Amana Top Load Washer NTW4516FW

WASHER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety messages.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t immediately follow instructions.

You can be killed or seriously injured if you don’t follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can happen if the instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using your appliance, follow basic precautions, including the following

- Read all instructions before using the appliance.

- Do not wash articles that have been previously cleaned in, washed in, soaked in, or spotted with gasoline, dry-cleaning solvents, or other flammable or explosive substances, as they give off vapors that could ignite or explode.

- Do not add gasoline, dry-cleaning solvents, or other flammable or explosive substances to the wash water.

These substances give off vapors that could ignite or explode. - Under certain conditions, hydrogen gas may be produced in a hot-water system that has not been used for 2 weeks or more. HYDROGEN GAS IS EXPLOSIVE. If the hot-water system has not been used for such a period, before using a washing machine, turn on all hot-water faucets and let the water flow from each for several minutes. This will release any accumulated hydrogen gas. As the gas is flammable, do not smoke or use an open flame during this time.

- Do not allow children to play on or in the appliance. Close supervision of children is necessary when the appliance is used near children.

- Before the appliance is removed from service or discarded, remove the door.

- Do not reach into the appliance if the tub or agitator is moving.

- Do not install or store this appliance where it will be exposed to the weather.

- Do not tamper with controls.

- Do not repair or replace any part of the appliance or attempt any servicing unless specifically recommended in the user maintenance instructions or in published user-repair instructions that you understand and have the skills to carry out.

- Do not use replacement parts that have not been recommended by the manufacturer (e.g. parts made at home using a 3D printer).

- See the Installation Instructions for grounding requirements and installation.

SAVE THESE INSTRUCTIONS

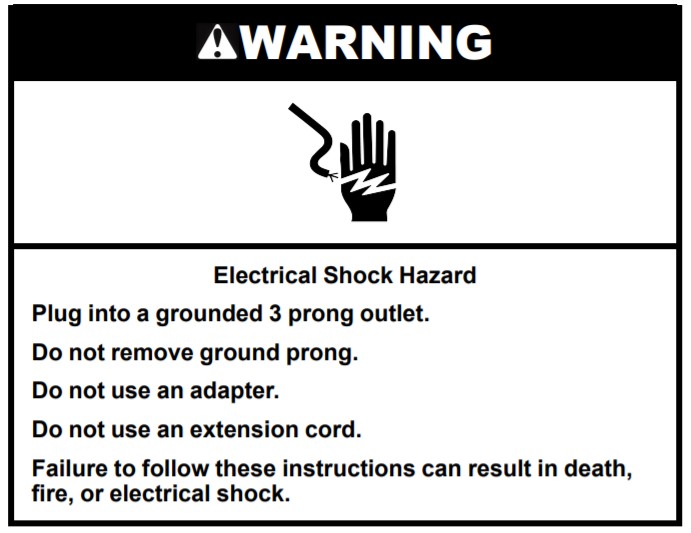

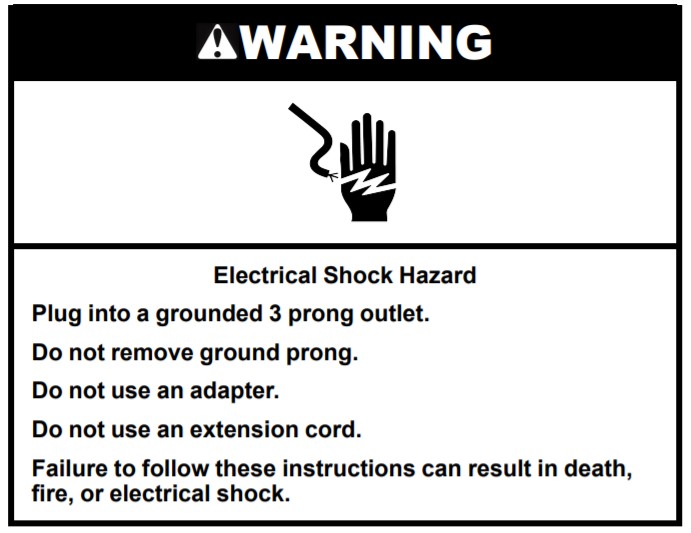

WARNING

Certain Internal parts are intentionally not grounded and may present a risk of electrical shock only during servicing.

Service personnel – Do not contact any component that is not an integral part of the frame or metal cabinet.

CHOOSING THE RIGHT DETERGENT

Use only High-Efficiency detergents. The package will be marked “HE” or “High Efficiency.” Low-water washing creates excessive

sudsing with a non-HE detergent. Using non-HE detergent will likely result in longer cycle times and reduced rinsing performance. It may also result in component malfunction and, over time, the buildup of mold or mildew. HE detergents should be low-sudsing and quick-dispersing to produce the right amount of suds for the best performance. They should hold soil in suspension so it is not redeposited onto clean clothes. Not all detergents labeled as High Efficiency are identical in the formulation and their ability to reduce suds. For example, natural, organic, or homemade HE detergents may generate a high level of suds.

