Dishwasher

SMS2HKW66G [en] User manual

en

Table of contents

Safety ……………………………………….. 4 General information…………………….. 4 Intended use………………………………. 4 Restriction on user group…………….. 4 Safe installation ………………………….. 4 Safe use ……………………………………. 6 Damaged appliance ……………………. 7 Risk to children ………………………….. 8 Preventing material damage …….. 10 Safe installation ………………………… 10 Safe use ………………………………….. 10 Environmental protection and saving energy………………………….. 11 Disposing of packaging …………….. 11 Saving energy…………………………… 11 AquaSensor……………………………… 11 Installation and connection………. 11 Scope of supply ……………………….. 11 Installing and connecting the appliance …………………………………….. 12 Drainage connection …………………. 12 Drinking water connection …………. 12 Electrical connection …………………. 12 Familiarising yourself with your appliance…………………………. 14 Appliance ………………………………… 14 Controls …………………………………… 15 Programmes ……………………………. 17 Information for test institutes ………. 18 Favourite ……………………………… 18 Additional functions ………………… 19 Features………………………………….. 19 Top basket……………………………….. 19 Bottom basket ………………………….. 20 Cutlery basket ………………………….. 20 Folding prongs …………………………. 21 Baking sheet spray head …………… 21

2

Basket heights………………………….. 22 Before using for the first time …… 22 Performing the initial configuration………………………………………….. 22 Water softening system……………. 23 Overview of water hardness settings………………………………………… 23 Setting the water softening system …………………………………………. 23 Special salt ………………………………. 24 Switching off the water softening system …………………………………….. 24 Regeneration of the water softening system ………………………. 25 Rinse aid system……………………… 25 Rinse aid …………………………………. 25 Setting the amount of rinse aid …… 26 Switching the rinse aid system off …………………………………………… 26 Detergent ………………………………… 26 Suitable detergents …………………… 26 Unsuitable detergents ……………….. 28 Information on detergents ………….. 28 Adding detergent ……………………… 28 Tableware ……………………………….. 29 Damage to glass and tableware …. 29 Arrange tableware …………………….. 30 Removing tableware………………….. 31 Basic operation ……………………….. 31 Switching on the appliance ………… 31 Setting a programme ………………… 31 Setting additional functions ………… 31 Setting timer programming ………… 31 Starting the programme …………….. 32 Activating button lock………………… 32 Deactivate button lock……………….. 32 Interrupting programme …………….. 32

Terminate programme……………….. 32 Switching off appliance ……………… 32

Basic settings………………………….. 33 Overview of basic settings …………. 33 Changing basic settings…………….. 34

Home Connect ………………………… 34 Home Connect quick start …………. 35 Home Connect settings……………… 35 Remote Start ………………………. 35 Remote Diagnostics …………………. 36 Software update ……………………….. 36 Data protection…………………………. 36

Cleaning and servicing …………….. 37 Cleaning the tub ……………………….. 37 Cleaning products …………………….. 37 Tips on appliance care………………. 37 Machine Care …………………….. 37 Filter system …………………………….. 38 Cleaning spray arms …………………. 39

Troubleshooting………………………. 41 Error code / Fault display / Signal…………………………………………… 41 Washing results ………………………… 43 Home Connect problem…………….. 50 Information on display panel………. 50 Malfunctions …………………………….. 50 Mechanical damage………………….. 51 Noise ………………………………………. 52 Clean wastewater pump…………….. 53

Transportation, storage and disposal ………………………………….. 53 Removing the appliance ……………. 53 Protect appliance from frost……….. 54 Transporting the appliance ………… 54 Disposing of old appliance ………… 54

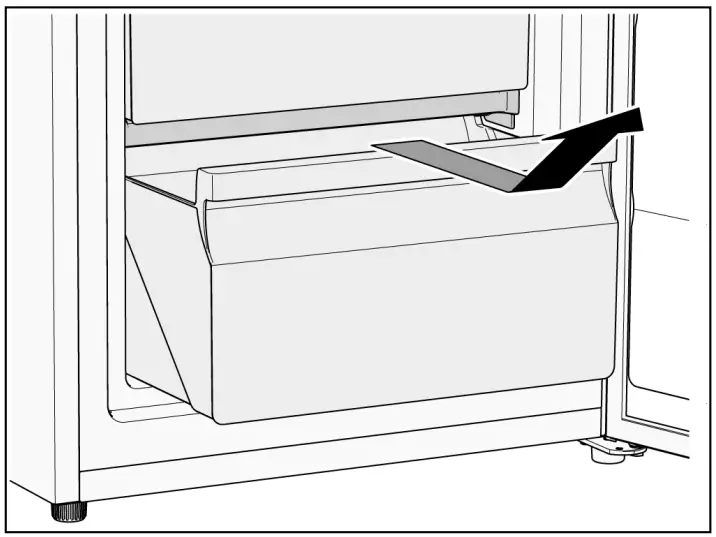

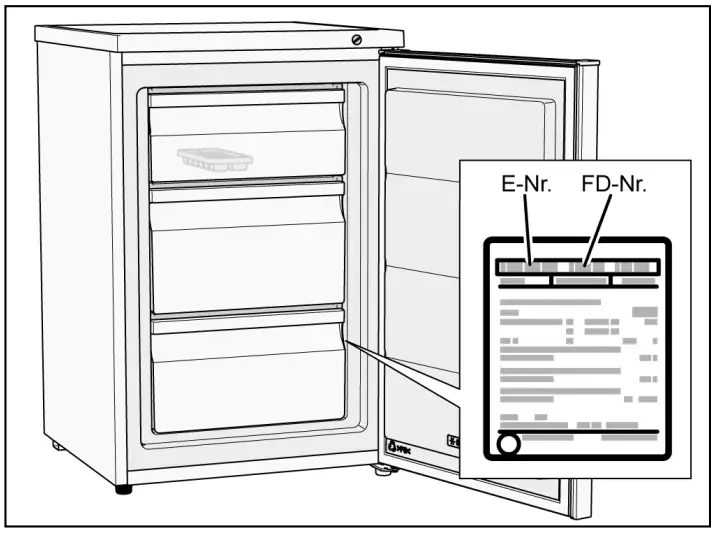

Customer Service…………………….. 54 Product number (E-Nr.), production number (FD) and consecutive numbering (Z-Nr.) ………………… 55

en Technical specifications…………… 55 Information regarding Free and Open Source Software ………………. 56 Declaration of Conformity ………….. 56

3

enSafety

Safety

Observe the following safety instructions. General information ¡ Read this instruction manual carefully. ¡ Keep the instruction manual and the product information safe

for future reference or for the next owner. ¡ Do not connect the appliance if it has been damaged in transit. Intended use Only use this appliance: ¡ For cleaning household tableware. ¡ In private households and in enclosed spaces in a domestic en-

vironment. ¡ Up to an altitude of max. 4000 m above sea level.

Restriction on user group This appliance may be used by children aged 8 or over and by people who have reduced physical, sensory or mental abilities or inadequate experience and/or knowledge, provided that they are supervised or have been instructed on how to use the appliance safely and have understood the resulting dangers. Children must not play with the appliance. Cleaning and user maintenance must not be performed by children unless they are being supervised. Keep children under the age of 8 years away from the appliance and power cable. Safe installation Follow these safety instructions when installing the appliance.

WARNING Risk of injury! Improper installation may cause injury. When installing and connecting the appliance, follow the in-

structions in the manual and installation instructions.

4

Safetyen

WARNING Risk of electric shock! Incorrect installation is dangerous. Connect and operate the appliance only in accordance with

the specifications on the rating plate. Always use the supplied power cable for the new appliance. Connect the appliance to a power supply with alternating

current only via a properly installed socket with earthing. The protective conductor system of the domestic electrical

installation must be properly installed. Never equip the appliance with an external switching

device, e.g. a timer or remote control. When the appliance is installed, the mains plug of the

power cord must be freely accessible. If free access is not possible, an all-pole isolating switch must be installed in the permanent electrical installation according to the installation regulations. When installing the appliance, check that the power cable is not trapped or damaged. WARNING Risk of fire! It is dangerous to use an extended power cord and non-approved adapters. Do not use extension cables or multiple socket strips. If the power cord is too short, contact Customer Service. Only use adapters approved by the manufacturer. WARNING Risk of burns! If the appliance is not installed properly, this may result in burns. With free-standing appliances, ensure that they are installed with the back panel against a wall.

5

enSafety

Safe use WARNING Risk of serious harm to health! Failure to comply with safety instructions and directions for use on packagings of detergent and rinse aid products may cause serious harm to health. Follow the safety instructions and directions for use on the packagings of detergent and rinse aid products. WARNING Risk of explosion!

¡ Adding solvents to the interior of the appliance may cause explosions. Never add solvents to the interior of the appliance.

¡ Highly caustic alkaline or highly acidic cleaning agents in conjunction with aluminium parts in the interior of the appliance may cause explosions. Never use highly caustic alkaline or highly acidic cleaning agents, in particular commercial or industrial products, in conjunction with aluminium parts (e.g. grease filters of extractor hoods or aluminium pans), e.g. for the Machine Care programme. WARNING Risk of injury!

¡ Leaving the appliance door open may result in injury. Only open the appliance door to load or unload tableware in order to prevent accidents, e.g. through tripping. Do not sit or stand on the appliance door when open.

¡ Knives and utensils with sharp points can cause injuries. Arrange knives and utensils with sharp points in the cutlery basket with the points downwards, on the knife shelf or in the cutlery drawer. WARNING Risk of scalding! If you open the appliance door while the programme is running, hot water may splash out of the appliance. Open the appliance door carefully if the programme is still running.

6

Safetyen

WARNING Risk of tipping! Overfilling the Baskets may cause the appliance to tip up. Never overfill the Baskets with free-standing appliances. WARNING Risk of electric shock! ¡ An ingress of moisture can cause an electric shock. Only use the appliance in enclosed spaces. Never expose the appliance to intense heat or humidity. Do not use steam- or high-pressure cleaners to clean the

appliance. ¡ If the insulation of the power cord is damaged, this is danger-

ous. Never let the power cord come into contact with hot appli-

ance parts or heat sources. Never let the power cord come into contact with sharp

points or edges. Never kink, crush or modify the power cord. Damaged appliance Follow the safety instructions if the appliance is damaged. WARNING Risk of electric shock! ¡ If the appliance or the power cord is damaged, this is dangerous. Never operate a damaged appliance. Never operate an appliance with a cracked or fractured sur-

face. Never pull on the power cord to unplug the appliance. Al-

ways unplug the appliance at the mains. If the appliance or the power cord is damaged, immediately

unplug the power cord or switch off the fuse in the fuse box and turn off the water tap. “Call Customer Service.” Page 54 Repairs to the appliance should only be carried out by trained specialist staff.

7

enSafety

¡ Incorrect repairs are dangerous. Repairs to the appliance should only be carried out by trained specialist staff. Only use genuine spare parts when repairing the appliance. If the power cord of this appliance is damaged, it must be replaced with a special connection cable, which is available from the manufacturer or his Customer Service.

Risk to children Follow the safety instructions if there are children in your home.

WARNING Risk of suffocation! ¡ Children may put packaging material over their heads or wrap

themselves up in it and suffocate. Keep packaging material away from children. Do not let children play with packaging material. ¡ Children may breathe in or swallow small parts, causing them to suffocate. Keep small parts away from children. Do not let children play with small parts. WARNING Risk of harm to health! Children can lock themselves in the appliance, thereby putting their lives at risk. With redundant appliances, unplug the power cord. Then

cut through the cord and damage the lock on the appliance door beyond repair so that the appliance door will no longer close. WARNING Risk of crushing! With higher-level appliances, children can become crushed between the appliance door and cabinet doors underneath. Keep an eye on children when opening and closing the appliance door.

8

Safetyen

WARNING Risk of chemical burns! Rinse aid and detergent may cause chemical burns to the mouth, throat and eyes. Keep children away from detergent and rinse aid products. Keep children away from the appliance when open. The wa-

ter in the interior of the dishwasher is not drinking water. It may contain residues of detergents and rinse aid. WARNING Risk of injury! Children may get their fingers caught in the slots of the tablet collecting tray and injure themselves. Keep children away from the appliance when open. WARNING Risk of suffocation! Children may become trapped in the appliance and suffocate. Use the childproof lock if fitted. Never let children play with or operate the appliance.

9

enPreventing material damage

Preventing material dam- Preventingmaterialdamage age

Preventing material damage

Safe installation

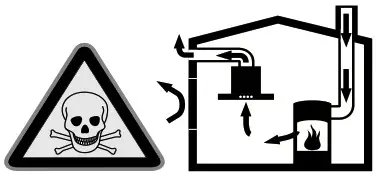

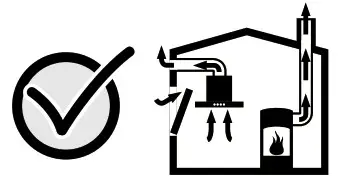

Follow the instructions when installing the appliance. ATTENTION! ¡ Improper installation of the appli-

ance may cause damage. If the dishwasher is installed

above or below other domestic appliances, follow the information on installation in combination with a dishwasher in the installation instructions for the individual appliances. If there is no information or if the installation instructions do not include the relevant information, contact the manufacturer of these appliances to check that the dishwasher can be installed above or below these appliances. If no information is available from the manufacturer, the dishwasher should not be installed above or below such appliances. To ensure the safe operation of all domestic appliances, continue following the installation instructions for the dishwasher. Do not install the dishwasher under a hob. Do not install the dishwasher near heat sources, e.g. radiators, heat storage tanks, ovens or other appliances that generate heat. ¡ Modified or damaged water hoses may result in material damage and damage to the appliance. Never kink, crush, modify or cut through water hoses. 10

Only use the water hoses supplied with the appliance or genuine spare hoses.

