EGO STX3800 56 Volt Lithium-Ion Cordless Line Trimmer

PRODUCT OVERVIEW

READ ALL INSTRUCTIONS!

READ OPERATOR’S MANUAL

Residual risk! People with electronic devices, such as pacemakers, should consult their physician(s) before using this product. Operation of electrical equipment

in close proximity to a heart pacemaker could cause interference or failure of the pacemaker.

WARNING: To ensure safety and reliability, all repairs and replacements should be performed by a qualified service technician.

SAFETY SYMBOLS

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols and the explanations with them deserve your careful attention and understanding. The symbol warnings do not, by themselves, eliminate any danger. The instructions and warnings they give are no substitutes for proper accident prevention measures.

WARNING: Be sure to read and understand

all safety instructions in this Operator’s Manual, including all safety alert symbols such as “DANGER,” “WARNING,” and “CAUTION” before using this tool. Failure to follow all instructions listed below may result in electric shock, fire, and/or serious personal injury.

SYMBOL MEANING

SAFETY ALERT SYMBOL: Indicates DANGER, WARNING, or CAUTION. May be used in conjunction with other symbols or pictographs.

WARNING: The operation of any power tools can result in foreign objects being thrown into your eyes, which can result in severe eye damage. Before beginning power tool operation, always wear safety goggles or safety glasses with side shields and a full face shield when needed. We recommend a Wide Vision Safety Mask for use over eyeglasses or standard safety glasses with side shields.

SAFETY INSTRUCTIONS

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the machine before attempting to assemble and operate it.

|

Safety Alert | Precautions that involve your safety. |

|

Read Operator’s Manual | To reduce the risk of injury, user must read and understand operator’s manual before using this product. |

|

Wear Eye Protection | Always wear safety goggles or safety glasses with side shields and a full face shield when operating this product. |

|

Wear Ear Protection | Always wear ear protection when operating this product. |

|

Wear Head Protection | Wear an approved safety hard hat to protect your head. |

2.4mm |

Line Diameter | The Diameter of the nylon cutting line |

38cm |

Cutting Width | The Max. cutting width of line trimmer |

|

Wear Protective Gloves | Protect your hands with gloves when handling blade or blade guard. |

|

Wear Safety Footwear | Wear non-slip safety footwear when using this equipment. |

|

Beware of blade thrust | Warn the operator of the danger of blade thrust. |

|

Do Not Expose To Rain | Do not use in the rain or leave outdoors while it is raining. |

|

Ricochet and Keep Bystanders Away | Thrown objects can ricochet and result in personal injury or property damage. Ensure that other people and pets remain away from the brushcutter when it is in use. |

| Keep Bystanders

Away |

Ensure that other people and pets remain at least 15m away from the line trimmer when it is in use. | |

|

||

|

No round blade |

Do not install round cutting blades. |

|

Noise |

Guaranteed sound power level. |

|

WEEE |

Waste electrical products should not be disposed of with household waste. Take to an authorized recycler. |

| IPX5 | IP Symbol | Protection against ingress of water degree 5 |

| V | Volt | Voltage |

| n0 | No Load Speed | Rotational speed, at no load |

| min-1 | Per Minute | Revolutions per minute |

| Direct Current | Type or a characteristic of current | |

| Kg | Kilogram | Weight |

GENERAL POWER TOOL SAFETY WARNINGS

WARNING: Read all safety warnings, instructions, illustrations and specifications provided with this power tool. Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

WORK AREA SAFETY

- Keep work area clean and well lit. Cluttered or dark areas invite accidents.

- Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, petrols or dust. Power tools create sparks which may ignite the dust or fumes.

- Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

PERSONAL SAFETY

- Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol medication. A moment of inattention while operating power tools may result in serious personal injury.

- Use personal protective equipment. Always wear eye protection. Protective equipment such as a dust mask, non-skid safety shoes, hard hat or hearing protection used for appropriate conditions will reduce personal injuries.

- Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

- Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

- Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

- Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

- If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust devices can reduce dust-related hazards.

- Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore tool safety principles. A careless action can cause severe injury within a fraction of a second.

POWER TOOL USE AND CARE

- Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

- Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

- Remove the battery pack, if detachable, from the power tool and/or activate any battery disabling device before clearing jammed material, making any adjustments, changing accessories, cleaning, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

- Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

- Maintain power tools and accessories. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

- Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

- Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

- Keep handles and grasping surface dry, clean and free from oil and grease. Slippery handles and grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

- Keep cables away from the working area of the tool. During operation cables may be hidden from view and can be accidentally damaged by the tool.

BATTERY TOOL USE AND CARE

- Recharge only with the charger specified by the manufacturer. A charger that is suitable for one type of battery pack may create a risk of fire when used with another battery pack.

