BOSCH Professional Mitre Saw

PARTs

Safety instructions

WARNING: Read all safety warnings, instructions, illustrations and specifications provided with this power tool. Failure to follow all instructions listed below may result in electric shock, fire and/ or serious injury.

Save all warnings and instructions for future reference. The term “power tool” in the warnings refers to your mains operated (corded) power tool or battery-operated (cordless) power tool.

Work area safety

- Keep work area clean and well lit. Cluttered or dark areas invite accidents.

- Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

- Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

Electrical safety - Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

- Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

- Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

- Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

- When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

- If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) protected supply. Use of an RCD reduces the risk of electric shock.

Personal safety - Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

- Use personal protective equipment. Always wear eye protection. Protective equipment such as a dust mask, non-skid safety shoes, hard hat or hearing protection used for appropriate conditions will reduce personal injuries.

- Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

- Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

- Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

- Dress properly. Do not wear loose clothing or jewellery. Keep your hair and clothing away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

- If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dust-related hazards.

- Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore tool safety principles. A careless action can cause severe injury within a fraction of a second.

Power tool use and care - Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

- Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

- Disconnect the plug from the power source and/or remove the battery pack, if detachable, from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

- Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

- Maintain power tools and accessories. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

- Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

- Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

- Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles and grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

Service - Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained. Safety Warnings for Mitre Saws

- Mitre saws are intended to cut wood or wood-like products, they cannot be used with abrasive cut-off wheels for cutting ferrous material such as bars, rods, studs, etc. Abrasive dust causes moving parts such as the lower guard to jam. Sparks from abrasive cutting will burn the lower guard, the kerf insert and other plastic parts.

- Use clamps to support the workpiece whenever possible. If supporting the workpiece by hand, you must always keep your hand at least 100 mm from either side of the saw blade. Do not use this saw to cut pieces that are too small to be securely clamped or held by hand. If your hand is placed too close to the saw blade, there is an increased risk of injury from blade contact.

- The workpiece must be stationary and clamped or held against both the fence and the table. Do not feed the workpiece into the blade or cut “freehand” in any way. Unrestrained or moving workpieces could be thrown at high speeds, causing injury.

- Push the saw through the workpiece. Do not pull the saw through the workpiece. To make a cut, raise the saw head and pull it out over the workpiece without cutting, start the motor, press the saw head down and push the saw through the workpiece. Cutting on the pull stroke is likely to cause the saw blade to climb on top of the workpiece and violently throw the blade assembly towards the operator.

- Never cross your hand over the intended line of cutting either in front or behind the saw blade. Supporting the workpiece “cross handed” i.e. holding the workpiece to the right of the saw blade with your left hand or vice versa is very dangerous.

- Do not reach behind the fence with either hand closer than 100 mm from either side of the saw blade, to remove wood scraps, or for any other reason while the blade is spinning. The proximity of the spinning saw blade to your hand may not be obvious and you may be seriously injured.

- Inspect your workpiece before cutting. If the workpiece is bowed or warped, clamp it with the outside bowed face toward the fence. Always make certain that there is no gap between the workpiece, fence and table along the line of the cut. Bent or warped workpieces can twist or shift and may cause binding on the spinning saw blade while cutting. There should be no nails or foreign objects in the workpiece.

- Do not use the saw until the table is clear of all tools, wood scraps, etc., except for the workpiece. Small debris or loose pieces of wood or other objects that contact the revolving blade can be thrown with high speed.

- Cut only one workpiece at a time. Stacked multiple workpieces cannot be adequately clamped or braced and may bind on the blade or shift during cutting.

- Ensure the mitre saw is mounted or placed on a level, firm work surface before use. A level and firm work surface reduces the risk of the mitre saw becoming unstable.

- Plan your work. Every time you change the bevel or mitre angle setting, make sure the adjustable fence is set correctly to support the workpiece and will not interfere with the blade or the guarding system. Without turning the tool “ON” and with no workpiece on the table, move the saw blade through a complete simulated cut to assure there will be no interference or danger of cutting the fence.

- Provide adequate support such as table extensions, saw horses, etc. for a workpiece that is wider or longer than the table top. Workpieces longer or wider than the mitre saw table can tip if not securely supported. If the cut-off piece or workpiece tips, it can lift the lower guard or be thrown by the spinning blade.

- Do not use another person as a substitute for a table extension or as additional support. Unstable support for the workpiece can cause the blade to bind or the workpiece to shift during the cutting operation pulling you and the helper into the spinning blade.

- The cut-off piece must not be jammed or pressed by any means against the spinning saw blade. If confined, i.e. using length stops, the cut-off piece could get wedged against the blade and thrown violently.

- Always use a clamp or a fixture designed to properly support round material such as rods or tubing. Rods have a tendency to roll while being cut, causing the blade to “bite” and pull the work with your hand into the blade.

- Let the blade reach full speed before contacting the workpiece. This will reduce the risk of the workpiece being thrown.