Never re-use water hoses that have been used before.

¡ If the water pressure is too high or too low, the appliance may not be able to operate properly. Make sure that the water pressure in the water supply system is min. 50 kPa (0.5 bar) and max. 1000 kPa (10 bar). If the water pressure exceeds the maximum value specified, a pressure-reducing valve must be installed between the drinking water connection and the hose set of the appliance.

Safe use

Follow the instructions when using the appliance. ATTENTION! ¡ Escaping water vapour can dam-

age fitted units. When the programme ends,

leave the appliance to cool down for a while before opening the door. ¡ Special salt for dishwashers can damage the tub due to corrosion. To make sure that any special salt that escapes is washed out of the tub, add the special salt to the dispenser for special salt immediately before the programme starts. ¡ Detergent may damage the water softening system. Only fill the dispenser of the water softening system with special dishwasher salt. ¡ Unsuitable cleaning agents may damage the appliance. Do not use a steam cleaner.

Environmental protection and saving energyen

So as not to scratch the finish on the appliance, do not use sponges with a rough surface or abrasive cleaning agents.

To prevent corrosion, do not use sponge cloths on dishwashers with a stainless steel front or rinse such cloths thoroughly several times before using them for the first time.

Environmental protection Environmentalprotectionandsavingenergy and saving energy

Environmental protection and saving energy

Disposing of packaging

The packaging materials are environmentally compatible and can be recycled. Sort the individual components by

type and dispose of them separately.

Saving energy

If you follow these instructions, your appliance will use less electricity and less water. Use the Eco 50 ° programme.

The Eco 50 ° programme is energy-efficient and environmentally friendly. “Programmes”, Page 17 If you do not have much tableware to wash, use the additional Half Load function.1 The programme will adjust to a lower load and consumption will be reduced. “Additional functions”, Page 19

AquaSensor

The AquaSensor is an optical measuring device (light barrier) which measures the turbidity of the rinsing water. You can save water with the AquaSensor. Use of the AquaSensor depends on the programme. If the soiling level is high, the rinsing water is drained off and replaced with fresh water. If the soiling level is lower, the rinsing water is used in the next wash cycle, so reducing water consumption by 3-6 litres. In the automatic programmes the temperature and run time are additionally adjusted to the level of soiling.

Installation and connec- Installationandconnection tion

Installation and connection

Scope of supply

After unpacking all parts, check for any damage in transit and completeness of the delivery. If you have any complaints, contact the dealer who sold you the appliance or our Customer Service. Note: The appliance has been tested at the factory to check it is in working order. It is possible that water has left marks on the appliance. These marks will disappear after the first wash cycle. The delivery consists of the following: ¡ Dishwasher ¡ Operating instructions ¡ Installation Instructions ¡ Warranty ¡ Installation material ¡ Inlet hose

1 Depending on the appliance specifications 11

enInstallation and connection

¡ Salt filling aid funnel ¡ Mains cable ¡ Quick reference guide

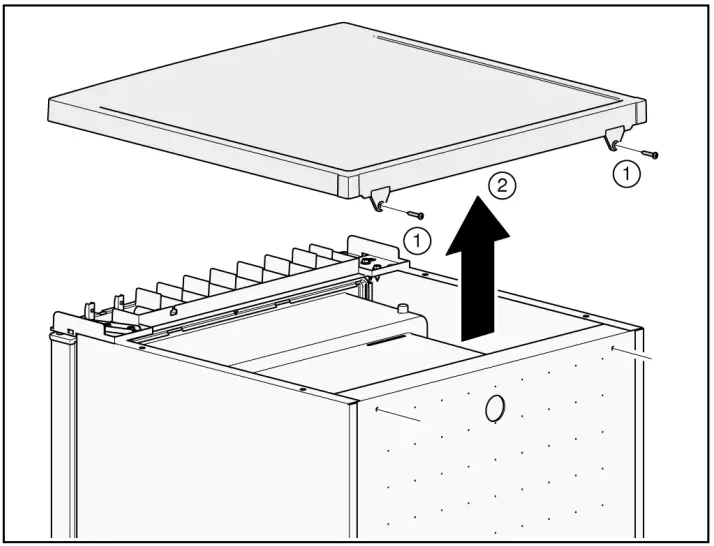

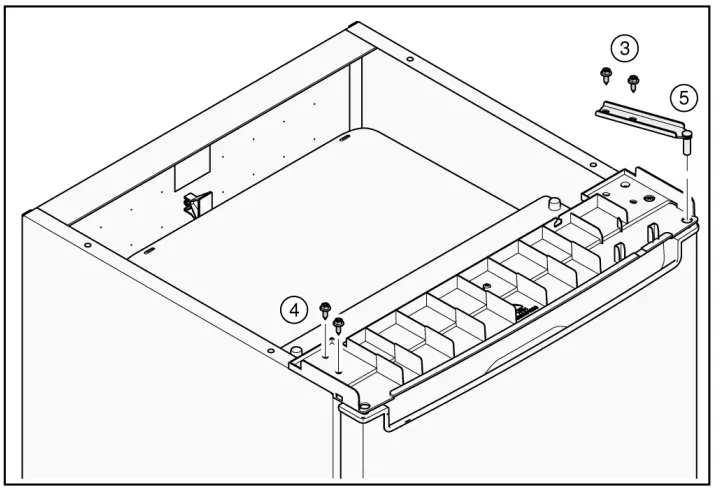

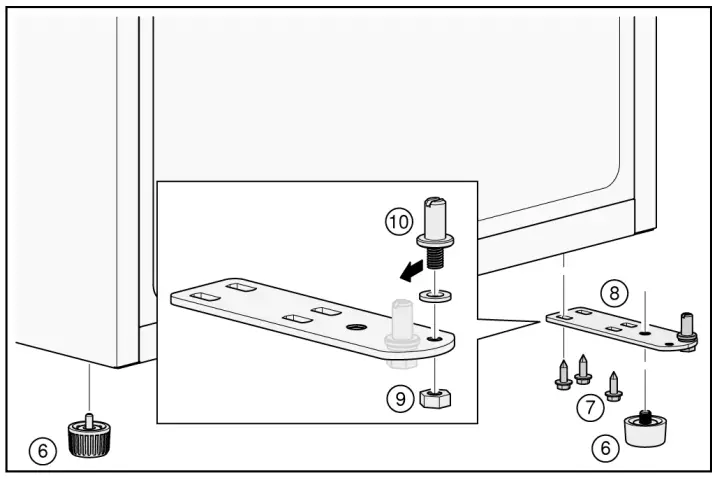

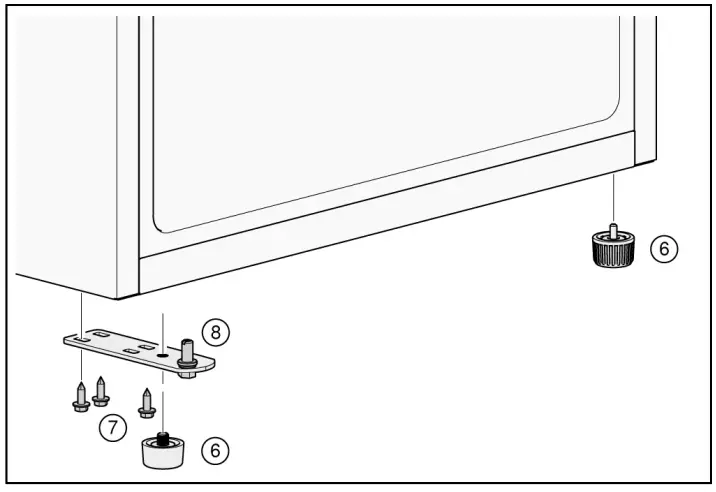

Installing and connecting the appliance

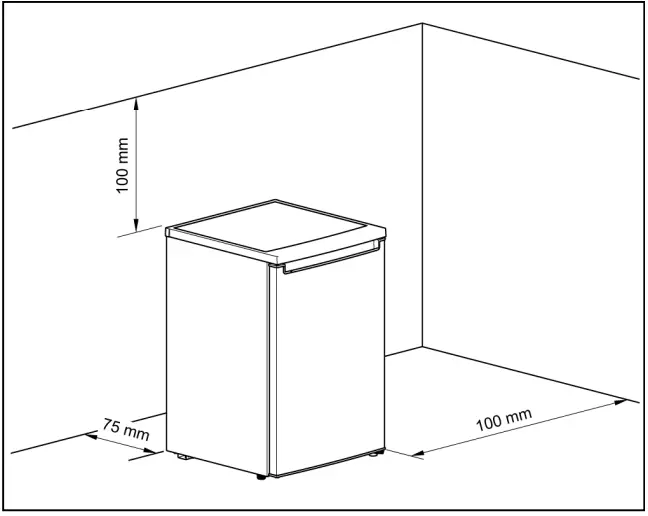

You can position your built-under or integrable appliance in a fitted kitchen between wooden and plastic walls. If you subsequently install your dishwasher as a free-standing appliance, you must stop it from tipping over, e.g. by screwing it to the wall or installing it under a continuous worktop that is securely connected to adjacent cabinets. 1. “Follow the safety instructions.”

Page 4 2. “Follow the instructions for elec-

trical connection.” Page 12 3. Check the Scope of supply and

the condition of the appliance. 4. Consult the installation instructions

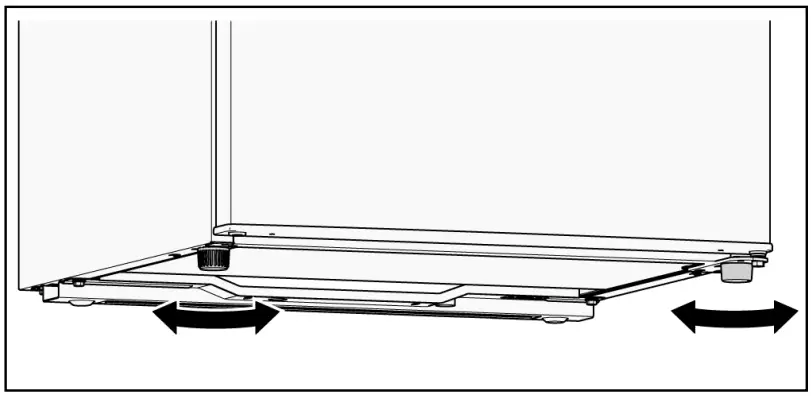

for the installation dimensions required. 5. Make the appliance level using the height-adjustable feet. Make sure that the appliance is standing on the floor securely. 6. “Install the drainage connection.” Page 12 7. “Install the drinking water connection.” Page 12 8. Connect the appliance to the power supply.

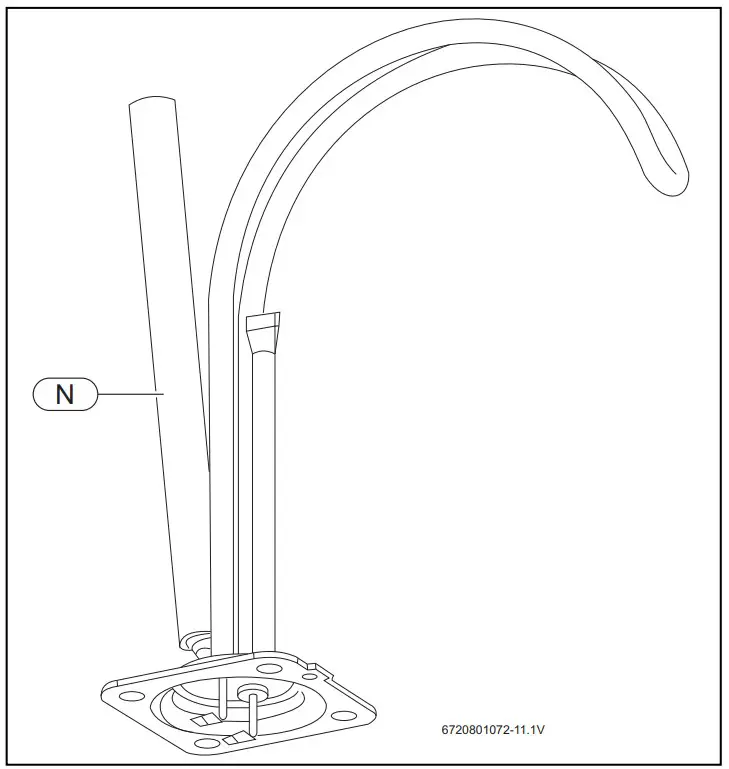

Drainage connection

Connect your appliance to drainage connection so dirty water is discharged via the wash cycle. Installing the drainage connection 1. Consult the installation instructions

supplied for the steps required here.

12

2. Connect the wastewater hose to the outlet connection of the siphon using the enclosed parts.

3. When doing so, check that the wastewater hose is not kinked, crushed or twisted.

4. Also check that there is no cover in the drainage system preventing the wastewater from being discharged.

Drinking water connection

Connect your appliance to a drinking water connection. Installing the drinking water connection Note ¡ If you are replacing the appliance,

you must use a new water supply hose. 1. Consult the installation instructions supplied for the steps required here. 2. Connect the appliance to the drinking water connection using the enclosed parts. Observe the “Technical data” Page 55. 3. When doing so, check that the drinking water connection is not kinked, crushed or twisted.