Always follow the detergent manufacturer’s instructions to determine the amount of detergent to use. Do not go over the Max Line on the dispenser. See Quick Start Guide for more information.

WASHER MAINTENANCE AND CARE

Water Inlet Hoses

Replace inlet hoses after 5 years of use to reduce the risk of hose failure. Periodically inspect and replace inlet hoses if bulges, kinks, cuts, wear, or leaks are found.

When replacing your inlet hoses:

• Mark the date of replacement on the label with a permanent marker.

•Check that the old washers are not stuck on the washer inlet valves.

•Use new washers in the new inlet hoses to ensure a proper seal.

NOTE: This washer may not include inlet hoses. See the Installation Instructions for more information.

Washer Care

Recommendations to help keep your washer clean and performing at its best

- Always use High Efficiency (HE) detergents and follow the HE detergent manufacturer’s instructions regarding the amount of HE detergent to use. Never use more than the recommended amount because that may increase the rate at which detergent and soil residue accumulate inside your washer, which in turn may result in undesirable odor.

- Use warm and hot wash water settings sometimes (not exclusively cold water washes), because they do a better job of controlling the rate at which soils and detergent accumulate.

- Always leave the washer lid open between uses to help dry out the washer and prevent the buildup of odor-causing residue.

Cleaning your top-loading washer Read these instructions completely before beginning the routine cleaning processes recommended below. This Washer Maintenance Procedure should be performed, at a minimum, once per month or every 30 wash cycles, whichever occurs sooner, to control the rate at which soils and detergent may otherwise accumulate in your washer.

Cleaning the inside of the washer

To keep your washer odor-free, follow the usage instructions provided above and use this recommended monthly cleaning procedure:

Recommended cycle for cleaning the washer

Some models have a “Clean Washer” cycle that uses higher water volumes in combination with affresh® Washer Cleaner or liquid

chlorine bleach to clean the inside of the washer.

If your model does not have a “Clean Washer” cycle, refer to the online Cycle Guide for the optimal cycle for cleaning the inside of

the washer. Use this cycle with affresh® Washer Cleaner or liquid chlorine bleach as described below.

Description of Clean Washer with affresh® cycle operation:

- This cycle will fill to a washer level high than in normal wash cycles to provide rinsing at a level above the water line for a normal wash.

- During this cycle, there will be some agitation and spinning to increase the removal of soils.

After this cycle is complete, leave the lid open to allow for better ventilation and drying of the washer interior.

Begin procedure

- Affresh® washer cleaner cycle procedure (recommended for best performance):

a. Open the washer lid and remove any clothing or items.

b. Place an afresh® Washer Cleaner tablet in the bottom of the washer basket.

c. Do not place an affresh® Washer Cleaner tablet in the detergent dispenser.

d. Do not add any detergent or other chemical to the washer when following this procedure.

e. Close the washer lid.

f. Select the cycle recommended for cleaning the inside of the washer.

g. Press the START button to start the cycle.

NOTE: For best results, do not interrupt the cycle. If the cycle must be interrupted, press POWER/CANCEL. (For models with no Power/Cancel button, press and hold START/PAUSE for three seconds.) After the cycle has stopped, run a Rinse & Spin cycle to rinse the cleaner from the washer. - Chlorine bleach procedure (alternative):

a. Open the washer lid and remove any clothing or items.

b. Add 1 cup (236 mL) of liquid chlorine bleach to the bleach compartment.

NOTE: Use of more liquid chlorine bleach than is recommended above could cause washer damage over time.

c. Close the washer lid.

d. Do not add any detergent or other chemical to the washer when following this procedure.

e. Select the cycle recommended for cleaning the inside of the washer.

f. Press the START button to start the cycle.

NOTE: For best results, do not interrupt the cycle. If the cycle must be interrupted, press POWER/CANCEL. (For models with no Power/Cancel button, press and hold START/PAUSE for three seconds.) After the cycle has stopped, run a Rinse & Spin cycle to rinse the cleaner from the washer.

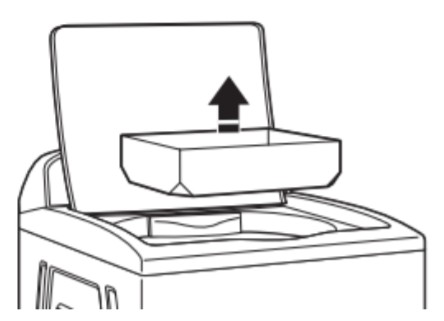

Cleaning the dispensers

After a period of using your washer, you may find some residue buildup in the washer’s dispensers.

IMPORTANT: Dispensers are not dishwasher-safe.

For non-removable dispensers:

To remove residue from the dispensers, wipe them with an affresh® Machine Cleaning Wipe or a damp cloth and towel dry.

Do not attempt to remove the dispensers or trim for cleaning. The dispensers and trim are not removable.

For removable dispensers:

If your model has a dispenser drawer, press tab(s) to remove the drawer and clean it with an affresh® Machine Cleaning Wipe or a

damp cloth and towel dry before or after you run the Clean Washer cycle. Use an all-purpose surface cleaner, if needed.