- If the workpiece or blade becomes jammed, turn the mitre saw off. Wait for all moving parts to stop and disconnect the plug from the power source and/or remove the battery pack. Then work to free the jammed material. Continued sawing with a jammed workpiece could cause loss of control or damage to the mitre saw.

- After finishing the cut, release the switch, hold the saw head down and wait for the blade to stop before removing the cut-off piece. Reaching with your hand near the coasting blade is dangerous.

- Hold the handle firmly when making an incomplete cut or when releasing the switch before the saw head is completely in the down position. The braking action of the saw may cause the saw head to be suddenly pulled downward, causing a risk of injury.

- Keep your work area clean. Material mixtures are particularly hazardous. Light metal dust may catch fire or explode.

- Do not use dull, cracked, bent or damaged saw blades. Unsharpened or improperly set saw blades produce narrow kerf causing excessive friction, blade binding and kickback.

- Do not use saw blades made from high speed steel (HSS). Such saw blades can easily break.

- Always use saw blades with correct size and shape (diamond versus round) of arbour holes. Saw blades that do not match the mounting hardware of the saw will run off-centre, causing loss of control.

- Never remove cuttings, wood chips, etc. from the cutting area while the power tool is running. Always guide the tool arm back to the neutral position first and then switch the power tool off.

- Do not touch the saw blade after working before it has cooled. The saw blade becomes very hot while working.

Products sold in GB only:

Your product is fitted with an BS 1363/A approved electric plug with internal fuse (ASTA approved to BS 1362). If the plug is not suitable for your socket outlets, it should be cut off and an appropriate plug fitted in its place by an authorised customer service agent. The replacement plug should have the same fuse rating as the original plug. The severed plug must be disposed of to avoid a possible shock hazard and should never be inserted into a mains socket elsewhere.

Symbols

The following symbols may be important for the operation of your power tool. Please take note of these symbols and their meaning. Correctly interpreting the symbols will help you to operate the power tool more effectively and safely.

Symbols and their meanings

- Keep hands away from the cutting area while the power tool is running. Contact with the saw blade can lead to injuries.

- Wear a dust mask.

- Wear safety goggles.

- Wear hearing protection. Exposure to noise can cause hearing loss.

- Danger area! Keep hands, fingers and arms away from this area.

Take note of the dimensions of the saw blade. The hole diameter must fit the tool spindle without play. If it is necessary to use reducers, ensure that the dimensions of the reducer are suitable for the base blade thickness and the saw blade hole diameter, as well as the tool spindle diameter. Wherever possible, use the reducers provided with the saw blade. The saw blade diameter must match the information specified on the symbol. When sawing bevel angles, the adjustable

fences must be pulled outwards or removed completely.

Product Description and Specifications

Read all the safety and general instructions. Failure to observe the safety and general instructions may result in electric shock, fire and/or serious injury. Please observe the illustrations at the beginning of this operating manual.

Intended Use

The power tool is intended as a stationary machine for making straight lengthways and crossways cuts. It is possible to cut mitre angles of –47° to +52° and bevel angles of 0° to 45°. The power tool is designed with sufficient capacity for sawing hardwood, softwood, chipboard and fibreboard, as well as aluminium and plastic.

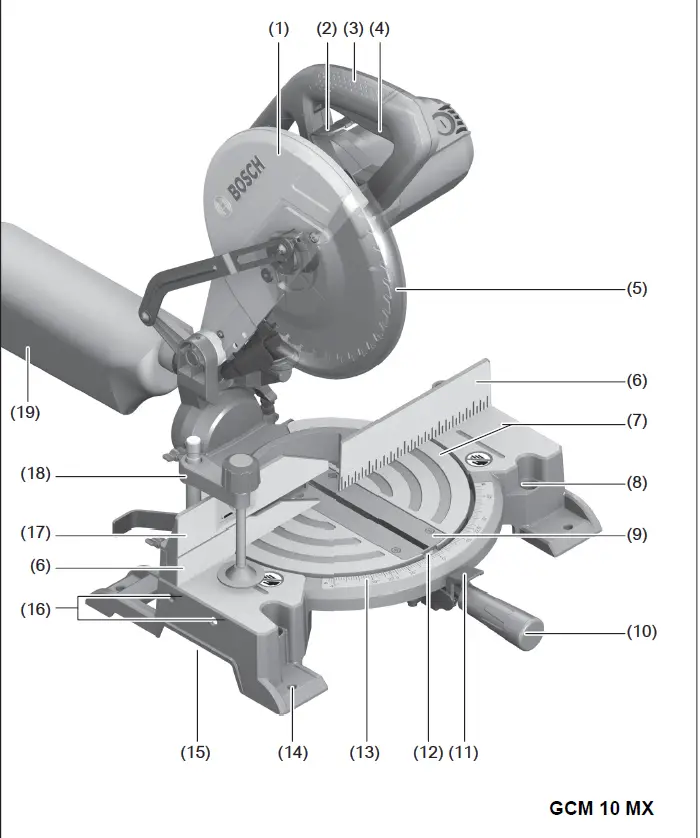

Product Features

The numbering of the product features refers to the diagram of the power tool on the graphics page.

