LAVAZZA Classy Mini Espresso Machine

SAFETY

IMPORTANT SAFEGUARDS

AT LEAST ONE COPY OF THIS MANUAL SHOULD BE KEPT IN A LOCATION AVAILABLE AT ALL TO MAINTENANCE AND MANAGEMENT STAFF. Safe Operation & Use

When using electrical appliances, basic safety precautions should be followed, including the following:

- Read all instructions before using.

- Do not touch hot surfaces. Use handles and knobs when available.

- This appliance must be properly installed and located in accordance with these in-structions before it is used.

- The use of accessory attachments not rec-ommended by the appliance manufacturer may result in fire, electrical shock or injury to persons.

- Do not place on or near a hot gas or elec-tric burner, or in a heated oven.

- Do not use outdoors.

- To protect against fire, electric shock and injury do not immerse cords, plugs or the appliance in water or any other liquid.

- Do not overfill the Water Reservoir with water.

- Use only water in this appliance! Do not put any other liquids or foods in the Wa-ter Reservoir except as instructed in the Cleaning Instructions in this guide.

- Unplug system before cleaning or main-tenance. Allow to cool before putting on or taking off parts and before cleaning the appliance. System automatically enters standby mode after 2 minutes of non use.

- For best operation, plug the appliance into its own electrical outlet on a dedicated cir-cuit to prevent flickering of lights, blowing of fuses or tripping a circuit breaker

- Do not operate any appliance with a dam-aged cord or plug or after the appliance malfunctions or is damaged in any manner. Contact Lavazza Customer Service to re-port any malfunction of or damage to the system.

- Do not let the cord hang over the edge of the table or counter, or touch hot surfaces.

- Close supervision is necessary when any appliance is used by or near children.

- Do not lift the Handle to open the sys-tem while brewing is in progress.

- Always keep the Water Reservoir Lid on the Water Reservoir unless you are refilling it.

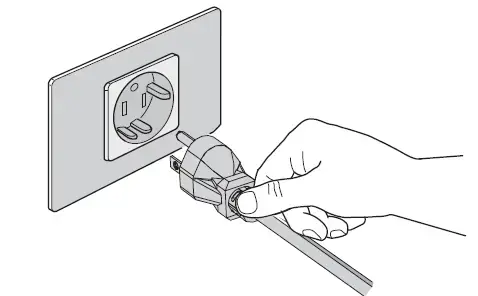

- This appliance is equipped with a Pow-er Cord having a grounding wire with a grounding plug. The appliance must be grounded using a 3-hole properly ground-ed outlet. In the event of an electrical short circuit, grounding reduces the risk of elec-trical shock.

- If the outlet is a standard 2-prong wall out-let, it is your personal responsibility and obligation to have it replaced with a prop-erly grounded 3-prong wall outlet.

- Do not, under any circumstances, cut or remove the third (ground) prong from the Power Cord or use an adapter.

- Consult a qualified electrician if the grounding instructions are not completely understood, or if doubt exists as to wheth-er the appliance is properly grounded.

- Do not use the appliance for other than its intended use.

- In case of failure, problems or a suspected fault resulting from falling of the machine, immediately unplug the machine. Do not attempt to operate a faulty machine. Servic-ing and repairs can only be performed by Authorized Service Centres. All liability for damages resulting from work not carried out by professionals is declined.

- To disconnect, turn the machine to stand-by status and then remove the plug from the wall outlet

- Only use capsules intended for this appliance. If the capsule does not fit, do not force the capsule into the appliance.

- Save these Instructions

AT LEAST ONE COPY OF THIS MANUAL SHOULD BE KEPT IN A LOCATION AVAILABLE AT ALL TO MAINTENANCE AND MANAGEMENT STAFF.

DO NOT permit children to use system unless there is adult supervision.

System dispenses very hot water.

CAUTION: There are sharp needles that puncture the Lavazza CLASSY Mini located above the Lavazza CLASSY Mini Holder and in the bottom of the Lavazza CLASSY Mini Holder. To avoid risk of injury, do not put your fingers in the Lavazza CLASSY Mini Assembly Housing.