Electrical connection

Connect your appliance to the power supply. Connecting the appliance to the electricity supply Notes ¡ Please follow the “Safety instruc-

tions” Page 4. ¡ Connect the appliance to alternat-

ing current only, in the range of 220 – 240 V and 50 Hz or 60 Hz.

¡ Please note that the water safety system is only functional if there is a power supply.

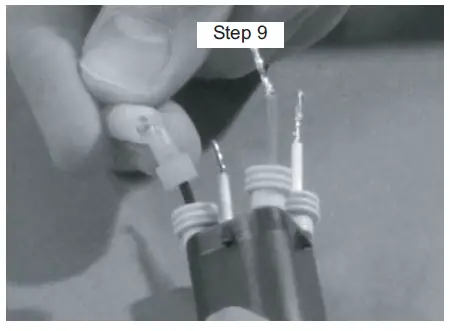

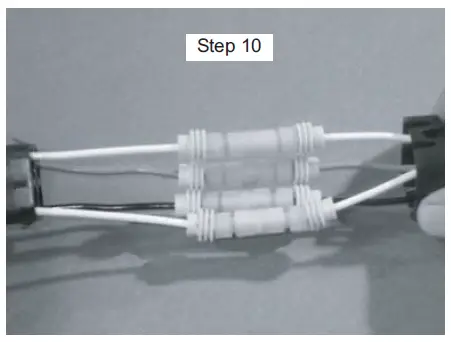

1. Insert the non-heating appliance plug of the power cable into the appliance.

2. Insert the mains plug of the appliance into a nearby socket. The connection data for the appliance can be found on the rating plate.

3. Check that the mains plug is inserted properly.

Installation and connectionen

13

enFamiliarising yourself with your appliance

Familiarising yourself with your appliance Familiarisingyourselfwithyourappliance