- Protective guard

- Lever for releasing the tool arm

- Handle

- On/off switch

- Retracting blade guard

- Fence

- Saw table

- Holes for screw clamp

- Insert plate

- Locking knob for all mitre angles

- Mitre presetting lever

- Angle indicator for mitre angles

- Scale for mitre angles

- Mounting holes

- Recessed handles

- Drill holes for extension bars

- Adjustable fence

- Screw clamp

- Dust bag

- Chip deflector

- Wing bolt for fixing the adjustable fence

- Hex key (6 mm)/cross-headed screwdriver

- Stop screw for 45° bevel angle

- Tilt protector

- Chip ejector

- Clamping handle for all bevel angles

- Transport safety lock

- Transport handle

- Spindle lock

- Depth stop adjusting screw

- Angle indicator for bevel angles

- Scale for bevel angles

- Stop screw for 0° bevel angle

- Holes for tilt protector

- “Tilt protector” fastening set

- Extension bar

- Fastening screw for extension bar

- Cross-head screw (retracting blade guard attachment)

- Hex socket screw for mounting the saw blade

- Clamping flange

- Saw blade

- Inner clamping flange

- Wing bolt for adjusting the height of the threaded rod

- Threaded rod

- Detents for standard mitre angles

- Screws for insert plate

- Hex socket screw for fence

- Screw for bevel angle indicator.

Technical Data

Mitre saw GCM 10 MX

Article number 3 601 M29 0..

Rated power input W 1700

No-load speed min-1 4800

Weight according to EPTA-Procedure

01:2014

kg 16.8

Protection class / II

Permitted workpiece dimensions (maximum/minimum): (see “Permissible workpiece dimensions”, page 17) The specifications apply to a rated voltage [U] of 230 V. These specifications may vary at different voltages and in country-specific models.

Dimensions of suitable saw blades

Saw blade diameter mm 254

Base blade thickness mm 1.8−2.8

Hole diameter mm 25.4

Noise Information

Noise emission values determined according to EN 62841-3-9. Typically, the A-weighted noise level of the power tool is: Sound pressure level 92 dB(A); sound power level 105 dB(A). Uncertainty K = 3 dB.

Wear hearing protection

The noise emission value given in these instructions has been measured in accordance with a standardised measuring procedure and may be used to compare power tools. It may also be used for a preliminary estimation of noise emissions. The noise emission value given represents the main applications of the power tool. However, if the power tool is used for other applications, with different application tools or is poorly maintained, the noise emission value may differ. This may significantly increase noise emissions over the total working period. To estimate noise emissions accurately, the times when the tool is switched off, or when it is running but not actually being used, should also be taken into account. This may significantly reduce noise emissions over the total working period.

Assembly

Avoid starting the power tool unintentionally. The mains plug must not be connected to the power supply during assembly or when carrying out any kind of work on the power tool.

Items included

See the list of items included at the start of the operating manual.

Check to ensure that all the parts listed below have been supplied before using the power tool for the first time:

Mitre saw with mounted saw blade

Dust bag (19)

Screw clamp (18)

Hex key/cross-headed screwdriver (22)

Tilt protector (24) with fastening set (35) (2 bolts, 2 washers, 2 square nuts)

Note: Check the power tool for possible damage. Before continuing to use the power tool, carefully check that all protective devices or slightly damaged parts are working perfectly and according to specifications. Check that the moving parts are working perfectly and without jamming; check whether any parts are damaged. All parts must be fitted correctly and all the conditions necessary to ensure smooth operation must be met. If the protective devices or any parts become damaged, you must have them properly repaired or replaced by an authorised service centre.

Fitting individual components

- Carefully remove all parts included in the delivery from their packaging.

- Remove all packing material from the power tool and the accessories provided.

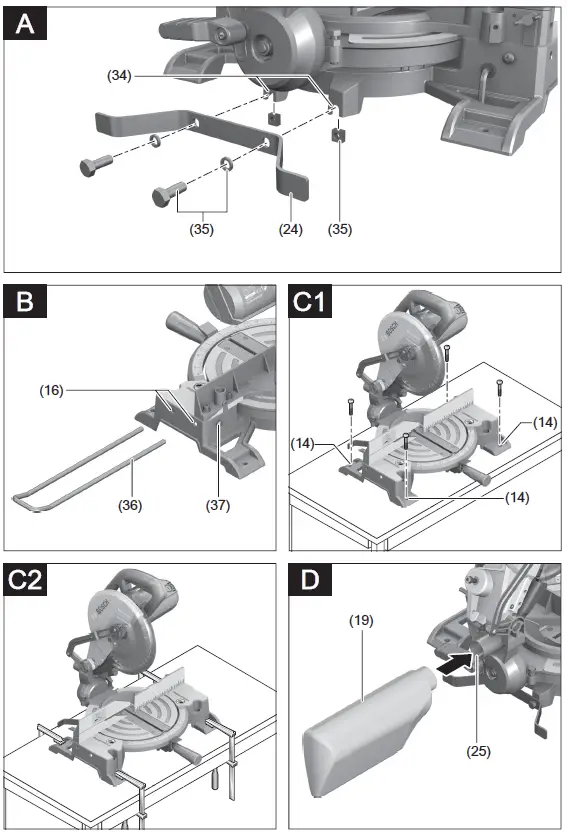

Mounting the tilt protector (see figure A) - Before the power tool is used for the first time, the tilt protector (24) must be installed.

