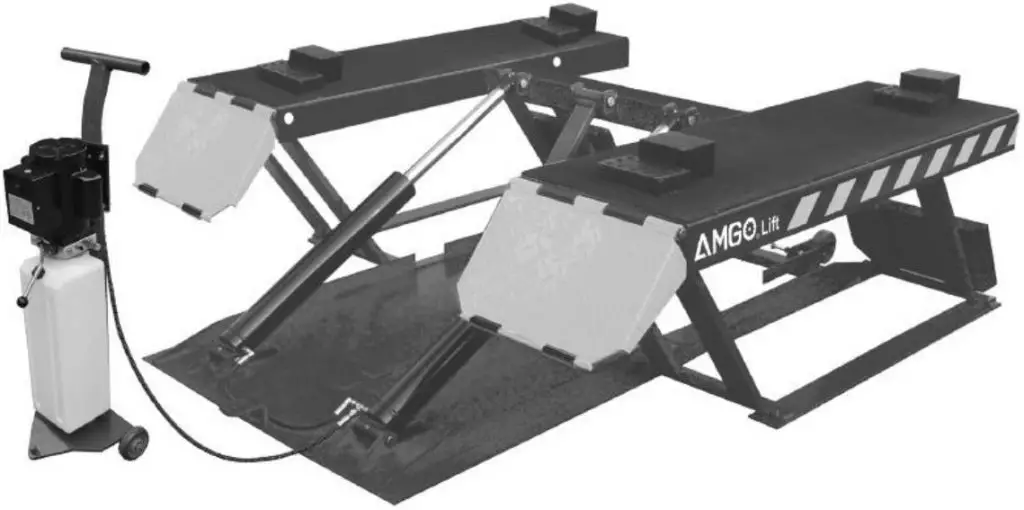

AMGO Hydraulics LR10 Portable Low-Rised Scissors Lift Installation Guide

PRODUCT FEATURES AND SPECIFICATIONS

PORTABLE LOW-RISED MODEL LR10

- Self-locking safety device: 3 stage safety lock, mechanical lock, automatic release.

- Portable unit is easy to move with the power unit stand.

- Double cylinder design.

- Multifunctional drive-in ramp, can also used as extension platform.

- High speed: From 0-23 5/8” in just 42 seconds

- Standard rubber pads included

MODEL LR10 SPECIFICATIONS

| Model | Lifting Capacity | Raised Height | Lifting Time | Overall Length | Overall Width | Lowered Height | Runway Width | Runway Length | Gross Weight | Motor |

| LR10 | 10000 LBS | 23 5/8” | 50S | 76 1/4” | 78” | 4 1/8” | 21 3/4” | 53 1/4” | 1,069lbs | 2.0 HP |

INSTALLATION REQUIREMENT

Tools requirement

- Screw Set

- Socket Head Wrench (8″)

- Wrench sets:(13 #、15 #、17 #、19 #)

- Grease gun

- Pliers

Power requirement

The electrical source must be 2.2KW minimum. The source cable size must be 2.5mm² and in good condition of contacting with floor.

