EAN 3663602799702

EAN 3663602799702

ERH18-Li

ORIGINAL INSTRUCTIONS

|

Safety instructions |

|

Product description |

|

Assembly |

|

Use |

|

Care & maintenance |

|

Guarantee |

|

Declaration of Conformity |

PRODUCT DESCRIPTION

GENERAL POWER TOOL SAFETY WARNINGS

WARNING! Read all safety warnings, instructions, illustrations, and specifications provided with this power tool. Failure to follow all instructions listed below may result in electric shock, fire, and/or serious injury.

Save all warnings and instructions for future reference. The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.”

WORK AREA SAFETY

a. Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b. Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust.

Power tools create sparks that may ignite dust or fumes.

c. Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

a. Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce the risk of electric shock.

b. Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges, and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for carrying, pulling, or unplugging the power tool. Keep cord away from heat, oil, sharp edges, or moving parts. Damaged or entangled cords increase the risk of electric shock.

e. When operating a power tool outdoors, use an extension cord suitable for outdoor use. The use of a cord suitable for outdoor use reduces the risk of electric shock.

f. If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) protected supply. Use of an RCD reduces the risk of electric shock.

PERSONAL SAFETY

a. Stay alert, watch what you are doing, and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

b. Use personal protective equipment. Always wear eye protection. Protective equipment such as a dust mask, nonskid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

c. Prevent unintentional starting. Ensure the switch is in the off-position before connecting to the power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energizing power tools that have the switch on invites accidents.

d. Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

e. Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts.

g. If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. The use of dust collection can reduce dust-related hazards.

h. Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore tool safety principles. A careless action can cause severe injury within a fraction of a second.

POWER TOOL USE AND CARE

a. Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate at which it was designed.

b. Do not use the power tool if the switch does not turn on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or remove the battery pack, if detachable, from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

d. Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

e. Maintain power tools and accessories. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tools operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control

g. Use the power tool, accessories and tool bits, etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

h. Keep handles and grasping surfaces dry, clean, and free from oil and grease. Slippery handles and grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

BATTERY TOOL USE AND CARE

a. Recharge only with the charger specified by the manufacturer. A charger that is suitable for one type of battery pack may create a risk of fire when used with another battery pack.

b. Use power tools only with specifically designated battery packs. Use of any other battery packs may create a risk of injury and fire.

c. When the battery pack is not in use, keep it away from other metal objects, like paper clips, coins, keys, nails, screws or other small metal objects, that can make a connection from one terminal to another. Shorting the battery terminals together may cause burns or a fire.

d. Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause irritation or burns.

e. Do not use a battery pack or tool that is damaged or modified. Damaged or modified batteries may exhibit unpredictable behavior resulting in fire, explosion, or risk of injury.

SERVICE

a. Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

b. Never service damaged battery packs. Service of battery packs should only be performed by the manufacturer or authorized service providers.

HAMMER SAFETY WARNINGS

a. Wear ear protectors. Exposure to noise can cause hearing loss.

b. Use auxiliary handle(s), if supplied with the tool. Loss of control can cause personal injury.

c. Hold power tool by insulated gripping surfaces when performing an operation where the cutting accessory may contact hidden wiring. Cutting accessory contacting a “live” wire may make exposed metal parts of the power tool “live” and could give the operator an electric shock.

d. Always wear a dust mask.

e. Persons under 16 years of age are not permitted to operate this machine.

f. Keep the tool and accessories out of the reach of children.

g. Always check walls and ceilings to avoid hidden power cables and pipes.

h. After long working periods, external metal parts and accessories could be hot.

i. Wear eye protection when operating this tool.

j. When using this product it is essential that the following rules for use are followed:

• When drilling it is common that the core/drill bit jams in the material being drilled. This will result in the drill trying to rotate around the drill bit and potentially come out of your grip. This product has a safety clutch mechanism. This safety clutch mechanism will be activated and stop the drive to the drill bit BUT only if you resist the initial forces caused by the jamming by securely holding the drill with both hands.

• ALWAYS ensure that the auxiliary handle is firmly affixed and secure.

• The auxiliary and main handle must be firmly held to resist any movement of the product when the core drill or drill bit becomes jammed.