- Use the “tilt protector” fastening set (35) for the installation.

- Insert the square nuts (35) into the corresponding holes (34) in the base plate.

- Place the washers (35) on the fastening screws (35) and use them to screw the tilt protector (24) into the inserted nuts.

- Do not remove the tilt protector. Without the tilt protector, the power tool will not be stable and can tip over especially when sawing maximum mitre/bevel angles.

Fitting the extension bar (see figure B) - The free end of long and heavy workpieces must have something placed underneath it or be supported.

- To extend the saw table further, extension bars can be mounted both to the left or right of the power tool.

- Push the extension bars (36) on both sides of the power tool all the way into the corresponding drill holes (16).

- Tighten the fastening screws (37) to secure the extension bars.

Stationary or flexible mounting

- To ensure safe handling, the power tool must be mounted on a flat, stable work surface (e.g. work bench) before use.

Mounting on a work surface (see figure C1−C2) - Use suitable screw fasteners to secure the power tool to the work surface. The holes (14) are used for this purpose. or

- Firmly clamp the base of the power tool to the work surface with commercially available screw clamps.

Mounting on a Bosch saw stand - With the height-adjustable legs, Bosch GTA saw stands provide firm support for the power tool on any surface. The workpiece supports of the saw stand are used for underlaying long workpieces.

- Read all the warnings and instructions included with the saw stand. Failure to observe the warnings and follow instructions may result in electric shock, fire and/or serious injury.

- Assemble the saw stand properly before mounting the power tool. Correct assembly is important to prevent the risk of collapsing.

- Mount the power tool on the saw stand in the transport position.

Dust/Chip Extraction

The dust from materials such as lead paint, some types of wood, minerals and metal can be harmful to human health. Touching or breathing in this dust can trigger allergic reactions and/or cause respiratory illnesses in the user or in people in the near vicinity. Certain dusts, such as oak or beech dust, are classified as carcinogenic, especially in conjunction with wood treatment additives (chromate, wood preservative). Materials containing asbestos may only be machined by specialists.

- Use a dust extraction system that is suitable for the material wherever possible.

- Provide good ventilation at the workplace.

- It is advisable to wear a P2 filter class breathing mask.

- The regulations on the material being machined that apply in the country of use must be observed.

- Avoid dust accumulation at the workplace. Dust can easily ignite.

- The dust/chip extraction system can be blocked by dust, chips or fragments of the workpiece.

- Switch the power tool off and pull the mains plug out of the socket.

- Wait until the saw blade has come to a complete stop.

- Determine the cause of the blockage and eliminate it.

Self-generated dust extraction (see figure D)

For basic chip collection, use the dust bag (19) provided.

- Attach the dust bag (19) to the chip ejector (25). During sawing, the dust bag must not come into contact with moving tool components.

- Always empty the dust bag in good time

- Check and clean the dust bag each time after using.

- When sawing aluminium, remove the dust bag to avoid the risk of fire.

External Dust Extraction - You can also attach a dust extraction hose (35 mm diameter) to the chip ejector (25) for extraction.

- Connect the dust extraction hose to the chip ejector (25). The dust extractor must be suitable for the material being worked.

- When extracting dry dust that is especially detrimental to health or carcinogenic, use a special dust extractor.

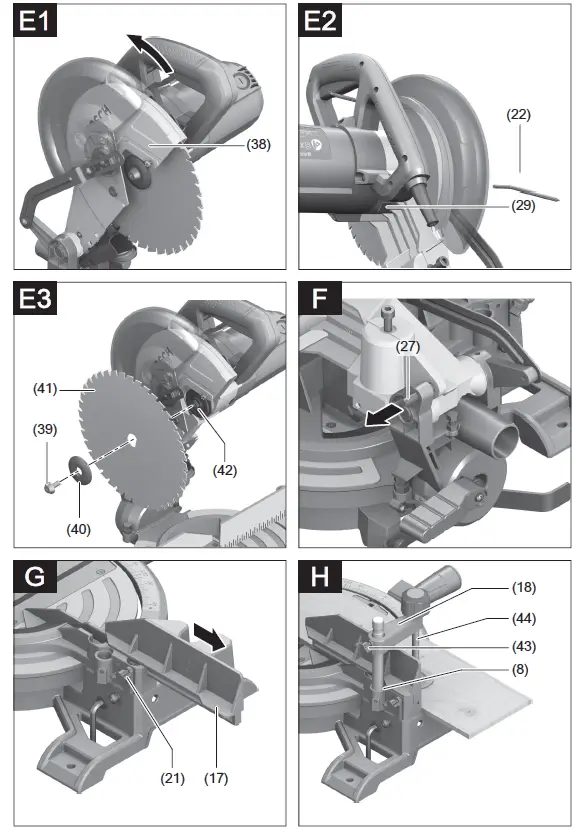

Changing the saw blade (see figures E1−E3)

- Pull the plug out of the socket before carrying out any work on the power tool.

