EARTYWAY Broadcast Spreader Bag Seeder Instructions

ASSEMBLY INSTRUCTIONS

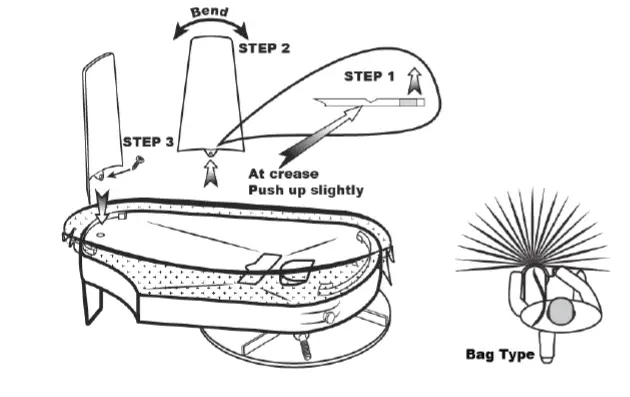

Your 2750 Seeder / Spreader is pre-assembled at the factory, leaving only the handle crank and the new bag supports for you to attach.

Assembly and Operation Instructions

CUSTOMER SERVICE

574.848.7941 | [email protected] | www.EARTHWAY.com | 1009 Maple Street, Bristol, IN 46507

ONE YEAR WARRANTY

EarthWay Products, Inc. warrants this product free of defects in original workmanship and materials for a period of one year to the end user with the original purchase receipt. If a manufacturing non-conformance is found, EarthWay Products, Inc. at its discretion will repair or replace the part(s)/product at no charge provided the failure is not the result of incorrect installation, mishandling, misuse, tampering, or normal wear and tear as determined by EarthWay.

EarthWay at its discretion may require that the part(s) or product be returned along with the original purchase receipt for examination and compliance with the terms of this warranty. Do not return any product without first receiving authorization from EarthWay Products, Inc.

To seek remedy under this warranty, contact EarthWay Products, Inc. at 574-848-7491, [email protected] or write to EarthWay Products, Inc. 1009 Maple Street, Bristol, IN 46507 and describe the nature of the manufacturing defect. SPECIFIC LIMITATIONS: This warranty covers only the part(s) or product; any labor charges associated with repair or replacement of non-conformances are specifically excluded. Due to the corrosive nature of most fertilizers and ice melt products, EarthWay Products, Inc. makes no warranty against and specifically excludes part(s) or product degradation or failure due to corrosion or its effects.

OPERATING INSTRUCTIONS

Before filling the bag, become familiar with the operation of your spreader.

- Obtain proper setting for material to be used from the rate-setting chart from the underside of the unit.

- Loosen wing nut and move setting indicator to proper setting. (When indicator is all the way forward it will be on setting number 1). Tighten wing nut after adjustment.

- To fill, make sure slide opening is in closed position. Fill bag approximately 1/2 to 2/3 full.

- Always start walking and turning handle crank before opening the feed slide. To open feed slide, simply pull slide lever back and place behind the indicator. Crank should make one revolution for each step taken with right foot to ensure proper distribution rate.

- To close feed slide, simply push up on slide lever and slide will trip to closed position.

The settings furnished on the Rate Setting Matrix are intended as a guide only. Variations in physical characteristics of material applied, walking speed, and roughness of ground surface may require slightly different spreader settings. Due to the above conditions, the manufacturer makes no warranty as to the uniformity of coverage actually obtained from the settings listed.

HOW TO ORDER SPARE PARTS

All spare parts listed herein may be ordered direct from the manufacturer. Be sure to give the following information when ordering.

- Model Number

- Part Number

- Part Description

You can contact us by calling (574) 848-7491 to place an order with a credit card, or purchase online at https://www.earthway.com/product-category/parts/ Questions? Email us at mailto:[email protected]