Cleaning the outside of the washer

IMPORTANT: To avoid damaging the washer’s finish, do not use abrasive products.

Use an affresh® Machine Cleaning Wipe, a soft, damp cloth, or a sponge to wipe away any spills. Use an affresh® Machine Cleaning Wipe or only mild soaps or cleaners when cleaning external washer surfaces.

Nonuse and Vacation Care

Operate your washer only when you are home. If moving, or not using your washer for a period of time, follow these steps:

- Unplug or disconnect power to the washer.

- Turn off the water supply to the washer to avoid flooding due to water pressure surge.

Winter Storage Care

IMPORTANT: To avoid damage, install and store the washer where it will not freeze. Because some water may stay in hoses, freezing can damage the washer. If storing or moving during freezing weather, winterize your washer.

To winterize washer:

- Shut off both water faucets; disconnect and drain water inlet hoses.

2. Put 1 L (1 quart) of R.V.-type antifreeze in the basket and run the washer on Rinse & Spin cycle for about 30 seconds to mix antifreeze and remaining water.

3. Unplug the washer or disconnect power.

Transporting Your Washer

- Shut off both water faucets. Disconnect and drain water inlet hoses.

- If the washer will be moved during freezing weather, follow “Winter Storage Care” directions before moving.

- Disconnect the drain hose from the drain system and drain any remaining water into a pan or bucket. Disconnect the drain hose from the back of the washer.

- Unplug the power cord.

- Place inlet hoses and drain hoses inside the washer basket.

- Drape the power cord over the edge and into the washer basket.

- Place original shipping materials back inside the washer. If you do not have shipping materials, place heavy blankets or towels into the basket opening. Close lid and place tape over the lid and down the front of the washer. Keep lid taped until washer is placed in the new location. Transport washer in the upright position.

Reinstalling/Using Washer Again

To reinstall washer after non-use, vacation, winter storage, or moving:

- Refer to Installation Instructions to locate, level, and connect the washer.

2. Before using it again, run the washer through the following recommended procedure:

To use the washer again:

- Flush water pipes and hoses.

- Reconnect water inlet hoses.

- Turn on both water faucets.

- Plug into a grounded 3 prong outlet or reconnect power.

- See your online Cycle Guide for information about which cycle(s) to run your washer through to clean the washer and remove antifreeze is used. Use only HE High-Efficiency detergent. Use half the manufacturer’s recommended amount for a medium-size load.

INSTALLATION INSTRUCTIONS

REQUIREMENTS

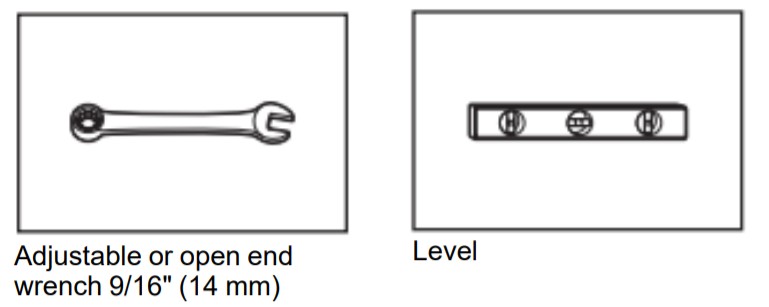

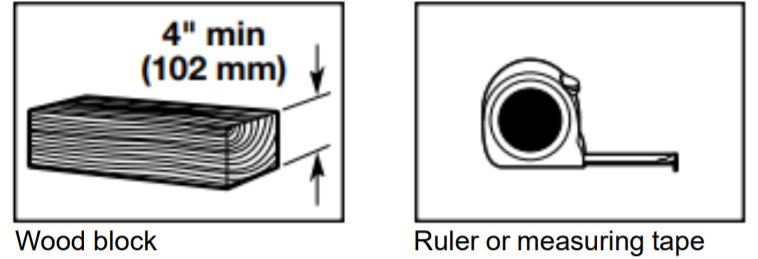

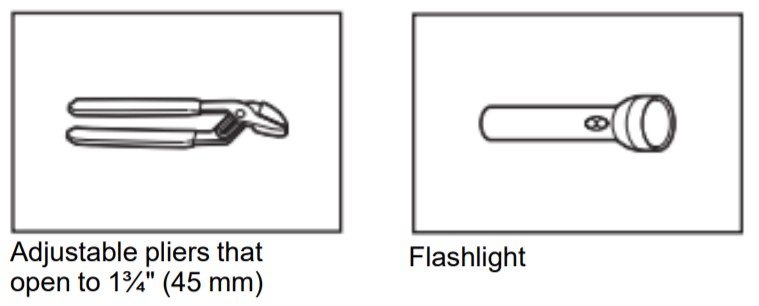

Tools and Parts

Gather required tools and parts before starting installation.

Tools Needed:

|

|

|

|

Parts Supplied:

NOTE: All parts supplied for installations are in the washer.

