Honeywell HZ432 True Zone Panel

INTRODUCTION

The Concept of Zoning

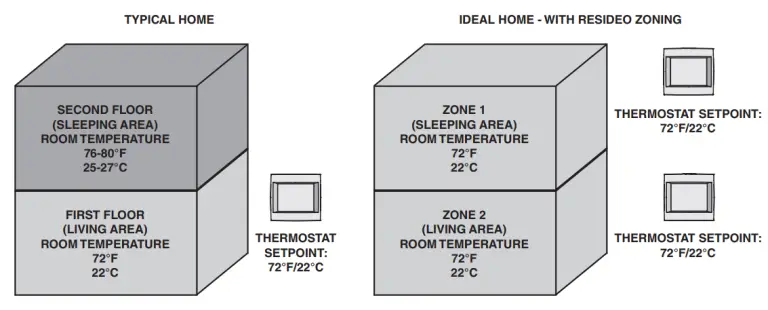

The basic principle of forced air zoning is to allow one HVAC system to be controlled by multiple thermostats, heating and cooling a building in zones rather than as a whole. This makes homes and businesses more comfortable. When combined with setback thermostats, zone setback is possible, resulting in significant energy savings. Forced air zoning makes a common HVAC system more efficient by concentrating the unit’s capacity where and when you need it instead of pouring air throughout the building regardless of the temperature in the individual rooms. According to a 2010 American Home Comfort Study, 68% of US homeowners are uncomfortable in their homes at certain times of the year. Zoning solves this problem. To accomplish this we utilize:

Zoning Panel–Receives requests from thermostats and coordinates the HVAC system and damper positions.

Thermostats–Requests conditioned air only in zones where required.

Duct Dampers–Directs air to rooms (zones) only when called for by a room thermostat.

A Pressure Relief Damper–Efficiently controls excess supply air as dampers open and close.

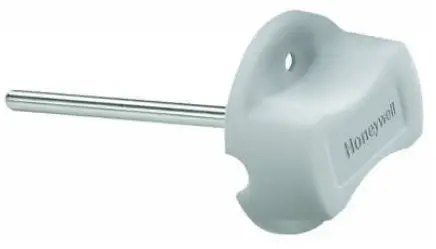

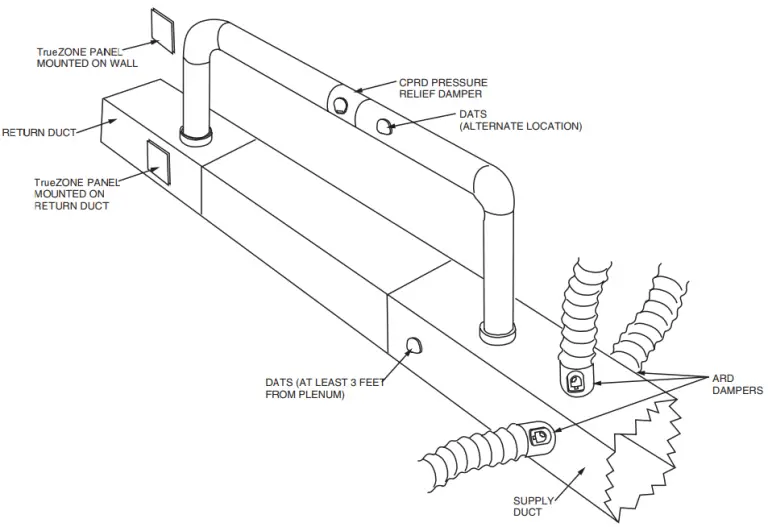

Discharge Air Temperature Sensor (DATS)–Avoids freeze-up and tripping on high limit by sensing the supply duct temperature. The zone panel cycles off the equipment when DATS limits are exceeded. The equipment is turned back on automatically.

Fig. 1 depicts typical home temperatures compared to those of a home with Resideo zoning.

Need Help?