- Wear protective gloves when fitting the saw blade. There is a risk of injury when touching the saw blade. Only use saw blades that have a maximum permitted speed higher than the no-load speed of the power tool. Only use saw blades that match the specifications given in this operating manual and that have been tested and marked in accordance with EN 847-1.

- Only use saw blades that are recommended by the power tool manufacturer and are suitable for use on the material you want to saw. This will prevent the saw teeth overheating when sawing.

Removing the saw blade

- Bring the power tool into the work position.

- Push the lever (2) and swing the retracting blade guard (5) back as far as it will go. Hold the retracting blade guard in this position.

- Loosen the screw (38) with the cross-headed screwdriver (22) provided until the retracting blade guard attachment can also be swivelled all the way back.

- Turn the hex socket screw (39) using the hex key (22) provided while pressing the spindle lock (29) until it engages.

- Press and hold the spindle lock (29) and loosen the screw (39) by turning it clockwise (left-hand thread).

- Remove the clamping flange (40).

- Remove the saw blade (41).

Fitting the saw blade - If required, clean all the parts you want to fit before installing them.

- Place the new saw blade on the inner clamping flange (42).

When fitting the saw blade, make sure that the cutting direction of the teeth (arrow direction on the saw blade) matches the direction of the arrow on the protective guard.

- Place on the clamping flange (40) and the screw (39). Press the spindle lock (29) until it engages and tighten the screw by turning it anticlockwise.

- Push the retracting blade guard (5) forwards and down until the screw (38) engages in the corresponding recess. To do so, you may need to hold the tool arm against the handle in order to generate sufficient pre-tension on the retracting blade guard.

- Fasten the retracting blade guard (5) again (tighten screw (38)).

- Push the lever (2) and guide the retracting blade guard down again.

- When attaching the clamping flange, ensure that the wide side faces the saw blade. The saw blade cannot be tightened if it is installed the other way round.

Operation

- Pull the plug out of the socket before carrying out any work on the power tool.

Transport safety lock (see figure F)

The transport safety lock (27) makes it easier to handle the power tool when transporting it to various working locations.

Unlocking the power tool (work position) - Press the tool arm down slightly by the handle (3) to release the transport safety lock (27).

- Pull the transport safety lock (27) all the way out.

- Slowly guide the tool arm upwards.

Note: Make sure that the transport safety lock is not pushed in when working, otherwise the tool arm will not be able to be swivelled to the required depth.

Locking the power tool (transport position) - Swivel the depth stop inwards so that the tool arm can be swivelled all the way downwards by the handle (3).

- Push the lever (2) while swivelling the tool arm downwards by the handle (3) until you can press the transport safety lock (27) all the way in. The tool arm is now securely locked and ready for transportation.

Preparing for operation - Moving the fence (see figure G)

- You have to move the adjustable fence (17) to saw bevel angles.

- Loosen the wing bolt (21).

- Pull the adjustable fence (17) all the way out.

- Retighten the wing bolt (21).

- After sawing the bevel angles, slide the adjustable fence (17) back again (loosen the wing bolt (21); slide the fence (17) all the way in; retighten the wing bolt).

Clamping the workpiece (see figure H)

To ensure maximum safety while working, the workpiece must always be firmly clamped. Do not saw workpieces that are too small to clamp firmly. - Press the workpiece firmly against the fences (6) and (17).

- Insert the supplied screw clamp (18) into one of the corresponding holes (8).

- Loosen the wing bolt (43) and adjust the screw clamp to the workpiece. Tighten the wing bolt again.

- Tighten the threaded rod (44) to fix the workpiece in place.

Releasing the workpiece - To loosen the screw clamp, turn the threaded rod (44) anticlockwise.

Setting mitre and bevel angles

- Pull the plug out of the socket before carrying out any work on the power tool.

- To ensure precise cuts, the basic settings of the power tool must be checked and adjusted as necessary after intensive use.

- Experience and suitable special tools are required for this. A Bosch after-sales service point will handle this work quickly and reliably.

- Always tighten the locking knob (10) firmly before sawing. Otherwise the saw blade can become wedged in the workpiece.