Parts Needed: (if not supplied with washer)

NOTE: Various inlet hose options are available; check your Quick Start Guide for ordering information.

Alternate Parts: (not supplied with washer)

Your installation may require additional parts. To order, please refer to the contact information referenced in your Quick Start Guide.

| If you have: | You will need: |

| Overhead sewer | Standard 20 gallon (76 L) 39″ (990 mm) tall drain tub or utility sink, sump pump, and connectors (available from local plumbing suppliers) |

| 1″ (25 mm) standpipe | 2″ (51 mm) diameter to 1″ (25mm) diameter standpipe adapter and connector kit |

| Drain hose too short | Extension drain hose and connector kit |

| Lint-clogged drain | Drain protector and connector kit |

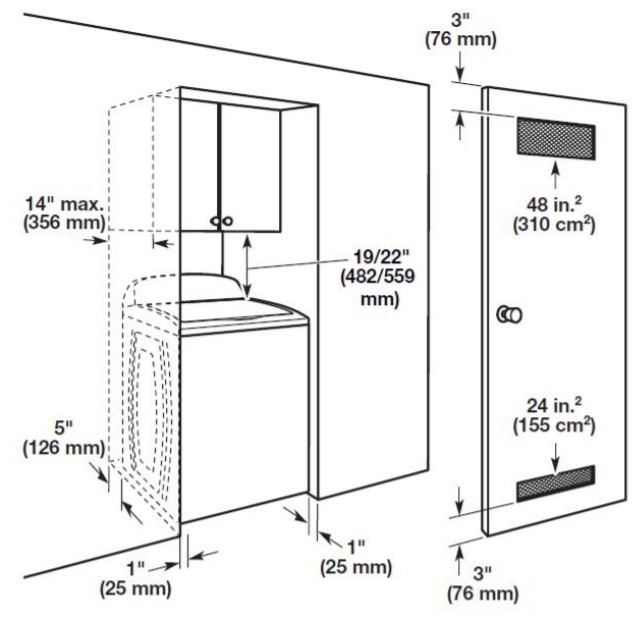

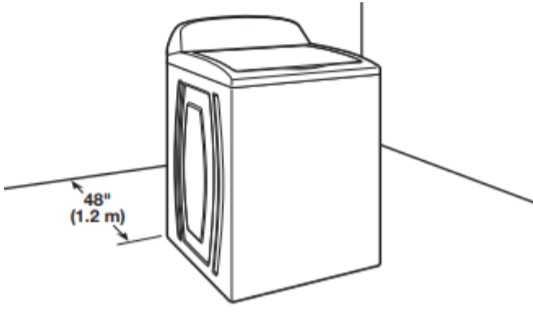

Location Requirements

Select a proper location for your washer to improve performance and minimize noise and possible “washer walk.” Install your washer in a basement, laundry room, closet, or recessed area.

IMPORTANT: Do not install, store, or operate a washer where it will be exposed to weather or in temperatures below 32°F (0°C).

Water remaining in the washer after use may cause damage in low temperatures. See “Washer Maintenance and Care” for winterizing information.

Proper installation is your responsibility.

You will need:

- A water heater is set to 120°F (49°C).

- A grounded electrical outlet is located within 4 feet (1.2 m) of the power cord on the back of the washer.

- Hot and cold water faucets located within 3 feet (0.9 m) of hot and cold water fill valves on the washer, and water pressure of 20– 100 psi (138–690 kPa).

A level floor with a maximum slope of 1″ (25 mm) under the entire washer. Installing on carpet or surfaces with foam backing is not recommended. - The floor must support the washer’s total weight (with water and load) of 315 lbs. (143 kgs).

Recessed area or closet installation

NOTE: All 27″ wide washers should have 19″ clearance, while all 29″ wide washers should have 22″ clearance.

All dimensions shown recommended spacing allowed, except for closet door ventilation openings, which are the minimum required.

This washer has been tested for installation with a spacing of 0″ (0 mm) clearance on the sides. Consider allowing more space for

ease of installation and servicing, and spacing for companion appliances and clearances for walls, doors, and floor moldings.

Add spacing of 1″ (25 mm) on all sides of the washer to reduce noise transfer. If a closet door or louvered door is installed, top and

bottom air openings indoor are required.

*For additional details (or information) specific to your model, refer to your Quick Start Guide.