STEPS OF INSTALLATION

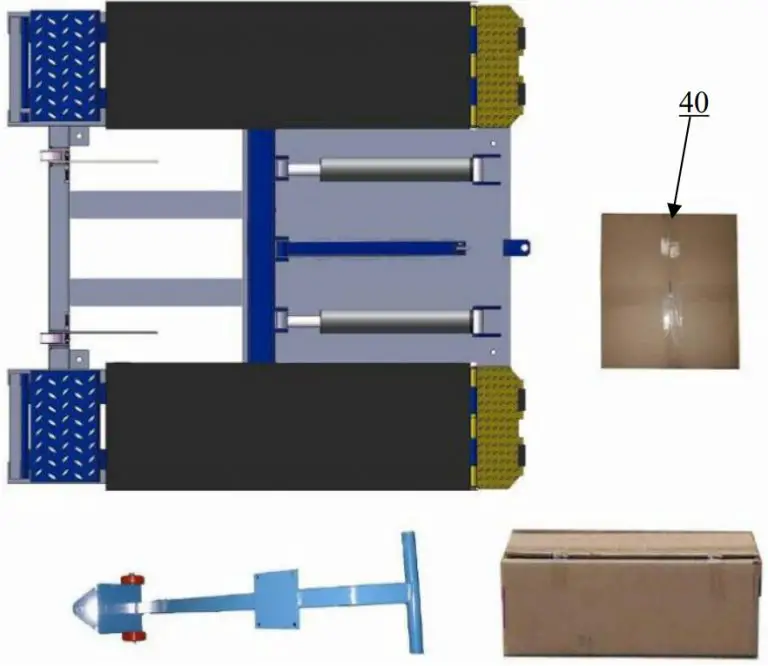

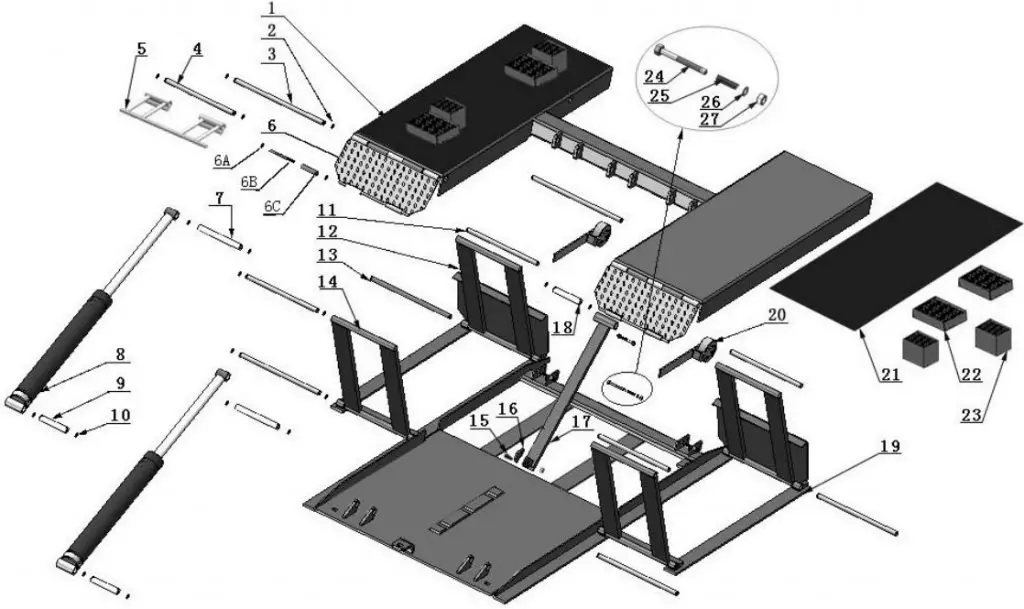

Check the parts before assembly, make sure all the parts are completed. 1.

- Packaged lift, Parts box, Power Unit and Power Unit Stand. Move aside the parts, Open the outer packing and check the parts according to the shipment parts list (See Fig. 3)

- Open the parts box, check the parts according to the part list (See Fig. 4)

- Check the parts of the parts bag according to the parts bag list (See Fig. 5).

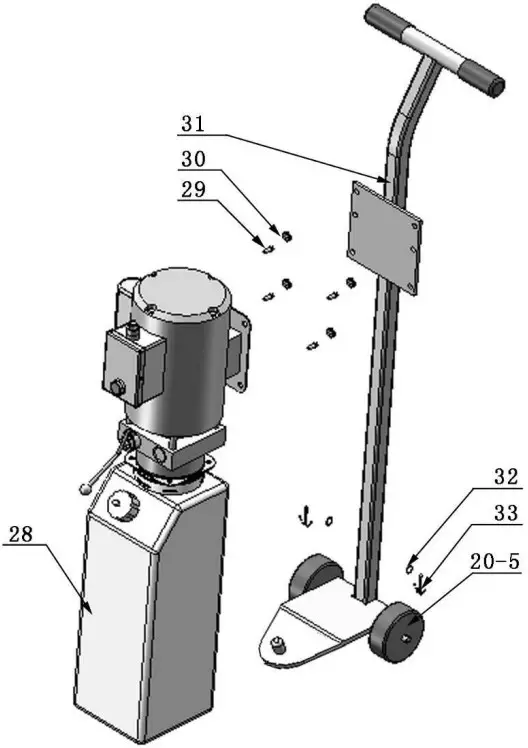

Install hydraulic power unit (See Fig. 6)