For assistance please visit customer.resideo.com or call the Zoning Hotline toll-free at 1-800-828-8367

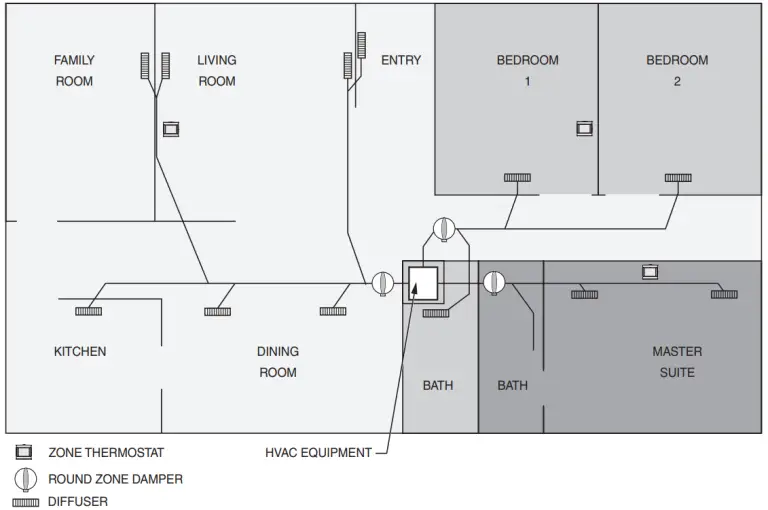

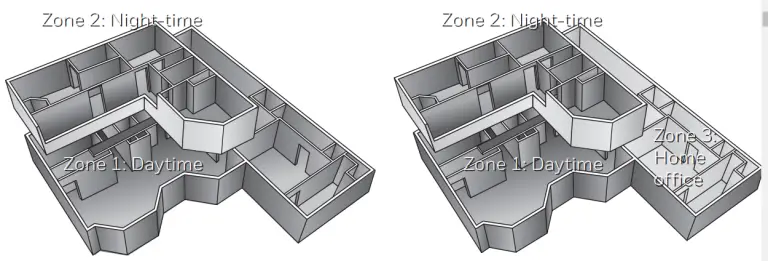

Fig. 2 depicts a typical residential layout with three zones. Zoning provides two key benefits:

- Customer Comfort: heating and cooling where you want it, when you want it.

- Energy Savings: heat and cool only zones that are occupied. In the following pages you will learn how to apply the principles of forced air zoning in new and existing projects, creating a more comfortable indoor environment.

Fig. 2. Typical residential layout with multiple zones on one HVAC system.

PLAN THE ZONES

In planning a zone system, here’s what you need:

Panel

- To Operate Dampers and Equipment

- Transformer to power panel

Thermostats

- Programmable or Non Programmable

Dampers

- Controls circulating air in heating/cooling systems

- Round or rectangular configuration

- Normally open/power closed actuator included

Pressure Relief Dampers:

- Provides static pressure buildup relief

- Actuator included

- No wiring necessary

Discharge Air Temperature Sensor (DATS):

- Sensor which protects HVAC equipment

Divide the Home Into Zones

Divide the Home Into Zones

There are a number of ways to divide a house into zones: by floor, in groups of rooms adjacent to each other, rooms grouped by compass orientation–here is a typical setup:

Zone 1: areas primarily used at night (bedrooms)

Zone 2: areas primarily used during the day (living room, kitchen)

Zone 3: a third space that would benefit from its own HVAC control, such as a master bedroom suite, a basement, living space above a garage, a home office, etc.

A good rule of thumb is to make no zone smaller than about 25% of total system capacity, measured in cubic feet/minute (CFM).

Fig. 3. Typical residential layout with multiple zones on one HVAC system.

DUCTS AND DAMPERS

Size the Ductwork

Size the Ductwork

In New Construction: ductwork is sized as usual for the size of the home; trunks are sized for the amount of air going to the zone. Ductwork should be designed normally, typically .10 or .08 in. w.c./100 ft. Proper duct design of a zoned system will:

- Maintain proper airflow through the HVAC unit when only one zone is open.

- And maintain proper airflow to all zones when all are open.

In Retrofit Applications: zones are somewhat limited by how the ducts were originally constructed, but any home can be zoned provided there is access to the ductwork. See page 10 for zoning information specific to retrofit applications.