CAUTION: There is extremely hot water in the Lavazza CLASSY Mini Holder during the brew process. To avoid risk of injury, do not lift the Handle or open the Lavazza CLASSY Mini Assembly Housing during the brewing process.

SHORT CORD INSTRUCTIONS: A short power supply cord is provided to reduce the risk of becoming entangled in or tripping over a longer cord. If an extension cord is used, (1) the marked electrical rating of the cord set or extension cord should be at least as great as the electrical rating of the appliance; (2) the cord should be arranged so that it will not drape over the counter top or tabletop where it can be pulled on by children or tripped over unintentionally; and (3) the extension cord must include a 3-prong grounding plug. THIS PRODUCT IS FOR HOUSEHOLD AND HOSPITALITY APPLICATIONS USE ONLY.

CAUTION: when you see this sign please refer to the safety precautions to avoid possible harm and damage.

INFORMATION: when you see this sign, please take note of the advise for the cor-rect and safe usage of your coffee machine.

DANGER: when you see this sign, is intended to alert the user to the presence of un-insulated “dangerous voltage” within the product’s enclosure that may be of sufficient magnitude to constitute a risk of fire or electric shock.

WARNING: THIS PRODUCT CONTAINS CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER AND BIRTH DEFECT OR OTHER REPRODUCTIVE HARM

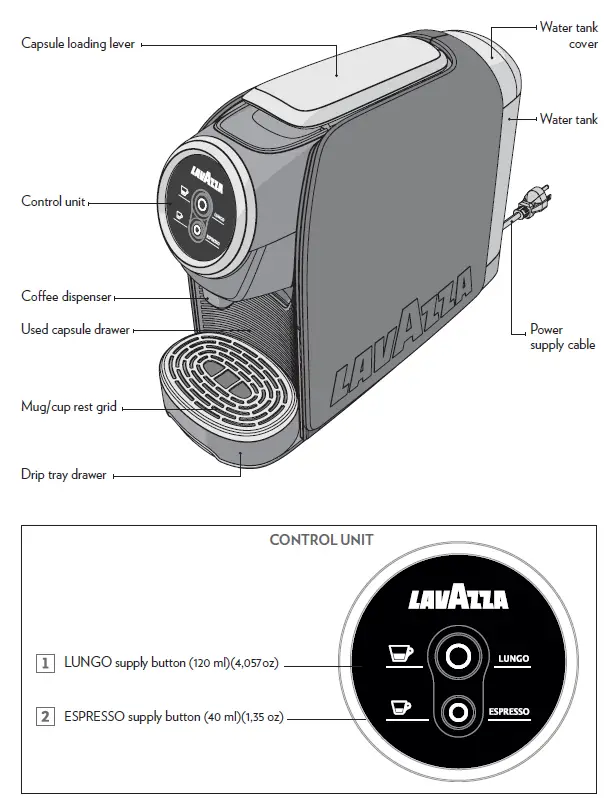

COMPONENTS AND CONTROLS

PREPARING THE MACHINE

We are not liable for any damages in case of:

- incorrect use and other uses than the intended purposes;

- repairs performed at unauthorized service centers;

- tampering with the power cord;

- tampering with any part of the machine;

- use of spare parts and accessories which are not original;

- no water softening;

- storage in rooms below 4°C (39,2°F);

- use below 5° C (41°F);

- use over 40° C (104°F);

- use in places with relative humidity above 95%;

- using non-compatible capsules. In any of these cases, the warranty is canceled.

STARTING THE MACHINE

Set the machine on a flat, stable surface, far away from water or heat sources. Do not connect the machine to the mains supply. Damage caused by failure to apply these instructions will void the guarantee.