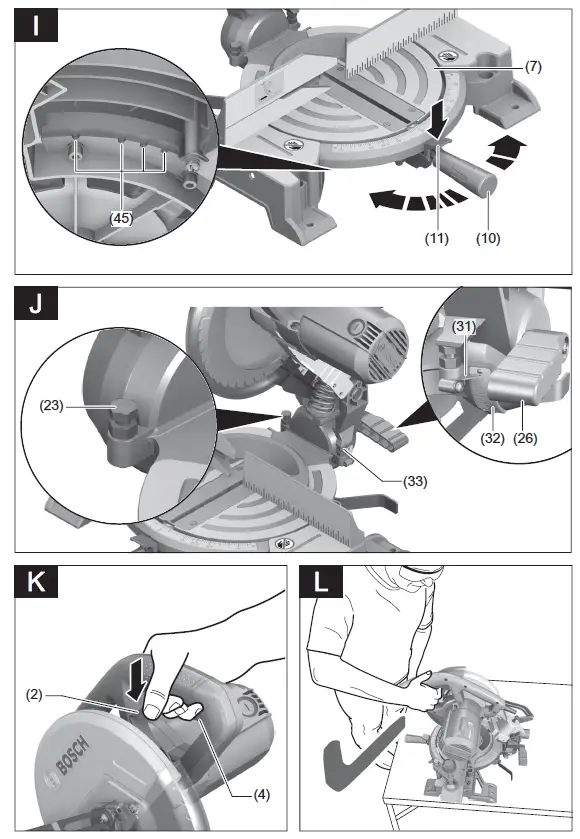

Setting mitre angles (see figure I) - The mitre angle can be set between 47° (left side) and 52° (right side).

- Loosen the locking knob (10) if it is tightened.

- Push the lever (11), turn the saw table (7) left or right by the locking knob and set the required mitre angle using the angle indicator (12).

- Retighten the locking knob (10). For quick and precise setting of commonly used mitre angles, detents (45) are provided on the saw table:

Left Right

0° 45°; 30°; 22.5°; 15° 15°; 22.5°; 30°; 45°

Loosen the locking knob (10) if it is tightened.

Push the lever (11) and turn the saw table (7) left or right to the required detent. Release the lever again. The lever must be felt to engage in the detent. Retighten the locking knob (10).

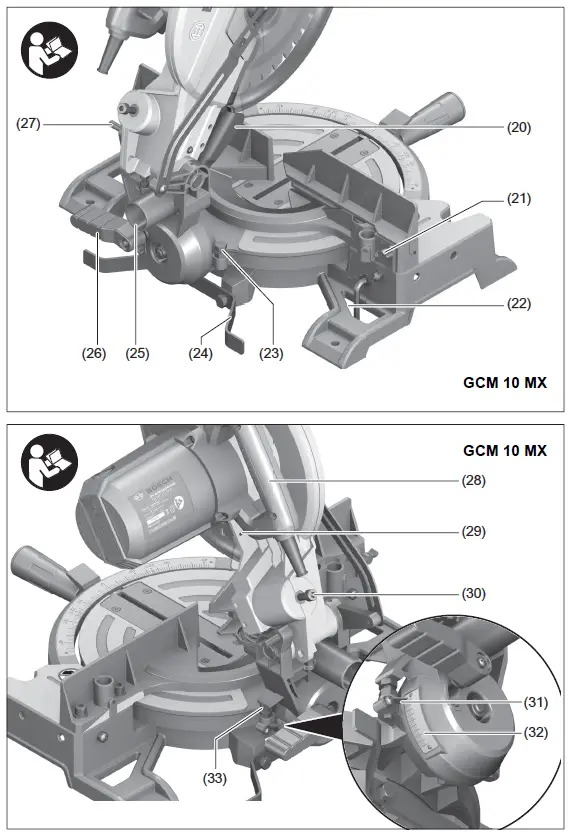

Setting bevel angles (see figure J)

The bevel angle can be set between 0° and 45°. Loosen the clamping handle (26).

- Use the handle (3) to swivel the tool arm until the angle indicator (31) shows the required bevel angle.

- Hold the tool arm in this position and retighten the clamping handle (26).

- To set the standard angles of 0° and 45° quickly and accurately, stop screws are provided ex-works ((33) and (23)).

- Loosen the clamping handle (26).

- Swivel the tool arm by the handle (3) all the way to the right (0°) or all the way to the left (45°).

- Retighten the clamping handle (26).

Start-up

- Pay attention to the mains voltage. The voltage of the power source must match the voltage specified on the rating plate of the power tool. Power tools marked with 230 V can also be operated with 220 V.

- Products that are only sold in AUS and NZ: Use a residual current device (RCD) with a nominal residual current of 30 mA or less.

Switching on (see figure K) - To start the tool, press the on/off switch (4) and keep it pressed.

Note: For safety reasons, the on/off switch (4) cannot be locked; it must remain pressed during the entire operation. - The tool arm can only be guided downwards by pushing the lever (2).

- For sawing, the lever (2) must therefore be pushed while the on/off switch (4) is pressed.

Switching off - To switch off, release the on/off switch (4).

Practical advice

General sawing instructions

- Always tighten the locking knob (10) and the clamping handle (26) firmly before sawing. Otherwise the saw blade can become wedged in the workpiece.

- For all cuts, it must first be ensured that the saw blade at no time can come in contact with the fence, screw clamps or other machine parts. Remove any mounted auxiliary stops or adjust them accordingly. Protect the saw blade against impact and shock. Do not subject the saw blade to lateral pressure.

