS.

Failure to comply with the precautions and instructions provided with this heater can result in death, serious bodily injury, property loss or damage from the hazards of fire, soot production, explosions, burns, asphyxiation or carbon monoxide poisoning. Only persons who can read and understand these instructions should use or service this heater.

WARNING DO NOT START THE HEATER WHEN EXCESS OIL HAS ACCUMULATED.

WARNING DO NOT START THE HEATER WHEN EXCESS OIL HAS ACCUMULATED.

WARNING DO NOT START THE HEATER WHEN THE CHAMBER IS HOT.

WARNING DO NOT START THE HEATER WHEN THE CHAMBER IS HOT.

WARNING: This product can expose you to chemicals, including lead, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

WARNING: This product can expose you to chemicals, including lead, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

MASSACHUSETTS RESIDENTS: Massachusetts state law prohibits the use of this heater in any building which is used in whole or in part for human habitation. Use of this heating device in Massachusetts requires a local fire department permit (M.G.L.C. 148, Section 10A).

NEW YORK CITY RESIDENTS: The New York City Fire Code prohibits the storage, handling and use of kerosene-fueled heaters for space heating. Any person violating that provision may be punished by a fine up to $10,000 and a term of imprisonment of up to 6 months.

THE INSTALLATION OF THIS HEATER SHALL COMPLY WITH THE REGULATIONS OF THE AUTHORITIES HAVING JURISDICTION.

Look for this icon throughout the manual for helpful tips on how to assemble, use and clean your OFR heater.

Look for this icon throughout the manual for helpful tips on how to assemble, use and clean your OFR heater.

WARNING

WARNING

RISK OF INDOOR AIR POLLUTION!

The products described in this manual are kerosene direct-fired, forced air heaters. Kerosene forced air heaters are primarily intended for use for temporary heating of buildings under construction, alteration or repair. Direct-fired means that all of the combustion products of the heater enter the heated space. This appliance is rated at 98%

combustion efficiency, but does produce small amounts of carbon monoxide.

DANGER

DANGER

CARBON MONOXIDE POISONING MAY LEAD TO DEATH!

Carbon monoxide is toxic. Humans can tolerate only small amounts of carbon monoxide and so precautions should be taken to provide proper ventilation. Failure to provide proper ventilation in accordance with the instructions in this manual can result in death. People with breathing problems should consult a physician before using this heater. Early signs of carbon monoxide poisoning resemble the flu. Symptoms of improper ventilation/carbon monoxide poisoning are:

Headache • Dizziness • Nausea • Dry Mouth Sore Throat • Burning of Nose and Eyes

If you experience any of these symptoms: GET FRESH AIR AT ONCE! Have your heater serviced and check for proper ventilation. Some people are more affected by carbon monoxide than others. These include pregnant women, those with heart or lung problems, anemia or those under the influence of alcohol or at high altitudes.

FOR OUTDOOR USE. INDOOR USE PERMITTED ONLY FOR: The temporary heating of adequately ventilated buildings or structures under construction, alteration or repair! Provide at least a three-square-foot (2,800 sq cm) opening of outside air for every 100,000 Btu/Hr (29 kW) heater rating. Refer to “Ventilation” on page 7 for further instructions.

WARNING

WARNING

RISK OF ELECTRIC SHOCK!

ALWAYS use only the electrical power (voltage and frequency) specified on the model plate of the heater. ALWAYS use only a three-prong, grounded outlet and extension cord.

ALWAYS use only 14 AWG or better extension cords.

ALWAYS unplug the heater when not in use. ALWAYS install the heater so that it is not directly exposed to water spray, rain, dripping water, or wind.

NEVER use fuels such as gasoline, benzene, paint thinners or other oil compounds in this heater.

NEVER refill the heater’s fuel tank while the heater is operating or still hot. This heater is EXTREMELY HOT while in operation.

NEVER block air outlet (front).

WARNING

WARNING

RISK OF BURNS, FIRE, AND EXPLOSION!

NEVER use ductwork in front of the heater.

NEVER move or handle the heater while still hot.

NEVER transport the heater with fuel in the tank.

NEVER use an external fuel tank.