• ALWAYS use this drill when standing on a firm and secure platform or the ground. (DO NOT USE ON LADDERS OR STEPS.)

• NEVER start the product with the core or drill jammed in position.

• DO NOT stretch to hold the product. Do not drill above shoulder height or below knee height, as the product cannot be securely held.

ADDITIONAL SAFETY WARNINGS FOR BATTERY

a. Do not connect the positive terminal and negative terminal of the battery to each other with any metal object (such as wire).

b. Do not carry or store the battery together with necklaces, hairpins, or other metal objects.

c. Do not pierce the battery with nails, strike the battery with a hammer, step on the battery, or otherwise subject it to strong impacts or shocks.

d. Do not solder directly onto the battery.

e. Do not expose the battery to water or salt water or allow the battery to get wet.

f. Do not disassemble or modify the battery.

g. Do not place the battery in or near the fire, on stoves, or in other high-temperature locations. Do not place the battery in direct sunlight, or use or store the battery inside cars in hot weather.

h. Do not place the battery in microwave ovens, high-pressure containers, or on induction cookware.

i. If you intend to store a battery for a period without use then store the battery at room temperature (19°C to 25°C), charged to about 30 – 50% of capacity. When storing for very long periods boost charge the battery once per year to prevent over-discharge.

The following information applies to professional users only but is good practice for all users:

ADDITIONAL SAFETY WARNING FOR CONSTRUCTION DUST

The updated Control of Substances Hazardous to Health Regulations 1st October 2012 now also targets to reduce the risks associated with silica, wood, and gypsum dust. Construction workers are one of the at-risk groups within this because of the dust that they breathe: silica dust is not just a nuisance; it is a real risk to your lungs!

Silica is a natural mineral present in large amounts in things like sand, sandstone, and granite. It is also commonly found in many construction materials such as concrete and mortar. The silica is broken into very fine dust (also known as Respirable Crystalline Silica or RCS) during many common tasks such as cutting, drilling and grinding. Breathing in very fine particles of crystalline silica can lead to the development of Lung cancer Silicosis Chronic Obstructive Pulmonary Disorder/Chronic obstructive pulmonary disease (COPD) And breathing in fine particles of wood dust can lead to the development of Asthma. The risk of lung disease is linked to people who regularly breathe construction dust over a period of time, not on the odd occasion.

To protect the lung, the COSHH Regulations sets a limit on the amount of this dust that you can breathe (called a Workplace Exposure Limit or WEL) when averaged over a normal working day. These limits are not a large amount of dust: when compared to a penny it is tiny – like a small pinch of salt: This limit is the legal maximum; the most you can breathe after the right controls have been used.

HOW TO REDUCE THE AMOUNT OF DUST?

1. Reduce the amount of cutting by using the best sizes of building products. Use a less powerful tool e.g. a block cutter instead of an angle grinder.

2. Using a different method of work altogether – e.g. using a nail gun to direct fasten cable trays instead of drilling holes first.

3. Please always work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles and use the dust extraction facility at all times. For more information please see the HSE website: http://www.hse.gov.uk/construction or cis69 [PDF]

WARNING! Some dust particles created by power sanding, sawing, grinding, drill, and other construction jobs contain chemicals that are known to cause cancer, birth defects, or other reproductive harm. Some examples of these chemicals are:

WARNING! Some dust particles created by power sanding, sawing, grinding, drill, and other construction jobs contain chemicals that are known to cause cancer, birth defects, or other reproductive harm. Some examples of these chemicals are:

- Lead from lead-based paints.

- Crystalline silica from bricks and cement and other masonry products.

- Arsenic and chromium from chemically treated timber.

- Your risk from these exposures varies, depending upon how often you do this type of work. To reduce your exposure to these chemicals:

- Work in a well-ventilated area.

- Work with approved safety equipment, such as those dust masks that are specially designed to filter microscopic particles

VIBRATION

The European Physical Agents (Vibration) Directive has been brought in to help reduce hand-arm vibration syndrome injuries to power tool users. The directive requires power tool manufacturers and suppliers to provide indicative vibration test results to enable users to make informed decisions as to the period of time a power tool can be used safely on a daily basis and the choice of tool.

