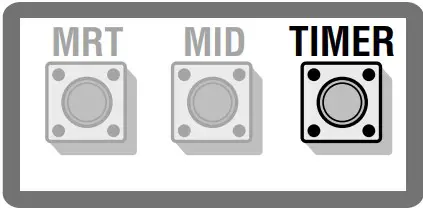

door opener on a one-piece door. The Timer-to-Close is to be used ONLY with sectional doors.

Important Safety Instructions

Safety Symbol and Signal Word Review

This garage door opener has been designed and tested to offer safe service provided it is installed, operated, maintained and tested in strict accordance with the instructions and warnings contained in this manual.

When you see these Safety Symbols and Signal Words on the following pages, they will alert you to the possibility of serious injury or death if you do not comply with the warnings that accompany them.

The hazard may come from something mechanical or from electric shock. Read the warnings carefully.

![]()

Warning Mechanical

Warning Electrical

When you see this Signal Word on the following pages, it will alert you to the possibility of damage to your garage door and/or the garage door opener if you do not comply with the cautionary statements that accompany it. Read them carefully.

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

- READ AND FOLLOW ALL WARNINGS AND INSTRUCTIONS.

- Install garage door opener ONLY on properly balanced and lubricated garage door. An improperly balanced door may NOT reverse when required and could result in SEVERE INJURY or DEATH.

- ALL repairs to cables, spring assemblies and other hardware MUST be made by a trained door systems technician BEFORE installing opener.

- Disable ALL locks and remove ALL ropes connected to garage door BEFORE installing opener to avoid entanglement.

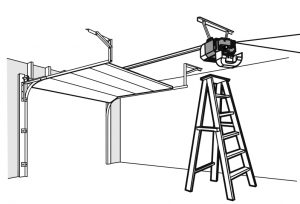

- Install garage door opener 7 feet (2.13 m) or more above fl oor.

- Mount the emergency release within reach, but at least 6 feet (1.83 m) above the fl oor and avoiding contact with vehicles to avoid accidental release.

- NEVER connect garage door opener to power source until instructed to do so.

- NEVER wear watches, rings or loose clothing while installing or servicing opener. They could be caught in garage door or opener mechanisms.

- Install wall-mounted garage door control:

• within sight of the garage door.

• out of reach of children at minimum height of 5 feet (1.5 m).

• away from ALL moving parts of the door. - Place entrapment warning label on wall next to garage door control.

- Place manual release/safety reverse test label in plain view on inside of garage door.

- Upon completion of installation, test safety reversal system. Door MUST reverse on contact with a 1-1/2″ (3.8 cm) high object (or a 2×4 laid fl at) on the fl oor.

- To avoid SERIOUS PERSONAL INJURY or DEATH from electrocution, disconnect ALL electric and battery power BEFORE performing ANY service or maintenance.

- DO NOT enable the Timer-to-Close functionality if operating either one-piece or swinging garage doors. To be enabled ONLY when operating a sectional door.

- SAVE THESE INSTRUCTIONS.

Operation

Your garage door opener is equipped with features to provide you with greater control over your garage door operation. Accessories provided with your garage door opener will vary depending on the garage door opener model purchased.

ALERT2CLOSE

The Alert2Close feature provides a visual and an audible alert that an unattended door is closing.

TIMER-TO-CLOSE (TTC)

The Timer-to-Close feature automatically closes the door after a specifi ed time period that can be adjusted using a TTC enabled door control (Models 881LM or 880LM). Prior to and during the door closing the garage door opener lights will fl ash and the garage door opener will beep.

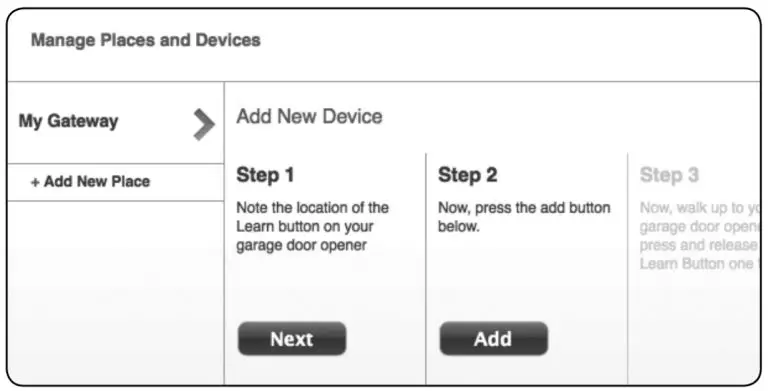

MyQ™

MyQ™ technology uses a 900MHz signal to provide two-way communication between the garage door opener and MyQ™ enabled accessories. Your garage door opener is compatible with up to 16 MyQ™ accessories.

REMOTE CONTROLS AND DOOR CONTROLS (SECURITY✚2.0™)

Your garage door opener has already been programmed at the factory to operate with your remote control, which changes with each use, randomly accessing over 100 billion new codes. Compatible with MyQ™ and Security✚ 2.0™.

NOTE: Older LiftMaster remote controls, door controls, and third party products are not compatible.