Keep all combustible materials away from this heater.

| Minimum Clearance From Combustibles | ||

| 80-OFR | 125-OFR-A | |

| To p | 4 ft. (122 cm) | 6 ft. (1853 cm) |

| Sides | 4 ft. (122 cm) | 6 ft. (183 cm) |

| Front | 8 ft. (244 cm) | 8 ft. (244 cm) |

ALWAYS locate heater on a stable and level surface. If your heater is equipped with a thermostat, once it is plugged in, it can start at any time in accordance with the thermostat setting.

WARNING

WARNING

CAUTION! HOT WHILE IN OP- ORATION. DO NOT OUCH. KEEP CHILDREN, ANIMALS, CLOTHING, AND COMBUSTIBLES AWAY FROM THE HEATER.

SPECIFICATIONS

| Model # | 80-OFR | 125-OFR-A |

| Rating: Btu/Hr | 80,000 | 125,000 |

| Fuel Consumption: Gal./Hr / LJHr | 0.63 / 2.38 | 0.85 / 3.22 |

| Fuel Tank Capacity: Gal. / L | 4 /15 | 14 / 53 |

| Max Operating Hours | 6 | 16 |

| Volts: AC/Hz | 120V / 60Hz | 120V / 60Hz |

| Amps | 315 | 315 |

| Heating Area: ft.2 | 2000 | 3125 |

Specifications are subject to change without notice.

FEATURES

80-OFR

125-OFR-A

WHAT’S IN THE BOX

80-OFR

Tools Needed:

– Phillips Head Screw Driver

Attach the handle while still in the box for easier unpacking (see Figures 1 and 2).

Attach the handle while still in the box for easier unpacking (see Figures 1 and 2).

ASSEMBLY

80-OFR

IMPORTANT: INSTALL HEAT SHIELD BEFORE OPERATING YOUR 80-OFR HEATER

- Remove existing screws from shell ring on either side of heater (see Figure 3) .

- Line up holes on heat shield with holes in shell ring. Attach with screws removed in step 1 (see Figures 4 and 5).

WHAT’S IN THE BOX

125-OFR-A

ASSEMBLY

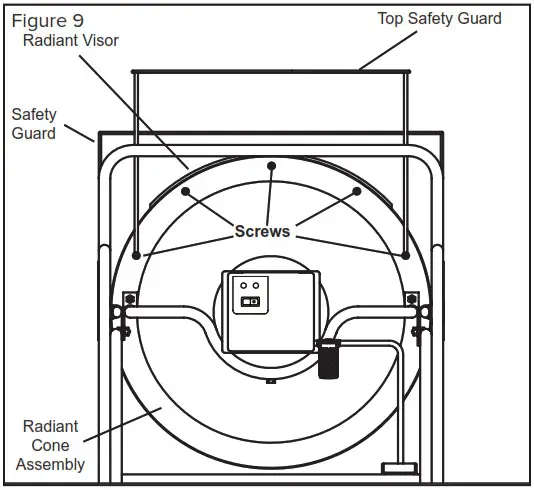

125-OFR-A

- Slide axle through Wheel Frame and attach wheels, washers and nuts (see Figure 6).

- Place main structure on wheel frame and fasten with long screws provided (see Figure 7).

- Attach safety guard to front of the heater with screws provided (see Figure 8).

- Attach Radiant Visors to the top and bottom rear of the Radiant Cone Assembly using extra screws included.

- Attach top safety guard using the two outer-most extra screws on the top of the radiant cone (see Figure 9).

Note: Save the box and packaging materials for future storage.

OPERATION

Fueling The Heater:

Kerosene

For optimal performance of this heater, it is strongly suggested that Kerosene be used. Kerosene has been refined to virtually eliminate contaminants, such as sulfur, which can cause rotten egg odor during the operation of the heater. Using diesel fuel can cause excess soot production. Do not use Bio-Diesel as this fuel will damage your heater’s seals nd filter. – CSA certified for use with K-1 kerosene, no. 1 & no. 2 diesel, JP8/Jet A Fuel, no. 1 and no. 2 fuel oil.

DANGER

DANGER

NEVER REFUELS THIS HEATER WHILE IT IS HOT OR OPERATING. FIRE OR EXPLOSION COULD RESULT.

NEVER FILL THE FUEL TANK INDOORS.

CAUTION

CAUTION

ALWAYS FILLS THE TANK OUTDOORS. BE SURE THAT THE HEATER IS ON LEVEL GROUND WHEN FUELING, AND NEVER OVERFILL

THE TANK.