- Do not saw warped/bent workpieces. The workpiece must always have a straight edge to face against the fence. The free end of long and heavy workpieces must have something placed underneath it or be supported. Make sure that the retracting blade guard operates properly and that it can move freely. The retracting blade guard must open when the tool arm is guided downward. When the tool arm is guided upward, the retracting blade guard must close again over the saw blade and lock in the uppermost position of the tool arm.

Only saw materials which are permitted within the scope of the intended use.

Position of the operator (see figure L)

- Do not stand in line with the saw blade in front of the power tool. Always stand to the side of the saw blade.

This protects your body against possible kickback. - Keep hands, fingers and arms away from the rotating saw blade.

- Do not reach one hand across the other when in front of the tool arm.

Permissible workpiece dimensions

Maximum workpiece dimensions:

Mitre angle Bevel angle Height x width [mm]

at max. height at max. width

0° 0° 89 x 89 62 x 130

45° 0° 86 x 67 65 x 91

0° 45° 44 x 95 32 x 130

45° 45° 44 x 67 32 x 91

Minimum workpiece dimensions (= all workpieces that can be secured left or right of the saw blade using the supplied quick-action clamp ): 110 x 130 mm (length x width)

Max. cutting depth (0°/0°): 89 mm

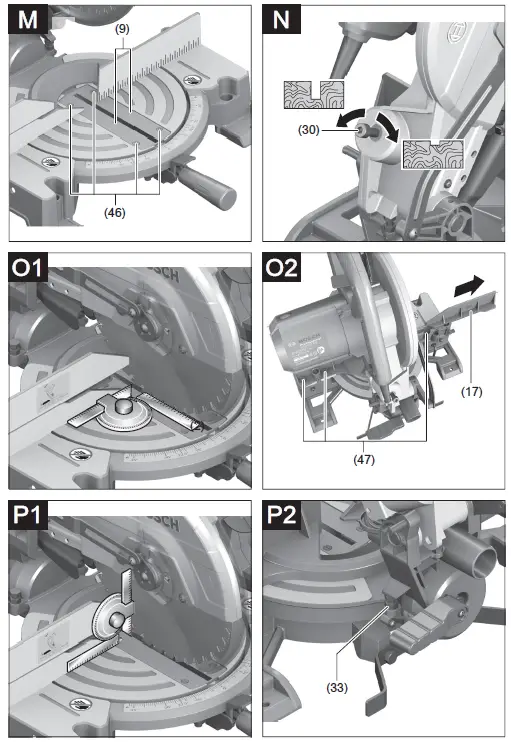

Replacing insert plates (see figure M)

The insert plate (9) can become worn after long use of the power tool.

Replace faulty insert plates.

- Bring the power tool into the work position.

- Unscrew the screws (46) using the cross-headed screwdriver (22) provided and remove the old insert plate.

- Screw the insert plate as far as possible to the right with the screws (46) so that the saw blade does not come into contact with the insert plate over the entire length of the possible cutting motion.

Sawing (cutting) - Firmly clamp the workpiece as appropriate for its dimensions.

- Set the required mitre and/or bevel angle.

- Set the height of the adjusting screw (30) so that the workpiece can be sawn through completely.

- Switch the power tool on.

- Push the lever (2) and slowly guide the tool arm downwards using the handle (3).

- Saw through the workpiece applying uniform feed.

- Switch off the power tool and wait until the saw blade has come to a complete stop.

- Slowly guide the tool arm upwards. Adjusting the depth stop (sawing the groove) (see figure N)

- The adjusting screw (30) of the depth stop has to be turned clockwise if you want to saw a groove.

- Swivel the tool arm by the handle (3) into the position at which the required groove depth is reached.

- Turn the adjusting screw (30) clockwise until the end of the screw touches the housing stop.

- Slowly guide the tool arm upwards.

Special workpieces

When sawing curved or round workpieces, these must be especially secured against slipping. At the cutting line, there should be no gap between the workpiece, fence and saw table. If necessary, you will need to manufacture special fixtures.

Working on mouldings

Mouldings can be sawn in two different ways: Always check the set mitre and/or bevel angle first by making trial cuts in scrap wood.

Always check the set mitre and/or bevel angle first by making trial cuts in scrap wood.

Checking and Adjusting the Basic Settings

To ensure precise cuts, the basic settings of the power tool must be checked and adjusted as necessary after intensive use. Experience and suitable special tools are required for this. A Bosch after-sales service point will handle this work quickly and reliably.

Aligning the fence

- Bring the power tool into the transport position.

- Turn the saw table (7) to the 0° detent (45). The lever (11) must be felt to engage in the detent.

- Pull the adjustable fence (17) all the way out.

Checking (see figure O1) - Set an angle gauge to 90° and position it flush with the saw blade (41) between the fence (6) and the saw blade on the saw table (7).

- The leg of the angle gauge must be flush with the fence over the complete length.

Setting (see figure O2) - Loosen all hex socket screws (47) with the hex key (22) provided.