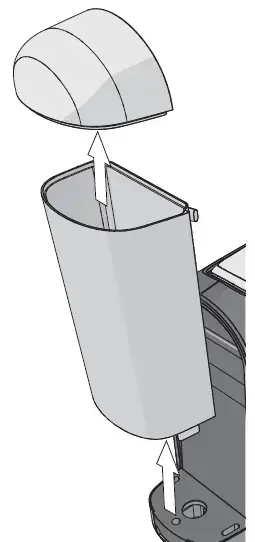

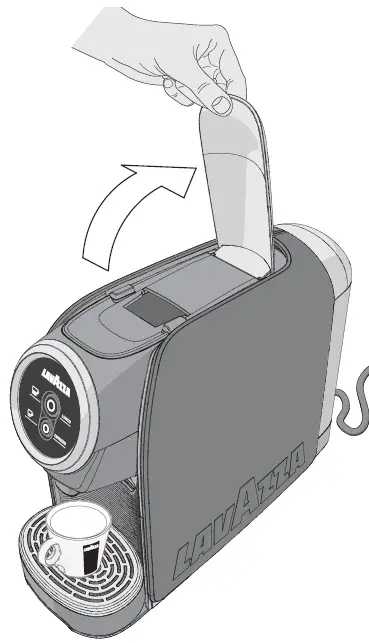

- Rinse the tank before use. Fill the water tank only with fresh, non-carbonated drinking water. The cover can be lifted to fill the tank directly.

- The use of a water filter (an optional accessory) improves water quality and prolongs machine life. Only use products specifically for coffee machines, commonly available on the market and in compliance with current pertinent standards. In order to insert the filter, follow the instruction sheet which comes with the accessory. Change the filter at the intervals indicated on the filter instructions sheet.

- The water level should never exceed the MAX indication and it must always be maintained above MIN. Only use non-carbonated fresh water. Hot water and other liquids can damage the tank.

- Make sure that the hands, the machine, the cord and the support surface of the machine are not wet.

- Insert the plug into the socket.

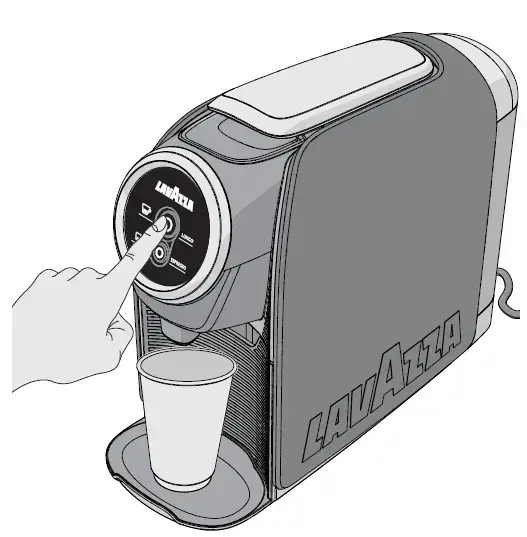

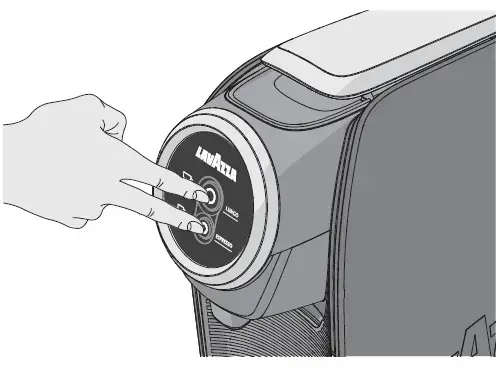

- Press one of the switch-on/supply buttons to switch the machine on.

- The coffee machine starts the heating cycle. The switch-on/supply buttons will start blinking to a light white.

- The machine will be ready for use when the switch-on/ supply buttons light up to a steady white light.

PREPARING THE MACHINE

- Place a glass below the dispensing spout. Prests h Le UNGO supply button and wait for the water to be supplied.

- In case water is not supplied, repeat the cycle several times (up to six times max.).

- Empty the full tank by performing again the dispensing cycles to end the rinsing procedure.

- Empty the glass every time it reaches its maximum capacity level, by temporarily interrupting the cycle.