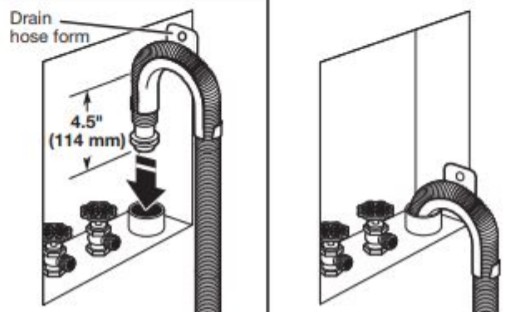

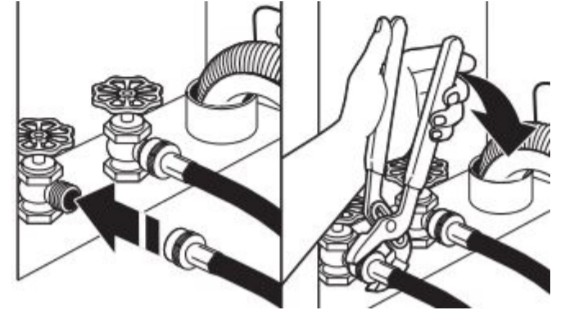

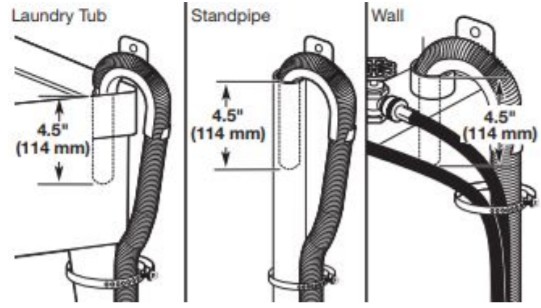

Drain System

A drain system can be installed using a floor drain, wall standpipe, floor standpipe, or laundry tub. Select the method you need.

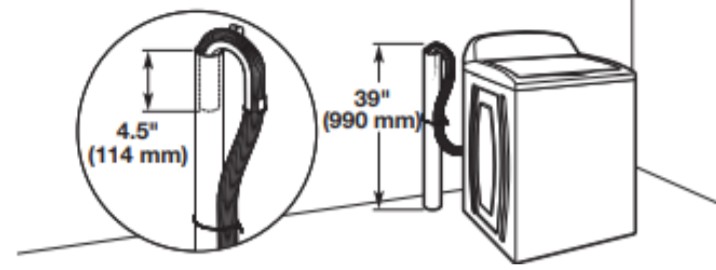

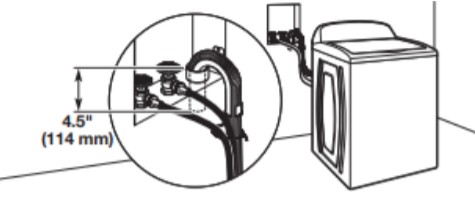

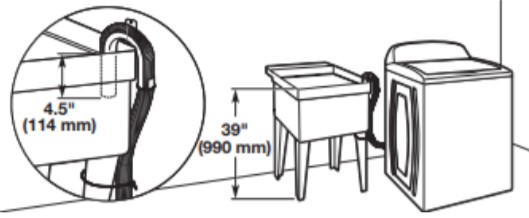

IMPORTANT: To avoid siphoning, no more than 4.5″ (114 mm) of drain hose should be inside the standpipe or below the top of the washtub. Secure drain hose with a cable tie.

Floor standpipe drain system

Minimum diameter for a standpipe drain: 2″ (51 mm). Minimum carry-away capacity: 17 gallons (64 L) per minute. Top of standpipe must be at least 39″ (990 mm) high; install no higher than 96″ (2.44 m) from the bottom of the washer. If you must install higher than 96″ (2.44 m), you will need a sump pump system.

Wall standpipe drain system

See requirements in the “Floor standpipe drain system” section.

Laundry tub drain System

Minimum capacity: 20 gallons (76 L). The top of the laundry tub must be at least 39″ (990 mm) above the floor; install no higher than 96″ (2.44 m) from the bottom of the washer.

Floor Drain System

The floor drain system requires a Siphon Break Kit, 2 Connector Kits, and an Extension Drain Hose that may be purchased separately; refer to the Quick Start Guide for online ordering information.

Minimum siphon break height: 28″ (710 mm) from the bottom of the washer (additional hoses may be needed).

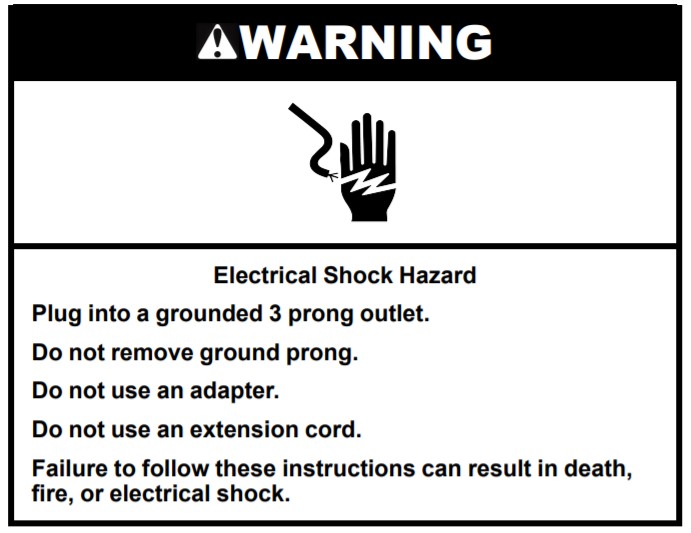

Electrical Requirements

- A 120 V, 60 Hz, AC only, 15 or 20 A, fused electrical supply is required. A time-delay fuse or circuit breaker is recommended.