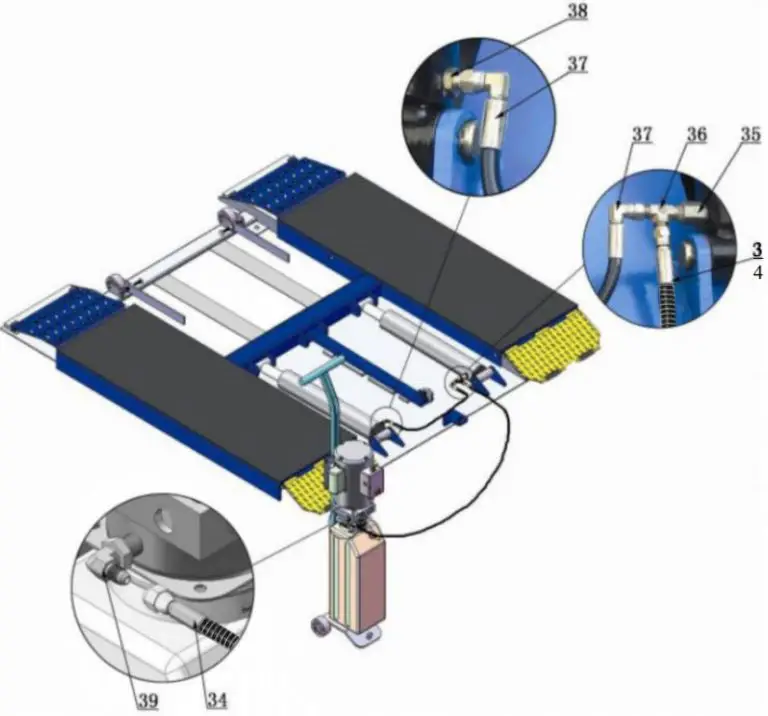

Install fitting to power unit, and then connecting oil hose (See Fig.7).

Install electrical system

Connect the power source on the data plate of power unit.

Note:

- For the safety of operators, the power wiring must contact the floor well.

- Pay attention to the direction of rotations when using three phrases motors.

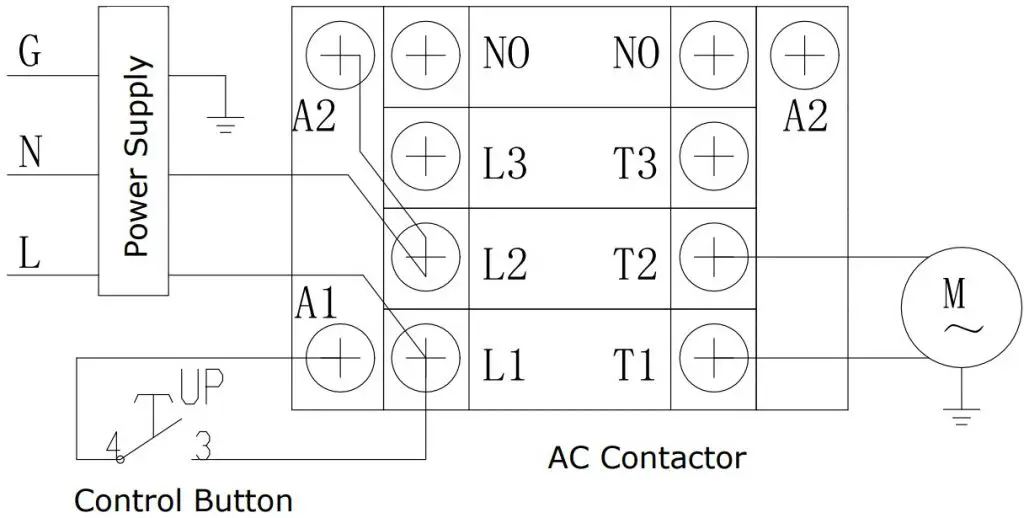

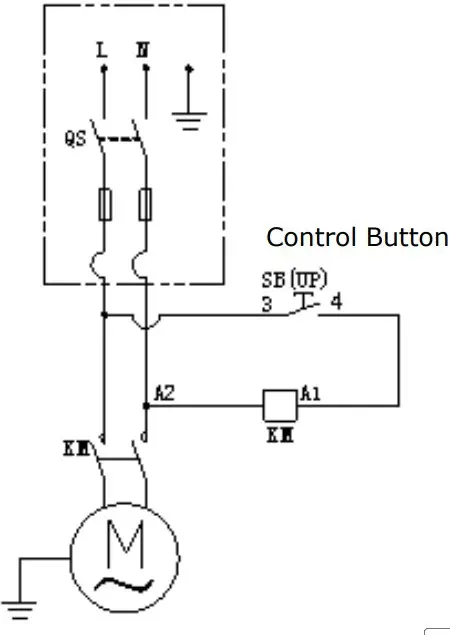

Single phase motor (Fig.8)

- Connecting the two power supply lines (fire wire L and zero wire N) to terminals of AC contactor marked L1, L2 respectively.