SEE TECHNICAL SPECIFICATIONS IN THE INSTRUCTION MANUAL FOR THE VIBRATION LEVELS OF YOUR TOOL.

The declared vibration emission value should be used as a minimum level and should be used with the current guidance on vibration.

Calculating the actual period of use can be difficult and the HSE website has further information.

The declared vibration emission has been measured in accordance with EN60745-1, EN60745-2-6 and may be used to compare one tool with another tool. The declared vibration emission value may also be used in a preliminary assessment of exposure.

WARNING! The vibration emission value during actual use of the power tool can differ from the declared value depending on the ways in which the tool is used depending on the following examples and other variations on how the tool is used:

WARNING! The vibration emission value during actual use of the power tool can differ from the declared value depending on the ways in which the tool is used depending on the following examples and other variations on how the tool is used:

- How the tool is used and the materials being cut or drilled.

- The tool is in good condition and well maintained.

- Use the correct accessories for the tool and ensure they are sharp and in good condition.

- The tightness of the grip on the handles.

- The tool is being used as intended by its design and these instructions.

WARNING! Identify safety measures to protect the operator that is based on an estimation of exposure in the actual conditions of use (taking account of all parts of the operating cycle such as the times when the tool is switched off and when it is running idle in addition to the trigger time).

WARNING! Identify safety measures to protect the operator that is based on an estimation of exposure in the actual conditions of use (taking account of all parts of the operating cycle such as the times when the tool is switched off and when it is running idle in addition to the trigger time).

While working with this power tool, hand/arm vibrations occur. Adopt the correct working practices in order to reduce the exposure to vibration. This tool may cause hand-arm vibration syndrome if its use is not adequately managed. Helping to minimize your vibration exposure risk. ALWAYS use sharp chisels, drills, and blades. Maintain this tool in accordance with these instructions and keep well lubricated (where appropriate).

Avoid using tools in temperatures of 10ºC or less. Plan your work schedule to spread any high vibration tool use across a number of days.

Note: The use of other tools will reduce the users’ total working period on this tool.

HEALTH SURVEILLANCE

All employees should be part of an employer’s health surveillance scheme to help identify any vibration-related diseases at an early stage, prevent disease progression and help employees stay at work.

RESIDUAL RISKS

Even if you are operating this product in accordance with all the safety requirements, potential risks of injury and damage remain. The following dangers can arise in connection with the structure and design of this product:

- Injuries and damage to property due to broken attachments or the sudden impact of hidden objects during use.

- The danger of injury and property damage caused by flying objects or poor power tool accessories.

PRODUCT DESCRIPTION

PRODUCT DESCRIPTION

| 1. SDS PLUS drill chuck. | 8. Battery pack (not included) |

| 2. Dust Protection Cap | 9. Power bar button |

| 3. Tool Holder Locking Sleeve | 10. Battery pack release button |

| 4. Function Mode Selection Switch | 11. Depth stop |

| 5. Forward / Reverse Rotation Control | 12. Quick clamp |

| 6. On/Off Switch With Variable Speed Control | 13. Auxiliary Handle |

| 7. Main handle | |

TECHNICAL SPECIFICATIONS

| Rated voltage: | 18V d.c. |

| Rated no load speed: | 1400/min |

| Impact rate: | 4500/min |

| Impact energy | 2J |

| Drilling capacity max: | |

| Masonry | 24mm |

| Steel | 13mm |

| Wood | 32mm |

| Weight: | 2.1kg |

Ambient temperature range for tool and battery use: -10°C to 40°C

For use with battery pack and charger as below:

Battery pack model: EBAT18-Li-2 / EBAT18-Li-4 / EBAT18-Li-5

Charger model: EC18-Li / EFC18-Li / EMC18-Li

NOISE DATA

A weighted sound pressure: LpA:90.5dB(A)

A weighted sound power: LwA:101.5dB(A)

Uncertainty KPA & KWA=3.0dB(A)

The noise for the operator may exceed 80 dB(A) and ear protection measures are necessary.