- Use power tools only with specifically designated battery packs. Use of any other battery packs may create a risk of injury and fire.

- When battery pack is not in use, keep it away from other metal objects, like paper clips, coins, keys, nails, screws or other small metal objects, that can make a connection from one terminal to another. Shorting the battery terminals together may cause burns or a fire.

- Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause irritation or burns.

- Do not use a battery pack or tool that is damaged or modified. Damaged or modified batteries may exhibit unpredictable behavior resulting in fire, explosion or risk of injury.

- Do not expose a battery pack or tool to fire

or excessive temperature. Exposure to fire or temperature above 100 °C may cause explosion. - Follow all charging instructions and do not charge the battery pack or tool outside the temperature range specified in the instructions. Charging improperly or at temperatures outside the specified range may damage the battery and increase the risk of fire.

SERVICE

- Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

- Never service damaged battery packs. Service

of battery packs should only be performed by the manufacturer or authorised service providers.

WARNING: Read all safety warnings, instructions, illustrations and specifications provided with this power tool. Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

TRAINING

- Read the instructions carefully. Be familiar with the controls and the proper use of the machine.

- Never allow people unfamiliar or children with these instructions to use the appliance. Local regulations can restrict the age of the operator.

- Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people or their property.

PREPARATION

- Never operate the machine while people, especially children, or pets are nearby.

- Wear eye protection and stout shoes at all times while operating the machine.

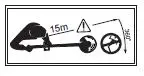

- The distance between the machine and bystanders shall be at least 15m.

- Never operate the machine while the operator is tired, ill or under the influence of alcohol or other drugs.

OPERATION

- Use the machine only in daylight or good artificial light.

- Never operate the machine with damaged guards or shields or without guards or shields in place.

- Switch on the motor only when the hands and feet are away from the cutting means.

- Always disconnect the machine from the power supply (i.e. remove the battery pack).

- whenever leaving the machine unattended;

- before clearing a blockage;

- before checking, cleaning, or working on the machine.

- after striking a foreign object;

- whenever the machine starts vibrating abnormally.

- Take care against injury to feet and hands from the cutting means.

- Always ensure that the ventilation openings are kept clear of debris.

MAINTENANCE AND STORAGE

- Disconnect the machine from the power supply (i.e. remove the battery pack) before carrying out maintenance or cleaning work.

- Use only the manufacturer’s recommended replacement parts and accessories.

- Inspect and maintain the machine regularly. Have the machine repaired only by an authorized repairer.

- When not in use, store the machine out of the reach of children.

OTHER SAFETY WARNINGS

- Avoid Dangerous Environments – Don’t use appliances on damp or wet slope.

- Keep guards in place and in working order.

- Keep hands and feet away from the cutting area

- To reduce the risk of injury, never work on a ladder or on any other insecure support. Never hold the cutting unit above waist height.

- Check the cutting unit at regular short intervals during operation, or immediately if there is a noticeable change in cutting behavior.

- For best results, your battery should be charged in a location where the temperature is greater than 5° C and less than 40° C. Do not store it outside or in vehicles.

- If you are approached, stop the motor and cutting unit.

- Warn the operator of the danger of blade thrust (only using with 3-teeth blade).

- Blade thrust may occur when the spinning blade contacts an object that it does not immediately cut.

- Blade thrust can be violent enough to cause the unit and/or operator to be propelled in any direction, and possibly lose control of the unit.

- Blade thrust can occur without warning if the blade snags, stalls or binds.

- Blade thrust is more likely to occur in areas where it is difficult to see the material being cut.

- Do not attach any blade to a unit without proper installation of all required parts. Failure to use the proper parts can cause the blade to fly off and seriously injure the operator and/or bystanders. Discard blades that are bent, warped, cracked, broken, or damaged in any way. Use a sharp blade A dull blade is more likely to snag and thrust (only using with 3-teeth blade).

- A coasting blade/line can cause injury while it continues to spin after the motor is stopped or trigger is released. Maintain proper control until the blade/line has completely stopped rotating.

- Use only with EGO’s battery packs and chargers listed below:

| BATTERY PACK | CHARGER |

| BAX1500 BH1000 | CHX5500E |

- Battery tools do not have to be plugged into an electrical outlet; therefore, they are always in operating condition. Be aware of possible hazards even when the tool is not operating. Take care when performing maintenance or service.

- Do not wash with a hose; avoid getting water in motor and electrical connections.

- If situations occur that are not covered in this manual, use care and good judgment. Contact the EGO Customer Service Center for assistance.

SAVE THESE INSTRUCTIONS!