- Connecting the two motor wires to terminals of AC contactor marked T1, T2.

- Connecting L2 to A2 of AC contactor.

- Connecting two wires of control button to A.C. contactor terminals marked A1、L1.

Electric diagram

EXPLODED VIEW

Rollers

PARTS LIST FOR MODEL LR10

| Item | Part# | Description | QTY. | Note |

| 1 | 11630001A | Platform | 1 | |

| 2 | 10206019 | Snap Ring φ19 | 24 | |

| 3 | 11630003 | Pin for drive-in ramp φ19*452 | 2 | |

| 4 | 11630106 | Bracket Pin φ19*410 | 2 | |

| 5 | 11620006A | Bracket | 2 | |

| 6 | 11630108 | Drive-in ramp | 2 | |

| 6A | 10209010 | Snap Ring φ10 | 8 | |

| 6B | 11620043 | Roller Pin for drive-in ramp | 4 | |

| 6C | 10620063 | Roller for drive-in ramp | 4 | |

| 7 | 11630109 | Cylinder Connecting pin φ25*92 | 2 | |

| 8 | 10630006 | Cylinder | 2 | |

| 9 | 11630007 | Cylinder case connecting pin φ25*132 | 2 | |

| 10 | 10206032 | Snap Ring φ25 | 10 | |

| 11 | 11630008 | Frame Support connect pin upper | 4 | |

| 12 | 11630009 | Frame support (front) | 2 | |

| 13 | 11630010 | Frame Support connect pin φ19*405 | 4 | |

| 14 | 11630011 | Frame Support | 2 | |

| 15 | 10630100 | Socket Bolt M10*40 | 1 | |

| 16 | 11630013 | Safety Block | 1 | |

| 17 | 11630014 | Safety Support | 1 | |

| 18 | 11630105 | Pin for Safety Support φ25*142 | 1 | |

| 19 | 11630111 | Base | 1 | |

| 20 | 10640024 | Roller | 2 | |

| 21 | 10630102 | Rubber Pad 438*1350*5 | 2 | |

| 22 | 10620034 | Rubber Pad 100*120*38 | 4 | |

| 23 | 10610070 | Rubber Pad 100*120*70 | 4 | |

| 24 | 10420020B | Hex Bolt M10*115 | 2 | |

| 25 | 10630015 | Spring φ15*φ12*55 | 2 | |

| 26 | 10209022 | Washer φ10 | 2 | |

| 27 | 10209056 | Self Locking Nut M10 | 3 | |

| 28 | 071101 | Power Unit | 1 | |

| 29 | 10209003 | Hex Bolt M8*25 | 4 | |

| 30 | 10209005 | Self Locking Nut M8 | 4 | |

| 31 | 11640021 | Power Unit Stand | 1 | |

| 32 | 10206006 | Washer φ12 | 2 | |

| 33 | 10420046 | Split Pin φ3*20 | 2 | |

| 34 | 1003035003 | Oil Hose Assy.(with spring) | 1 | |

| 35 | 10630103 | Straight Fitting | 1 | |

| 36 | 10209062 | T fitting | 1 | |

| 37 | 10630104 | Oil Hose 1/4*550 | 1 | |

| 38 | 10209064 | Straight fitting for cylinder | 1 | |

| 39 | 10209060 | 90 degree fitting for power unit | 1 | |

| 40 | 10630501A | Parts Box | 1 |

| Item | Part# | Description | QTY. | Note |

| Parts for Roller | ||||

| 20-1 | 11630031 | Rollers handle | 2 | |

| 20-2 | 10630032 | Snap Ring | 8 | |

| 20-3 | 11630033 | Connecting Shaft | 2 | |

| 20-4 | 11630034 | Roller Shaft | 2 | |

| 20-5 | 10640023 | Roller | 4 | |