WARNING

WARNING

DO NOT USE GASOLINE OR CRANKCASE DRAININGS.

– NEVER use fuel such as, benzene, alcohol, white gas, camp stove fuel, farm diesel, paint thinners, or other oil compounds in this heater. THESE ARE VOLATILE FUELS HAT CAN CAUSE A FIRE OR EXPLOSION.

– NEVER store Kerosene in the living space. Kerosene should be stored in a well-ventilated area outside the living area.

– NEVER store Kerosene in direct sunlight or near a source of heat.

– NEVER use Kerosene that has been stored from one season to the next. Kerosene deteriorates over time. OLD Kerosene WILL NOT BURN PROPERLY

IN THIS HEATER.

NOTE: Kerosene should only be stored in a blue container that is clearly marked “Kerosene.” Never store Kerosene in a red container. Red is associated with gasoline.

Ventilation:

DANGER

DANGER

CARBON MONOXIDE POISONING MAY LEAD TO DEATH!

– Risk of indoor air pollution and Carbon Monoxide Poisoning. Use heater only in well-ventilated areas.

– Refer to Safety Information on pages 2-3 for information about Carbon Monoxide Poisoning.

– ALWAYS provide a fresh air opening in the heated space of at least 2,800 square centimeters (3 sq. ft) for each 100,00 Btu/Hr. (29 kW) of heater output. Provide a larger opening if more heaters are being used.

| Minimum Ventilation Opening Needed | |

| 80-OFR | 125-OFR-A |

| 2.4 ft. | 3.75 ft.2 |

| 2230 cm 2 | 3484 cm 2 |

Starting the Heater (Ignition):

- Fill the tank with Kerosene or other approved fuel until the needle on the fuel gauge points to “F”.

- Replace fuel cap and tighten firmly.

- Connect the heater to a three-prong (grounded) power source. You must use a three-prong (grounded) extension cord that is at least 1.8 meters long and is a minimum of 14 AWG rating.

NOTE: On the first ignition or after refueling, you may hear a grinding sound just before ignition. This is the fuel pump removing the air from the fuel line.

Your heater will start up within seconds. If it does not start repeat start-up procedures with fuel gauge reading at least 1/2 tank.

NOTE: Smoking may occur on first ignition.

NOTE: The electrical components of these

heaters are protected by a fuse mounted in the PC board. If the heater fails to ignite, check this fuse first and replace if necessary. Also check the power source to be sure the proper voltage is being provided to the heater.

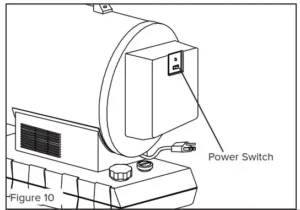

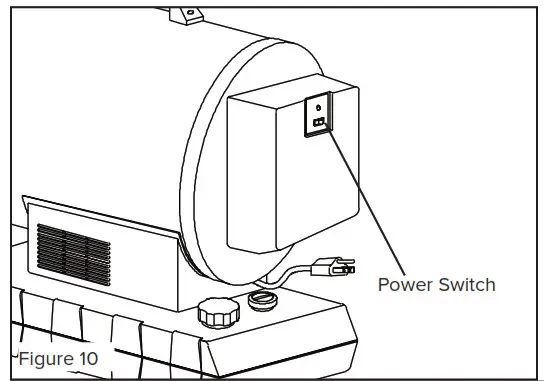

- Complete steps 1-3 above.

- Push the power switch to the “ON” position.

The power indicator lamp will light and the heater will ignite (see Figure 10).

Stopping the Heater (Cool Down):

- Turn the power switch to the “OFF” position.

Combustion will stop and the Cooling Cycle will begin.

– 80-OFR: approx. 5 mins

– 125-OFR-A: approx 3 mins

When the Cooling Cycle is complete the fan will stop running and it will be safe to unplug the heater.

NOTE: Unplugging the heater before the Cooling Cycle has been completed may cause overheating, possible damage to the heater and heat plate.

WARNING

WARNING

DO NOT disconnect the heater from the power source before the cooling cycle has been completed.

Restarting the Heater:

- Wait ten seconds after Cooling Cycle has been completed.

- Follow all start-up procedures above.