SPECIFICATIONS

| Voltage | 56 V |

| No-load Speed | Up to 5800 /min |

| Cutting Mechanism | Bump Head |

| Cutting Line Type | 2.4mm nylon twist line |

| Cutting Width | 38 cm |

| Recommended Operating Temperature | 0°C-40°C |

| Recommended Storage Temperature | -20°C-70°C |

| Weight (without battery pack) | 5.8 kg |

| Guaranteed sound power level | 70dB(A) |

PACKING LIST

| PART NAME | QUANTITY |

| Line Trimmer | 1 |

| Guard assembly | 1 |

| Loop handle assembly | 1 |

| Safety barrier bar | 1 |

| Locking pole for safety barrier bar | 1 |

| Screw | 2 |

| Combi-wrench | 1 |

| Allen key | 1 |

| Operator’s manual | 1 |

| Out flange | 1 |

| Nut | 1 |

DESCRIPTION

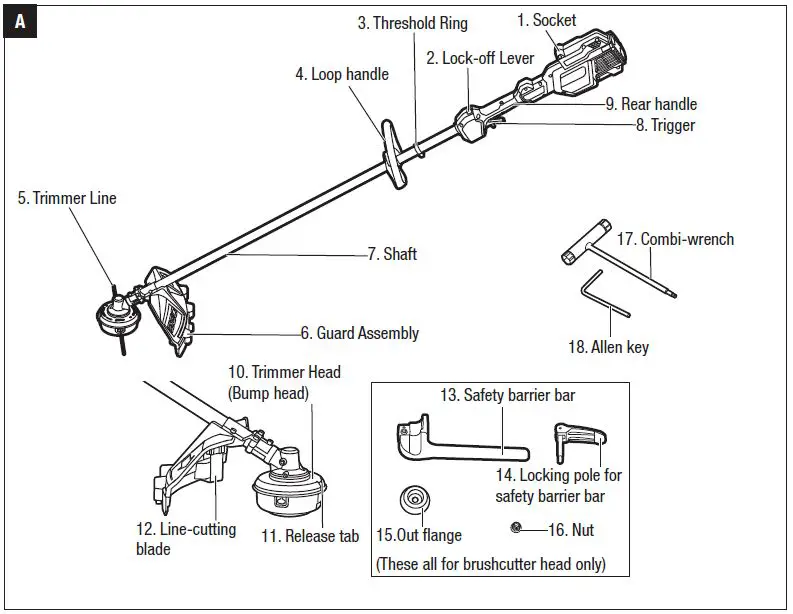

KNOW YOUR LINE TRIMMER (Fig. A)

- Socket

- Lock-off Lever

- Threshold Ring

- Loop handle

- Trimmer Line

- Guard Assembly

- Shaft

- Trigger

- Rear handle

- Trimmer Head(Bump head)

- Release tab

- Line-cutting blade

- Safety barrier bar (For brushcutter head only)

- Locking pole for safety barrier bar (For brushcutter head only)

- Out flange (For brushcutter head only)

- Nut (For brushcutter head only)

- Combi-wrench

- Allen key

ASSEMBLY

WARNING:

- If any parts are damaged or missing, do not operate this product until the parts are replaced. Use of this product with damaged or missing parts could result in serious personal injury.

- Do not attempt to modify this product or create accessories not recommended for use with this line trimmer. Any such alteration or modification is misuse and could result in a hazardous condition leading to possible serious personal injury.

- To prevent accidental starting that could cause serious personal injury, always unplug the battery connector from the socket when assembling parts.

When the tool is equipped with brushcutter head, the safety barrier bar should be mounted.

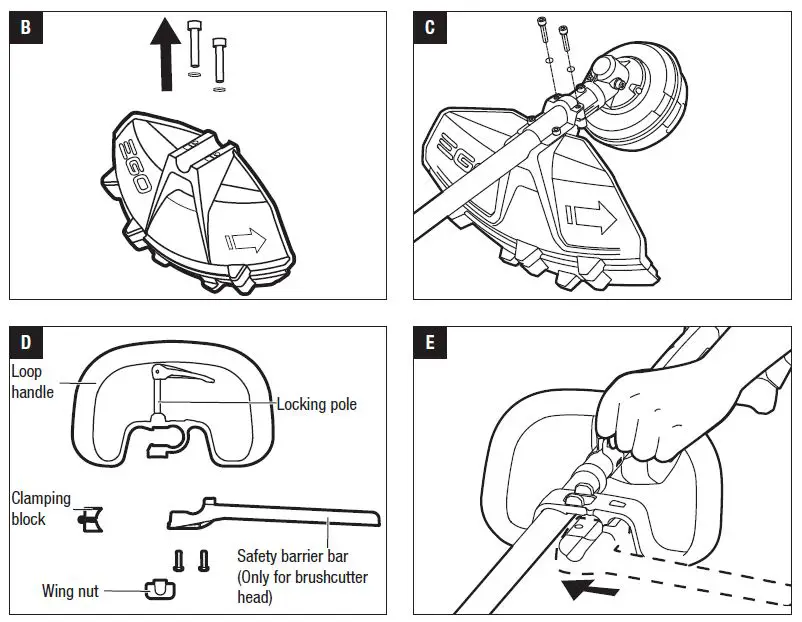

MOUNTING THE GUARD

WARNING:

- Always wear gloves when mounting or replacing the guard. Take care of the blade on the guard and protect your hand from cutting.

- Never operate the tool without the guard firmly in place. The guard must always be on the tool to protect the user! When the guard is fixed, never attempt to remove or adjust the guard, if a replacement is needed, it should be performed by a qualified service technician!

- Loosen and remove the two screws from the guard (Fig. B), align the guard mounting holes with the assembly holes and then lock the guard onto the shaft base with the two screws, together with two spring washers (Fig. C). Make sure the guard is fixed according to Fig. B & C, any reverse fixing will cause great danger!

MOUNTING AND ADJUSTING THE LOOP HANDLE

- Stop the motor and unplug the battery connector from the socket., if installed.

- Loosen the wing nut to separate the adjustable loop handle (Fig. D).

NOTICE:

Install the safety barrier bar assembly onto the loop handle with the two screws when the tool is equipped with brushcutter head.

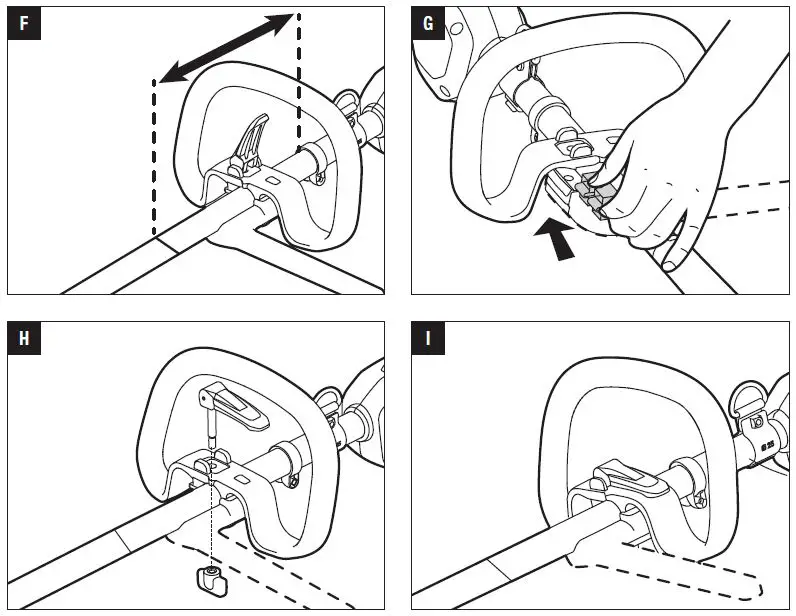

There are two kinds of locking pole, the shorter one is for trimmer head. The longer one is for brushcutter head. Be carefully to choose the correct locking pole when using the tool. - Push the loop handle onto the shaft at the front of threshold ring. Never place it between the threshold ring and rear handle area.(Fig. E).

NOTICE: Adjust the loop handle between the threshold ring and the warning label when the tool is equipped with brushcutter head (Fig. F). - Insert the clamping block into the handle slot

(Fig. G). - Mount the locking pole, and pre-tighten them with the wing nut. Make sure that the loop handle is upwards and points toward the top of the rear handle (Fig. H).

- Adjust the loop handle between the threshold ring and the label until find the comfortable position when using the trimmer. .

- Lock the lever of the locking pole (Fig. I). WARNING: Never operate the tool without the loop handle firmly in place.

WARNING: Only fix the loop handle between the threshold ring and the label.