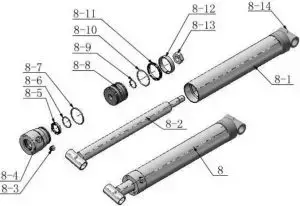

Cylinder

| Item | Part No. | Description | QTY. | Note |

| 8-1 | 11630029 | Bore Weldment | 2 | |

| 8-2 | 11630026 | Piston Rod | 2 | |

| 8-3 | 10201034 | Bleeding Plug | 2 | |

| 8-4 | 11630030 | Head cap | 2 | |

| 8-5 | 10209078 | Dust ring | 2 | |

| 8-6 | 10201035 | O – Ring | 2 | |

| 8-7 | 10620049 | O – Ring | 2 | |

| 8-8 | 11630028 | Piston | 2 | |

| 8-9 | 10620050 | O-Ring | 2 | |

| 8-10 | 10630027 | O-Ring | 2 | |

| 8-11 | 10620054 | Y-Ring | 2 | |

| 8-12 | 10620055 | Support Ring | 2 | |

| 8-13 | 10206071 | Nut | 2 | |

| 8-14 | 10620064 | Greasing Fitting | 4 |

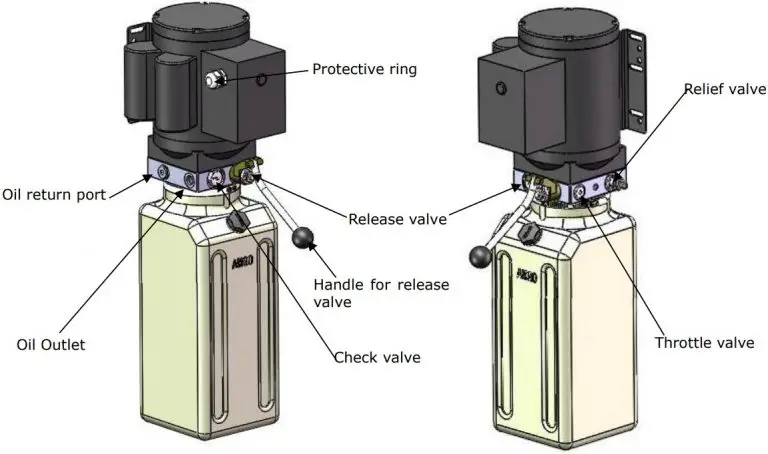

Manual Power Unit (071101)

Manual Power Unit 220V/50/60HZ Single Phase

| Item | Part No. | Description | QTY. | Note |

| 1 | 81400180 | Rubber Pad | 2 | |

| 2 | 81400130 | Starting capacitor | 1 | |

| 3 | 81400088 | Running capacitor | 1 | |

| 4 | 10420148 | Cup head bolts with washer | 4 | |

| 5 | 81400066 | Cover for capacity | 2 | |

| 6 | 81400363 | Motor Connecting Shaft | 1 | |

| 7 | 090106 | Manifold Block | 1 | |

| 8 | 10209149 | Lock Washer | 4 | |

| 9 | 81400276 | Plug | 1 | |

| 10 | 81400259 | Plug | 1 | |

| 11 | 85090142 | Socket Bolt | 4 | |

| 12 | 81400280 | Gear pump | 1 | |

| 13 | 10209034 | Lock Washer | 2 | |

| 14 | 81400295 | Socket Bolt | 2 | |

| 15 | 81400365 | O Ring | 1 | |

| 16 | 10209152 | Belt | 1 | |

| 17 | 85090167 | Magnet | 1 | |

| 18 | 81400290 | Filter | 1 | |

| 19 | 81400413 | Motor | 1 | |

| 20 | 10420070 | Push Button | 1 | |

| 21 | 41030055 | AC Contactor | 1 | |

| 22 | 81400287 | Cover of Motor terminal box | 1 | |

| 23 | 71111216 | AMGO label | 1 | |

| 24 | 81400560 | Throttle valve | 1 | |

| 25 | 81400266 | Relief Valve | 1 | |

| 26 | 81400284 | Plug | 1 | |

| 27 | 10720118 | Elastic latch | 1 | |

| 28 | 81400451 | Release valve handle | 1 | |

| 29 | 10209020 | Black plastic ball | 1 | |

| 30 | 81400421 | Release valve Nut | 1 | |

| 31 | 81400422 | Release valve washer | 1 | |

| 32 | 81400449 | Release valve seat | 1 | |

| 33 | 070001 | Release Valve | 1 | |

| 34 | 070002 | Check valve | 1 | |

| 35 | 81400288 | Oil suction pipe | 1 | |

| 36 | 81400289 | Oil return pipe | 1 | |

| 37 | 81400364 | Clamp | 1 | |

| 38 | 81400263 | Oil tank cap | 1 | |

| 39 | 81400275 | Oil tank | 1 |

Illustration of hydraulic valve for power unit

OPERATION INSTRUCTIONS

- Install the oil hose between oil cylinder and power unit, connect well the power supply wire. The machine can be ready to use.