STAND-BY FUNCTION

- To ensure energy conservation the machine automatically passes to the standby mode after 30 minutes of not being used. The machine can be set to the standby mode manually, first of the 30 minutes’ time, by keeping both buttons pressed down for at least 3 seconds. This mode is indicated by the switching off of the buttons. The machine can be reactivated by pressing the buttons again.

- Empty the glass every time it reaches its maximum capacity level, by temporarily interrupting the cycle.

PREPARATION FOR COFFEE BREWING

- The coffee machine features two positions for preparing the coffee: espresso cup/mug or glass. Place the cup or small cup under the coffee dis-penser, if you wish to have traditional espresso cof-fee.

- Remove the drop collecting tray to use a glass, if you wish to have weak coffee.

PREPARING THE COFFEE

ESPRESSO DELIVERY

- Make sure that the switch-on/supply buttons lights up to a steady white light.

- Place the cup/coffee cup as shown (see PREPARATION FOR COFFEE BREWING).

- To always have a coffee at the perfect temperature, it is recommended to preheat the cup with hot water. Position the cup under the dispensing spout without inserting the capsule. Press one of the switch-on/supply buttons to supply hot water enough to pre-heat the cup.

- Lift the capsule loading lever until it locks into position to open the pod fitting compartment.

- Never put fingers or objects in the capsule holder. Only Lavazza or compatible capsules must be introduced in the capsule holder.

- Put a Lavazza capsule into the capsule fitting compartment.

- Single-dose capsules are prepared to dis- pense one coffee/product. DO NOT use the capsules more than once. Inserting two or more capsules can cause the machine to malfunction.

- Single-dose capsules are prepared to dis- pense one coffee/product. DO NOT use the capsules more than once. Inserting two or more capsules can cause the machine to malfunction.

- Lower the capsule loading lever to close the pod fitting compartment.

PREPARING THE COFFEE

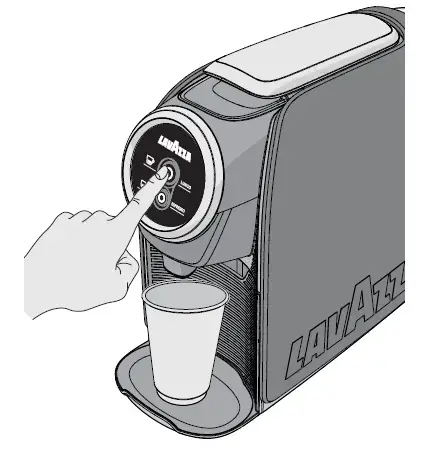

- Press the ESPRESSO button to start delivery. The machine will stop delivery automatically when the programmed measure is reached (40 ml) (1,35 oz).

- The switch-on/supply button will light up to a blinking white light when the product is being supplied.

- If power supply is interrupted during the coffee supply cycle, restore power supply and restart the coffee supply procedure.

- If during the supply cycle, water lacks in the tank, water lack will be indicated by white steady LED on the selected button, while the LED on the other button will start flashing, then proceed as follows:

- Fill the water tank up to the MAX level indicated.

- Press the power-on/supply button previously se-lected. The button will start flashing and the coffee supply procedure will restart.

- For a new supply cycle, wait for supply buttons and multifunction button turning on with steady white light.

- Once supply is over, lift and then lower the capsule loading lever to unload the exhausted capsule.

- Press the LUNGO button to start delivery. The machine will stop delivery automatically when the programmed measure is reached (120 ml)(4,057oz).

- For a new supply cycle, wait for supply buttons and multifunction button turning on with steady white light.

- Once supply is over, lift and then lower the capsule loading lever to unload the exhausted capsule.

- After 5 supplies the switch-on/supply buttons start blinking fast with white light to indicate that the capsules drawer is filled. Empty the capsules draw-er and press one of the buttons to reset the ma-chine. Now the machine is ready for a new supply.

- In case of soluble pods, it is recommended that a brief plain (i.e. by using only water) supply should be dispensed before inserting the pod, so that you can best enjoy the product.

PREPARING THE COFFEE

COFFEE DOSE PROGRAMMING

- Measures are always programmed using the same button; any other buttons are ignored. The programmed amount of brewed coffee can be changed by repeating the programming.