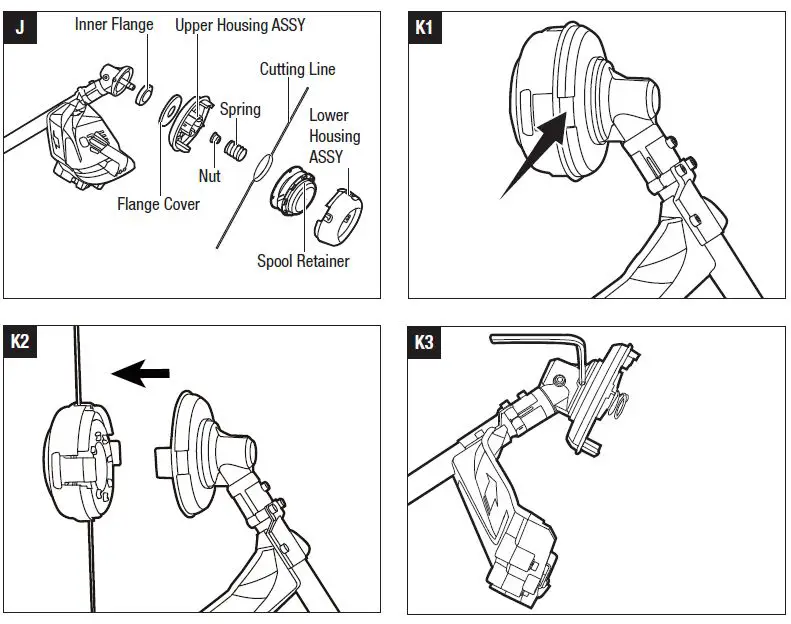

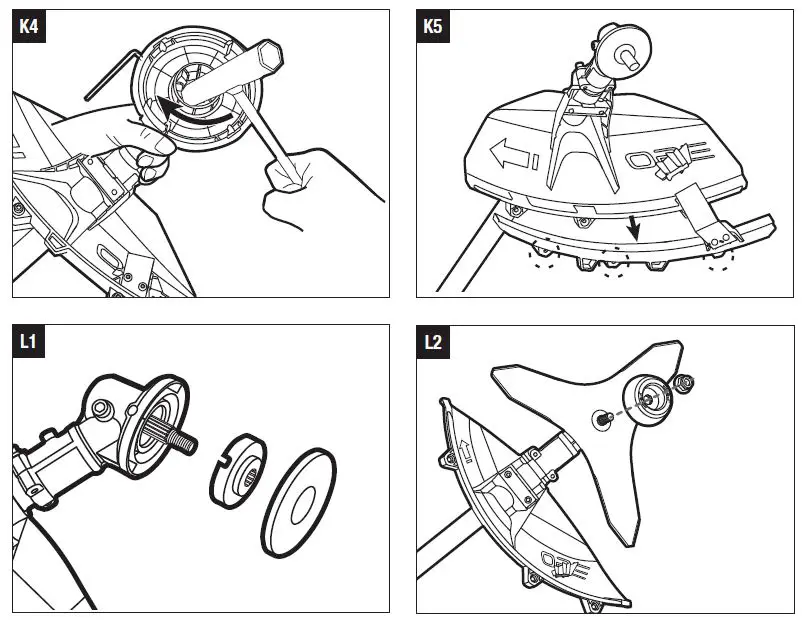

REPLACE THE TRIMMER HEAD WITH THE 3-TEETH BLADE

Know the trimmer head as Fig. J shown. Then disassemble the trimmer head and mount the 3-teeth blade on the brushcutter.

- Press the release tabs on the spool retainer and remove the spool retainer by pulling it straight out (Fig. K1 & K2).

- Rotate the upper housing assembly to align the slot in the flange with the shaft-locking hole in the gear case and insert a stabiliser into the hole (Fig. K3).

- Rotate the socket wrench clockwise to remove the nut and upper housing assembly (Fig. K4).

- Remove the guard accessory by loosening the three screws with washer (Fig. K5).

NOTICE: To protect against injury, you have to wear gloves prior to any operation with the 3-teeth blade. - Mount the inner flange and flange cover into its place (Fig. L1).

- Mount the blade onto the motor shaft, ensuring that the surface of the blade is flush with the surface of the inner flange bulge. Mount the outer flange and the nut (Fig. L2). Pre-tighten the nut in a COUNTERCLOCKWISE direction by hand.

- Position the gear case against a solid surface for support. With one hand hold the brushcutter shaft and the other hand grasp the multi-function wrench to tighten the nut following the directional arrow icon marked on the outer flange (Fig. L3).

OPERATION

WARNING:

- Do not allow familiarity with this product to make you careless. Remember that a careless fraction of a second is sufficient to inflict serious injury.

Always wear eye protection, along with hearing protection. Failure to do so could result in objects being thrown into your eyes and other possible serious injuries. - Do not use any attachments or accessories not recommended by the manufacturer of this product. The use of attachments or accessories not recommended can result in serious personal injury.

- To prevent serious personal injury, unplug the battery connector from the socket before servicing, cleaning, changing attachments or removing material from the unit.You may use this product for the purposes listed below:

- Trimming: used for removing grass and weeds up against walls, fences, trees and borders.

- Cutting: used for cutting the grass that is difficult to reach using a normal mower.