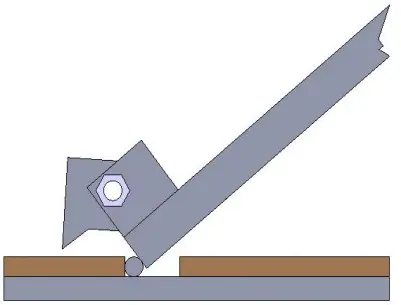

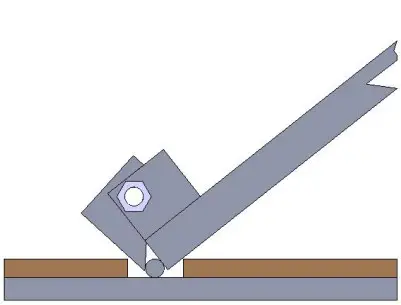

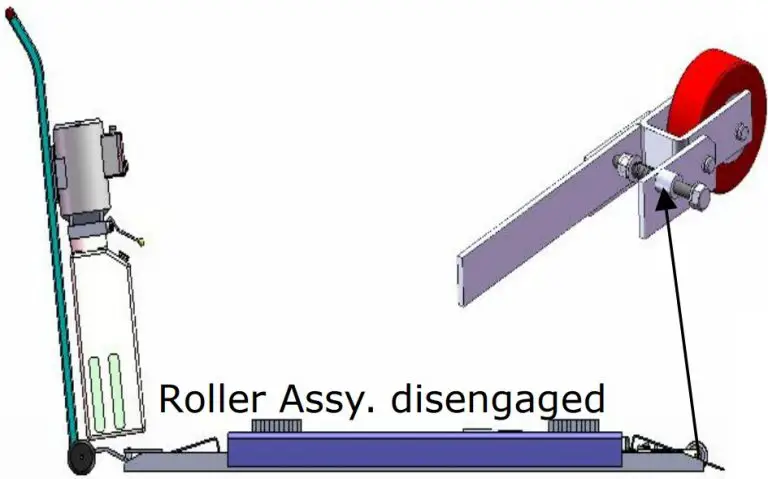

- The roller must be disengage when lifting vehicle (See Fig.15). To raise and lock the lift: Press the button up till the lift is raised to the required height and the locks are in engaged (See Fig.13), then push release handle of the power unit, the lift would be locked.

- To lower lift:Press the button UP, until the safety lock is in the released position (See Fig.14), lower lift by pushing lowering handle.

- Move lift: Pull up roller bracket, lock two roller to the lift with roller shaft. (See Fig. 15& 16 ). Moving the lift by the power unit stand.

- There are four fixed holes in the machine, can fix the machine on ground by 3/4 X 4 3/4” anchor bolts (See Fig.17).

MAINTENANCE SCHEDULE

Monthly:

- Lubricate all moving parts with lubricant.

- Check all connectors, bolts and pins to insure proper mounting.

- Make a visual inspection of all hydraulic hoses/lines for possible wear or leakage.

Every six months:

- Make a visual inspection of all moving parts for possible wear, interference or damage.

- Check all fastener and re-torque.

TROUBLE SHOOTING

| TROUBLE | CAUSE | REMEDY |

| Motor does not run |

|

|

| Motor runs but the lift is not raised |

|

|

| Lift does not stay up |

|

Repair or replace |

| Lift raises slowly |

|

|

| Lift can not lower |

|

|

Lift disposal

When the car lift cannot meet the requirements for normal use and needs to be disposed, it should follow local laws and regulations.

Contact Us

AMGO HYDRAULIC CORPORATION

1931 Joe Rage’s Blvd. Manning. South Carcana.

Zip. 29102

Tel: (803) 505-6410

Fax (803) 505-6410

Manual Part No. : 72106503

Revision Date: : 2020/08