Familiarising yourself with your appliance

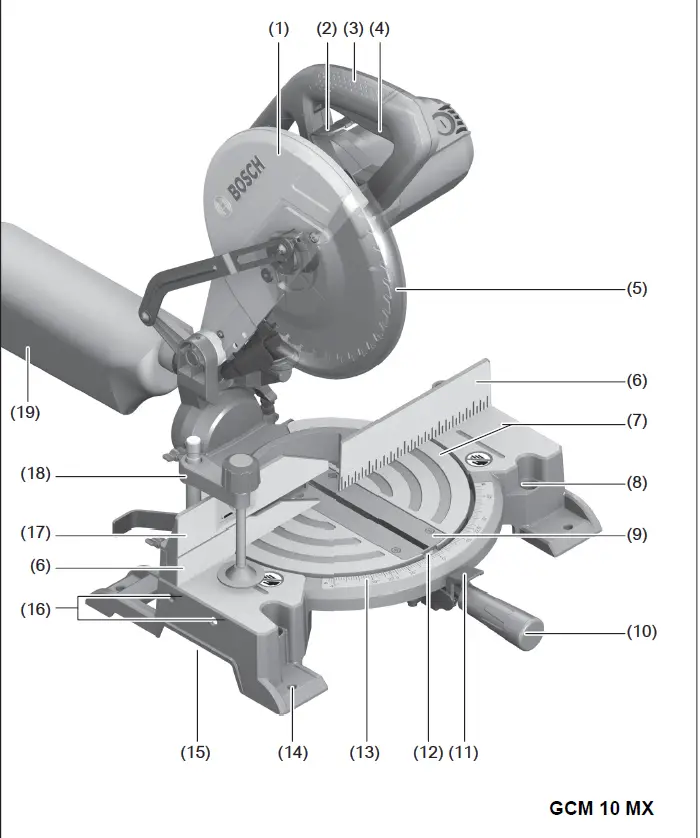

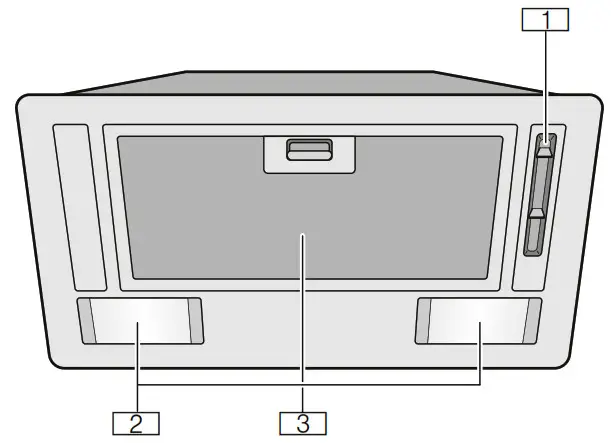

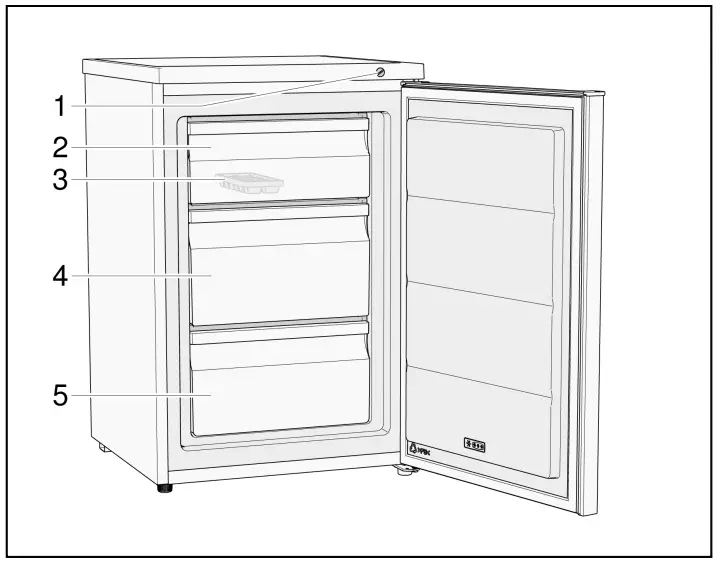

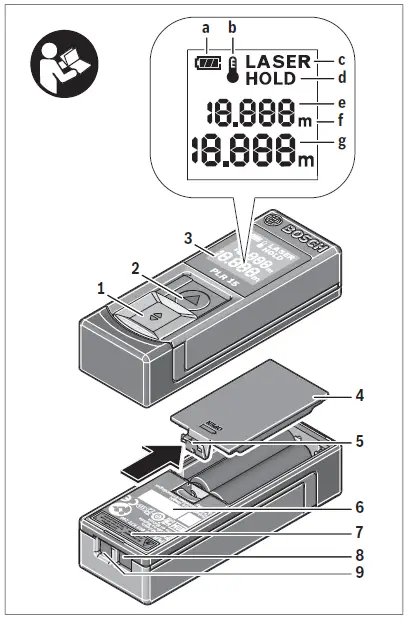

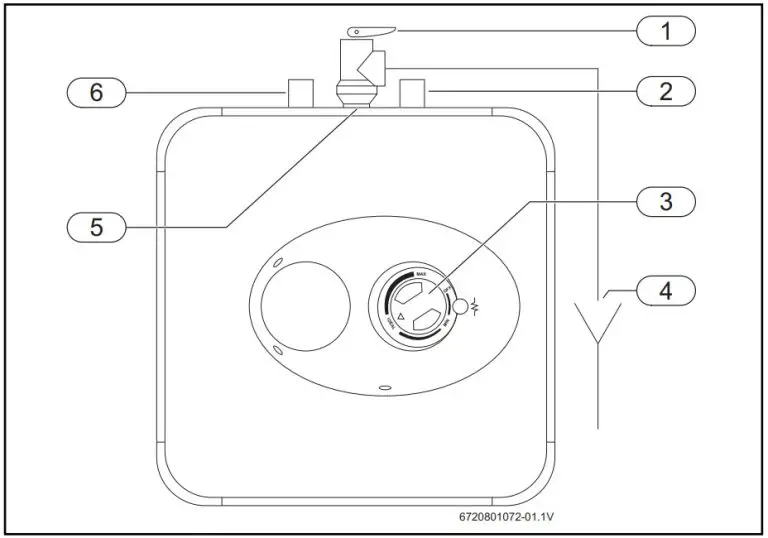

Appliance

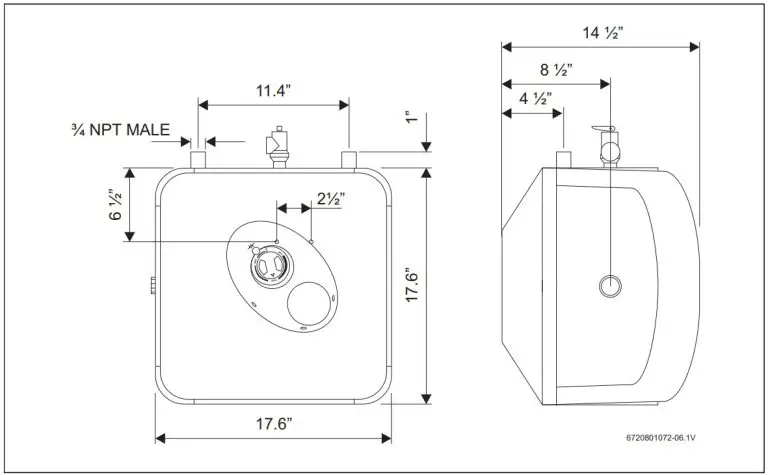

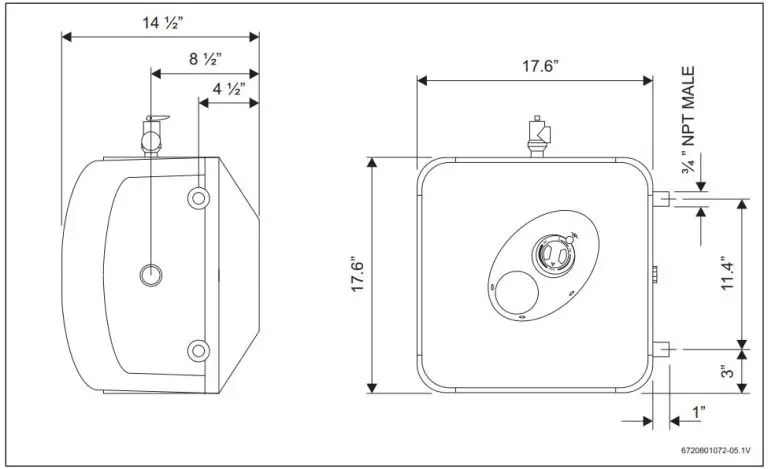

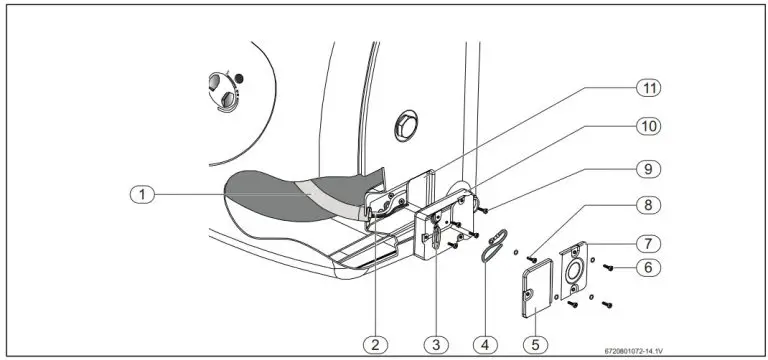

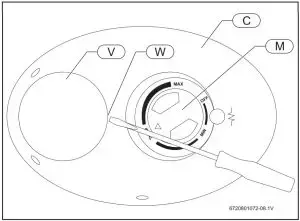

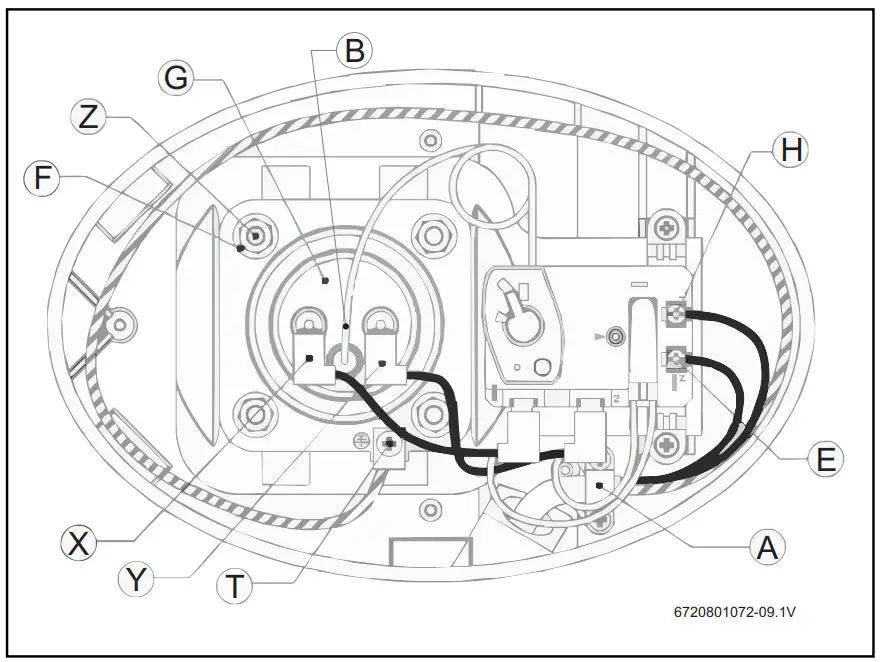

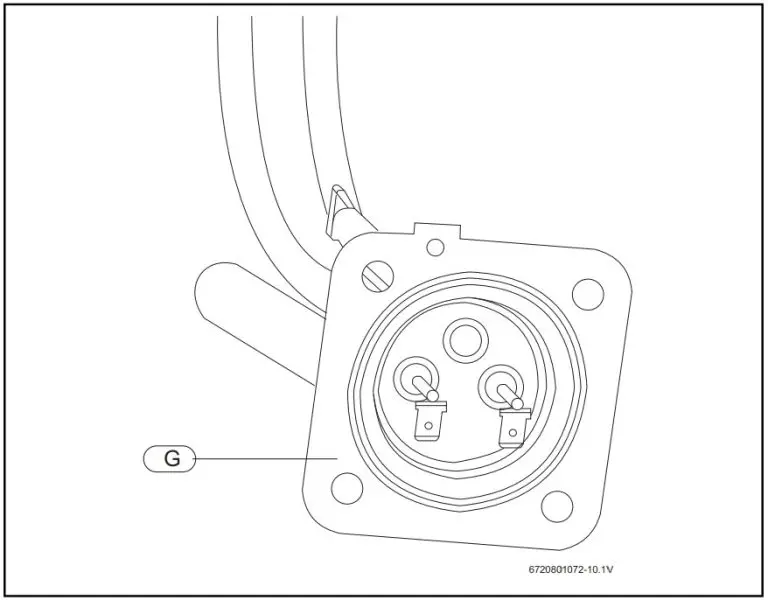

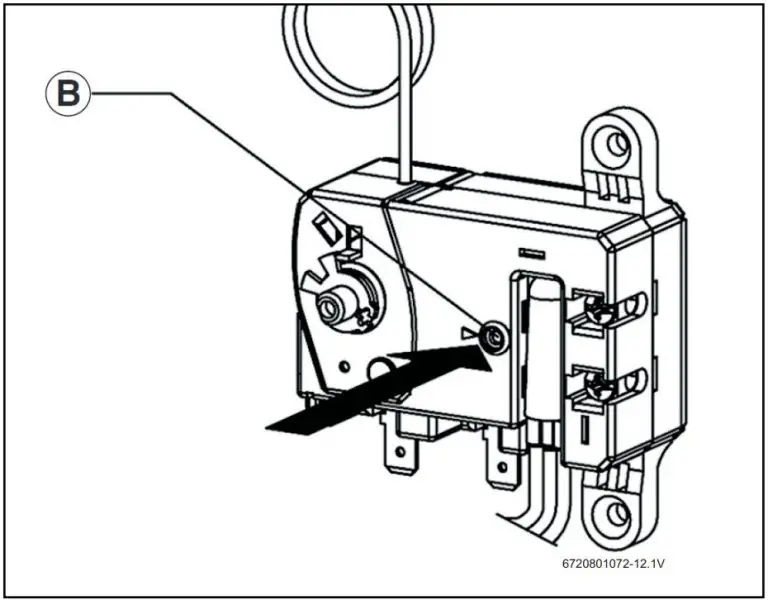

You can find an overview of the parts of your appliance here.

7

8

6

9

5

4

10

3

11

2

12

1

1

Rating plate

Rating plate with “E number and FD number” Page 55. The data you need for “Customer Service” Page 54.

1 Depending on the appliance specifications

14

Familiarising yourself with your applianceen

2

Detergent dispenser

“Detergent” Page 26 is added to the detergent dispenser.

3

Bottom basket

“Bottom basket” Page 20

4

Dispenser for special salt

Add the special salt to the dispenser for special salt. “Water softening system”, Page 23

5

Lower spray arm

The lower spray arm washes the tableware in the bottom basket. If the tableware has not been washed properly, clean the spray arms. “Cleaning spray arms”, Page 39

6

Tablet collecting tray

During the wash cycle tablets automatically fall out of the detergent dispenser into the tablet collecting tray where they can fully dissolve.

7

Top basket

Top basket

8

Cutlery shelf1

Cutlery shelf

9

Upper spray arm

The upper spray arm washes the tableware in the top basket. If the tableware has not been washed properly, clean the spray arms. “Cleaning spray arms”, Page 39

10 Filter system

“Filter system” Page 38

11 Cutlery basket

“Cutlery basket” Page 20

12 Dispenser for rinse aid

Add rinse aid to the dispenser for rinse aid. “Rinse aid system”, Page 25

1 Depending on the appliance specifications

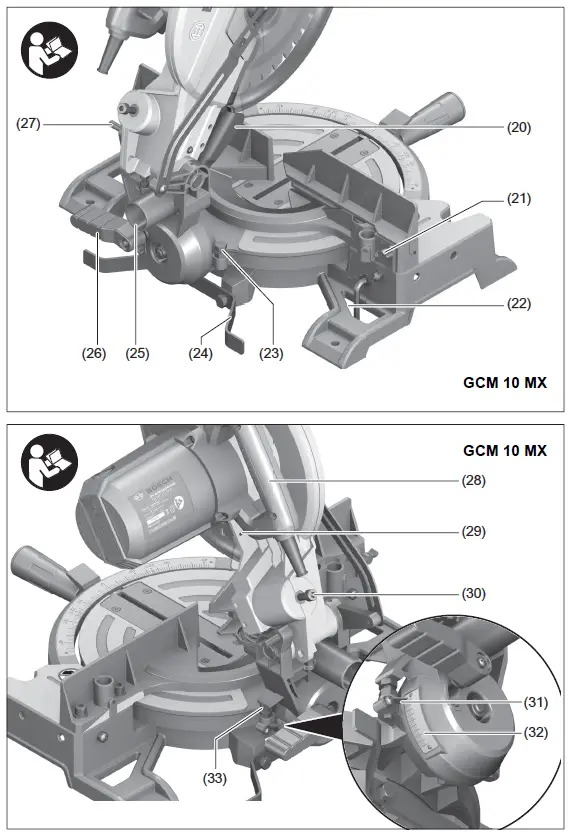

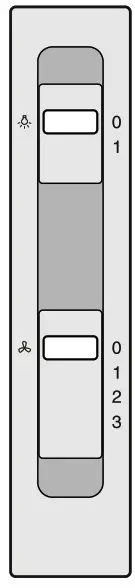

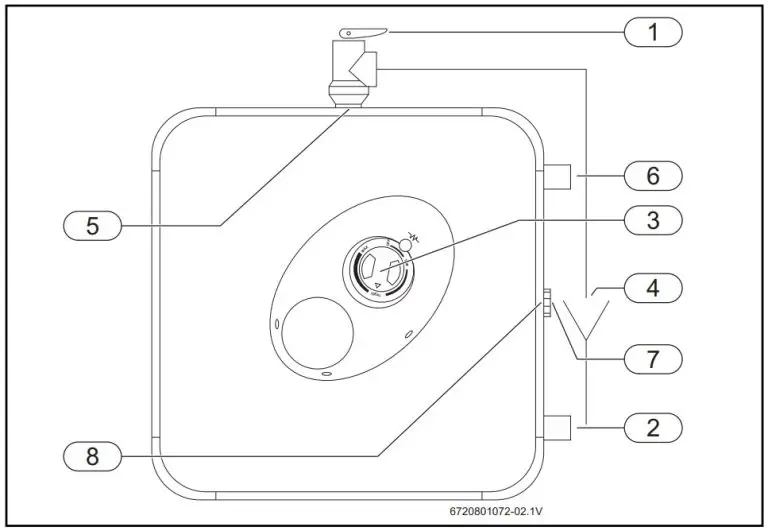

Controls

You can use the control panel to configure all functions of your appliance and to obtain information about the operating status. With some buttons you can perform different functions.

15

enFamiliarising yourself with your appliance

1 2 3 4 5 6 7 8 9 10

14 13 12 11

1

ON/OFF button and reset button

“Switching on the appliance” Page 31 “Switching off the appliance” Page 32

“Terminating the programme” Page 32

2

Programme button

“Programmes” Page 17

3

Special salt refill indicator

“Water softening system” Page 23

4

Rinse aid refill indicator

“Rinse aid system” Page 25

5

WLAN display

“Home Connect” Page 34

6

Water supply display

Display for water supply

7

Timer programming

“Setting timer programming” Page 31

8

Remote Start

“Remote Start “, Page 35

9

button

If you press

for approx. 3 seconds,

you can open the basic settings.

10 Start button

“Starting the programme” Page 32

11

Programme buttons and additional functions

“Programmes” Page 17 “Additional functions” Page 19

12 Door opener1

Opening the appliance door

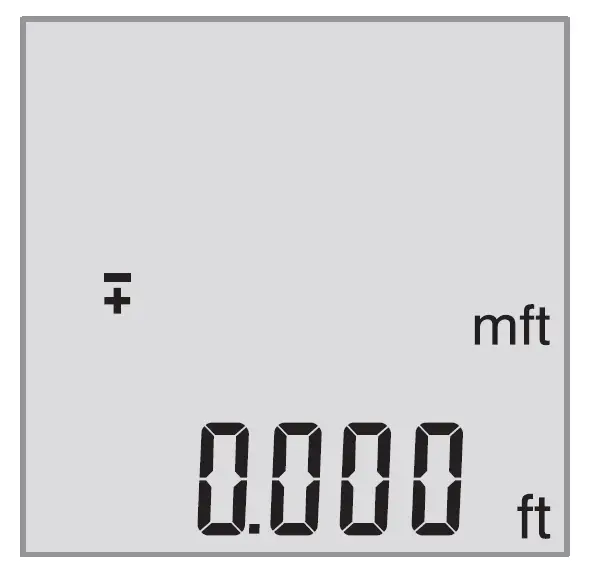

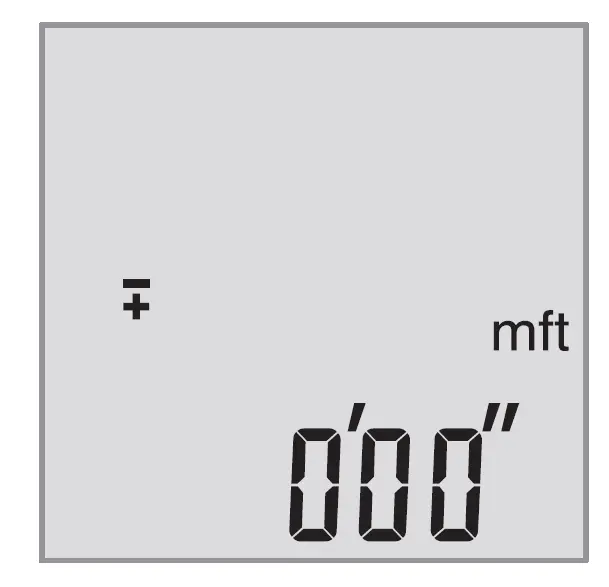

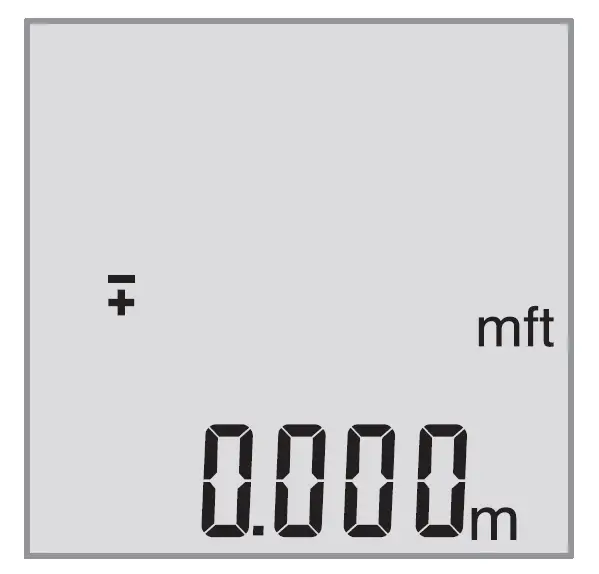

13 Display

The display shows information about the remaining running time or the basic settings. You can change the basic settings via the display and the setting buttons.

14 Programmes

“Programmes” Page 17

1 Depending on the appliance specifications

16

Programmesen

Programmes Programmes

You Programmes can find an overview of the programmes that can be selected here. Different programmes, which can be found on the control panel of your appliance, are available depending on the appliance configuration. The running time may vary depending on the programme selected. The running time depends on the water temperature, the quantity of tableware, the level of soiling and the additional function selected. The run-

ning time will change if the rinse aid system is switched off or rinse aid needs to be added. The consumption values can be found in the quick reference guide. The consumption values relate to normal conditions and a water hardness of 16 – 20 °E. Different influencing factors such as water temperature or pipe pressure may result in deviations.

Programme Intensive 70°

Auto 45-65° Eco 50°

Use

Programme sequence Additional func-

tions

Tableware:

Intensive:

¡ Washing pots and pans, ¡ Pre-Rinse

non-fragile tableware and ¡ Cleaning 70 °C

cutlery.

¡ Intermediate rinse

Level of soiling:

¡ Final rinse 69 °C

¡ Removing stubborn burned or dried-on food

¡ Drying

remnants containing

starch and protein.

All “Additional functions”, Page 19

Tableware:

Sensor-controlled:

All

¡ Cleaning mixed table- ¡ Optimised by sensors de- “Additional

ware and cutlery.

pending on the soiling of functions”,

Level of soiling:

the rinsing water.

Page 19

¡ Removing common

household food remnants

lightly dried-on.

Tableware:

Most economical pro-

¡ Cleaning mixed table- gramme:

ware and cutlery.