- Rotate the fence (6) until the angle gauge is flush over the complete length.

- Re-tighten the screws.

Setting the Standard 0° Bevel Angle - Bring the power tool into the transport position.

- Turn the saw table (7) to the 0° detent (45). The lever (11) must be felt to engage in the detent.

Checking (see figure P1) - Set an angle gauge to 90° and place it on the saw table (7).

- The leg of the angle gauge must be flush with the saw blade (41) along its entire length.

Setting (see figure P2) - Loosen the clamping handle (26).

- Loosen the lock nut of the stop screw (33) using a commercially available ring spanner or open-ended spanner (13 mm).

- Turn the stop screw as far in or out as needed until the leg of the angle gauge is flush with the saw blade along its entire length.

- Retighten the clamping handle (26).

- Then retighten the lock nut of the stop screw (33). If the angle indicator (31) is not aligned with the 0° mark on the scale (32) following adjustment, loosen the screw (48) using a commercially available cross-headed screwdriver and align the angle indicator along the 0° mark. (See figure R)

Setting the standard 45° bevel angle - Bring the power tool into the work position.

- Turn the saw table (7) to the 0° detent (45). The lever (11) must be felt to engage in the detent.

- Loosen the clamping handle (26) and use the handle (3) to swivel the tool arm all the way to the left (45°).

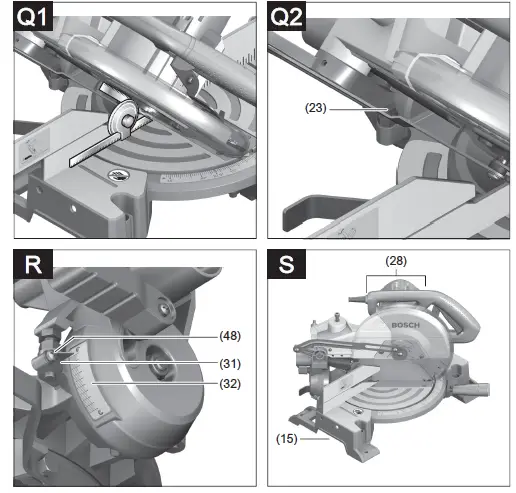

Checking (see figure Q1)

- Set an angle gauge to 45° and place it on the saw table (7).

- The leg of the angle gauge must be flush with the saw blade (41) along its entire length.

Setting (see figure Q2) - Loosen the lock nut of the stop screw (23) using a commercially available ring spanner or open-ended spanner (13 mm).

- Turn the stop screw as far in or out as needed until the leg of the angle gauge is flush with the saw blade along its entire length.

- Retighten the clamping handle (26).

- Then retighten the lock nut of the stop screw (23).

- If the angle indicator (31) is not aligned with the 45° mark on the scale (32) following adjustment, first check the 0° setting for the bevel angle and the angle indicator once more. Then repeat the adjustment of the 45° bevel angle.

Transport (see figure S) - Before transporting the power tool, the following steps must be carried out:

- Bring the power tool into the transport position.

- Remove all accessories that cannot be securely fitted to the power tool.

- If possible, transport unused saw blades in a closed container.

- Carry the power tool by the transport handle (28) or hold it by the recessed handles (15) on the sides of the saw table.

- Only use the transport devices to transport the power tool and never the protective devices.

Maintenance and servicing

Maintenance and cleaning

- Pull the plug out of the socket before carrying out any work on the power tool.

- To ensure safe and efficient operation, always keep the power tool and the ventilation slots clean. In order to avoid safety hazards, if the power supply cord needs to be replaced, this must be done by Bosch or by an after-sales service centre that is authorised to repair Bosch power tools.

- The retracting blade guard must always be able to move freely and retract automatically. It is therefore important to keep the area around the retracting blade guard clean at all times.

- Always remove dust and chips after working by blowing out with compressed air or using a brush.

Accessories

Article number

3 601 M29 040, 3 601 M29 0B0: Extension bar 1 619 PA6 916

Saw blades for hardwood, composites, plastic and nonferrous metals

254 x 25.4 mm saw blade, 100 teeth 1 609 B00 844

Saw blades for wood and fibreboard, panels and strips

254 x 25.4 mm saw blade, 40 teeth 2 608 673 047

254 x 25.4 mm saw blade, 100 teeth 2 608 640 904

After-Sales Service and Application Service

Our after-sales service responds to your questions concerning maintenance and repair of your product as well as spare parts. You can find explosion drawings and information on spare parts at: www.bosch-pt.com The Bosch product use advice team will be happy to help you with any questions about our products and their accessories. In all correspondence and spare parts orders, please always include the 10‑digit article number given on the nameplate of the product.

Cambodia

Robert Bosch (Cambodia) Co., Ltd Unit 8BC, GT Tower, 08th Floor, Street 169, Czechoslovakia Blvd, Sangkat Veal Vong

Khan 7 Makara, Phnom Penh

VAT TIN: 100 169 511

Tel.: +855 23 900 685