Select Dampers

Select Dampers

Use ZD dampers for rectangular ducts. Use ARD or RRD dampers for round ducts in residential systems up to 2000 CFM.

For systems over 2000 CFM or commercial systems, see page 11.

Install the Dampers

A supply air damper should not be placed closer than 6 ft. to a diffuser. The damper should also be at least 3 ft. away from the plenum. (Less than 6 ft. between damper and diffuser could create objectionable air noise in the conditioned space and 3 ft. of duct off the plenum will reduce turbulence.) These minimums are recommendations for optimal performance; however, each installation presents its own challenges, so each installation will vary. For instance, in some installations the damper may need to be mounted directly on the plenum.

Allow for Access

Dampers should be installed in a location that can be accessed for service. If a damper needs to be “buried,” place a decorative register over it to provide access.

Balancing Dampers

Balancing dampers should be included in the duct work, because a zoned home needs to be balanced just as a non-zoned home does.

PRESSURE RELIEF DAMPERS AND DATS

Size the Pressure Relief Damper

Size the Pressure Relief Damper

Install between supply and return.

All zoning systems should be installed with a supply-to-return pressure relief damper. A Constant Pressure Regulating Damper (CPRD) is used to bypass excess airflow from the supply duct into the

return duct. Supply duct systems should be sized to handle the total airflow when all zones are open, and use a CPRD bypass capable of handling the excess air when only the smallest zone is calling. Excess air should be bypassed into the return air duct. Determine the size of the bypass as follows:

CFM System

= CFM Bypass

Table 1. CPRD Sizes.

| Round CPRD | |

| Model Number | Bypass |

| CPRD8 | 600 CFM |

| CPRD10 | 1000 CFM |

| CPRD12 | 1400 CFM |

| CPRD14 | 1700 CFM |

Use duct collars (not supplied) when connecting a CPRD round bypass to rectangular ducting.

For example, on a 4-ton system …………………………………

with the smallest zone designed to handle ……………. – 400 CFM Smallest Zone

the bypass must be able to handle …………………………… = 1200 CFM of airflow in bypass

When few zones are calling, static pressure in the system increases, and air is bypassed from supply to return. This ensures that the throw of air at the register is correct whether one zone is calling or all zones are calling.

This method of duct design is also a great way to control excess humidity in the home, especially in southern climates. Bypassing air from the supply duct into the return duct accelerates the dehumidification ability of the equipment, creating greater comfort for the homeowner.

Alternative Pressure Relief Methods

If pressure relief dampers are not allowed in your state/region, or if the space is too confined to install a bypass back to the return, use one of the below methods for reliving the pressure

- If the system has 2-3 zones that are similar in size, you may be able to get by without any pressure relief damper.

If the equipment has a high-speed/low-speed fan terminal (typically labeled DS, BK, ODD, DHUM, or DEHUM) wire this to the DS/BK on the zone panel. This lowers fan speed when a single zone is calling for cooling (or heat with heat pump systems). Then test each zone individually to verify pressure is not too high. - If there is no space for bypass ductwork, the zone dampers can be set to allow some air to leak. By setting the larger zone dampers to a minimum position, excess air pressure can be relieved even when only one zone is calling. Minimal leakage to zones that are not calling for heat or cooling does not typically cause noticeable temperature swings, but the homeowner should be advised that air will be coming from these registers even when that zone is not calling.

- Instead of running the pressure relief damper from the supply to the return ducting, you might be able to run the duct from supply to a “alternate pressure relief area” in some houses. This would be an area of the house in which overheating or cooling o the space is not a concern; for example a hallway, false ceiling, or basement.