¡ Pre-Rinse

Level of soiling:

¡ Cleaning 50 °C

¡ Removing common

¡ Intermediate rinse

household food remnants ¡ Final rinse 61 °C

lightly dried-on.

¡ Drying

All “Additional functions”, Page 19

17

enProgrammes

Programme

Use

Programme sequence

Silence 50°

Express 65° – 1h

Machine Care Favourite

Tableware:

Reduced noise:

¡ Cleaning mixed table- ¡ Pre-Rinse

ware and cutlery.

¡ Cleaning 50 °C

Level of soiling:

¡ Intermediate rinse

¡ Removing common

¡ Final rinse 63 °C

household food remnants lightly dried-on.

¡

Drying

Tableware:

Time-optimised:

¡ Cleaning mixed table- ¡ Cleaning 65 °C

ware and cutlery.

¡ Intermediate rinse

Level of soiling:

¡ Final rinse 69 °C

¡

Removing common household food remnants

¡

Drying

lightly dried-on.

Only when using unloaded Machine Care 70 °C appliance.

–

–

Additional functions All “Additional functions”, Page 19

Extra Dry “Additional functions”, Page 19

None –

Note: The relatively long running time in the Eco 50 ° programme is due to longer soaking and drying times. This results in optimal consumption values.

Information for test institutes

Test institutes are provided with information for comparability tests, e.g. according to EN60436. These are the conditions for conducting the tests, however they are not the results or consumption values. E-mail enquiries to: [email protected] The product number (E-Nr.) and the production number (FD) are required here. They can be found on the rating plate on the appliance door.

Favourite

You can save a combination of a programme and an additional function to the button. You can save the programme via the Home Connect app. The pre-rinse program is saved to this button at the factory. Pre-rinse is suitable for all types of tableware. The tableware undergoes intermediate cleaning via cold rinsing. When programmes have been downloaded and on delivery of the appliance, the name of the programme will be displayed in the app. The display alternately shows “APP” and the remaining running time. Tip: You can use the Home Connect app to download additional programmes and save them to the button.1

1 Depending on the appliance specifications 18

Additional functions Additionalfunctions

You can find an overview of the addi- Additionalfunctions tional functions that can be selected here. Different additional functions, which can be found on the control panel of your appliance, are available depending on the appliance configuration.

Additional func- Use tion

SpeedPerfect+

¡ The run time is shortened by 15% to 75% depending on the rinse programme.

¡ The additional function can be activated before the start of the programme and at any time when the programme is running.

¡ Energy and water consumption are increased.

Half Load

¡ Switch on with small loads.

¡ It is recommended adding less detergent to the detergent dispenser than for a full machine load.

¡ The run time is shortened.

¡ Energy and water consumption are reduced.

Extra Dry

¡ For a better drying result the final rinse temperature is increased and the drying phase extended.

¡ Especially suitable for drying plastic parts.

¡ There is a slight increase in energy consumption and the run time is extended.

Additional functionsen

Features Features

You Features can find an overview of the possible features of your appliance and how to use them here. These features depend on the model of your appliance.

Top basket

Arrange cups and glasses in the top basket.

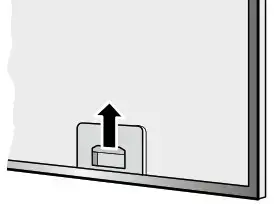

You can adjust the height of the top basket to make room for larger items of tableware. Adjusting top basket with pairs of rollers To wash large items of tableware in the baskets, adjust the shelf position of the top basket. 1. Pull out the top basket. 2. Remove the basket.

19

enFeatures 3. Re-attach the basket to the upper

rollers (setting 3) or lower rollers (setting 1). “Basket heights”, Page 22

Check that the basket is level on both sides. 4. Slide the basket back in.

Bottom basket

Arrange pans and plates in the bottom basket.

Cutlery basket

Arrange cutlery in the cutlery basket, always without sorting it and with the sharp points downwards.

a

Cutlery basket 1 Large plates up to a diameter of 31 cm can be arranged in the bottom basket as shown.

1 Depending on the appliance specifications 20

Folding prongs

Use the folding prongs to position tableware securely, e.g. plates.

Featuresen

Baking sheet spray head

Use the baking sheet spray head to clean large items of tableware, e.g. trays, grilles and plates.

You can fold the prongs down to position pans, bowls and glasses better.1

Folding down prongs1 If you do not need the prongs, fold them down. 1. Push the lever forwards and fold

down the prongs .

1

2

Arrange max. 2 baking sheets and 2 grilles as shown to ensure that the spray jet can reach all parts. Note: Check that the appliance is always operated with the top basket or the baking sheet spray head.

Inserting baking sheet spray head Use the baking sheet spray head instead of the top basket to clean large trays, grilles and plates. 1. Remove top basket.

2. To use the prongs again, fold them back up.

a The prongs audibly click into position.

1 Depending on the appliance specifications 21

enBefore using for the first time 2. Insert the baking sheet spray head

in the holder and turn to the right .

Removing baking sheet spray head If you no longer require the baking sheet spray head, remove it from the appliance.

1. Turn the baking sheet spray head anticlockwise and remove from the holder.

2. Insert the top basket in the appliance.

a The baking sheet spray head clicks into position.

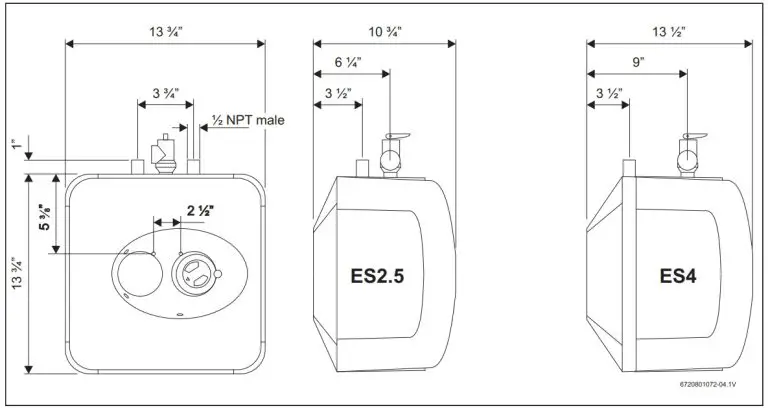

Basket heights

Set the baskets at the right height.

Appliance height 81.5 cm with cutlery basket

Setting 1 max. ø 2 max. ø 3 max. ø

Top basket 22 cm 24.5 cm 27 cm

Bottom basket 31 cm 27.5 cm 25 cm

Before using for the Beforeusingforthefirsttime first time

Configure the settings for initial start- Beforeusingforthefirsttime up.

Performing the initial configuration

On initial start-up or after a reset to the factory settings, you will need to make settings. Tip: Connect your appliance to a mobile device. You can conveniently change all settings via the

Home Connect app. “Home Connect quick start”, Page 35 Requirement: “The appliance has been installed and connected.” Page 11 1. “Add special salt.” Page 24 2. “Add rinse aid.” Page 25 3. “Switch on the appliance.”

Page 31 4. “Setting the water softening sys-

tem.” Page 23 5. “Set the amount of rinse aid to be

dispensed.” Page 26 6. “Add detergent” Page 26.

22

Water softening systemen

7. Start the Programme with the highest cleaning temperature without tableware. To remove any marks from water or other residues, we recommend you operate the appliance without tableware before using it for the first time.

Tip: You can change these settings and other “Basic settings” Page 33 at any time.

Water softening system Watersofteningsystem

Hard water leaves limescale on the Watersofteningsystem tableware as well as the washing tank and parts of the appliance may become blocked. To ensure good dishwashing results, you can treat the water with special salt and the water softening system. To avoid damage to the appliance, water with a hardness above 9 °E must be softened.

Overview of water hardness settings

You can find an overview of the water hardness values that can be selected here. You can find out how hard your water is from your local water company or by using a water hardness tester.

Water hardness °E 0 – 8 9 – 10 11 – 12 13 – 15 16 – 20 21 – 26 27 – 38 39 – 62

Hardness range Soft Soft Medium Medium Medium Hard Hard Hard

mmol/l 0 – 1.1 1.2 – 1.4 1.5 – 1.8 1.9 – 2.1 2.2 – 2.9 3.0 – 3.7 3.8 – 5.4 5.5 – 8.9

Setting value H00 H01 H02 H03 H04 H05 H06 H07

Note: Set the water hardness determined on your appliance. “Setting the water softening system”, Page 23 With a water hardness of 0 – 8 °E you can dispense with special salt for dishwashers and switch off the water softening system. “Switching off the water softening system”, Page 24

Setting the water softening system

Set the water hardness on your appliance. 1. Determine the water hardness and

the appropriate setting value. “Overview of water hardness settings”, Page 23 2. Press . 3. To open the basic settings, press

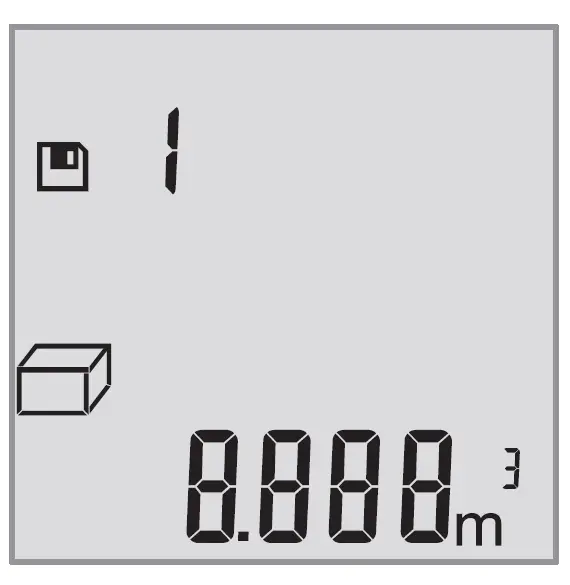

for 3 seconds. a The display shows Hxx. a The display shows .

23

enWater softening system

4. Press

repeatedly until the

right water hardness has been set.

The value H04 is set at the factory.

5. To save the settings, press for 3 seconds.

Special salt

You can use special salt to soften water. Adding special salt If the special salt refill indicator lights up, add special salt to the dispenser for special salt just before the programme starts. The amount of special salt required depends on the water hardness: the higher the water hardness, the greater the amount of special salt required.

ATTENTION! ¡ Detergent may damage the water

softening system. Only fill the dispenser of the wa-

ter softening system with special dishwasher salt. ¡ Special salt for dishwashers can damage the tub due to corrosion. To make sure that any special salt that escapes is washed out of the tub, add the special salt to the dispenser for special salt immediately before the programme starts.

1. Unscrew the lid of the dispenser for special salt and remove.

2. On initial start-up: Fill the dispenser right up with water.

3. Note: Only use special salt for dishwashers. Do not use salt tablets. Do not use table salt. Add the special salt to the dispenser.

a

Funnel 1 Fill the dispenser right up with special salt. The water in the dispenser is displaced and forced out. 4. Place the lid back on the dispenser and turn to close.

Switching off the water softening system

If you find the special salt refill indicator irritating, e.g. when using combined detergents with salt replacement substances, you can switch the salt refill indicator off. Note To avoid damage to the appliance, only switch off the water softening system in the following cases: ¡ The water hardness is max. 26 °E

and you are using combined detergents with salt replacement substances. According to manufacturers, combined detergents with salt replacement substances can gen-

1 Depending on the appliance specifications 24

erally only be used up to a water hardness of 26 °E without adding special salt. ¡ The water hardness is 0 – 8 °E. You do not need to use special salt.

1. Press .

2. To open the basic settings, press for 3 seconds.

a The display shows Hxx. a The display shows .

3. Press

repeatedly until the dis-

play shows H00.

4. To save the settings, press for 3 seconds.

a The water softening system is switched off and the salt refill indic-

ator is deactivated.

Regeneration of the water softening system

In order to obtain fault-free function of the water softening system, the appliance performs regeneration of the water softening system at regular intervals. Regeneration of the water softening system takes place before the end of the main rinse cycle in all programmes. It will increase the run time and consumption values, e.g. water and electricity.

Overview of consumption values with regeneration the water softening system Here you can find an overview of the maximum additional run time and consumption values during regeneration of the water softening system.

Regeneration of the water softening 6 system after x rinse cycles

Additional run time in minutes

7

Additional water consumption in 5 litres

Rinse aid systemen Additional power consumption in 0.05 kWh The consumption values specified are laboratory measurements determined in accordance with the currently applicable standard and using the Eco 50° programme and the factory value of the water hardness is set to 16 – 20°E.

Rinse aid system Rinseaidsystem

You can use the rinse aid system Rinseaidsystem and rinse aid to get tableware and glasses rinsed perfectly without marks.

Rinse aid

For optimum drying results, use rinse aid. Only use rinse aid for domestic dishwashers. Adding rinse aid If the rinse aid refill indicator lights up, top up with rinse aid. Only use rinse aid for domestic dishwashers. 1. Press the catch on the lid of the

dispenser for rinse aid and lift .

2

1

25

enDetergent 2. Add rinse aid up to the max mark.

max

3. If rinse aid spills out, remove it from the tub. Spilled rinse aid can cause excessive frothing during the wash cycle.

4. Close the lid of the dispenser for rinse aid.

a The lid clicks into position.

Setting the amount of rinse aid

If there are streaks or water marks on tableware, change the amount of rinse aid.

1. Press .

2. To open the basic settings, press for 3 seconds.

a The display shows Hxx. a The display shows .

3. Press

repeatedly until

the display shows the value set at

the factory r05.