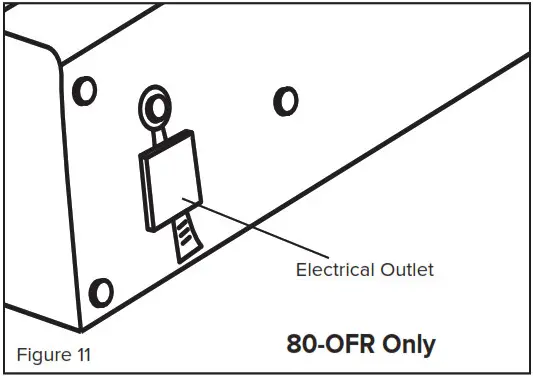

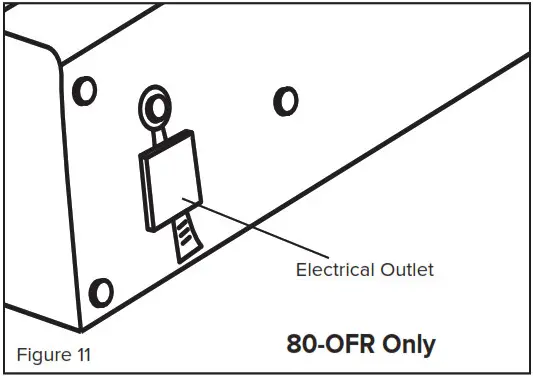

Electrical Outlet (80-OFR Only):

– Never plug an appliance with more than a 5 amp rating into this outlet (see Figure 11).

– Always keep outlet covered when not in use

MAINTENANCE

Long Term Storage (80-OFR):

- Unscrew the fuel cap.

- Using an approved siphon, remove the Kerosene or diesel.

- Using a small amount of Kerosene or diesel, rinse and swirl the fuel inside the fuel tank

NOTE: NEVER MIX WATER WITH FUEL. It will cause rust inside the tank. - Empty the tank completely.

Long Term Storage (125-OFR-A):

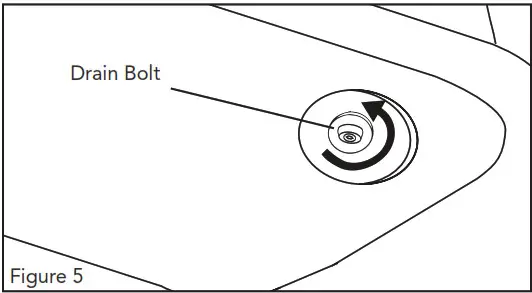

- Drain fuel through the drain bolt in the bottom of the fuel tank.

- To remove the drain bolt, unscrew counterclockwise (see Figure 5).

- Using a small amount of kerosene, rinse and swirl the kerosene inside of the fuel tank, empty the tank fully.

- To replace the drain bolt, insert the drain head fully into the drain hole and screw clockwise.

IMPORTANT: Never store leftover Kerosene between seasons, using old fuel can damage the heater.

Store the Heater in a dry, well-ventilated area.

– Be sure that the storage area is free of dust and corrosive vapors. Repack the heater in the original packaging and keep the user’s manual in an easily accessible place.

WARNING

WARNING

Never service the heater while it is plugged in or hot!

Service:

DO NOT TAMPER WITH THE UNIT. HAVE AN EXPERIENCED SERVICEMAN MAKE ANY NECESSARY ADJUSTMENTS OR REPAIRS. We suggest following a maintenance schedule as follows:

TIP: Follow the long-term storage instructions to flush the tank.

FUEL / FUEL TANK:

Flush tank every 200 hours of operation or as needed. DO NOT flush with water, use fresh Kerosene only.

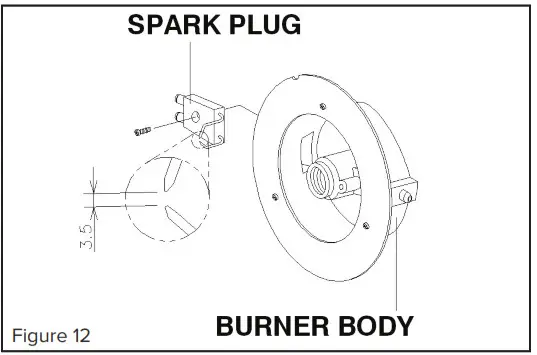

SPARK PLUG:

Clean and re-gap every 600 hours of operation or replace as needed. After removing the Spark Plug, clean the terminals with a wire brush. Re-gap the terminals to 0.140” (3.5 mm) (see Figure 12).