NOTICE: The tool is to be used only for its prescribed purpose. Any other use, for example hedge trimming, is deemed to be a case of misuse.

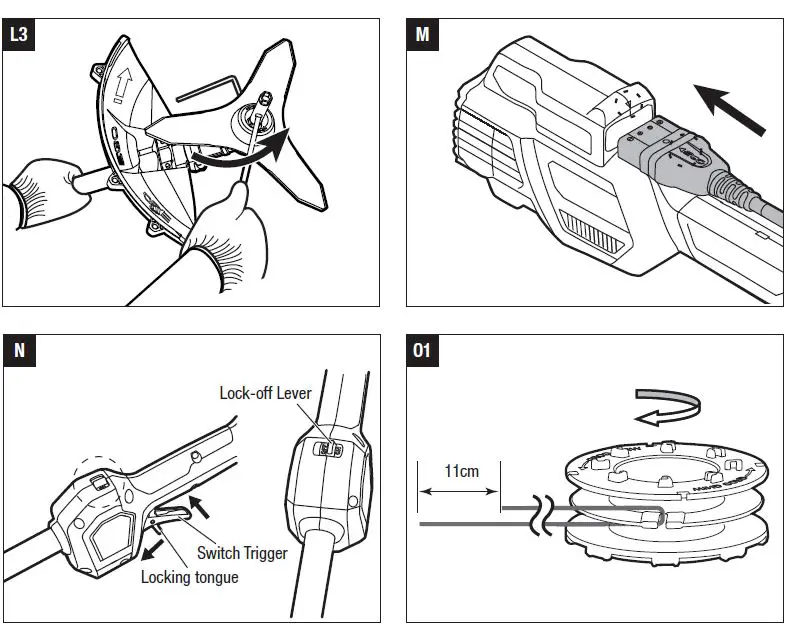

ATTACHING/DETACHING THE BATTERY CABLE

Fully charge before first use. To Install Battery cable (Fig.M)

Align of plug with of line trimmer. Insert the plug into the machine until the green seal completely disappeared into the socket.

To Remove

Release the battery cord from the mounting groove and pull out the plug from the line trimmer.

STARTING/STOPPING THE LINE TRIMMER (Fig. N)

To Start

Push the lock-off Lever to position “ON”, push the locking tongue forward then depress the switch trigger. The trigger is stepless speed adjusting. The more you pull up the trigger, the higher speed it is.

To Stop

Release the switch trigger and push the lock-off button back to position “OFF”.

WARNING: Always unplug the battery connector from the socket during work breaks and after finishing work.

USING THE LINE TRIMMER

WARNING:

To avoid serious personal injury, wear goggles or safety glasses at all times when operating this unit. Wear a face mask or dust mask in dusty locations.

Clear the area to be cut before each use. Remove all objects, such as rocks, broken glass, nails, wire, or line, that can be thrown or become entangled in the cutting attachment. Clear the area of children, bystanders, and pets. At a minimum, keep all children, bystanders and pets at least 15m away; there still may be risk to bystanders from thrown objects. Bystanders should be encouraged to wear eye protection. If you are approached, stop the motor and cutting attachment immediately.

Before each use, check for damage/worn parts

Check the bump head, guard and loop handle and replace the parts that are cracked, warped, bent, or damaged in any away.

The line-cutting blade on the edge of the guard can

dull over time. It is recommended that you periodically sharpen it with a file or replace it with a new blade.

After each use, clean the trimmer.

CAUTION: Obstructions in the vents will prevent the air from flowing into the motor housing and result in overheating or damaged of the motor.

- Use only mild soap and a damp cloth to clean the tool. Never let any liquid get inside the tool; never immerse any part of the tool into a liquid.

- Keep air vents in the motor housing from debris at all times.

WARNING: Never use water for cleaning your trimmer. Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from various types of commercial solvents. Use clean cloths to remove dirt, dust, oil, grease, etc.

ADJUSTING CUTTING LINE LENGTH

The trimmer head allows the operator to release more cutting line without stopping the motor. As line becomes frayed or worn, additional line can be released by lightly tapping the bump knob on the ground while operating the trimmer.

NOTICE:

Line release will become more difficult if the cutting line becomes too short.

WARNING:

Do not remove or alter the line-cutting blade assembly. Excessive line length will cause the motor to overheat and may result in serious personal injury.

