Model No: CS300

Batch No: PR3564

Warning! Read all instructions before use and retain for future reference. When using electric garden tools, basic safety precautions should always be followed to reduce the risk of fire and injury: For safe operation, read and understand all instructions before using this product. Follow all safety instructions. Failure to follow all safety instructions listed can result in serious personal injury.

ELECTRICAL SAFETY RULES:

- Do not allow children or untrained individuals to use this unit.

- Wear safety glasses or goggles that are marked to comply with EN standards and hearing protection when operating this unit.

- Wear heavy long trousers, boots, and gloves. Do not wear loose fitting clothing, shorts, jewellery of any kind, or go barefoot.

- Secure long hair so it is above shoulder level to prevent entanglement in any moving parts.

- Keep all bystanders, children and pets at least SOft, (15m) away.

- Do not operate this unit when you are tired, ill, or under the Influence of alcohol, drugs, or medication.

- Do not operate in poor lighting. Use the unit only in daylight or good artificial light.

- Keep firm footing and balance. Do not overreach. Overreaching can result in loss of balance & possible injury.

- Keep all parts of your body away from any moving part.

- Inspect unit before each use for loose fasteners, damaged or missing parts. Failure to do so can cause serious injury.

- Use only original manufacturer’s replacement parts. Failure to do so, may cause poor performance or possible injury.

- Do not, under any circumstance, use any attachment or accessory on this product, which was not provided with the product, or identified as appropriate for use with this product in the operator’s manual.

- Do not handle the product with wet hands.

- Do not use the product if the switch does not turn the product on or off. A product that cannot be controlled with the switch is dangerous and must be repaired.

- Avoid accidental starting; never carry the product with your finger on the trigger.

- Use common sense when using this product. Stay alert and pay attention to what you are doing.

- Do not force the product. It will do a better job with less likelihood of a risk of injury when you operate it at the rate for which it was designed.

- Pull the plug out immediately if the mains or extension lead is damaged or severed.

- Disconnect the product from the power supply when it is not in use, before servicing and when changing accessories.

- Do not use in the rain.

- Keep hands and fingers well away from the blade.

- Always hold both handles when operating the unit.

- Do not attempt to free a jammed blade before first switching off the machine and disconnecting it from the mains supply.

- If you are interrupted when operating, complete the process and switch off before looking up.

- This appliance is approved solely for use in accordance with the description and safety instructions specified in this user’s manual.

- Use for cutting wood only.

- For domestic use only.

- Use extreme caution when cutting small-sized brush and saplings because slender material may catch the saw chain and be whipped toward you or pull you off balance.

- DO NOT OVERLOAD THE MACHINE.

- Make sure the cord is located so that it will not be stepped on, tripped over, or otherwise subjected to damage or stress.

- Do not abuse the power cord. Never carry the product by the cord. Never pull the plug out of the power point by the cord. Keep the cord away from heat, oil and sharp edges.

- Only use extension cords approved for outdoor use with adequate protection against splashing water. Cross strands extension cords should be corresponding to the input of the unit and cable length.

- Inspect extension cords for deterioration, cuts or cracks in the insulation. Repair or replace the cords if any defects appear.

- A nameplate on the product indicates the unit’s voltage. Never connect the product to an AC voltage that differs from this voltage.

- If the power cord or extension cable becomes damaged during use, disconnect the cord from the supply immediately. DO NOT TOUCH THE CORD BEFORE DISCONNECTING THE SUPPLY.

DESCRIPTION OF SYMBOLS:

Some of the following symbols may be used on your tool. Please study them and Jearn their meaning. Proper Interpretation of these symbols will allow you to operate the tool more safely and effectively:

|

Indicates a potential personal injury hazard. | Current | |

| User must read and understand this manual before using this product. | Current | ||

| Always wear eye and head protection. | Frequency | ||

| DANGER! Risk of electrocution! Keep too! 50ft away from electrical lines. Keep all bystanders at least 50ft away. | Power | ||

| Do not expose to rain or use in damp locations. | Time | ||

| Avoid bar nose contact. | Rotational speed at no load | ||

| Failure to keep your hands away from the blade will result in serious personal injury. | Double Insulated construction. | ||

| Hold and operate the Grip Saw properly with both hands. | Revolutions, strokes, surface speed, orbits, etc, per minute. | ||

| Wear non-slip, heavy duty gloves when handling the Grip Saw and blade. | |||

| Wear non-slip safety footwear when using this equipment. |

The safe use of this product requires an understanding of the information on the product and this operator’s manual, as well as knowledge of the project you are attempting. Before use of this product, familiarise yourself with all operating features and safety rules.