- Place the mug/cup as shown (see PREPARATION FOR COFFEE BREWING).

- Lift the capsule loading lever until it locks into po-sition to open the pod fitting compartment.

- Put a Lavazza capsule into the capsule fitting compartment.

- Lower the capsule loading lever to close the pod fitting compartment.

- Press and hold one of the two coffee delivery but-tons. After about 3 seconds, the selected key will flash and the coffee machine will enter the pro-gramming mode.

- Once the desired amount of coffee has been obtained, stop supply by releasing the button.

- If the programmed measure exceeds the maximum allowed (220 ml-7,44 oz) the machine will automatically stop delivery, the delivery button will blink and the last programmed measure will be saved in the memory. If there is a power failure during programming, the last programmed value remains in the memory. If during a dose programming, water lack is indicated, the machine stops the supply and the dose being program won’t be saved. Once filled the water tank, repeat the dose programming procedure.

MAINTENANCE AND CLEANING

- Never use solvents, alcohol or other aggressive substances or ovens for drying the coffee machine components. Wash machine components (electric components excluded) with cold/luke-warm water and nonabrasive clothes/sponges. All removable components can be cleaned by using a dishwasher. Do not leave water in the tank and water circuit for more than 3 days. If this is the case, drain the tank and circuit, rinse it and refill it with fresh water, then carry out a de- livery without capsule before making any coffee or other beverage.

MACHINE WASHING CYCLE

To clean the dispenser, perform a weekly COF- FEE BREWING procedure without inserting the capsule.

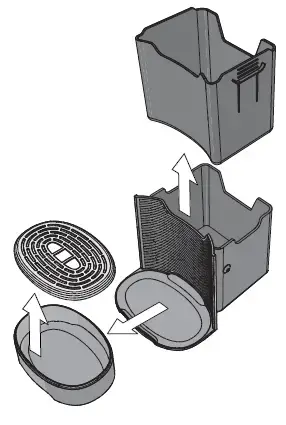

CLEANING THE USED CAPSULE DRAWER, THE DRIP TRAY DRAWER AND THE COFFEE DISPENSER

- The used pod collecting drawer and the drop collecting drawer should be emptied and cleaned after making coffee 5 times or every two/three days.

- Remove the used capsule drawer/drip tray.

- Remove and empty the used capsule collecting drawer.

- Remove the cup / small cup supporting grid, then empty the fluids from inside the drop collecting tray.

- Clean the components with cold or lukewarm water, then dry it and refit it correctly.

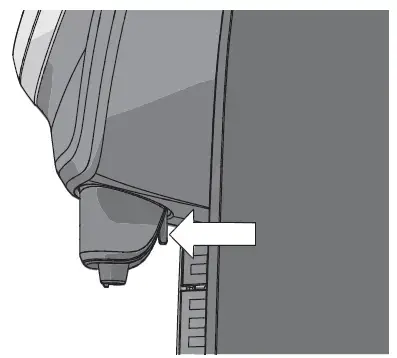

- Press the tab on the back of the dispenser to remove it from the machine. Wash the spouts with cold or warm water.

- The dispenser must be washed every 3 months.

- The dispenser must be washed every 3 months.

- Insert the spouts into the machine, paying attention to the click that indicates its proper functioning.

- Regularly verify that the used pod collecting draw-er and the drop collecting drawer will not be full, to avoid machine malfunctions and damage.

DESCALING

Lime-scale normally builds up with extended use of the appliance; the machine needs descaling every 2 months and/or whenever a reduction in water flow is noticed.

- In the event of any operational conflict, this use and maintenance manual shall prevail on any indication specified on accessories and/or components sold separately.

- For descaling can be used a descaling product for coffee machines of non-toxic and/or harmful type, commercially available.

- Check there is no capsule inside the capsule containing a compartment.

- Do not drink the descaling solution and products dispensed until the completion of the cy-cle. Never use vinegar as a descaling solution.

- Remove and empty the water tank.

- Refill the tank with a descaling solution and water as specified on the package of the descaling product. Refit the tank.