Service (Continued):

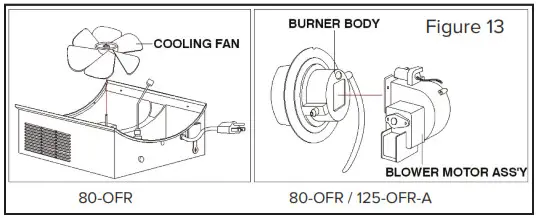

FAN BLADES: The fan blades should be cleaned at least once per heating season, depending on conditions. Remove all accumulated dust and dirt with a burst of condensed air (see Figure 13).

PRESSURE ADJUSTMENTS:

Proper pressure is dependent on the fuel type the unit will be running. When smoking or non-ignition occurs, remove the lower panel. Locate the Phillips screw with a nut on the fuel pump to the left of the fuel line. There is a small “P” next to the pressure screw. The ideal pressure is 107 psi (7.5 kg/cm 2 ).

If you are experiencing smoking or fuel dripping from the unit, turn the screw clockwise 1/8 to 1/4 of a turn to increase the fuel pressure until the unit is operating properly.

If you are experiencing extended flames from the front of the unit, turn the screw 1/8 to 1/4 of a turn counterclockwise to reduce the air pressure until the unit is operating properly.

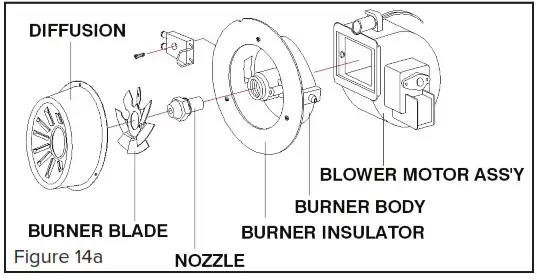

NOZZLES:

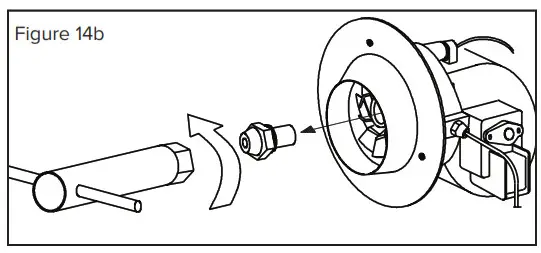

Nozzles should be cleaned or replaced at least once per heating season. Contaminated fuel could make this necessary immediately. To clean dirt from the nozzle, blow compressed air through the nozzle front. It may be necessary to soak nozzle in clean Kerosene or diesel to help loosen any particles (see Figure 14a and 14b).

80-OFR Nozzle

125-OFR-A Nozzle

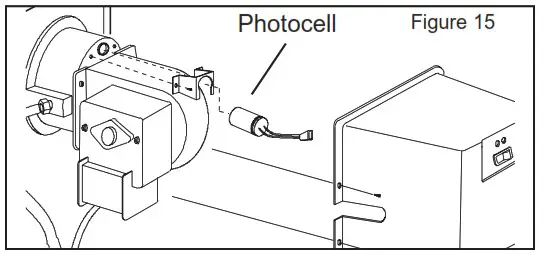

PHOTOCELL:

PHOTOCELL:

The photocell should be cleaned at least once per heating season or more depending on conditions. Use a cotton swab and water or alcohol to clean the lens of the photocell.

Be certain to reinstall the photocell in the proper position as shown below (see Figure 15).

FILTERS:

The fuel filter and oil filter should be cleaned at least twice per heating season by rinsing it in clean Kerosene or diesel. Contaminated or old fuel could make cleaning necessary immediately.