4. Press

repeatedly until the

right amount of rinse aid has been

set.

A low setting adds less rinse aid during the wash cycle and reduces streaking on tableware.

A higher setting adds more rinse aid during the wash cycle, reduces water marks and improves the drying result.

5. To save the settings, press for 3 seconds.

Switching the rinse aid system off

If you find the rinse aid refill indicator irritating, e.g. when using combined detergents with a rinse aid component, you can switch the rinse aid system off.

Tip: The function of rinse aid is limited with combined detergents. You will generally get better results using rinse aid.

1. Press .

2. To open the basic settings, press for 3 seconds.

a The display shows Hxx. a The display shows .

3. Press

repeatedly until

the display shows the value set at

the factory r05.

4. Press

repeatedly until the dis-

play shows r00.

5. To save the settings, press for 3 seconds.

a The rinse aid system is switched off and the rinse aid refill indicator is deactivated.

Detergent Detergent

Find Detergent out which detergents are suitable for your appliance.

Suitable detergents

Only use detergents that are suitable for dishwashers. Both separate and combined detergents are suitable. For optimum washing and drying results, use separate detergent, adding “Special salt” Page 24 and “Rinse aid” Page 25 separately.

26

Modern, powerful detergents mainly use a low-alkaline formulation with enzymes. Enzymes break down starch and remove protein. Oxygenbased bleaching agents are generally used to remove coloured marks, e.g. tea or ketchup. Note: Follow the manufacturer’s instructions for each detergent.

Detergent Tabs

Powder detergent Liquid detergent

Description Tabs are suitable for all cleaning functions and do not need to be measured out. With shorter “Programmes” Page 17 tabs sometimes do not dissolve entirely and leave residues of detergent. This may impair the cleaning effect. Powder detergent is recommended for shorter “Programmes” Page 17. The dosage can be adjusted to the level of soiling. Liquid detergent works faster and is recommended for shorter “Programmes” Page 17 without PreRinse. Sometimes liquid detergent may leak out despite the detergent dispenser being closed. This is not a fault and is non-critical if you remember the following: ¡ Only choose a pro-

gramme without PreRinse. ¡ Do not select timer programming for starting the programme.

The dosage can be adjusted to the level of soiling.

Detergenten

Tip: Suitable detergents are available online via our website or from “Customer Service” Page 54.

Separate detergents Separate detergents are products that do not contain components other than detergent, e.g. powder detergent or liquid detergent. With powder and liquid detergent the dosage can be individually adjusted to the level of soiling of the tableware. For better washing and drying results and to avoid damage to the appliance, please additionally use “Special salt” Page 24 and “Rinse aid” Page 25.

Combined detergent Besides conventional separate detergents, a number of products are available with additional functions. These products contain not only detergent but also rinse aid and salt replacement substances (3in1) and, depending on the combination (4in1, 5in1, …), additional components such as glass protection or stainless steel cleaner. According to manufacturers, combined detergents generally only function up to a water hardness of 26 °E. With a water hardness above 26 °E you will need to add special salt and rinse aid. For the best washing and drying results we recommend using special salt and rinse aid from a water hardness of 17 °E. If you are using combined detergent, the washing programme is adjusted automatically to ensure the best possible washing and drying result.

27

enDetergent

Unsuitable detergents

Do not use detergent which could cause damage to the appliance or present a risk to health.

Detergent

Description

Hand washing-up Hand washing-up liquid

liquid

can cause increased froth-

ing and damage the appli-

ance.

Detergent containing chlorine

Chlorine residue on tableware may present a risk to health.

Information on detergents

Follow the instructions on detergents in everyday use. ¡ Detergents marked as “organic” or

“ecological” (environmentally friendly) generally contain lower levels of active agents or completely dispense with certain substances. The cleaning effect may be restricted here. ¡ Set the rinse aid and the water softening system to the separate detergent or combined detergent in use. ¡ According to manufacturers, combined detergents with salt replacement substances can only be used up to a certain water hardness, usually 26 °E, without adding special salt. For the best washing and drying results we recommend using special salt from a water hardness of 17 °E. ¡ To prevent sticking, only touch detergents in a water-soluble pouch with dry hands and only ever place them in a dry detergent dispenser. ¡ Even if the rinse aid and special salt refill indicators light up, washing programmes will run properly with combined detergents.

¡ The function of rinse aid is limited with combined detergents. You will generally get better results using rinse aid.

¡ Use tablets with a special drying performance.

Adding detergent

1. To open the detergent dispenser, press the locking latch.

2. Add the detergent to the dry detergent dispenser.

50 ml 25 ml 15 ml

If you are using tablets, one is enough. Insert the tablets in a horizontal position. If you are using powder or liquid detergent, follow the manufacturer’s instructions and quantities for dosage in the detergent dispenser. 20 ml 25 ml detergent is sufficient for normal soiling. If tableware is only lightly soiled, slightly less than the amount of detergent specified is usually sufficient.

28

3. Close the lid of the detergent dispenser.

a The lid clicks into position. a The detergent dispenser will open

automatically at the optimum time during the programme. Powder or liquid detergent will spread around the washing tank and dissolve there. Tablets will fall into the tablet collecting tray and dissolve in the right dosage. In order to ensure that tablets can dissolve evenly, do not place any other objects in the tablet collecting tray. Tip: If you use powder detergent and select a program with pre-rinse, you can also add a little detergent to the interior door of the appliance.

Tableware Tableware

Only Tableware clean tableware that is suitable for dishwashers. Note: Decorated glassware and parts made of aluminium or silver may fade or discolour with dishwashing. Delicate types of glass may turn cloudy after a few washing cycles.

Tablewareen

Damage to glass and tableware

Avoid damage to glass and tableware.

Cause

Recommendation

The following table- Only put tableware in

ware is not dish-

the dishwasher if it is

washer-safe:

marked as dish-

¡ Items of cutlery washer-safe by the

and tableware manufacturer.

made from wood

¡ Decorated glass-

ware, antique and

hand-crafted table-

ware

¡ Plastic parts not

resistant to heat

¡ Tableware made

from copper or tin

¡ Tableware soiled

with ash, wax, lub-

ricating grease or

paint

¡ Very small items of

tableware

Glass and tableware was not dishwashersafe.

Only put glasses and china in the dishwasher if it is marked as dishwasher-safe by the manufacturer.

The chemical composition of the detergent causes damage.

Use a detergent marked as gentle on tableware by the manufacturer.

Highly caustic alkaline If you are using highly

or highly acidic clean- caustic alkaline or

ing agents, in particu- highly acidic cleaning

lar commercial or in- agents, in particular

dustrial cleaning

commercial or indus-

agents, are not suit- trial cleaning agents,

able for dishwashers do not put aluminium

in conjunction with parts in the dish-

aluminium.

washer interior.

29

enTableware

Cause

Recommendation

The water temperat- Select a programme

ure of the programme with lower temperat-

is too high.

ures.

After the programme

has ended, take glass-

ware and cutlery out

of the appliance

without delay.

Arrange tableware

Arrange tableware correctly to optimise the dishwashing result and prevent damage to both the appliance and tableware. Tips ¡ Using the appliance allows you to

save energy and water compared to washing-up by hand. ¡ See our website for examples of how to load your appliance efficiently, free of charge. ¡ To save energy and water, load the machine with the number of place settings specified. “Technical specifications”, Page 55 ¡ For better washing and drying results, position items with curves or recesses at an angle so water can run off.

To save resources, do not prerinse tableware under running water. 2. Observe the following when arranging tableware: Put heavily soiled tableware in

the bottom basket, e.g. pans. The more powerful the spray jet, the better the dishwashing result will be. To prevent damage to tableware, arrange it so it is stable and cannot tip over. To prevent injury, arrange cutlery with the points and sharp edges facing down. Position containers with the openings facing down so no water can collect in them. Do not block the spray arms make sure that they can turn freely. Do not place small parts in the tablet collecting tray and do not block it with tableware so as not to obstruct the lid of the detergent dispenser.

1. Remove large remnants of food from your tableware.

30

Removing tableware

WARNING Risk of injury! Hot tableware can cause burns to the skin. When hot, tableware is sensitive to shock, may crack and can result in injury. When the programme has ended,

do not empty the appliance until the tableware has cooled down for a while. 1. To prevent water dripping on the tableware, unload it starting at the bottom and working up. 2. Check the washing tank and accessories for soiling and clean if necessary. “Cleaning and servicing”, Page 37

Basic operation Basicoperation

Basic operation

Switching on the appliance

Press . The Eco 50° programme is set by default. The Eco 50° programme is an especially environmentally friendly programme and ideal for normally soiled tableware. It is the most efficient programme for the combination of energy/water consumption for this type of tableware and evidences conformity with the EU Ecodesign Directive. If you do not perform any actions on the appliance for 10 minutes, the appliance will automatically switch off.

Basic operationen

Setting a programme

To adjust the wash cycle to the soiling level of the tableware, select a suitable programme. Press the programme button re-

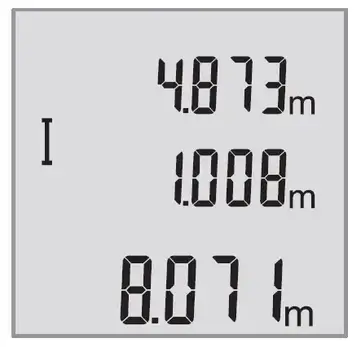

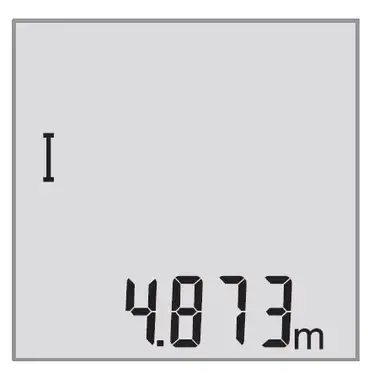

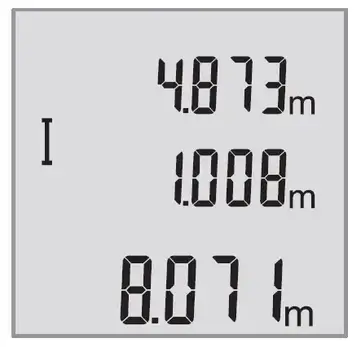

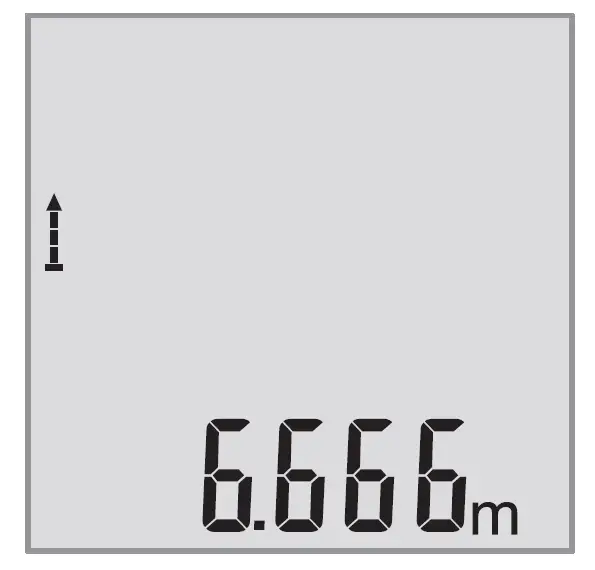

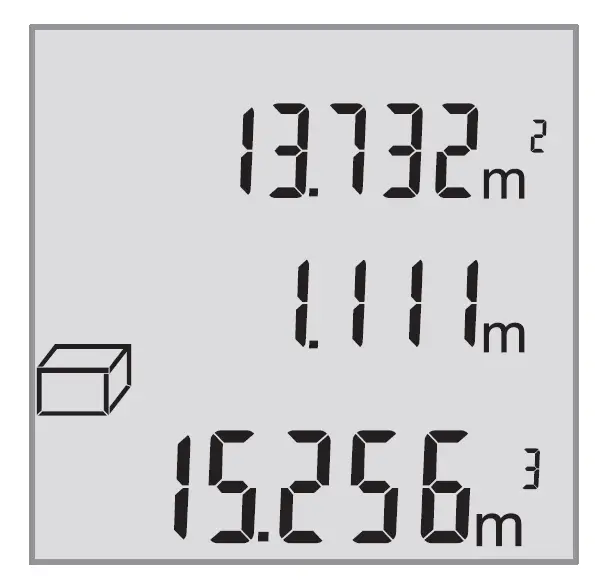

peatedly until the right programme has been selected. “Programmes”, Page 17 a The programme is set and the LED flashes. a The remaining running time of the programme appears on the display.

Setting additional functions

You can set additional functions to complete the washing programme selected. Note: The additional functions which can be used depend on the programme selected. “Programmes”, Page 17 Press the button for the relevant

additional function. “Additional functions”, Page 19 a The additional function is set and the additional function button flashes.

Setting timer programming

You can delay the start of the programme by up to 24 hours. 1. Press . a “h:01” appears in the display. 2. Use to set the required start

time for the programme. 3. Press . a This activates timer programming. Tip: To deactivate timer programming, press repeatedly until “h:00” appears in the display.