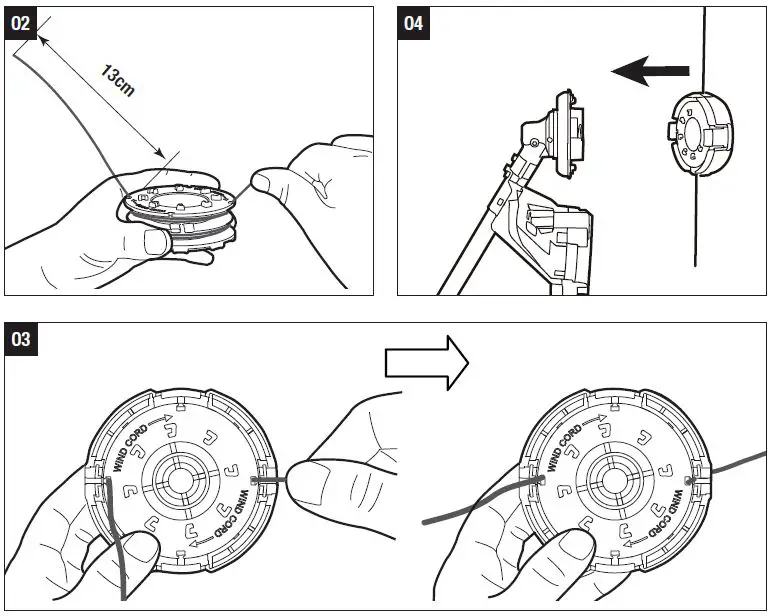

Line replacement

Always use the recommended nylon cutting line with a diameter that does not exceed 3.0 mm. Using line other than that specified may cause the line trimmer to overheat or become damaged. Never use metal-reinforced line, wire, or rope, etc. These can break off and become dangerous projectiles.

- Press the release tabs on the spool retainer and pull the spool retainer out (Fig. K1 & K2).

- Fold and wind trimmer line onto the spool as Fig. O1 shown. Then place the line ends through the two opposite notches in the spool (Fig. O2)

- Place the spool into its retainer with notches aligned with retainer eyelets (Fig. O3).

- 4. Align the retainer slots with the tabs on the spool base and press the retainer evenly, ensuring that it snaps into place (Fig.O4).

MAINTENANCE

WARNING:

- When servicing, use only identical replacement parts. Inspect and maintain the machine regularly. To ensure safety and reliability, all repairs should be performed by a qualified service technician.

- Battery tools do not have to be plugged into an electrical outlet; therefore, they are always in operating condition. To prevent serious personal injury, take extra precautions and care when performing maintenance, service or for changing the cutting attachment or other attachments.

- To prevent serious personal injury, unplug the battery connector from the socket before servicing, cleaning, changing add-on attachments or removing material from the unit.

LUBRICATE THE GEAR CASE

For best operation and longer lifetime, lubricate the gear case with a special grease (4-5g each time) after every 50 hours operation.

The special grease should meet the following requirements.

- Belong to DIN51818: NLGI-1 cone penetration degree.

- Ester base grease.

- Excellent low-temperature startup, EP, mechanical shearing, abrasion resistance and oxidative stability properties.

- Operation temperature must contain -40~180°C. Remove the battery plug and the sealing screw. Lubricating the gear case through the oil-hole.

WARNING: Do not lubricate while the brushcutter isstill connected with battery or running.

CLEANING THE UNIT

- Clean the unit using a damp cloth with a mild detergent.

- Do not use any strong detergents on the plastic housing or the handle. They can be damaged by certain aromatic oils, such as pine and lemon, and by solvents such as kerosene. Moisture can also cause a shock hazard. Wipe off any moisture with a soft dry cloth.

STORING THE UNIT

- Unplug the battery connector from the socket from the line trimmer when it is not in use.

- Clean the tool thoroughly before storing it.

- Store the unit in a dry, well-ventilated area, locked up or up high, out of the reach of children. Do not store the unit on or adjacent to fertilizers, petrol, or other chemicals.

- Use of a transport cover for metal blades during transport and storage.

Protecting the environment

Do not dispose of electrical appliances as unsorted municipal waste, use separate collection facilities.

Contact your local government for information regarding the collection systems available.

If electrical appliances are disposed of in landfills or dumps, hazardous substances can leak into the groundwater and get into the food chain, damaging your health and well-being.

TROUBLESHOOTING

| PROBLEM | CAUSE | SOLUTION |

|

Fail to start |

▪ The battery pack is not attached to the line trimmer.

▪ No electrical contact between the trimmer and battery. ▪ The battery pack is depleted. |

▪ Attach the battery pack to the line trimmer.

▪ Re insert the battery pack with the specified charger. ▪ Charge the battery pack. |

|

Stop working |

▪ The guard is not mounted on the trimmer, resulting in an overly long cutting line and motor overload.

▪ Heavy cutting line is used.

▪ The motor shaft or trimmer head is winded with grass. ▪ The motor is overloaded.