It is recommended that a separate circuit breaker serving only this appliance be provided. - This washer is equipped with a power supply cord having a 3-prong grounding plug.

- To minimize possible shock hazards, the cord must be plugged into a mating, 3-prong, grounding-type outlet, grounded in

accordance with local codes and ordinances. If a mating outlet is not available, it is the personal responsibility and obligation

of the customer to have the properly grounded outlet installed by a qualified electrician. - If codes permit and a separate ground wire is used, it is recommended that a qualified electrician determine that the ground path is adequate.

- Do not ground to a gas pipe.

- Check with a qualified electrician if you are not sure the washer is properly grounded.

- Do not have a fuse in the neutral or ground circuit.

GROUNDING INSTRUCTIONS

For a grounded, cord-connected appliance:

This appliance must be grounded. In the event of a malfunction or breakdown, grounding will reduce the risk of electric shock by providing a path of least resistance for electric current. This appliance is equipped with a cord having an equipment-grounding conductor and a grounding plug.

The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

WARNING: Improper connection of the equipment-grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or serviceman if you are in doubt as to whether the appliance is properly grounded. Do not modify the plug provided with the appliance: If it will not fit the outlet, have a proper outlet installed by a qualified electrician.

For a permanently connected appliance:

This appliance must be connected to a grounded metal, permanent wiring system, or an equipment-grounding conductor must be run with the circuit conductors and connected to the equipment-grounding terminal or lead on the appliance.

SAVE THESE INSTRUCTIONS

INSTALLATION

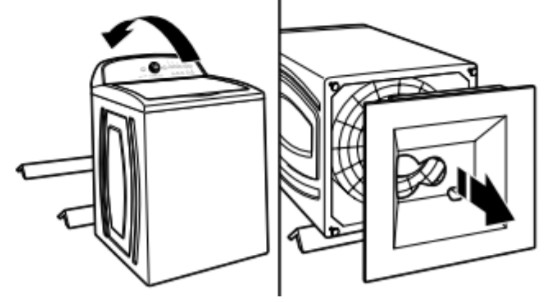

Unpacking

Excessive Weight Hazard

Use two or more people to move and install or uninstall the appliance.

Failure to do so can result in back or another injury.

Before you start: Remove shipping materials.

It is necessary to remove all shipping materials for proper operation and to avoid excessive noise from the washer.

- Move Washer

NOTE: To avoid floor damage, set the washer onto cardboard before moving it and make sure the lid is taped shut.

- Remove shipping base

IMPORTANT: Removing the shipping base is necessary for proper operation. If your washer includes a sound shield, please refer to the instructions included with the sound shield to install it at this time.

- Remove packaging material from the inside washer

NOTE: Keep packaging material inside the washer in case you need to move the washer later.

- Free power cord

Gently place the power cord over the console to allow free access to the back of the washer.