VIBRATION DATA

Hammer drilling into concrete ah,HD =13.8m/s²

Chiselling ah,CHeq= 10.0m/s2

Uncertainty K =1.5m/s²

RATING LABEL EXPLANATION

ERH18-Li = MODEL NUMBER

E = ERBAUER

RH = ROTARY HAMMER

18 = 18V d.c.

Li = LITHIUM ION

ASSEMBLY

- SYMBOLS

|

Read the instruction manual |

|

Wear eye protection |

|

Wear hearing protection. |

|

Wear a dust mask. |

|

Do not dispose of battery packs in rivers or immerse in water. |

|

Do not dispose of battery packs in fire. They will explode and cause injury. |

|

Do not expose battery packs to heat in excess of 40°C |

|

Brushless motor |

| Keep Cool Battery Technology | |

|

SDS Plus Chuck |

|

Manufacturing date code: Year of manufacturing (20yy) and week of manufacturing (Wxx) |

2. UNPACKING

Unpack all parts and lay them on a flat, stable surface.

- Remove all packing materials and shipping devices, if applicable.

- Make sure the delivery contents are complete and free of any damage. If you find that parts are missing or show damage do not use the product but contact your dealer. Using an incomplete or damaged product represents a hazard to people and property.

- Ensure that you have all the accessories and tools needed for assembly and operation. This also includes suitable personal protective equipment.

WARNING! The product and the packaging are not children’s toys! Children must not play with plastic bags, sheets, and small parts! There is a danger of choking and suffocation!

3. ASSEMBLING THE MACHINE

CHARGING YOUR BATTERY PACK

The battery has been shipped in a low-charge condition. Charge it fully before first use.

Refer to the charger instruction manual for the details.

TO REMOVE OR INSTALL THE BATTERY PACK (A1, A2)

Depress the battery pack release button to release and slide the battery pack out from your tool. After recharge, slide it back into your tool. A simple push and slight pressure will be sufficient.

BATTERY PACK POWER BAR

The Li-Ion battery pack (8) is equipped with a POWER BAR which is used to give an indication of the battery pack’s remaining charge. Press the POWER BAR button (9) to check the battery charge as below. The LED will stay lit for approximately 5 seconds.

INSERTING AND REMOVING DRILL BIT IN SDS (B)

INSERTING AND REMOVING DRILL BIT IN SDS (B)

Take care that the dust protection cap (2) is not damaged when changing tools.

INSERTING

Clean and lightly oil the bit before inserting. Insert the dust-free bit into the bit holder with

a twisting motion until it latches.

The bit locks itself. Check the locking by pulling on the bit.

NOTE: This tool is only to be used with SDS PLUS drill bits unless an additional keyed chuck adaptor (not supplied) is used.

NOTE: This tool is only to be used with SDS PLUS drill bits unless an additional keyed chuck adaptor (not supplied) is used.

WARNING! Your new Rotary Hammer generates powerful forces to get your job done quickly and effectively. These forces may cause inferior quality SDS bits to break and jam in the chuck. We, therefore, recommend that only high-quality SDS bits be used with this tool.

WARNING! Your new Rotary Hammer generates powerful forces to get your job done quickly and effectively. These forces may cause inferior quality SDS bits to break and jam in the chuck. We, therefore, recommend that only high-quality SDS bits be used with this tool.

REMOVING

Retract back the bit holder locking sleeve (3) and pull out the bit.

AUXILIARY HANDLE (C)

Slide the handle onto the hammer and rotate to the desired working position. To clamp the auxiliary handle, rotate the handle clockwise. To loosen the auxiliary handle, rotate the handle anti-clockwise.

WARNING! Always use the auxiliary handle.

WARNING! Always use the auxiliary handle.

DEPTH STOP (D)

- Depress the quick-clamp (12) then insert the depth stop (11) through the hole. Make sure the rippled part is on the bottom side.

- Align the tip of the depth stop (11) with the drill tip. Now pull the depth stop (11) back by the required drilling depth.

- Release the quick-clamp (12) to lock the depth stop (12) in position.

1. INTENDED USE

The machine is intended for hammer drilling in concrete, brick, and stone as well as for light chiseling work. It is also suitable for drilling without impact in wood, metal, ceramic, and plastic.