▪ The battery pack or line trimmer is too hot. ▪ The connector of battery pack is disconnected from the tool. ▪ The battery pack is depleted. |

▪ Unplug the battery connector from the socket and mount the guard on the trimmer.

▪ Use recommended nylon cutting line with diameter no greater than 3.0mm. ▪ Stop the trimmer, remove the battery, and remove the grass from the shaft and trimmer head. ▪ The machine will recover when the load is removed. For continuous working, reduce the load of the machine. ▪ Allow the battery pack or trimmer to cool until the temperature drops below 67°C. ▪ Re-plug in the connector again.

▪ Charge the battery pack. |

|

The cutting line can’t be released. |

▪ The motor shaft or trimmer head is wound with grass.

▪ There is not enough line in the trimmer head.

▪ The trimmer head is dirty.

▪ Line is tangled in the trimmer head

▪ The line is too short. |

▪ Stop the trimmer, remove the battery and remove the grass from the motor shaft and trimmer head.

▪ Remove the battery and replace the cutting line; follow the section “LINE REPLACEMENT” in this manual. ▪ Remove the battery and clean the lower cover assembly, spool and upper cover. ▪ Remove the battery, remove the line from the spool and rewind; follow the section “LINE REPLACEMENT” in this manual. ▪ Remove the battery and pull the lines while alternately pressing down on and releasing the trimmer head. |

| Grass wraps around trimmer head and motor housing | ▪ Cutting tall grass at ground level. | ▪ Cut out the weeds into several sections from top to ground level. |

WARRANTY

EGO WARRANTY POLICY

2 year warranty on EGO outdoor power equipment and 2 year warranty on EGO Power+ System battery packs and

chargers.

Please contact EGO customer service on Australia 1300 000 EGO(1300 000 346),

New Zealand 0508 000 EGO (0508 000 346) any time you have questions or warranty claims.

LIMITED SERVICE WARRANTY

FOR TWO YEARS from the date of original retail purchase, this EGO product is warranted against defects in material or workmanship. Defective product will receive free repair.

FOR TWO YEARS from the date of original retail purchase, the EGO Power+ System battery pack and charger are warranted against defects in material or workmanship. Defective product will receive free repair.

This warranty does not cover the blade, which is a part that can wear out from normal use within the warranty period.

- This warranty applies only to the original purchaser at retail and may not be transferred.

- Warranty for commercial use is 1 year on all product, battery and chargers. The Commercial Series Product Warranty for commercial users is 2 years for product, battery and charger.

- This warranty is void if the product has been used for rental purpose.

- This warranty does not cover the damage resulting from modification, alteration or unauthorized repair.

- This warranty only covers defects arising under normal usage and does not cover any malfunction, failure or defect resulting from misuse, abuse (including overloading of the product beyond capacity and exposure to water or rain), accidents, neglect or lack of proper installation, and improper maintenance or storage.

- This warranty does not cover normal deterioration of the exterior finish, including but not limited to scratches, dents, paint chips, or to any corrosion or discoloring by heat, abrasive and chemical cleaners.

HOW TO OBTAIN SERVICE

For warranty service, please contact EGO customer service on Australia 1300 000 EGO(1300 000 346), New Zealand 0508 000 EGO (0508 000 346). When requesting warranty service, you must present the original dated sales receipt. An authorized service center will be selected to repair the product according to the stated warranty terms.

ADDITIONAL LIMITATIONS

Chervon Australia Pty Ltd ABN 36 165 077 501(“Chervon”) warrants to the original domestic purchaser that this product will be free from defects in materials and workmanship for 2 years from date of purchase, and any battery or charger will be free from defects in materials and workmanship for 2 years from date of purchase. To make a claim, return the faulty item together with proof of purchase directly to your closest service agent or to the place of purchase. Any handling and transportation costs (and other expenses incurred in claiming this warranty) are not covered by this warranty and will not be borne by Chervon. The replacement product or part or repaired product will be made available for your collection at an address nominated by Chervon. Where a valid warranty claim is made, Chervon will replace the defective product or repair the fault. Where the product is repaired, Chervon may use refurbished parts. This warranty does not cover normal wear and tear, misuse or abuse. This warranty may also be further limited or voided as specifically detailed in the product Manual. Chervon has no other liability under this warranty.The benefits to you given by this warranty are in addition to other rights and remedies imposed by State and Federal legislation that cannot be excluded. Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a major failure and compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure. Chervon Australia Pty Ltd, Unit Unit 14, 5 Kelletts Road, Rowville, VIC 3178. Phone Number: Australia 1300 000 EGO(1300 000 346), New Zealand 0508 000 EGO (0508 000 346).

Email address: [email protected].