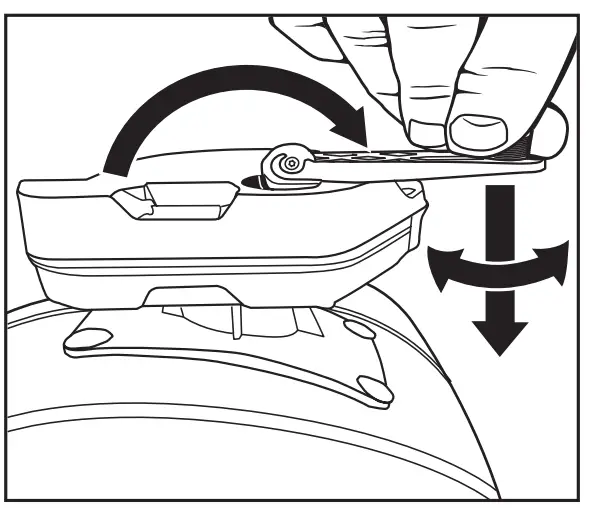

Setting the Regulator

The CPRD is factory set to open at approximately .5″WC.” This setting is satisfactory for most installations. Some systems have higher static pressure. Test this by:

- Make all zones call fan, heat, or cool; whichever has the highest CFM.

- Verify that the damper position indicator points to closed.

- If it does not point to closed:

• Flip the adjustment crank out (see Fig. 4)

• Push down on the adjustment crank with gentle pressure. Caution:

• Do not rotate the adjustment crank without first pushing it down

• Turn the adjustment crank clockwise until the indicator points to closed

• When done, flip the adjustment crank back into the locked position - Make only the smallest zone call for fan, heat, or cool.

- Verify that the airflow into that zone is not objectionable. If it is, then set the regulator to a lower pressure.

Fig. 4. Adjustment crank.

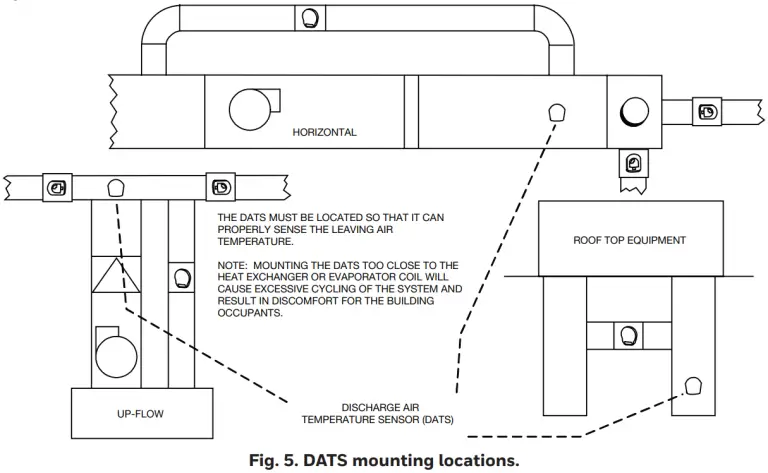

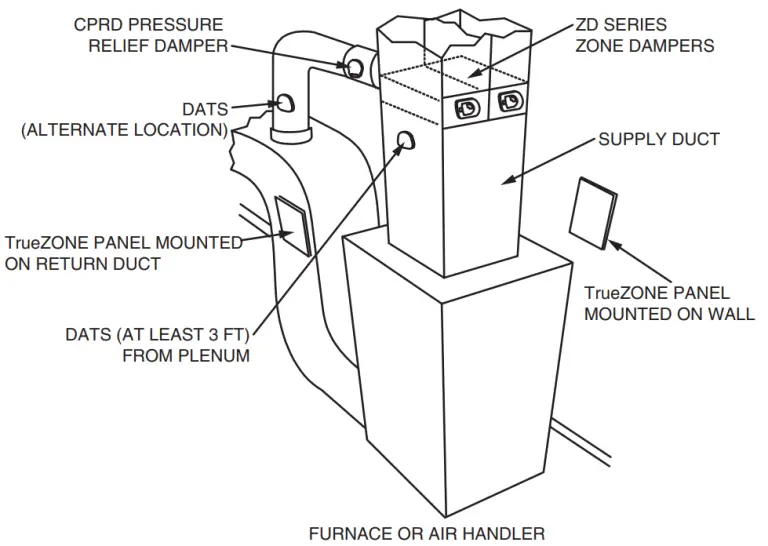

Discharge Air Temperature Sensor (DATS)

The DATS should be located in the supply trunk between the evaporator coil or heat exchanger and the first zone damper. If this is not possible, it is permissible to mount the DATS in the bypass duct. It is recommended to set the high limit approximately 15°F below the furnace high limit. Some modern furnaces have low high limit settings, so make sure the correct zone panel is selected for the equipment.