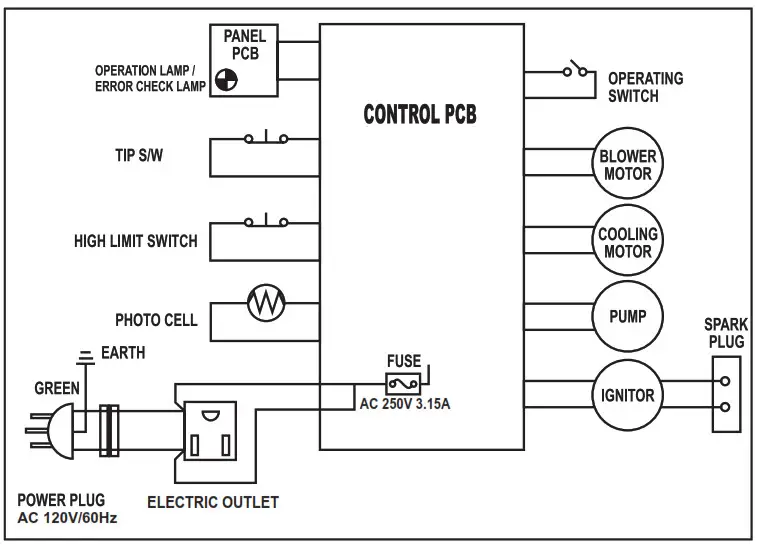

WIRING DIAGRAMS

80-OFR

125-OFR-A

TROUBLESHOOTING GUIDE

| Problem | Possible Cause | Solution |

| Heater fires. but shuts down after a short period of time. |

|

1. Clean/replace Fuel Filter.

2.Clean/replace Nozzle 3.Clean/replace Photocell. 4.Adjust Photocell position. S. Replace Photocell, 6. Check wiring connections (See Wiring Diagrams. Page 111. 7. Check to be sure the cooling fan is not obstructed. 8. Adjust pump pressure. |

| Heater will not operate. or motor runs for short time. |

|

|

| Fan does not operate when the heater is plugged in and Operating Switch is in the ON position. |

|

|

| The heater makes a grinding noise. | I. Air in the fuel pump. | 1. Sound will stop after 3 seconds. If the grinding sound continues. add fuel to the tank. |

| Heater does not turn on and the lamp is not lit. |

|

|

| Poor combustion and/or soot production. | I. Pump Pressure. 2. Poor fuel quality. |

|

EXPLODED VIEW

80-OFR

PARTS LIST:

80-OFR

| Item # | Description | Part Number |

| 1 | Fuel Filter | 75-023-0285 |

| 2 | Fuel Line | 75-024-0740 |

| 3 | Fuel Gauge | 75-028-0200 |

| 4 | Fuel Cap | 70-006-0140 |

| 5 | Cooling Fan Housing / Cooling Fan Housing Panel | 75-011-0685 / 75-011-0690 |

| 6 | Operating Switch | 72-012-0120 |

| 7 | Operating Switch Wire | 75-012-0220 |

| 8 | Electric Pump | 75-027-0650 |

| 9 | Ignitor | 75-025-0120 |

| 10 | Main PCB Assembly | 75-025-0490 |

| 11 | Tip-Over Sensor | 75-051-0200 |

| 12 | Cooling Motor Assembly | 75-047-0250 |

| 13 | Cooling Fan | 75-047-0200 |

| 14 | Handle | 75-001-0060 |

| 15 | Temperature Limit Switch | 75-040-0100 |

| 16 | Heat Plate | 75-012-0600 |

| 17 | Shell Ring | 75-011-0650 |

| 18 | Safety Guard | 75-012-0310 |

| 19 | Burner Body | 75-036-0180 |

| 20 | Spark Plug | 75-075-0200 |

| 21 | Burner Blade | 75-036-0120 |

| 22 | Nozzle | 75-036-0460 |

| 23 | Nipple | 75-040-0610 |

| 24 | Diffusion Cap | 75-036-0500 |

| 25 | Blower Motor Assembly | 75-045-0200 |

| 26 | Photocell | 72-038-0200 |

| 27 | Return Pipe | 75-055-0100 |

| 28 | Return Hose | 75-055-0205 |

| 29 | Electronic Pump Bracket | 75-027-0255 |

| 30 | Heat Shield | 75-012-0320 |

| 31 | Fuel Pressure Gauge | 70-028-0200 |

EXPLODED VIEW

125-OFR-A

PARTS LIST:

125-OFR-A

| Item # | Description | 125-OFR-A |

| 1 | Fuel Filter | 72-022-0100 |

| 2 | Fuel Cap | 70-006-0130 |

| 3 | Wheel | 70-041-1400 |

| 4 | Axle | 72-041-0200 |

| 5 | Drain Bolt | 72-002-0220 |

| 6 | Height Adjustment Knob | 72-042-0500 |

| 7 | Return Fuel Line | 72-023-0260 |

| 8 | Intake Fuel Line | 72-023-0260 |

| 9 | Fuel Filter Assembly | 72-020-0100 |

| 10 | Fuel Pump | 72-027-0100 |

| 11 | Main PCB and Fuse | 72-025-0450 |

| 12 | Tip Over Sensor | 75-051-0200 |

| 14 | Power Switch | 72-012-0120 |

| 15 | Back Cover | 72-013-0110 |

| 16 | Panel sub-PCB | 72-014-0100 |

| 17 | Blower Motor Assembly | 72-045-0100 |

| 18 | Photocell | 72-038-0200 |

| 19 | Spark Plug | 75-075-0200 |

| 20 | Burner Body | 72-035-0210 |

| 21 | Nozzle | 72-036-0100 |

| 22 | Burner Blade | 72-035-0510 |

| 23 | Diffusion Cap | 72-036-0210 |

| 24 | Ignitor | 72-037-0350 |

| 25 | Temperature Overheat Sensor | 72-040-0100 |

| 26 | Heat Plate | 72-012-0400 |

| 27 | Safety Guard | 72-012-0200 |

| 28 | Front Frame | 72-042-0410 |

| 29 | Top Safety Guard | 72-012-0250 |

| 30 | Radiant Visors | 72-012-0220 |

| 31 | Radiant Cone Gaskets | 72-035-0630 |

| 32 | Burner Housing Assembly | 72-035-0615 |

LIMITED WARRANTY (5-YEAR MOTOR WARRANTY)

Pinnacle Climate Technnologies, Inc. warrants this heater to the original retail purchaser only, to be free from defects in material and workmanship for a period of one (1) year from the date of initial purchase. This product must be properly installed, maintained, and operated in accordance with the instructions provided.

Pinnacle Climate Technnologies, Inc. requires reasonable proof of your date of purchase from an authorized retailer or distributor. Therefore, you should keep your sales slip, invoice or canceled check from the original purchase.

This Limited Warranty shall be limited to the repair or replacement of parts, which prove defective under normal use and service within the warranty period, and which Pinnacle Climate Technnologies, Inc. shall determine at its reasonable discretion.

This warranty does not apply to products purchased for rental use.

This Limited Warranty does not cover any failures or operating difficulties due to normal wear and tear, accident, abuse, misuse, alteration, misapplication, improper installation or improper maintenance and service by you or any third party. Failure to perform normal and routine maintenance on the heater, shipping damage, damage related to insects, birds or animals of any kind, and damage due to weather conditions are also not covered. In addition, the Limited Warranty does not cover damage to the finish, such as scratches, dents, discoloration, rust or other weather damage, after purchase.

All transportation costs for the return of damaged products or parts will be the responsibility of the purchaser. Upon receipt of a damaged item, Pinnacle Climate Technnologies, Inc. will examine the item and determine if defective. Pinnacle Climate Technnologies, Inc. will repair or replace and return the item, freight pre-paid.

If Pinnacle Climate Technnologies, Inc. finds the item to be in normal operating condition, or not defective the item will be returned freight collect. This Limited Warranty is in lieu of all other express warranties. Pinnacle Climate Technnologies, Inc. disclaims all warranties for products that are purchased from sellers other than authorized

dealers or distributors.

AFTER THE PERIOD OF THE ONE (1) YEAR EXPRESS WARRANTY EXPIRES, Pinnacle Climate Technnologies, Inc. DISCLAIMS ANY AND ALL IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR APPLICATION. FURTHER, Pinnacle Climate Technnologies, Inc. SHALL HAVE NO LIABILITY WHATSOEVER TO PURCHASER OR ANY THIRD PARTY

FOR ANY SPECIAL, INDIRECT, PUNITIVE INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

Pinnacle Climate Technnologies, Inc. assumes no responsibility for any defects caused by third parties. This Limited Warranty gives the purchaser specific legal rights; a purchaser may have other rights depending upon where he or she lives. Some states do not allow the exclusion or limitation of special, incidental or consequential damages, or limitations on how long a warranty lasts, so the above exclusion and limitations may not apply to you.