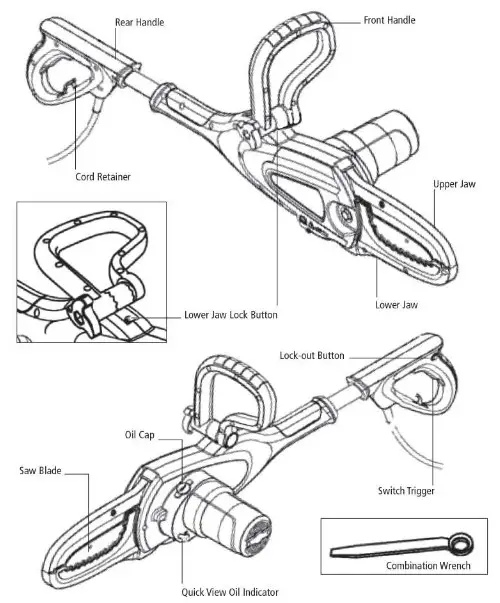

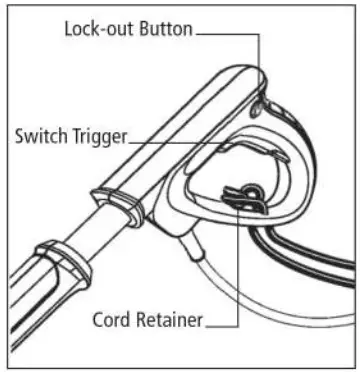

CORD RETAINER: A convenient cord retainer helps keep the extension cord connection secure during tool operation.

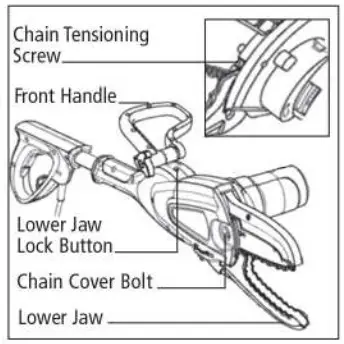

FRONT HANDLE: The front handle is used to activate the Grip Saw jaws. The handle assembly can also be adjusted for ease of operation and to help prevent loss of control.

LOCK-OUT BUTTON: To help prevent accidental starting, the lock-out button must be depressed along with the switch trigger to activate the tool.

LOWER JAW LOCK BUTTON: The lower jaw lock button allows the lower jaw to be locked open to perform maintenance on the bar and chain. This button is exposed when the front handle is pulled all the way back. The motor for the Grip Saw will be disabled when this button is engaged.

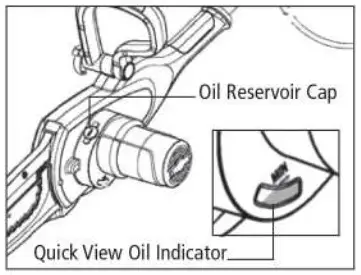

QUICK-VIEW OIL INDICATOR: Semi-transparent bar lube reservoir that allows user to see when to add lubricant.

STORAGE AND TRANSPORTATION RULES:

- Stop the motor when you are waiting to cut or when you are walking from one cutting location to another.

- Store the product in a cool, dry place.

- Store the product up high or lock it up to prevent unauthorised use or damage. Keep the product out of the reach of children.

- Secure the product when transporting it.

- Save these instructions. Refer to them frequently and use them to instruct others who may use this product. if you loan someone this product, loan these instructions also.

- Oil the blade to prevent rust.

STORING THE PRODUCT:

- Disconnect from power supply and store out of the reach of children.

- Clean all foreign material from the product. Store idle unit indoors in a dry, well ventilated area that is inaccessible to children. Keep away from corrosive agents such as garden chemicals and de-icing salts.

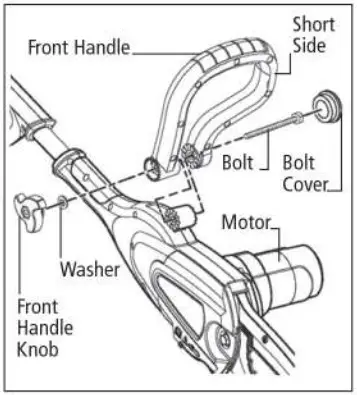

INSTALLING THE FRONT HANDLE:

Install the front handle so that the short side of the handle is on the same side as the motor.