2. OPERATION

ON/OFF SWITCH WITH VARIABLE SPEED CONTROL (E)

Depress the ON/OFF switch (6) to start and release to stop your tool. This tool has a variable speed switch

(6) that delivers higher speeds with increased trigger pressure – speed is controlled by varying the pressure applied to the switch.

FORWARD AND REVERSE ROTATION CONTROL (F1, F2)

With the drill pointing away from you, push the forward/reverse rotation control (5) to the left for forwarding rotation. Push the forward/reverse rotation control (5) to the right for reverse rotation

WARNING! Never change the direction of rotation while the tool is rotating, wait until it has stopped.

WARNING! Never change the direction of rotation while the tool is rotating, wait until it has stopped.

SWITCH LOCK (F3)

The switch trigger can be locked in the OFF position. This helps to reduce the possibility of accidental starting when not in use. To lock the switch trigger, place the rotation control (5) in the center position.

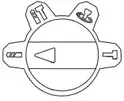

FUNCTION MODE SELECTION

The operation of the gearbox for each application is set with the function mode selection switch (4). To change between functions, depress the unlocking button and rotate the selector to the desired operating mode.

|

For impacting only – for light chipping, chiseling, and demolition applications choose the Hammer position. |

|

For drilling into steel, wood and plastics choose the Rotary drilling position. |

|

For simultaneous drilling and impacting of concrete or masonry, choose the Hammer drilling position. |

|

Adjustable working angle when using a flat chisel. (The tool must not be operated when the switch is in that position) |

WORKING HINTS FOR YOUR HAMMER

If your power tool becomes overheated, set the speed to maximum and run no load for 2-3 minutes to cool the motor. SDS-plus tungsten carbide drill bits should always be used for concrete and masonry.

When drilling in metal, only use HSS drill bits in good condition. Where possible use a pilot hole before drilling a large diameter hole.

OVERLOAD, TEMPERATURE, AND CHARGING PROBLEM

| Problem | Tool/ Battery Status | Possible cause | Solution |

| Overload protection | Product suddenly Stops; The LED work light (if fitted) is flashing | Extremely high torque, binding and stalling situations, overloading of the tool | Relieve the load immediately, reset the tool by switching off and back on again |

| Temperature extremely high | The first and the third LED light of the POWER BAR will be flashing alternately | Battery temperature exceeds 77°C during operation | Cooldown the battery to below 77°C for operation and below 57°C for charging |

| Low charge | Power for the tool will drop quickly: The first LED on the POWER BAR begins to flash | The battery pack is under 5% charge | Remove the battery pack from the tool and charge it |

| Other problems | Short charges | Not fully charged | Make sure that the battery is fully charged every time by allowing the charger to complete its full charging cycle |

| Poor storage condition | Always remove the battery from the tool and charger when not in use and store it in a dry secure place. Avoid charging or storing your battery in temperatures below 5°C and above 40°C. Cooldown a hot battery pack from a tool that has just been operated for approximately 30 minutes before storage |

CARE and MAINTENANCE

MAINTENANCE

Your tool requires no additional lubrication or maintenance. There are no user-serviceable parts in your power tool. Never use water or chemical cleaners to clean your power tool. Wipe clean with a dry cloth. Always store your power tool in a dry place. Keep the motor ventilation slots clean. Keep all working controls free of dust.

RECYCLING AND DISPOSAL

![]() Waste electrical products should not be disposed of with household waste. Please recycle where facilities exist. Check with your Local Authority or retailer for recycling advice. For further information visit www.recycle-more.co.uk

Waste electrical products should not be disposed of with household waste. Please recycle where facilities exist. Check with your Local Authority or retailer for recycling advice. For further information visit www.recycle-more.co.uk

DISPOSAL OF AN EXHAUSTED BATTERY PACK

![]() To preserve natural resources, please recycle or dispose of the battery pack properly. This battery pack contains Li-Ion batteries. Consult your local waste authority for information regarding available recycling and/or disposal options. Discharge your battery pack by operating your tool, then remove the battery pack from the tool housing and cover the battery pack connections with heavy-duty adhesive tape to prevent short circuit and energy discharge. Do not attempt to open or remove any of the components.