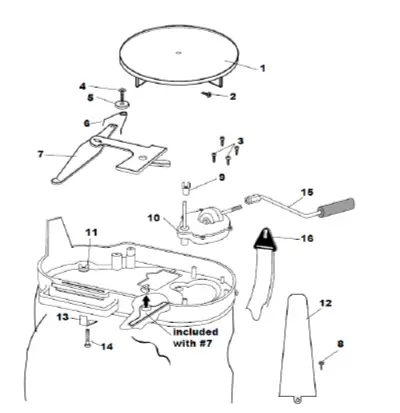

| 2750 Handle Crank/Bag Support Parts List | ||

| KEY # | PART # | DESCRIPTION |

| 1 | 12109 | IMPELLER (9″ DIA) |

| 2 | 31103 | #6 X 1/2″ HWHS SCREW |

| 3 | 31113 | #6 X 5/8″ PHPS SCREW |

| 4 | 31152 | #6 X 1 UNSHW SCREW |

| 5 | 43029 | TORSION WASHER |

| 6 | 70117 | TORSION SPRING |

| 7 | 12330 | SHUT OFF ASSEMBLY |

| 8 | 31138 | #8 X 3/8″ PMT SCREW |

| 9 | 12329 | CAM |

| 10 | 60411 | GEAR CASE ASSEMBLY |

| 11 | 32106 | 10-24 WING NUT |

| 12 | 12189 | BAG SUPPORT |

| 13 | 12334 | INDICATOR |

| 14 | 37103 | #10-24 X 3/4″ CARRIAGE BOLT |

| 15 | 60117 | HAND CRANK ASSEMBLY |

| 16 | 12328 | STRAP HOOK |

| You can find replacement Nuts and Bolts at your local hardware store. | ||

| FIELD SEED | SPREAD WIDTH | SETTING RATE | LBS. per ACRE | FIELD SEED | SPREAD WIDTH | SETTING RATE | LBS. per ACRE |

| Alfalfa | 18 | 2 ½ | 20 | Rape | 21 | 2 ½ | 6 ¾ |

| Kentucky 31 | 11 | 3 ½ | 5 | Sweet Sudan Grass | 24 | 3 ¾ | 25 |

| Birdsfoot Trefoil | 20 | 1 ¾ | 4 | Timothy | 14 | 1 | 2 ¾ |

| Clovers | 18 | 2.25 | 8 | Wheat | 25 | 4 ½ | 90 |

| Flax or Millet | 18 | 2 ½ | 25 | Yellow Mustard | 20 | 2 ½ | 7 2/3 |

| Hairy Vetch | 18 | 3 ½ | 20 | ||||

| Kentucky Blue Grass | 8 | 3 ½ | 49 ½ | SETTING RATE | LBS. per 1,000 SQ. FT. | ||

| Lespedeza Unhulled | 16 | 2 | 15 | LAWN SEED | SPREAD WIDTH | ||

| Lespedeza Hulled | 16 | 2 | 12 | Bermuda | 7 ½ | 1 | 2 ¼ |

| Oats | 16 | 6 | 64 | Merlon Blue | 7 ½ | 2 ½ | ¼ |

| Orchard Grass | 10 | 2 ½ | 14 | Rye Grass | 13 | 4 ½ | 1 |

| Red Top | 10 | 1 ½ | 6 | Fine Seed Mixtures | 10 | 3 ½ | 4 |

| Imperial White Tall Clover | 18 | 1 ¾ | 8 | Coarse Seed Mixtures | 12 | 4 ½ | 1 |

Hand Crank Spreader Rate Setting Instructions

YOU WILL NEED

- Tape measure

- Pencil & Pad

- Scale

- Bucket/container

To Calculate RATE SETTINGS: (Use the Chart on the next page to fill in numbers)

- Determine how much material is to be applied per 1,000 sq./ft. This is determined on the bag based on bag weight and total area of coverage if not directly stated on the bag the recommended number of pounds per 1,000 sq./ft.

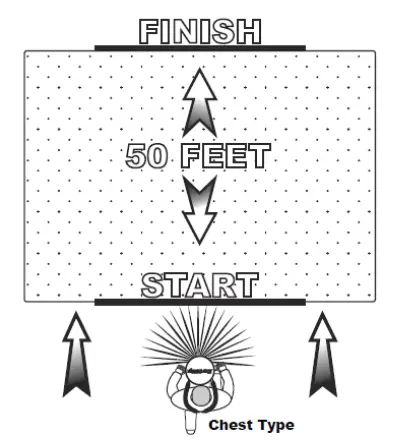

- Measure off a distance of 50 feet, preferably on a paved surface such as a parking lot.

- Weigh out enough of the material to be applied to fill the bag/hopper at least half full.

- Record the weight for future use.

- With the unit positioned correctly for comfortable use, (on your left hip for 2700A/2750 or on your chest for the 3100/3200 models) and the

bag/hopper at least half full of the material to be spread, position the yourself far enough before the beginning of the 50 foot test area so that you will achieve the desired speed before you reach the starting line. - Select the Setting Rate position that you feel would be an appropriate setting on the seeder/spreader (start in the middle).

- Start walking at a NORMAL pace cranking the handle so that it makes one revolution for each step with either your right or left foot to ensure the proper distribution rate.

- As you cross the starting line (of the 50 feet) move the rate lever to the open position against the stop.

- Continue from the starting line with the unit spreading the material. As you cross the finish line move the rate control lever to the closed position.

- Stop walking and measure the spread width and note it below.

- Return to the start point and empty the remaining material from the hopper into your weighing container and re-weigh.

Spreading Paths

CHART

Desired Application Rate (lbs./1,000 sq. ft.) __________

To determine the desired application rate divide the area (sq. ft.) that the bag says it should cover, by the weight of the

bag, and then multiply by 1,000. (Example: 5,000 sq. ft. / 25 lbs. = .005 x 1,000 = 5lbs. per 1,000 sq. ft.)

__________ Weight of Material Placed in Bag/Hopper

__________ Subtract the Weight of Material Left in Bag/Hopper

__________ Weight of Material Used

__________ Multiply by the Width of Spread Area by Length (50 feet)

__________ Total Spread Area

Divide the Weight of Material Used by the Total Spread Area = __________ lbs.sq. ft. Multiply the lbs.sq. ft. from

above times 1,000 = __________ lbs.1,000 sq. ft.

Compare the results of your test to the desired application rate.

Adjust the rate setting stop accordingly and run through the test again. Repeat this process until you have achieved the

desired application rate.

These settings are intended as a guide only. Variations in physical characteristics of material applied, brisk walking speed

(3 mph.), and roughness of ground surface may require slightly different spreader settings. Due to the above conditions,

Earthway Products, Inc. makes no warranty as to the uniformity of coverage actually obtained from the setting listed.