- Disconnect the Grip Saw from the power supply.

- Rotate the front handle knob anti-clockwise to remove. Set knob and washer aside.

- Remove the bolt cover and bolt.

- With the jaws of the Grip Saw closed, install the front handle in the vertical upright position.

- Reinstall the bolt and bolt cover.

- Reinstall the washer and front handle knob; Do not position handle forward rotate knob clockwise to tighten securely, of the vertical upright position

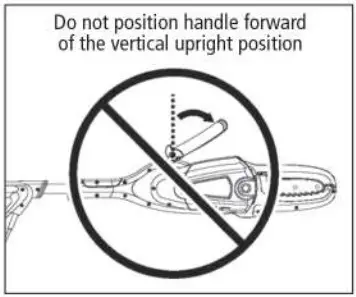

WARNING: Never position the front handle so that it is forward of the vertical upright position, Positioning the handle in this forward area could cause the operator to lose control of the Grip Saw and result in serious personal injury.

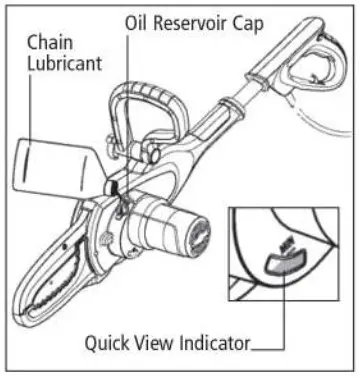

ADDING BAR AND CHAIN LUBRICANT:

Use premium bar and chain lubricant. It is designed for chains and chain oilers, and is formulated to perform over a wide temperature range with no dilution required.

NOTE: The Grip Saw comes from the factory with no bar and chain oil added. The level should also be checked after every 20 minutes of use and refilled as necessary.

- Disconnect from the power supply.

- Remove the oil reservoir cap.

- Carefully pour the bar and chain lubricant into the tank. Quick View Indicator

- Wipe off excess lubricant.

- Check and fill the oil tank when quick view oil indicator is below the MIN indicator line.

- Repeat as needed.

NOTE: Do not use dirty, used, or otherwise contaminated lubricants. Damage may occur to the bar or chain.

NOTE: It is normal for oil to seep from the saw when not in use. To prevent seepage, empty the oil tank after each use then run for one minute. When storing the unit for a long period of time (three months or longer) be sure the chain is lightly lubricated; this will prevent rust on the chain and bar sprocket.

CONNECTING TO POWER SUPPLY:

This product is designed with a cord retainer that prevents the extension cord from being pulled loose while using.

Always use the cord retainer to properly attach the extension cord to your Grip Saw. Failure to use the cord retainer may result in damage to the item and/or extension cord.

- Form a loop with the end of the extension cord.

- Insert loop portion of extension cord through opening in the bottom of the rear handle and place over cord retainer.

- Slowly pull loop against cord retainer until the slack is removed.

- Plug product into extension cord.

NOTE: Failure to remove all excess cord slack from extension cord retainer could result in plug loosening from receptacle.

To start the motor:

- Connect the Grip Saw to power supply.

- Press the lock-out button and the switch trigger at the same time.

To stop the motor:

- Release the switch trigger.

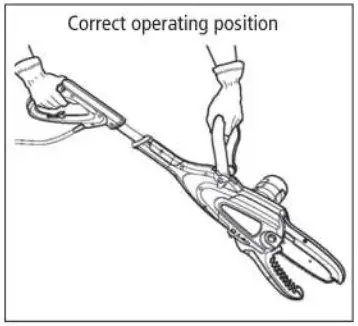

HOLDING THE GRIP SAW:

The unit has both a front and rear handle. With the blade directed away from you, hold the unit by both handles. Wear non-slip gloves for maximum grip and protection.

WARNING: Always keep both hands on the handles. Never hold tree limbs with one hand and operate the Grip Saw with the other. improper operation of the Grip Saw could result in serious injury.

CUTTING TIPS:

- WARNING: If the bar and chain become jammed, stop the motor, allow the chain to stop, and disconnect the plug from the power source before attempting to remove ais the obstruction.

- Failure to follow these steps could result in accidental starting of the Grip Saw and ai cause serious personal injury.