The HZ221 zone panel is for heat pumps only and has a fixed high limit (120°F for heat pump and 160°F for aux heat) and low limit (45°F).

The HZ311 has a fixed high limit (160°F) and low limit (45°F).

The HZ322 and HZ432 zone panels have adjustable high limit (110°F180°F) and low limit (30°F60°F).

Note: It is often advisable to install the DATS in the bypass duct rather than supply duct for heat pumps with electric auxiliary heat.

Fig. 5. DATS mounting locations.

ZONE PANEL

Install the Panel

Install the Panel

Mount on return, stud, wall, or roof truss.

Zone Panels should not be exposed to weather or installed in a location where they might get wet. Like a damper, they must be accessible for service, if required. Select a zone control panel kit using Table 2.

Table 2. Conventional Zone Panel Selection Guide.

| APPLICATION | CONVENTIONAL 1-HEAT/1-COOL |

HEAT PUMP WITH SINGLE STAGE COMPRESSOR AND ELECTRIC AUXILIARY HEAT STAGE. |

|

|

|

| WIRED THERMOSTATS | 2 ZONES. WIRED THERMOSTATS | HZ311K | HZ221K (Heatpump thermostats with O wire only. For conventional thermostats or heatpump thermostats with B changeover, use HZ322K. | HZ322K | HZ432K (C7089U1006 wired outdoor sensor needed for dual fuel) |

| 3 ZONES. WIRED THERMOSTATS. | HZ311K | HZ322K | HZ432K (C7089U1006 wired outdoor sensor needed for dual fuel) | ||

| 4-32 ZONES | HZ432K for the first 4 zones. Add a TAZ-4 + separate transformer for each additional 4 zones | HZ432K for the first 4 zones. Add a TAZ-4 + separate transformer for each additional 4 zones, (C7089U1006 wired outdoor sensor needed for dual fuel) | |||

| WIRELESS THERMOSTATS | 2-3 zones WIRELESS ZONING WITH TH6320R or TH5320R RedLINK WIRELESS THERMOSTATS | HZ322K + THM4000R adaptor | HZ432K + THM4000R adaptor (C7089R1013 wireless outdoor sensor needed for dual fuel) |

| 4 zones WIRELESS ZONING WITH TH6320R or TH5320R RedLINK WIRELESS THERMOSTATS | HZ432K + THM4000R adaptor | ||

| 2-3 zones WIRELESS ZONING With TH8110R, TH8320R, or TH8321R RedLINK WIRELESS THERMOSTATS | HZ322K + THM4000R* adaptor. (Cannot do remote scheduling when THM4000R and THM6000R gateway are used. TH8321R loses IAQ control when used with THM4000R) |

HZ432K + THM4000R adaptor. (TH8110R, TH8320R, and TH8320R models can do remote scheduling when wired to the panel. These models cannot do remote scheduling when THM4000R and THM6000R gateway are used.

TH8321R loses IAQ control when used with THM4000R). |

|

| 4 zones WIRELESS ZONING With TH8110R, TH8320R, or TH8321R RedLINK WIRELESS THERMOSTATS | HZ432K + THM4000R* adaptor. (Cannot do remote scheduling when THM4000R and THM6000R gateway are used. TH8321R loses IAQ control when used with THM4000R) |

||

| 5-32 zones WIRELESS ZONING WITH TH6320R or TH5320R RedLINK WIRELESS THERMOSTATS | HZ432K for the first 4 zones. Add a TAZ-4 + separate transformer for each additional 4 zones. THM4000 CANNOT be used for systems with over 5 zones. A separate THM5320R EIM is needed for each TH5320R or TH6320R wireless thermostat. (C7089U1006 wired outdoor sensor needed for dual fuel) | ||

| 5-32 zones WIRELESS ZONING With TH8110R, TH8320R, or TH8321R RedLINK WIRELESS THERMOSTATS | HZ432K for the first 4 zones. Add a TAZ-4 + separate transformer for each additional 4 zones. THM4000 CANNOT be used for systems with over 5 zones. A separate THM5421R1021 EIM is needed for each TH8110R, TH8320R, or TH8321R wireless thermostat. EIMs should be spaced at least 2 feet apart. (C7089U1006 wired outdoor sensor needed for dual fuel) | ||