31

enBasic operation

Starting the programme

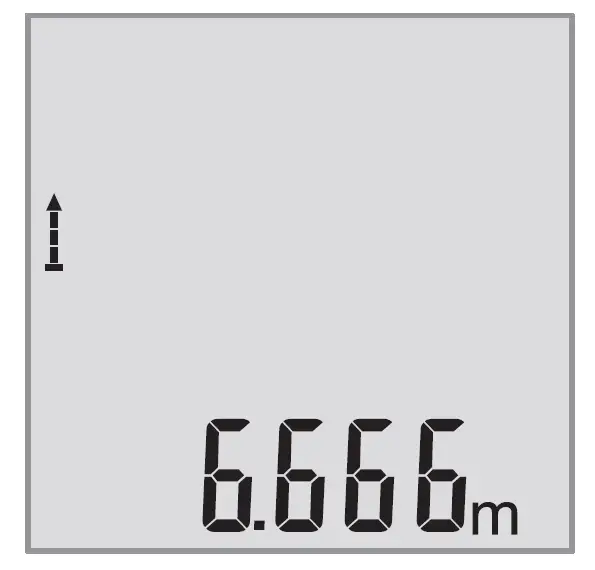

Press . a The programme has ended when

the display shows “0h:00m”. Notes ¡ If you want to add more tableware

while the appliance is running, do not use the tablet collecting tray as a handle for the top basket. You might touch the partially dissolved tablet. ¡ You can only change a programme when running if you cancel it. “Terminate programme”, Page 32 ¡ The appliance switches off automatically 1 minute after the end of the programme to save energy. If you open the appliance door immediately after the programme has ended, the appliance will switch off after 4 seconds.

Activating button lock

The button lock prevents the appliance from being operated accidentally or incorrectly while running. Press for approx. 3 seconds. a The button lock is activated and

will be automatically deactivated at the end of the programme. a When the appliance is operated,

flashes on the display. a The button lock remains activated

with a power failure.

Deactivate button lock

Press for approx. 3 seconds.

Interrupting programme

Note: When you open the appliance door once the appliance has heated up, leave the door slightly ajar for a

32

few minutes and then close it. This will help prevent excess pressure building up in the appliance and stop the appliance door bursting open. 1. Press . a The programme is saved and the

appliance switches off. 2. Press to resume the pro-

gramme.

Terminate programme

To end a programme early or to switch from a programme that has already started, you will need to cancel it first.

Press

for approx.

4 seconds.

a All displays light up.

a As soon as the displays are off,

the display shows “0h:01m” and

the residual water is pumped out.

a The programme is cancelled and

ends after approx. 1 minute.

Switching off appliance

1. Please note the information on “Safe use” Page 10.

2. Press . 3. To prevent damage from dripping

water, turn the water tap off tight (not applicable to appliances with Aqua-Stop). Tip: If you press during the wash cycle, the programme currently running will be interrupted. When you switch the appliance back on, the programme continues automatically.

Basic settingsen

Basic settings Basicsettings

You Basicsettings can configure the appliance to meet your needs.

Overview of basic settings

The basic settings depend on the features of your appliance.

Basic setting Water hardness

Display text Selection

H04 1

H00 – H07

Rinse aid dispensing r05 1

r00 – r06

Intensive drying

d00 1

d00 – d01

Hot water

A00 1

A00 – A01

1 Factory setting (may vary according to model)

Description Set the water softening system to your water hardness. “Setting the water softening system”, Page 23 Level H00 switches the water softening system off.

Set the amount of rinse aid to be dispensed. “Setting the amount of rinse aid”, Page 26 Switch the rinse aid system off with level r00.

The temperature is increased during the final rinse, which improves the drying result. This may increase the run time slightly. Note: Not suitable for delicate items of tableware. Switch Extra Dry on “d01” or off “d00”.

Set cold water or hot water connection. Only set the appliance to hot water if this can be prepared with little energy and a suitable installation is available, e.g. solar heating system with circulation line. The water temperature should be at least 40 °C and max. 60 °C. Switch hot water on “A01” or off “A00”.

33

enHome Connect

Basic setting Wi-Fi

Display text Selection

Cn0

Cn0 – Cn1

Remote Start

rc1

rc0 – rc2

Factory setting

rE

Start with YES Confirm with

1 Factory setting (may vary according to model)

Description Switch the wireless network connection on or off. Level “Cn0” switches the wireless network connection off. The basic setting “Wi-Fi” is only available once the appliance is connected to the Home Connect app. “Home Connect “, Page 34 Activate or deactivate “Remote Start “, Page 35. The following settings are possible: ¡ With the setting “rc0”, the func-

tion is permanently deactivated. ¡ With the setting “rc1”, the func-

tion can be selected via the button. “Activating Remote Start “, Page 36 ¡ With the setting “rc2”, the function is permanently activated. This basic setting is not available until after you have connected the device with the Home Connect app. “Home Connect “, Page 34 Restore changed settings to the factory settings. The settings for initial start-up must be configured.

Changing basic settings

1. Press .

2. To open the basic settings, press for 3 seconds.

a The display shows Hxx. a The display shows .

3. Press

repeatedly until

the display shows the required set-

ting.

4. Press

repeatedly until the dis-

play shows the right value.

You can change several settings.

5. To save the settings, press for 3 seconds.

34

Home Connect HomeConnect

This HomeConnect appliance is network-capable. Connect your appliance to a mobile device to control its functions via the Home Connect app. The Home Connect services are not available in every country. The availability of the Home Connect function depends on the availability of Home Connect services in your country. You can find information about this at: www.home-connect.com.

To be able to use Home Connect, you must first set up the connection to the WLAN home network (Wi-Fi1) and to the Home Connect app. ¡ “Connecting the appliance to

WLAN home network (Wi-Fi)”, Page 35 The Home Connect app guides you through the entire login process. Follow the instructions in the Home Connect app to configure the settings. Tips ¡ Please consult the documents supplied by Home Connect. ¡ Please also follow the instructions in the Home Connect app. Note: Please note the safety precautions in this instruction manual and make sure that they are also observed when operating the appliance via the Home Connect app. “Safety”, Page 4

Home Connect quick start

Connect your appliance to a mobile device quickly and easily. Installing app 1. Install the Home Connect app on

your mobile device.

2. Start the app and set up access for Home Connect. The Home Connect app guides you through the entire login process.

Home Connect en Connecting the appliance to WLAN home network (Wi-Fi) Requirements ¡ Home Connect app is installed on

your mobile device. ¡ Wi-Fi on the router is activated. ¡ The appliance receives signals

from the WLAN home network (WiFi) at its installation location. 1. With the help of the Home Connect App scan the QR code.

2. Follow the instructions in the Home Connect app.

Home Connect settings

Adapt Home Connect to your needs. You can find the Home Connect settings in the basic settings for your appliance. Which settings the display shows will depend on whether Home Connect has been set up and whether the appliance is connected to your home network.

Remote Start

You can use the Home Connect app to start the appliance with your mobile device. Tip: If you select “rc2” in the “Basic settings” Page 34 of this function, the function is permanently activated and you can start your appliance with a mobile device at any time.

1 Wi-Fi is a registered trademark of the Wi-Fi Alliance. 35

enHome Connect

Activating Remote Start When you have selected “rc1” in the basic settings of this function, activate the function on your appliance. Requirements ¡ The appliance is connected to your

WLAN home network. ¡ The appliance is connected to the

Home Connect app. ¡ “rc1” is selected in the “Basic set-

tings ” Page 34 of this function. ¡ A programme is selected. Press .

If you open the appliance door, the function is automatically deactivated. a button lights up. Tip: To deactivate the function, press .

Remote Diagnostics

Customer Service can use Remote Diagnostics to access your appliance if you contact them, have your appliance connected to the Home Connect server and if Remote Diagnostics is available in the country in which you are using the appliance. Tip: For further information and details about the availability of Remote Diagnostics in your country, please visit the service/support section of your local website: www.home-connect.com

Software update

You can use this function to update the software of your appliance, e.g. for optimisation, troubleshooting or safety-relevant updating. The Home Connect app informs you about available software updates.

Data protection

Please see the information on data protection. The first time your appliance is registered on a home network connected to the Internet, your appliance will transmit the following types of data to the Home Connect server (initial registration): ¡ Unique appliance identification

(consisting of appliance codes as well as the MAC address of the Wi-Fi communication module installed). ¡ Security certificate of the Wi-Fi communication module (to ensure a secure data connection). ¡ The current software and hardware version of your appliance. ¡ Status of any previous reset to factory settings. This initial registration prepares the Home Connect functions for use and is only required when you want to use the Home Connect functions for the first time. Note: Please note that the Home Connect functions can only be utilised with the Home Connect app. Information on data protection can be retrieved in the Home Connect app.

36

Cleaning and servicingen

Cleaning and servicing Cleaningandservicing

To keep your appliance working effi- Cleaningandservicing ciently for a long time, it is important to clean and maintain it carefully.

Cleaning the tub

WARNING Risk of harm to health! Using detergents containing chlorine may result in harm to health. Never use detergents containing

chlorine. 1. Remove any coarse soiling in the

interior with a damp cloth. 2. Add detergent to the detergent dis-

penser. 3. Select the programme with the

highest temperature. “Programmes”, Page 17 4. “Start the programme without tableware.” Page 32

Cleaning products

Only use suitable cleaning products to clean your appliance. “Safe use”, Page 10

Tips on appliance care

Follow the tips on appliance care to make sure your appliance functions properly at all times.

Action

Benefit

Wipe the door seals, This ensures the parts the front of the dish- of the appliance will washer and the con- remain clean and hytrol panel regularly us- gienic. ing a damp cloth and washing-up liquid.

If the appliance is not This will prevent ungoing to be used for a pleasant odours. while, leave the door slightly ajar.

Machine Care

Deposits, e.g. from remnants of food and limescale, can cause your appliance to malfunction. To avoid such faults and reduce odours, we recommend cleaning your appliance at regular intervals. Machine Care combined with machine care products and machine cleaners is the right programme for the care of your appliance.

Tip: You can get our tested and approved Dishwasher Care and Machine Cleaner for Dishwashers online at https://www.bosch-home.com/ store or from customer service. Machine Care is a programme which removes various deposits in one washing cycle. Cleaning takes place in two phases:

Phase 1

2

Removal of Grease and limescale

Food remnants and deposits

Detergent

Placement

Liquid machine care product Appliance interior, e.g. bottle

or machine descaler in

hung in the cutlery basket or

powder form.

powder in the interior.

Machine cleaner

Detergent dispenser

37

enCleaning and servicing

To ensure optimum cleaning performance, the programme doses the detergents independently of each another during the relevant cleaning phase. Correct placement of the detergents is necessary here. Run Machine Care without tableware if the indicator for Machine Care lights up on the control panel or if advised to do so by the display. The indicator will go out after you have run Machine Care. If your appliance does not have a reminder function, we recommend performing Machine Care every 2 months.

Running Machine Care Run the Machine Care programme if the indicator for Machine Care lights up on the control panel or if advised to do so by the display. Notes ¡ Run the Machine Care programme

without any tableware in the dishwasher. ¡ Only use machine care products and machine cleaners specially designed for dishwashers. ¡ Make sure that there are no aluminium parts, e.g. extractor hood grease filters or aluminium pans, in the interior of the appliance. ¡ If you have not run Machine Care after 3 washing cycles, the indicator for Machine Care will go out automatically. ¡ For optimum cleaning performance, ensure the correct placement of cleaners. ¡ Follow the safety instructions given on the packagings of the machine care products and machine cleaners. 1. Remove any coarse soiling in the interior with a damp cloth. 2. Clean the filters.

3. Place the machine care product in the appliance interior. Only use machine care products specially designed for dishwashers.

4. Pour the machine cleaner into the detergent dispenser until it is filled completely. Do not place any additional machine cleaner in the appliance interior.

5. Press . 6. Press . a Machine Care is run. a Once the programme has ended,

the indicator for Machine Care goes out.

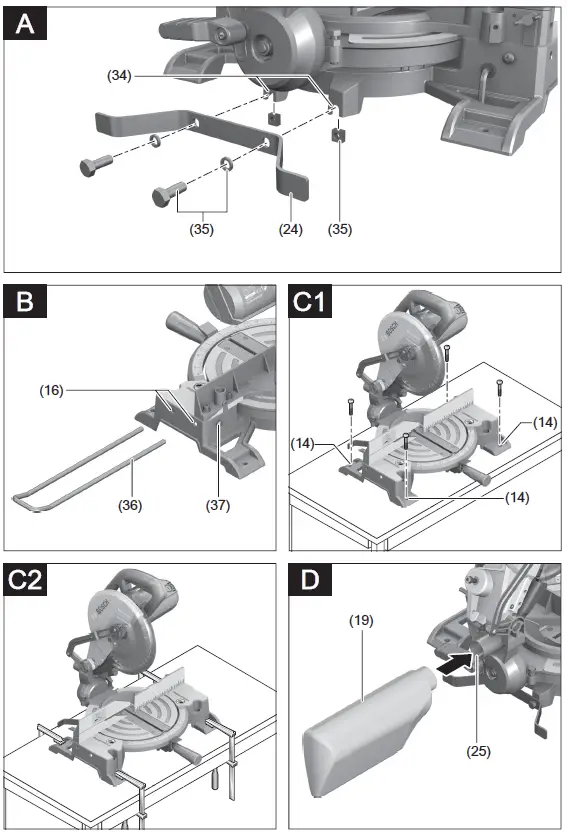

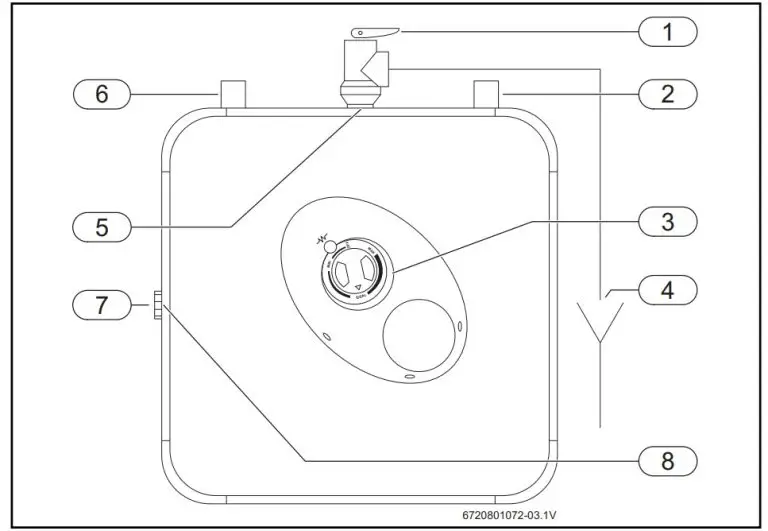

Filter system

The filter system removes coarse soiling from the dishwashing cycle.