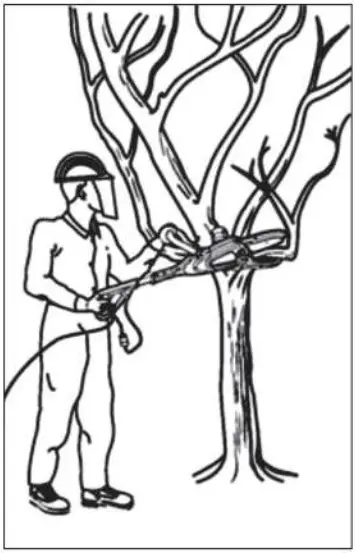

- This unit is designed for felling small trees no taller than you and trimming small branches and limbs up to 10centimetes in diameter.

For best results, observe the following precautions: - To prevent electrocution, do not operate within 15m of overhead electrical lines.

- Keep bystanders and pets at least 15m away.

- Plan the cut carefully. Be aware of the direction in which the tree or branch will fall. Branches may fall in unexpected directions. Do not stand directly under the branch being cut.

- Remove long branches in several stages.

- Cut lower branches first to allow higher branches more room to fall.

OPERATION:

- Do not cut from a ladder, rooftop, or other unstable support; this is extremely dangerous, Leave larger cutting operations for professionals.

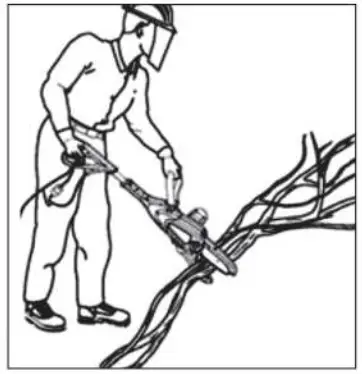

- When cutting branches that are lying on the ground, make sure the location Is clear of other objects, electric wires, cables etc. before cutting, Also be aware of the position of your feet before cutting items on the ground.

- Pull the front handle back to open the jaws and “clamp” around the branch you want to cut.

- Make sure the tool is running at full speed before attempting to cut

- Allow the chain to cut for you; exert only slight downward pressure. If you force the cut, damage to the bar, chain, or motor may occur.

- Release the trigger as soon as the cut Is completed, them release the jaws.

Failure to follow proper cutting procedures can result in the bar and chain binding and becoming pinched or trapped in the limb. If this should happen:

- Stop the motor and disconnect from the, power supply.

- If the limb can be reached from the ground, lift the limb while holding the saw. This should release the “pinch” and free the saw.

- If the saw is still trapped, call a professional for assistance.

MAINTENANCE:

WARNING: When servicing, use only identical replacement parts. Use of any other parts could create a hazard or cause product damage.

WARNING: Always wear eye protection and head protection. Failure to do so could result in objects being thrown into your eyes and other possible serious injuries.

WARNING: Before inspecting, cleaning or servicing the unit, stop the motor, Wait for all moving parts to stop, and disconnect from power supply. Failure to follow these instructions can result in serious personal Injury or property damage.

GENERAL MAINTENANCE:

Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from various types of commercial solvents and may be damaged by their use. Use clean cloths to remove dirt, dust, oil, grease, etc.

WARNING: Do not at any time let brake fluids, gasoline, petroleum-based products, penetrating oils, etc., come in contact with plastic parts. Chemicals can damage, weaken, or destroy plastic, which could result in serious personal injury.

CHAIN TENSION WARNING: To avoid possible serious injury, never touch or adjust the chain while the motor is running. The saw chain is very sharp; always wear protective gloves when performing maintenance to the chain.

- Stop the motor and disconnect from power supply.

- Pull the front handle all the way back and Lower Jaw depress the lower jaw lock button. Keep the button depressed while releasing the handle to lock the lower jaw in the open position.

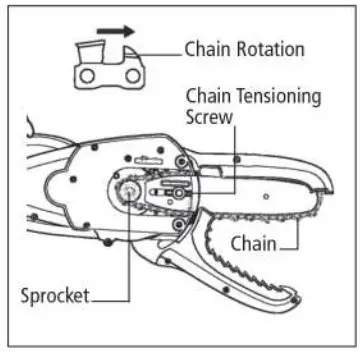

- Loosen the chain cover bolt to finger tight using the combination wrench provided, then tum the chain tensioning screw clockwise to tension the chain. Refer to replacing the bar and chain for additional information.