Pinnacle Climate Technnologies, Inc. does not authorize any person or company to assume for it any other obligation or liability in connection with the sale, installation, use,

removal, return or replacement of its equipment, and no such representations are binding on Pinnacle Climate Technnologies, Inc.

Always be sure to specify the model number and serial number when making any claim with Pinnacle Climate Technnologies, Inc. For your convenience, use the space

provided below to list this information.

Locating Your Serial Number:

Your serial number can be found on a blue label on the left side cover. It will begin with the letter “S” followed by 9 digits. For Example S160901126. Have your Serial Number ready before calling customer service at 800-641-6996.

- Model #:________________________________

- Serial #:________________________________

- Date of Purchase: ________________________

Sauk Rapids, MN 56379 USA

Toll Free: (800) 641-6996

Fax: 320-251-2922 • Web: www.masterindustrialproducts.com

Email: [email protected]

DOWNLOAD RESOURCES

- MASTER Kerosene Radiant Heater MH-80-OFR [pdf] User Manual Kerosene Radiant Heater MH-80-OFR, MH-125-OFR-A

- Read more: https://manuals.plus/master/kerosene-radiant-heater-mh-80-ofr-manual#ixzz7ohVnnkoa

FAQ’S

How do I know if I have a MH-80-OFR or a MH-125-OFR-A?

The only difference between the two is that the MH-125-OFR-A has a larger burner. Both models have the same heating capacity.

What is the warranty on my heater?

Pinnacle Climate Technologies provides a 1 year parts and labor warranty on all of our heaters. Warranty does not include shipping charges for replacement parts, but does include return shipping for defective parts. Warranty does not cover misuse, neglect, or normal wear and tear.

How do I clean my heater?

Your heater should be cleaned after each use with warm water and mild soap or detergent to remove any residue from fuel, dust, or dirt. Allow to dry before storing in an upright position or packing away for long periods of time. Do not allow water to enter your unit while cleaning as this can cause damage to internal components.

What type of fuel should I use in my heater?

Kerosene is recommended for best performance and safety when using this heater.

What type of oil should I use in my generator?

SAE 30 engine oil is recommended for best performance and safety when using this generator.

Are radiant kerosene heaters safe?

In addition to carbon monoxide, kerosene heaters can emit such pollutants as carbon dioxide, nitrogen dioxide and sulfur dioxide. Breathing these substances can create a risk, especially to such people as pregnant women, asthmatics, individuals with cardiovascular disease, elderly persons and young children.

Why is my kerosene heater not working?

If your kerosene heater won’t light:

Make sure your heater is filled with quality K-2 grade kerosene, and that the wick has been soaked for at least an hour before attempting to light it. When you push the “ignite” button, the igniter should move into position above the wick surface and glow a bright orange.

How do I know if my kerosene heater needs a new wick?

Here are the signs that you may need to replace the wick in your kerosene heater.

The flame is ragged, uneven, irregular, or won’t reach ½ inch above the burn plate.

Lighting the wick is difficult – see how to light a kerosene heater.

The wick lights but it takes a very long time for it to get to normal burn position.

How do you reset a kerosene heater?

Drain the fuel tank and remove the wick assembly. Replace the wick and wick assembly and refill the fuel tank with kerosene.

Light the kerosene heater with little kerosene in the fuel tank. Allow it to burn dry until the flame starts to go out. …

Wait one hour, relight the wick with a match and let it burn out again.

What is difference between convection and radiant kerosene heater?

Key differences: Radiant Vs convection heat

Radiant heat warms objects and surfaces without heating the air in between. Those objects warm up directly and radiate back. Convection warms the air, which is a triple inefficiency.

Do radiant heaters get hot to touch?

Radiant panels work the same way as space heaters but without the same risk. Like space heaters, radiant panels get very hot in order to warm up a room they are not safe to the touch.

How do I get more heat out of my Master kerosene heater?

Second, and perhaps the most important thing, I placed a couple of fire bricks directly on top of the combustion chamber. The bricks heat up and then radiate the heat into the space rather than working solely by convection. I feel that this increases dramatically the efficiency of the heater.

MASTER Kerosene Radiant Heater MH-80-OFR

https://masterindustrialproducts.com/