* For full functionality of TH8110R , TH8320R, and TH8321R thermostats, use a separate THM5421R1021 EIM for each thermostat rather than a single THM4000R. The EIMs should be spaced a least 2 feet apart and wired to the zone connections of HZ322 or HZ432 that the thermostat controls. With THM4000R, the lost functionality is:

- Cannot link to remote indoor sensor.

- Cannot do remote scheduling or humidity control through app when THM6000R gateway is used for Internet access.

- Loss of IAQ control for TH8321R(humidifier, dehumidifier, or ventilator). TH8110R and TH8320R don’t control IAQ either way.

The zone panel is typically installed near the indoor unit, in a garage, crawl space, basement, or attic. Zone panels are often installed on the return air duct. However, in some heat pump applications, the homeowner or building occupant may require access to the panel to change into the emergency heat mode. To meet these needs,

Fig. 6. Typical upflow HVAC system.

Fig. 7. Typical horizontal HVAC system.

Thermostats

Install thermostats using instructions provided with thermostat. Wireless thermostats can be used to speed installation.

Transformer

Mount and wire a dedicated transformer to the zone panel. The AT140A1042 is rated to 130°F (54°C). If it is to be mounted in an attic that may get much hotter, install the AT175A1008, which is rated to provide 50 VA at 165°F (74°C). Connect power to the zone control panel after all other wires are attached.

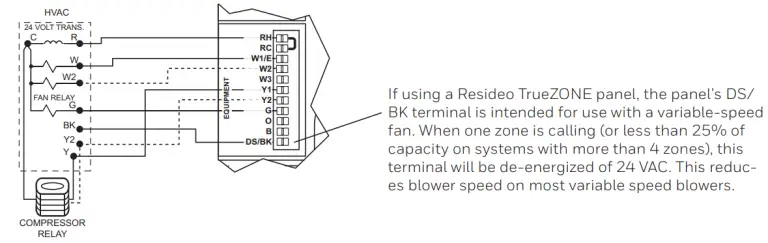

Variable Speed Fan

A variable speed fan or ECM blower changes blower speed to deliver a constant CFM regardless of static pressure. To use zoning with a variable speed fan, plan and install zoning normally, and use a CPRD or MARD (round) damper with static pressure control (SPC) for bypass.

Fig. 8. Wiring variable speed fan to TrueZONE panel

RETROFIT APPLICATIONS

For retrofit applications, first you have to ensure that the duct system is adequate for room/zone loads, and that the existing HVAC system is properly sized to deliver heat/cool. After that, planning the zone system is very similar to new construction.

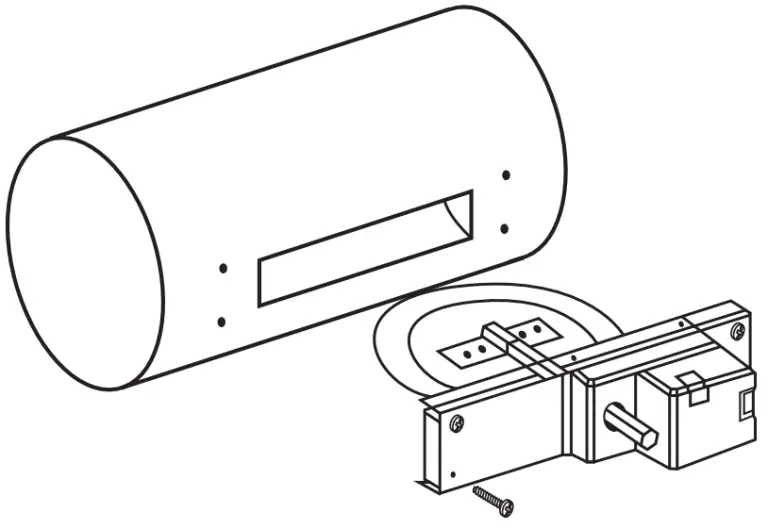

Rigid Duct, Rectangular Sheet Metal Duct, Knockdown (KD) Duct

Using a retrofit round damper (RRD) significantly reduces labor– it installs in a fraction of the time–and overall system installation cost. A retrofit damper slides into rigid round pipe for quick installation. The RRD dampers are available in 5-, 6-, 7-, and 8-in. diameters. Multiple RRD dampers may be wired in parallel.