NOTE: A cold chain is correctly tensioned when there is no slack on the underside of the guide bar, the chain is snug, but it can be turned by hand without binding.

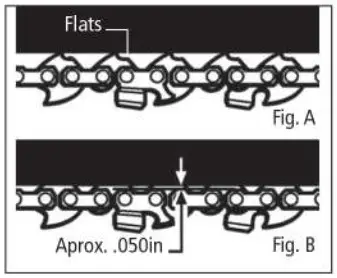

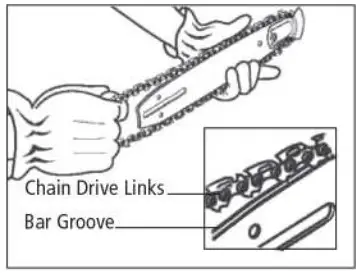

- Chain must be re-tensioned whenever the ae flats on the drive links hang out of the bar groove as shown In fig.A.

- During normal operation, the temperature of the chain will Increase. The drive links of a correctly tensioned warm chain will hang approximately .050in. out of the bar groove, as shown in fig.B.

- Retighten the chain cover bolt securely.

- Return the lower jaw to the closed position by pulling back on the front handle and allowing the handle to move all the way forward.

NOTE: New chains tend to stretch; check chain tension frequently and tension as required.

NOTICE: Chain tensioned while warm, can be too tight upon cooling. Check the “cold tension” before next use.

REPLACING THE BAR AND CHAIN:

WARNING: To avoid possible serious injury, stop the motor and disconnect from power supply before replacing the bar, chain, or performing any maintenance operation.

CAUTION: Always wear gloves when handling the bar and chain; these components are sharp and may contain burrs.

- Pull the front handle all the way back and depress the lower jaw lock button. Keep the button depressed while releasing the handle to lock the lower jawin the open position.

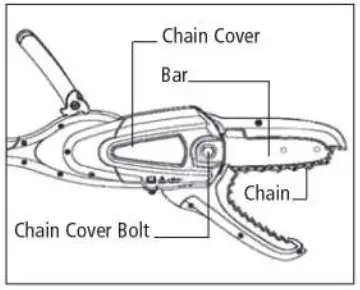

- Remove the chain cover bolt using the combination wrench provided. Remove the chain cover and set aside.

- Rotate the chain tensioning screw anticlockwise as needed to release the chain tension.

- Remove the bar and chain from the mounting surface.

- Remove the old chain from the bar.

- Lay out the new saw chain in a loop and straighten any kinks.

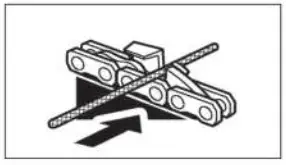

- The cutters should face In the direction of chain rotation. If they face backwards, turn the loop over.

- Place the chain drive links into the bar groove as shown.

NOTE: Make certain of direction of chain. pls Chain Rotation

- Position the chain so there is a loop at the back of the bar.

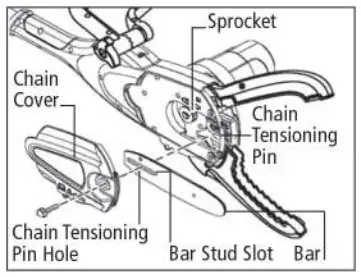

- While holding the chain in position on the bar, reinsert the bar and chain through the opening between the jaws and place the loop around the sprocket.

- Fit the bar flush against the mounting surface so that the bar stud is in the long slot of the bar.

WARNING: When placing the bar on the bar studs, ensure that the chain tensioning pin is in the chain tension pin hole, Failure to properly place the chain tensioning pin in the chain tensioning pin hole could cause the chain to come loose, resulting in serious personal injury.

- Remove all slack from the chain by turning the chain tensioning screw clockwise, assuring that the chain seats into the bar groove during tensioning.

- Lift the tip of the bar up to check for sag. Release the tip of the bar, and turn the chain tensioning screw 1/2 turn clockwise. Repeat this process until sag does not exist.

- Chain is correctly tensioned when there is no slack on the underside of the bar, the chain is snug, but it can be tured by hand without binding.

- Replace the chain cover. Reinstall the chain cover bolt and tighten securely.