- Power the machine ON and place a suitable container under the spout.

- Press the LUNGO button and supply two cups (approximately 120 ml each).

- Allow the descaling solution to work for about 15-20 minutes.

- Switch on the machine by pressing one of the switch-on/ supply buttons, then proceed as described in steps and .

- Repeat the steps described in point water tank is completely empty.

- Remove the tank and rinse it with fresh drinking water. Fill it completely.

- Switch the machine on by pressing one of the switch-on/supply buttons. Place a suitable container under the dispenser. Press the LUNGO button and supply the entire contents of the tank.

- When the water is finished, refill the tank and repeat the steps described in point 9.

- When finished, the end of the descaling cycle is completed.

TROUBLESHOOTING

| N° | Problem encountered | Possible causes | Solution | Result |

| 1 | Machine does not turn on. Power lights are off after having pressed the switch-on/ supply buttons. | 1 – The machine is not connected to the power source. | Connected the machine to the power source. | OK: call solved.

Non-OK: go to step 2 |

| 2 – The machine is connect to power strip not working. | Connected the machine directly to the power source. | OK: call solved.

Non-OK: go to step 3 |

||

| 3 – Power supply not present. | Connect another device to check the power supply. | OK machine being serviced.

Non-OK: electric system fault. |

||

| 2 | The machine requires a lot of time to heat up. | 1 – Machine storage at low temperatures

(e.g.: cellar/garage). |

Store the coffee machine in a proper environment and run 2 supplies without capsules. | OK: call solved.

Non-OK: go to step 2 |

| 2 – The machine has lime scale build-up. | De-scale the machine. | OK: call solved.

Non-OK: machine being serviced |

||

| 3 | The machine is very noisy. | 1 – Machine not is on a flat and stable surface. | Check the surface. | OK: call solved.

Non-OK: go to step 2 |

| 2 – Power supply cable incorrectly positioned. | Check the correct position of the cable into the base of the machine. | OK: call solved.

Non-OK: go to step 3 |

||

| 3 – Movable parts not fitted properly. | Fit the movable parts properly. | OK: call solved.

Non-OK: go to step 4 |

||

| 4 – No water in the tank. | Top up the tank with fresh drinking water. | OK: call solved.

Non-OK: go to step 5 |

||

| 5 – Capsule not present. | Insert Lavazza

capsule or compatible. |

OK: call solved.

Non-OK: machine being serviced |

||

| 4 | No supply. | 1 – Electrical failure: buttons not working. | Press one of the buttons and check the operation of the pilot light (ON with white blinking light) and the machine power-on. | OK: call solved.

Non-OK: go to step 2 |

| 2 – No water in the tank. | Top up the tank with fresh drinking water. | OK: call solved.

Non-OK: go to step 3 |

||

| 3 – Tank not inserted correctly. | Insert the tank correctly. | OK: call solved.

Non-OK: go to step 4 |

||

| 4 – Power-on failed. | Repeat the coffee machine power-on procedure

(6 attempts at supplying). |

OK: call solved.

Non-OK: machine being serviced |

| N° | Problem encountered | Possible causes | Solution | Result |

| 5 | Water leaks at the front side of the coffee machine. | 1 – Spent capsule drawer not inserted correctly. | Insert the spent capsule drawer correctly. | OK: call solved.

Non-OK: go to step 2 |

| 2 – Spent capsule drawer filled. | Empty the spent capsule drawer and the drip tray. | OK: call solved.

Non-OK: go to step 3 |

||

| 3 – Capsule stuck. | Lift and lower the capsule loading lever. If this is not enough, disconnect the machine from power mains and operate manually to remove the capsule from the duct. | OK: call solved.

Non-OK: go to step 4 |

||

| 4 – Capsule not compatible. | Use Lavazza capsules or compatibles. | OK: call solved.

Non-OK: machine being serviced. |

||

| 6 | Water leaks at the rear side of the coffee machine. | 1 – Tank not inserted correctly. | Insert the tank correctly. | OK: call solved.

Non-OK: go to step 2 |

| 2 – Tank damaged. | Check for leaks in the tank keeping it separate from the machine. | OK: call solved.