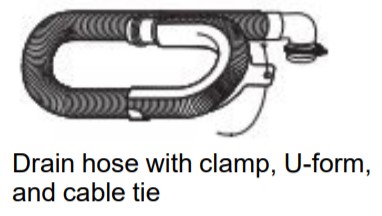

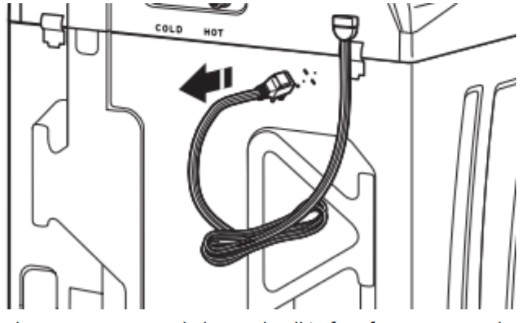

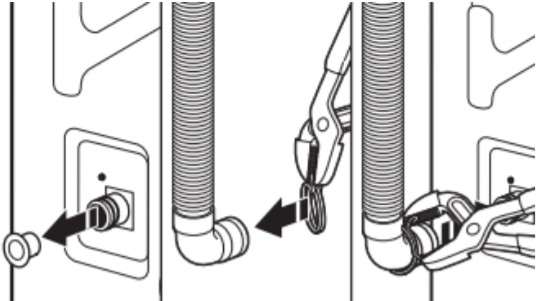

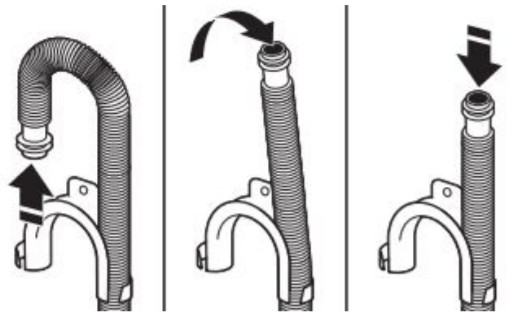

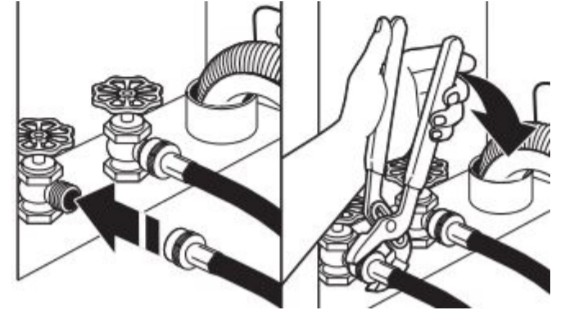

Connect Drain Hose - Attach drain hose to drain port

If the clamp is not already in place on the elbow end of the drain hose, slide it over the end as shown. Squeeze clamp with pliers and slide black elbow end of drain hose onto black drain port and secure with clamp.

For a laundry tub or standpipe drain, go to step 6.

For a floor drain, remove the pre-installed drain hose form as shown in step 7. You may need additional parts with separate

directions. See the “Alternate Parts” section. - Place drain hose in the standpipe

the bottom of the laundry tub. Drain hose form must be used.

Place the hose into the standpipe (shown in the picture) or over the side of the laundry tub. - Remove drain hose from (floor drain installations only)

It is the responsibility of the installer to install and secure the drain hose into the provided plumbing/drain in a manner that

will avoid the drain hose coming out of and leaking from the plumbing/drain.

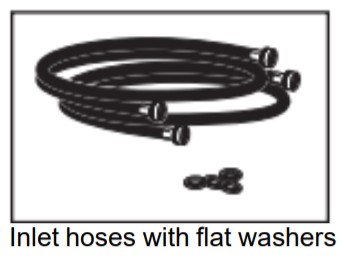

Connect Inlet Hoses

The washer must be connected to water faucets with new inlet hoses with flat washers (not provided). Do not use old hoses.

NOTE: Both hoses must be attached and have water flowing to inlet valves. If you are only connecting to a cold water faucet, you must use a Y-adapter (not provided). - Connect inlet hoses to water faucets

Attach the hose to a hot water faucet. Screw on coupling by hand until it is seated on the washer. Use adjustable pliers to tighten couplings an additional two-thirds turn. Repeat this step with a second hose for the cold water faucet. - Clearwater lines

Make note of which hose is connected to hot water to help in attaching hoses to the washer correctly. - Connect inlet hoses to the washer

•Do not overtighten the hose or use tape or sealants on the valve.

Damage to the valves can result.

•Periodically inspect and replace hoses if bulges, kinks, cuts, wear, or leaks are found.

Attach the hot water hose to the red hot water inlet valve. Screw coupling by hand until it is snug. Use pliers to tighten couplings an additional two-thirds turn. Repeat with the cold water inlet valve.

- Check for leaks

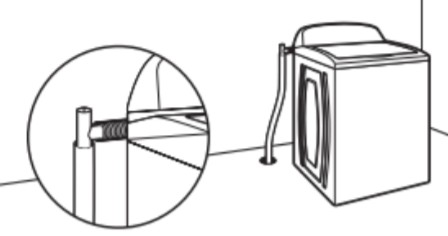

- Secure drain hose

It is the responsibility of the installer to install and secure the drain hose into the provided plumbing/drain in a manner that will avoid the drain hose coming out of or leaking from the plumbing/drain.

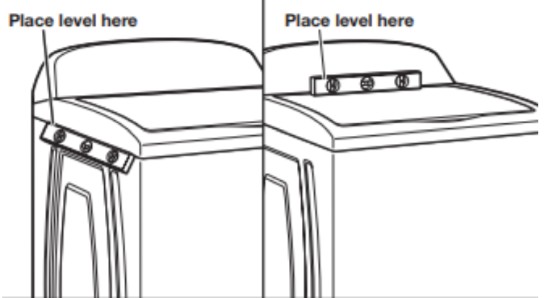

Level Washer

NOTE: Level washer properly to reduce excess noise and vibration.

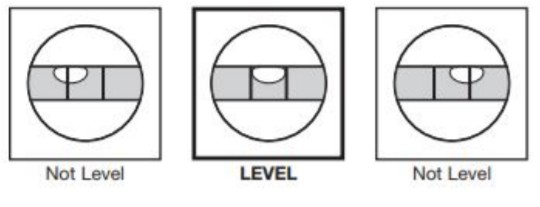

- Check levelness of washer

Move the washer to its final location. Place a level on the top edges of the washer. Use side seam as a guide to check the levelness of sides. Check the levelness of the front using a lid, as shown. Rock washer back and forth to make sure all four feet make solid contact with the floor. If the washer is level, skip stepping 15.

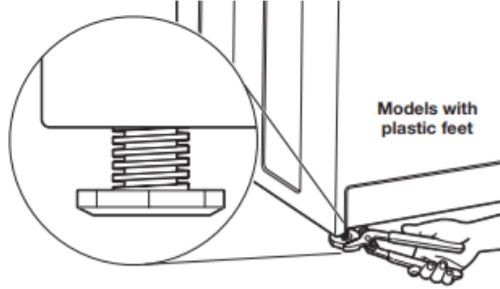

- Adjust leveling feet

Use adjustable pliers to turn the plastic leveling foot counterclockwise to lower the washer or clockwise to raise the washer.