NOTE: If the chain is too tight, it will not rotate. Loosen the chain cover bolt slightly and tum chain tensioning screw 1/4 turn anti-clockwise. Lift the tip of the bar up and retighten bolt, Ensure that the chain will rotate without binding.

- Return the lower jaw to the closed position by pulling back on the front handle and allowing the handle to move all the way forward.

CHAIN LUBRICANT:

Use premium bar and chain lubricant. It is designed for chains and chain oilers and is formulated to perform over a wide temperature range with no dilution required.

- Stop the motor and disconnect from power supply.

- Remove the oil reservoir cap and carefully pour approximately 60ml of bar and chain lubricant Into the tank.

- Replace the cap and tighten securely.

- Check and refill the tank every time the Grip Saw is used.

- NOTE: Do not use dirty, used, or otherwise contaminated lubricants. Damage may occur to the oil pump, bar, or chain.

CHAIN MAINTENANCE:

Only use a low-kickback chain on this saw.

This fast-cutting chain will provide kickback reduction when properly maintained.

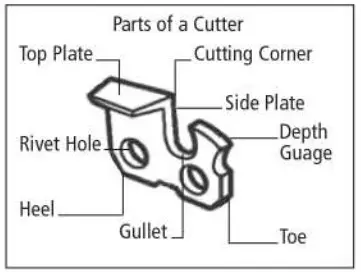

For smooth and fast cutting, the chain needs to be maintained properly. The chain requires sharpening when wood chips become small and powdery, the chain must be forced through the wood during cutting, or the chain cuts to one side. During maintenance of your chain, consider the following:

- Improper filing angle of the side plate can increase the risk of a severe kickback.

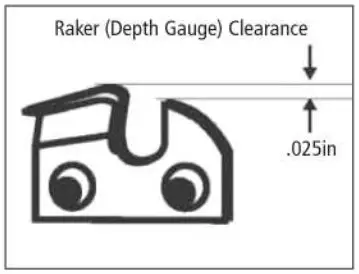

- Raker (depth gauge) clearance:

- Too low increases the potential for kickback.

- Not low enough decreases cutting ability.

- If cutter teeth have hit hard objects such as nails and stones, or have been abraded by mud or sand on the wood – have a service dealer sharpen the chain.

NOTE: Inspect the drive sprocket for wear or damage when replacing the chain. If signs of wear or damage are present, have the drive sprocket replaced by an authorised service dealer.

NOTE: Inspect the drive sprocket for wear or damage when replacing the chain. If signs of wear or damage are present, have the drive sprocket replaced by an authorised service dealer.

HOW TO SHARPEN THE CUTTERS:

Be careful to file all cutters to the specified angles and to the same length, as fast cutting can be obtained REPENS only when all cutters are uniform.

- Stop the motor and disconnect from power supply.

- Tighten the chain tension enough that the chain does not wobble. Do all of your filing at the mid-point of the bar. Wear gloves for protection.

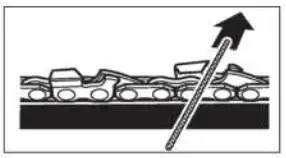

- Use a 5/32 in. diameter round file and holder.

- Keep the file level with the top plate of the tooth.

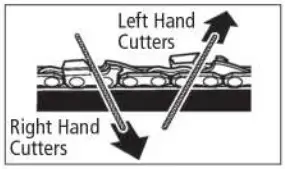

Do not let the file dip or rock. Left Hand p - Using light but firm pressure, stroke towards the front corner of the tooth. Lift file away from the steel on each return stroke.

- Put a few firm strokes on every tooth. File all left hand cutters in one direction. Then move to the other side and file the right hand cutters in the opposite direction. Occasionally remove filings from the file with a wire brush.

NOTICE: Dull or improperly sharpened chain can cause excessive motor speed during cutting which may result in severe motor damage.

WARNING: Improper chain sharpening increases the potential of kickback. Failure to replace or repair a damaged chain can cause serious injury.

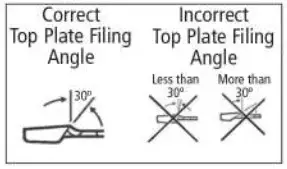

TOP PLATE FILING ANGLE:

- CORRECT 30° – File holders are marked with guide marks to align file property to produce correct top plate angle.

- LESS THAN 30° – For cross cutting.

- MORE THAN 30° – Feathered edge dulls quickly.