To preserve natural resources, please recycle or dispose of the battery pack properly. This battery pack contains Li-Ion batteries. Consult your local waste authority for information regarding available recycling and/or disposal options. Discharge your battery pack by operating your tool, then remove the battery pack from the tool housing and cover the battery pack connections with heavy-duty adhesive tape to prevent short circuit and energy discharge. Do not attempt to open or remove any of the components.

REPAIR

This product does not contain any parts that can be repaired by the consumer. Contact an authorized service center or a similarly qualified person to have it checked and repaired.

STORAGE

- Switch the product off and remove the battery pack.

- Clean the product as described above.

- Store the product and its accessories in a dark, dry, frost-free, well-ventilated place.

- Always store the product in a place that is inaccessible to children.

- We recommend using the original package for storage or covering the product with a suitable cloth or enclosure to protect it against dust.

TRANSPORTATION

- Switch the product off and remove the battery pack.

- Attach transportation guards, if applicable.

- Always carry the product by its handle.

- Protect the product from any heavy impact or strong vibrations which may occur during transportation in vehicles.

- Secure the product to prevent it from slipping or falling over.

At Erbauer we take special care to select high-quality materials and use manufacturing techniques that allow us to create ranges of products incorporating design and durability. That’s why we offer a 2-year trade guarantee against manufacturing defects on our Erbauer power tool products.

This power tool is guaranteed for 2 years from the date of purchase, if bought in-store, delivered, or bought online. You may only make a claim under this guarantee upon presentation of your sales receipt or purchase invoice. Please keep your proof of purchase in a safe place.

This guarantee covers product failures and malfunctions provided the Erbauer power the tool was used for the purpose for which it is intended and subject to installation, cleaning, care, and maintenance in accordance with standard practice and with the information contained above and in the user manual. This guarantee does not cover defects and damage caused by or resulting from:

- Normal wear and tear, including accessory wear

- Overload, misuse, or neglect

- Repairs attempted by anyone other than an authorized agent

- Cosmetic damage

- Damage caused by foreign objects, substances, or accidents

- Accidental damage or modification

- Failure to follow manufacturer’s guidelines

- Loss of use of the goods

This guarantee is limited to parts recognized as defective. It does not, in any case, cover ancillary costs (movement, labor) and direct and indirect damage.

If the Erbauer power tool is defective during the guarantee period, then we reserve the right, at our discretion, to replace the item with a product of equivalent quality and functionality or to provide a refund.

This guarantee only applies to the country of purchase or delivery and is not transferrable to any other country. This guarantee is non-transferrable to any other person or product. Relevant local law will apply to this guarantee.

Guarantee-related queries should be addressed to a store affiliated with the distributor you purchased the Erbauer power tool from.

This guarantee is in addition to and does not affect your statutory rights relating to faulty goods as a consumer.

DECLARATION OF CONFORMITY

DECLARATION OF CONFORMITY

![]()

EU Declaration of Conformity

We

Kingfisher International Products Limited

3 Sheldon Square

London W2 6PX

United Kingdom

Declare that the product:

Erbauer 18V cordless rotary hammer ERH18-Li

Serial number 00001-99999

Complies with the essential health and safety requirements of the following directives:

2006/42/EC The Machinery Directive

References to the following harmonized standard were made:

EN 60745-1:2009 + A11:2010

EN 60745-2-6:2010

2014/30/EU Electromagnetic Compatibility directive

References to the following harmonized standard were made:

EN55014-1:2017

EN55014-2:2015

(EU) 2015/863 amending 2011/65/EU Restrictions of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment

Authorized signatory and technical file holder:

Kingfisher International Products Limited

3 Sheldon Square

London W2 6PX

United Kingdom

on: 18/06/2018

Lisa Davis

Group Quality Director

Manufacturer:

Kingfisher International Products Limited

3 Sheldon Square London W2 6PX

United Kingdom

www.kingfisher.com/products

DISTRIBUTOR:

B&Q plc,

Chandlers Ford, Hants, SO53 3LE

United Kingdom

www.diy.com

Screwfix Direct Limited,

Trade House, Mead Avenue,

Yeovil, BA22 8RT, United Kingdom

www.screwfix.com

To view instruction manuals online,

visit www.kingfisher.com/products