Non-OK: machine being serviced. |

||

| 7 | The loading lever does not reach the supply position or requires an excessive closing effort. | 1 – Spent capsule drawer filled. | Empty the spent capsule drawer. | OK: call solved.

Non-OK: go to step 2 |

| 2 – Capsule fitted incorrectly. | Repeat the sequence, lever in the off position, lever in the brewing position; if this is not enough, operate manually

to remove the capsule from the duct with the machine disconnected from power mains. |

OK: call solved.

Non-OK: machine being serviced. |

||

| 8 | Blinking red warning light ON . | 1 – The temperature measured inside the machine is lower than 5°C (41 °F) | Disconnect the plug from the socket, then allow the machine to rest at ambient temperature for the necessary time.

(N.B. Depending on the initial temperature, this time may be of up to 2 hours). Connect the machine plug again to the socket, then press either push-button. |

OK: call solved.

Non-OK: machine being serviced |

| 9 | Pilot lights ON with white light and blinking fast. | 1 – Spent capsule drawer filled. | Empty the spent capsule drawer and press one of the power on/supply buttons to reset the machine. | OK: call solved.

Non-OK: machine being serviced |

| 10 | Coffee is dispensed too fast and, therefore, it is not so creamy. | 1 – Capsule not compatible. | Use Lavazza capsules or compatibles. | OK: call solved.

Non-OK: go to step 2 |

| 2 – Insertion of a soluble product pod instead of a coffee one. | Use a Lavazza coffee pod

(or any one compatible pod). |

OK: call solved.

Non-OK: machine being serviced |

| N° | Problem encountered | Possible causes | Solution | Result |

| 11 | The coffee is cold. | 1 – Coffee pours out in drops, water circuit clogged. | Run the machine washing cycle. | OK: call solved.

Non-OK: go to step 2 |

| 2 – The machine has lime scale build-up. | De-scale the machine. | OK: call solved.

Non-OK: machine being serviced |

||

| 12 | Dispensed coffee is insufficient or excessive. | 1 – Coffee pours out in drops, water circuit clogged. | Run the machine washing cycle. | OK: call solved.

Non-OK: go to step 2 |

| 2 – The machine has lime scale build-up. | De-scale the machine. | OK: call solved.

Non-OK: machine being serviced |

||

| 13 | Coffee not supplied and steam coming out of the capsule compartment. | 1 – The loading lever was not set to the brewing position. | Set the loading lever to the brewing position. | OK: call solved.

Non-OK: machine being serviced |

| 14 | Coffee pours out in drops. | 1 – Faulty capsule. | Replace the capsule. | OK: call solved.

Non-OK: go to step 2 |

| 2 – Pump working improperly. | Check for abnormal noise of the machine. | OK: call solved.

Non-OK: go to step 3 |

||

| 3 – Spout/water circuit clogged. | Clean the coffee dispensing spout

(see MAINTENANCE AND CLEANING). |

OK: call solved.

Non-OK: go to step 4 |

||

| 4 – The machine has limescale build-up. | De-scale the machine. | OK: call solved.

Non-OK: machine being serviced. |

||

| 15 | One of the two buttons is not working and the relevant LED is off. | 1 – Mechanical blocking. | Try to power the machine off by disconnecting the power plug for 10 seconds then reconnect it. Power the machine on and check the correct operation of both buttons. | OK: call solved.

Non-OK: machine being serviced |

| If the problem persists, the machine can continue to be used with the other button; in this case, the button working regularly will no longer have the automatic dosing but will be free dosing, and the user will decide when stopping the dose. |

TECHNICAL SPECIFICATIONS

- Power supply: 120V / 60Hz

- Nominal power: 1250 W

- Water tank capacity: 0,7 L (23,66 oz) – Removable type

- Weight: 3,5 kg (7,7 lb)

- Materials used for the body: thermoplastic

- Size: Height 26 cm – Width 13,5 cm – Depth 34 cm Height 10,2 in – Width 5,3 in – Depth 13,3 in

- Thermo fuses