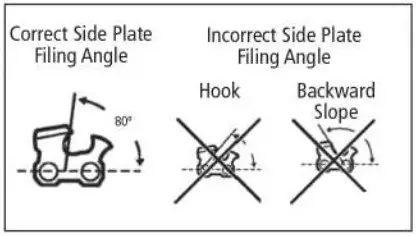

SIDE PLATE ANGLE:

- CORRECT -80° Produced Correct Side Plate Incorrect Side Plate automatically if correct diameter file Filing Angle Filing Angle is used in file holder. Hook Backward

- HOOK -“Grabs” and dulls quickly. Increases potential of KICKBACK Results from using a file with diameter too small, or file held too low.

- BACKWARD SLOPE -Needs too much feed pressure, causes excessive wear to bar and chain. Results from using a file with diameter too large, or file held too high.

DEPTH GAUGE CLEARANCE:

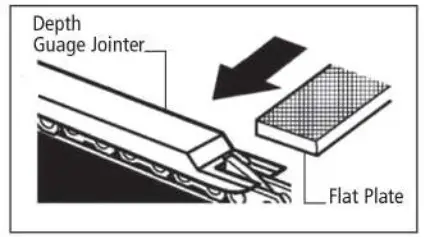

- The depth gauge should be maintained at a clearance of 0.025 in use a depth gauge too! for checking the depth gauge clearances.

- Every time the chain is filed, check the depth gauge clearance.

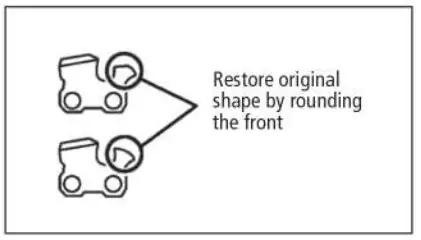

Use a flat file and a depth gauge jointer to lower all gauges uniformly. Depth gauge jointers are available in .020in to .035in. Use a.025in depth gauge jointer. After lowering each depth gauge, restore original shape by rounding the front. Be careful not to damage adjoining drive links with the edge of the file.

Depth gauges must be adjusted with the flat file in the same direction the adjoining cutter was filed with the round file. Use care not to contact cutter face with flat file when adjusting depth gauges.

GUIDE BAR MAINTENANCE:

When the quide bar shows signs of wear, reverse it on the saw to distribute the wear for maximum barlife. The bar should be cleaned every day of use and checked for wear and damage.

Feathering or burring of the bar rails is a normal process of bar wear. Such faults should be smoothed with a file as soon as they occur.

A bar with any of the following faults should be replaced:

- Wear inside the bar rails which permits the chain to lay over sideways.

- Bent guide bar.

- Cracked or broken rails.

- Spread rails.

Lubricate guide bars with a sprocket at their tip weekly. Using a grease syringe, lubricate weekly in the lubricating hole. Turn the guide bar and check that the lubrication holes and chain groove are free from impurities.

SPECIFICATION:

| Chain Lubricant Tank Capacity: | 60 ml |

| Bar Length: | 20.3 cm |

| Bar Type: | Oregon, Chainsaw Guide Bar, Double Guard, 91. Low Kickback. |

| Cutting Capacity: | 10 cm |

| Chain Pitch: | 3/8in |

| Chain Gauge: | 0.050 in |

| Chain Type: | Low Profile Skip Tooth Narrow Kerf |

| Drive Sprocket: | 6-tooth |

| Input: | 230-240V– 50Hz, 600W |

| Weight: | 3.85kg |

TROUBLESHOOTING:

| PROBLEM | CAUSE | SOLUTION |

| Bar and chain running hot and smoking. | Check chain tension for over tightened condition. | Tension chain. Refer to Chain Tension earlier in this manual. |

| Oil reservoir empty. | Check oil reservoir. | |

| Motor runs, but chain is not rotating. | Chain tension too tight. | Retention chain. Refer to Chain Tension earlier in this manual. |

| Check guide bar and chain assembly. | Refer to Replacing the Bar and Chain earlier in this manual. | |

| Check guide bar and chain for damage. | Inspect guide bar and chain for damage. |

DISPOSAL

Dispose of all paper, cartons, and plastic in accordance with your local recycling regulations. At the end of the product’s lifespan please dispose of it at an authorised household waste recycling center.

PLEASE SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

www.lenoxx.com.au

![]() 1300 666 848

1300 666 848