Fig. 9. Installing retrofit round damper.

Flex Duct

For retrofit applications in flex duct, use round ARD dampers. The round ARD is a galvanized steel single blade damper with a low-leakage gasket, and comes in a range of sizes from 520 in. Up to 4 ARD dampers can be wired in parallel to a zone as long as the transformer has sufficient VA. Use an SDCR isolation relay for zones with more than 4 ARD dampers.

Thermostats

The existing thermostat can often be used for one zone, but as it might be difficult to run wires to the other zones, Red Link wireless thermostats can be

COMMERCIAL ZONING

Zoning for commercial buildings makes just as much sense as zoning for residential buildings: in a large office building, each office suite could have its own zone, giving each occupant the ability to set the heat/cool to his or her comfort.

Zone Design

While a typical residential building might have a system of 5 tons or less, commercial buildings typically have much larger (up to 20 ton) HVAC units. A commercial zoning system will likely have more zones, and the ducts might be bigger, but the basic principles of design and the devices used to implement zoning remain the same.

Pressure Relief Damper

The pressure relief damper may be a motorized damper such as the MARD, controlled by a static pressure control. The MARD is then wired to a static pressure control (SPC) to modulate the bypass air.

Zone Damper

Zone dampers must be able to handle the higher airflow and static pressure of a larger HVAC system. Use a MARD or RRD for round ducts. Honeywell Home doesn’t offer commercial-rated rectangular dampers. Commercial dampers made by other companies can be used if they are powered by 24 volts AC. These could be either spring-open/ power-closed, or power-open/power-closed models. The zone panel sends a constant voltage to either open or closed, so verify the damper used is compatible with constant voltage.

CHECK EQUIPMENT FOR CORRECT OPERATION

HZ221 or HZ311 panels

Call for heat or cool from each zone individually. Verify the equipment comes on and dampers go to correct position. Verify CPRD relief damper is adjusted correctly (see “Setting the Regulator” on page 7).

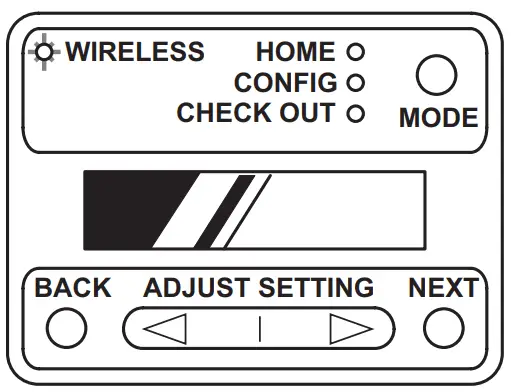

HZ322 or HZ432 panels

From the home mode, press mode button twice to enter checkout mode on zone panel. In checkout mode you can:

- Test every heat stage.

- Test every cool stage.

- Test emergency heat operation (if zone panel is con-

figured for a heat pump with aux heat). - Open and close each zone damper.

After checkout mode you should make a call for heat or cool from each thermostat to verify correct communication to the zone panel. Also, verify CPRD relief damper is adjusted correctly (see “Setting the Regulator” on page 7).

Resideo Technologies, Inc. 1985 Douglas Drive North, Golden Valley, MN 55422 1-800-633-3991 70-2321–06 M.S. Rev. 03-20 | Printed in United States

Resideo Technologies, Inc. 1985 Douglas Drive North, Golden Valley, MN 55422 1-800-633-3991 70-2321–06 M.S. Rev. 03-20 | Printed in United States

© 2020 Resideo Technologies, Inc. All rights reserved. The Honeywell Home trademark is used under license from Honeywell International, Inc. This product is manufactured by Resideo Technologies, Inc. and its affiliates.