Recheck the levelness of the washer and repeat as needed.

HELPFUL TIPS:

•You may need to adjust two different feet to level your unit. Ensure each foot remains secured to the washer’s base.

•You may want to prop upfront of the washer about 4” (102 mm) with a wood block or similar object that will support the weight of the washer.

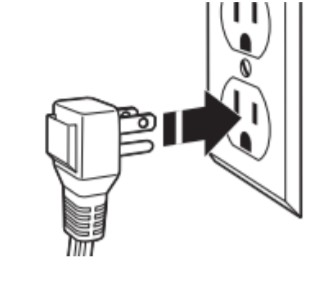

- Plug into a grounded 3-prong outlet

Complete Installation Checklist

- Check electrical requirements. Be sure you have the correct electrical supply and recommended grounding method.

- Check that all parts are now installed. If there is an extra part, go back through the steps to see what was skipped.

- Check that you have all of your tools.

- Check that the shipping material was completely removed from the washer.

- Check that the washer is level.

- Check that the water faucet is on.

- Check for leaks around faucets and inlet hoses.

- Remove protective film from the console and any tape remaining on the washer.

- Check that washer is plugged into a grounded 3-prong outlet.

- Dispose of/recycle all packaging materials.

- Read the “Washer Maintenance and Care” section.

- To test and clean your washer, measure 1/2 of the normal recommended amount of powdered or liquid HE detergent and pour it into a washer basket or detergent dispenser (on some models). Close lid. Select any cycle. Start the washer and allow to complete a full cycle.

W11436596A

©2020 All rights reserved. Used under license in Canada.

FAQ’S

What is the difference between a washer and a dryer?

The washer is used for washing clothes. The dryer is used for drying clothes.

Where do you put the detergent in a top loading Amana washer?

Do not fill past the Max-fill lines on the dispenser. Many detergents, including concentrated detergents, should be well below the Max-fill lines when following the detergent manufacturer’s directions. You can add powdered or liquid color-safe bleach to the detergent dispenser.

Why is my Amana washer not spinning or draining?

If your washer is not spinning and water is standing in the tub, check for proper drain hose installation, especially if your “spin” light is on. This light will turn on after 10 minutes of the drain pump being on with no water level change. This can happen if the drain hose is too far down the drain pipe.

How do I clean the filter on my Amana washing machine top loader?

Take a bowl, pour the cleaning solution into it, dip the brush, sponge, or rag in the solution and then start scrubbing the filter. Just be gentle and make sure to avoid over-scratching the filter unit. 3. Once the filter is thoroughly cleaned, you can rinse it under running water.

How do I reset my Amana top load washer?

Turn off the power to your Amana washer.

Unplug the machine from the power outlet.

Once the power shuts down, you have to press and hold the “Start or Pause” button for five seconds.

Plugin the unit back. Now, your Amana washing machine has been reset.

Do top load washers have filters?

“Top loaders tend to have filters on the valves,” said Amber Peabody, Service Manager at Dunnett Inc. The valve filters sift the water going in and out of the pump and hoses. If you do happen to have a removable filter, consult your owner’s manual on how to properly remove it.

What can I do if my clothes are not getting clean?

Make sure that you are using enough detergent. Make sure that you are using enough water. Make sure that you are not overloading your machine. Make sure that there are no holes or rips in your clothing. Make sure that you are using enough bleach if needed. If all else fails, call a repairman to take a look at your machine.

How do I get rid of mildew smell in my laundry?

First, check to see if there is any mold growing in your machine or on your clothes. If there is, clean it out with bleach and water or with vinegar and water. Next, make sure that you are using enough detergent and bleach in your wash cycle. Also, make sure that you are running enough cycles to properly clean your clothes (usually 3 cycles should be enough). Finally, make sure that you are running hot water through your machine during each cycle (this will help kill any mildew). If all else fails, call a repairman to take a look at your machine because it may be broken or damaged and need to be fixed or replaced.

Why did my Amana washer stop working?

Make sure the power cord is plugged into a grounded three-prong outlet, not an extension cord. Then check your household circuit breaker, Ground Fault Circuit Interrupter (GFCI), and/or fuses to make sure they’re in good working order.

How do I test my Amana washer in diagnostic mode?

Test um once you hit start with no lights and you get a red light you know that’s your lid lock and you’ll hear that click. And that’s how you know it’s working.

How do I change the belt on my Amana washing machine?

If the belt is still on your machine we can just roll that off by rotating. It off at the pulley. And discard it now next we’ll need to clean both the transmission pulley and the motor pulley.

How long does an Amana washer take to wash?

The base, or default, time for a casual cycle is 43 minutes; 56 if you select an extra rinse. The run time can vary a bit dependent on things like:

If the machine has to add more water during the wash cycle, it will add on some time.