3

2

1

1 Micro filter 2 Fine filter 3 Coarse filter

Cleaning filters Soiling in the dishwashing water may block the filters. 1. After each wash check the filters

for residue.

38

2. Turn the coarse filter anticlockwise and remove the filter system .

Check that no foreign objects fall into the sump.

2

1

3. Pull down the micro filter to remove.

Cleaning and servicingen

Carefully clean the rim of dirt between the coarse and the fine filter. 6. Re-assemble the filter system. Make sure that the locking catches on the coarse filter click into position. 7. Insert the filter system into the appliance and turn the coarse filter clockwise. Make sure that the arrow markings match up.

Cleaning spray arms

Limescale and soiling in the dishwashing water may block the nozzles and bearings on the spray arms. Clean the spray arms regularly. 1. Unscrew the upper spray arm

and pull down to remove .

4. Press the locking catches together and lift the coarse filter out . 2 1

1

2

2. Pull up the lower spray arm to remove.

5. Clean the filter elements under running water. 39

enCleaning and servicing 3. Check the outlet nozzles on the

spray arms for blockages under running water and remove any foreign bodies. 4. Insert the lower spray arm. a The spray arm clicks into position. 5. Insert the upper spray arm and screw it firmly in place.

40

Troubleshootingen

Troubleshooting Troubleshooting

You Troubleshooting can rectify minor faults on your appliance yourself. Read the troubleshooting information before contacting after-sales service. This will avoid unnecessary costs.

WARNING Risk of electric shock! Incorrect repairs are dangerous. Repairs to the appliance should only be carried out by trained specialist

staff. Only use genuine spare parts when repairing the appliance. If the power cord of this appliance is damaged, it must be replaced with a

special connection cable, which is available from the manufacturer or his Customer Service.

Error code / Fault display / Signal

Fault

Cause

E:20-60 lights up alternately. Appliance has detected calcified heating element.

E:30-00 will light up altern- Water protection system is

ately.

activated.

E:31-00 will light up altern- Water protection system is

ately.

activated.

E:34-00 will light up altern- Water is continuously run-

ately.

ning into the appliance.

E:32-00 will light up alternately or indicator for water supply lights up.

Supply hose is kinked.

Water tap is turned off. Water tap is jammed or furred up.

The filters in the water connection of the supply or AquaStop hose are blocked.

Troubleshooting 1. Descale the appliance. 2. Operate the appliance with the wa-

ter softening system.1 1. Turn off the water tap. 2. Call “Customer Service”

Page 54. 1. Turn off the water tap. 2. Call “Customer Service”

Page 54. 1. Turn off the water tap. 2. Call “Customer Service”

Page 54. Install the supply hose without

kinks. Turn on the water tap. Turn on the water tap.

The flow rate must be at least 10 l/ min when the water supply is open. 1. Switch off the appliance. 2. Pull out the mains plug. 3. Turn off the water tap.

1 Depending on the appliance specifications 41

enTroubleshooting

Fault E:32-00 will light up alternately or indicator for water supply lights up.

Cause

Troubleshooting 4. Unscrew the water connection. 5. Remove the filter from the supply

hose

E:92-40 will light up alternately. E:61-03 will light up alternately. Water is not drained.

E:61-02 will light up alternately.

6. Clean the filter. 7. Re-insert the filter in the supply

hose. 8. Screw the water connection back

on. 9. Check the water connection for

leaks. 10. Restore the power supply. 11. Switch the appliance on.

Filters are soiled or blocked. Clean the filters. “Cleaning filters”, Page 38

Wastewater hose is blocked 1. Reposition the wastewater hose

or kinked.

without kinks.

2. Remove residues.

Siphon connection is still sealed.

Check the connection to the siphon and open if necessary.

Cover of the wastewater pump is loose.

Secure the cover of the “Wastewater pump ” Page 53 so it clicks into position.

Wastewater pump is blocked.

Clean the wastewater pump. “Clean wastewater pump”, Page 53

Cover of the wastewater pump is loose

Secure the cover of the “Wastewater pump ” Page 53 so it clicks into position.

42

Troubleshootingen

Fault E:90-01 will light up alternately.

Cause Mains voltage is too low.

A different error code ap- A technical fault is present. pears in the display window. E:01-00 to E:90-10

Troubleshooting This is not a fault on the appliance. 1. Contact an electrician. 2. Have the mains voltage and elec-

trical installation checked by an electrician.

1. Press . 2. Unplug the appliance or switch off

the fuse. 3. Wait at least 2 minutes. 4. Insert the mains plug of the appli-

ance in a socket or switch on the fuse. 5. Switch the appliance on. 6. If the problem occurs again:

Press . Turn off the water tap. Pull out the mains plug. Contact “Customer Service”

Page 54 and give the error code.

Washing results

Fault Tableware is not dry.

Cause No rinse aid used or dosage set too low.

Programme or programme option has no drying phase, or the drying phase is too brief.

Troubleshooting 1. Add “Rinse aid” Page 25. 2. Set the amount of rinse aid to be

dispensed. “Setting the amount of rinse aid”, Page 26

“Select a programme with drying, e.g. intensive, strong or ECO programme.” Page 17 Some option buttons decrease the drying result, e.g varioSpeed.

43

enTroubleshooting

Fault Tableware is not dry.

Cause

Troubleshooting

Water collects in recesses of Position tableware at an angle

the tableware or cutlery.

where possible.

Plastic tableware is not dry. Cutlery is not dry.

Appliance interior still wet after wash cycle.

The combined detergent used has a poor drying performance.

1. Use rinse aid to improve drying performance.

2. Use a different combined detergent with a better drying performance.

Extra Dry not activated to im- Activate Extra Dry. prove drying performance.

Tableware removed too early or drying process not yet ended.

1. Wait until the programme ends. 2. Only remove tableware 30 minutes

after the programme has ended.

Rinse aid used has a limited Use a name-brand rinse aid.

drying performance.

Eco products may have limited ef-

fectiveness.

Not a fault. As plastic does No remedial action possible. not store heat so well, it also does not dry as well.

Cutlery not arranged properly in the cutlery basket or cutlery drawer.

Droplets can form on the cutlery contact points. 1. “Arrange cutlery individually where

possible.” Page 30 2. Avoid points of contact.

Not a fault. The condensation drying principle causes water droplets in the tub they are indeed desirable here. The moisture in the air condenses on the inside walls, runs off and is pumped out.

No action required.

44

Troubleshootingen

Fault Remnants of food on tableware.

Detergent residue in the appliance

Cause

Troubleshooting

Tableware is placed too close together or basket is overfilled.

1. Arrange tableware with sufficient space in between. The spray jets must reach the surfaces of the tableware.

2. Avoid points of contact.

Spray arm rotation is blocked.

Arrange tableware so that it does not obstruct spray arm rotation.

Spray arm nozzles are blocked.

Clean the “Spray arms” Page 39.

Filters are soiled.

Clean the filters. “Cleaning filters”, Page 38

Filters are inserted incorrectly and/or not engaged.

1. Insert the filters properly. “Filter system”, Page 38

2. Engage the filters.

Washing programme selec- Select a more intensive washing

ted too weak.

programme.

“Programmes”, Page 17

Tableware has been pre- Only remove large remnants of food

cleaned too intensely. The

and do not prerinse tableware.

sensors chose a weaker pro-

gramme. Stubborn soiling

cannot be entirely removed.

Tall narrow receptacles in Do not position tall narrow recept-

corner areas are not rinsed acles at too great an angle or in

adequately.

corner areas.

Top baskets on right and left Set the top baskets on the left and

are not set to same height.

right to the same level.

Lid of the detergent dispenser is blocked by items of tableware parts and will not open.

1. Arrange tableware in the top basket tableware so the tab collecting tray is not obstructed by tableware. “Arrange tableware”, Page 30 Items of tableware are blocking the dispenser lid.

2. Do not place tableware or fragrance dispensers in the tablet collecting tray.

The lid of the detergent dis- Position the tab in the detergent dispenser is blocked by the tab penser crosswise, not vertically. and will not open.

45

enTroubleshooting

Fault Detergent residue in the appliance

Cause

Troubleshooting

Tabs are used in the quick Select a more intensive “Pro-

or short programme. Dissolv- gramme” Page 17 or use

ing time of the tab is not at-

“Powder detergent” Page 26.

tained.

Washing effect and dissolving performance are reduced after a prolonged storage time or detergent is very lumpy.

Change your “detergent” Page 26.

Water marks on plastic parts.

Due to laws of physics

Select a more intensive pro-

droplet formation on plastic gramme.

surfaces is unavoidable.

“Programmes”, Page 17

After drying water marks are visible.

Position tableware at an angle. “Arrange tableware”, Page 30

Use rinse aid. “Rinse aid”, Page 25

Set the water softening system higher.

Wipeable or water-soluble Detergent substances are Change your “detergent”

coatings are present inside deposited there. These coat- Page 26.

the appliance or on the door. ings cannot generally be removed with chemicals.

Clean the appliance mechanically.

White coating is deposited in 1. Set the water softening system cor-

the appliance interior.

rectly.

In most cases you will need to increase the setting.

2. Change your detergent if required.

Special salt dispenser is not Screw the special salt dispenser

screwed tight.

tight.

Stubborn white coatings are Detergent substances are Change your “detergent”

present on tableware, inside deposited there. These coat- Page 26.

the appliance or the door.

ings cannot generally be removed with chemicals.

Clean the appliance mechanically.

The hardness range is set in- Set the Water softening system to

correctly or the water hard- the water hardness or add special

ness is greater than 62 °E

salt.

(8,9 mmol/l).

3in1/organic/eco detergent Set the Water softening system to

is not effective enough.

the water hardness and use separ-

ate detergents (proprietary deter-

gent, special salt, rinse aid).

46

Troubleshootingen

Fault

Cause

Troubleshooting

Stubborn white coatings are Too little detergent is being Increase the amount of detergent

present on tableware, inside used.

used or change “Detergent ”

the appliance or the door.

Page 26.

Washing programme selec- Select a more intensive washing

ted too weak.

programme.

“Programmes”, Page 17

Tea residue or lipstick marks Washing temperature is too Select a programme with a higher

on tableware.

low.

washing temperature.

“Programmes”, Page 17

Too little detergent is being used or is unsuitable.

Use a suitable “Detergent ” Page 26 and follow the manufacturer’s instructions for the amount to be used.

Tableware has been pre- Only remove large remnants of food

cleaned too intensely. The

and do not prerinse tableware.

sensors chose a weaker pro-

gramme. Stubborn soiling

cannot be entirely removed.

Coloured coatings (blue, yel- The formation of films is due Clean the appliance.

low, brown) that are difficult or impossible to remove are present inside the appliance or on stainless steel tableware.

to substances contained in vegetables (cabbage, celery, potatoes, noodles, etc.) or tap water (manganese).

You can remove deposits with “Mechanical cleaning” Page 37 or a machine cleaning product. It may not always be possible to completely remove deposits but they

are harmless to health.

The formation of films is due Clean the appliance.

to metal components on silver or aluminium tableware.

You can remove deposits with “Mechanical cleaning” Page 37

or a machine cleaning product. It

may not always be possible to com-

pletely remove deposits but they

are harmless to health.

47

enTroubleshooting

Fault

Cause

Troubleshooting

Coloured deposits (yellow, The formation of films is due 1. Check the setting of the water

orange, brown) that are easy to ingredients of food rem-

softening system.

to remove are present inside nants and tap water (limes- 2. Add special salt.

the appliance (mainly at the cale) “soaplike”.

“Adding special salt”, Page 24

bottom).

3. If you are using combined deter-

gents (tabs), activate the water

softening system.

Follow the information about detergents. “Information on detergents”, Page 28

Plastic parts inside the appli- Plastic parts inside the appli- Discolouration can come about and

ance are discoloured.

ance may become discol-

will not impair functioning of the ap-

oured during the life of the

pliance.

dishwasher.

Plastic parts are discoloured.

Washing temperature is too Select a programme with a higher

low.

washing temperature.

“Programmes”, Page 17

Tableware has been pre- Only remove large remnants of food

cleaned too intensely. The

and do not prerinse tableware.

sensors chose a weaker pro-

gramme. Stubborn soiling

cannot be entirely removed.

Removable streaks are present on glasses, glassware with a metallic appearance and cutlery.

Amount of rinse aid to be dispensed is set too high. No rinse aid has been added.

Set the rinse aid system to a lower setting.

“Adding rinse aid”, Page 25

Detergent residue is present 1. Arrange tableware in the top basket