Accessories (Security✚ 2.0™): MEMORY CAPACITY

Remote Controls: Up to 24

Door Controls: Up to 2 Smart Control Panels or 4 of any other Security+ 2.0™ door controls

Keyless Entries: Up to 2

THE PROTECTOR SYSTEM® (SAFETY REVERSING SENSORS)

When properly connected and aligned, the safety reversing sensors will detect an obstruction

in the path of the infrared beam. If an obstruction breaks the infrared beam while the door is

closing, the door will stop and reverse to full open position, and the opener lights will fl ash

10 times. If the door is fully open, and the safety reversing sensors are not installed, or are

misaligned, the door will not close from a remote control. However, you can close the door

if you hold the button on the door control or keyless entry until the door is fully closed. The

safety reversing sensors do not affect the opening cycle.

ENERGY CONSERVATION

For energy effi ciency the garage door opener will enter sleep mode when the door is fully closed. The sleep mode shuts the garage door opener down until activated. The sleep mode is sequenced with the garage door opener light bulb; as the light bulb turns off the sensor LEDs will turn off and whenever the garage door opener lights turn on the sensor LEDs will light.

LIGHTS

The garage door opener light bulbs will turn on when the opener is initially plugged in; power is restored after interruption, or when the garage door opener is activated. The lights will turn off automatically after 4-1/2 minutes. An incandescent A19 light bulb (100 watt maximum) or for maximum energy effi ciency a 26W (100W equivalent) compact fl uorescent light (CFL) bulb may be used.

Light Feature

The garage door opener is equipped with an added feature; the lights will turn on when someone enters through the open garage door and the safety reversing sensor infrared beam is broken. For added control over the light bulbs on your garage door opener.

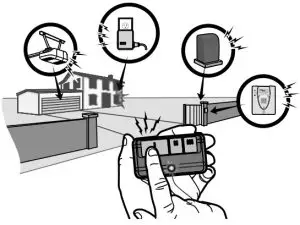

USING YOUR GARAGE DOOR OPENER

The garage door opener can be activated through a wall-mounted door control, remote control, wireless keyless entry or MyQ™ accessory. When the door is closed and the garage door opener is activated the door will open. If the door senses an obstruction or is interrupted while opening the door will stop. When the door is in any position other than closed and the garage door opener is activated the door will close. If the garage door opener senses an obstruction while closing, the door will reverse. If the obstruction interrupts the sensor beam the garage door opener lights will blink 10 times. However, you can close the door if you hold the button on the door control or keyless entry until the door is fully closed.

The safety reversing sensors do not affect the opening cycle. The safety reversing sensor must be connected and aligned correctly before the garage door opener will move in the down direction.

Using the Door Control

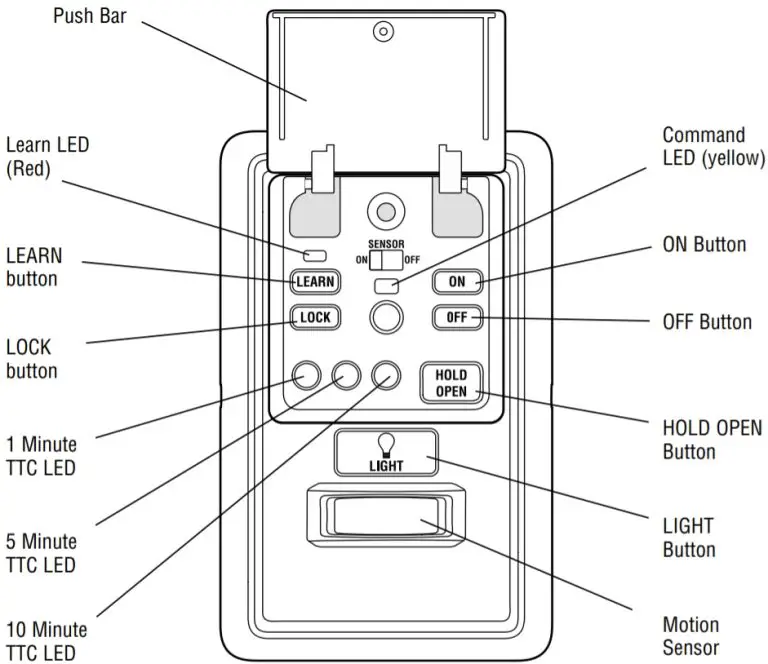

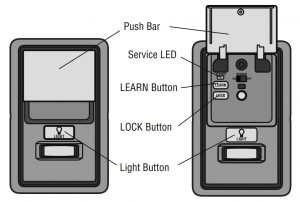

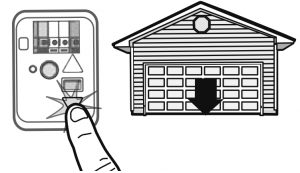

PUSH BAR

Press the push bar to open and close the door.

LIGHT BUTTON

Press the LIGHT button to turn the garage door opener lights on or off. When the lights are turned on they will stay on until the LIGHT button is pressed again, or until the garage door opener is activated. Once the garage door opener is activated the lights will turn off after the specified period of time (the factory setting is 4-1/2 minutes). The LIGHT button will not control the lights when the door is in motion. The duration of the light timing can be adjusted using the door control.

Light Button

MOTION-DETECTING CONTROL PANEL The following features are accessible by lifting the push bar:

LEARN A DEVICE

Any compatible remote controls, wireless keyless entry, or MyQ™ accessories can be programmed to the garage door opener by pressing the Learn button on the Motion-Detecting Control Panel.

LOCK

The LOCK feature is designed to prevent activation of the garage door opener from remote controls while still allowing activation from the door control and keyless entry. This feature is useful for added peace of mind when the home is empty (i.e. vacation).

AUTOMATIC LIGHT

Motion Sensor

Factory default is set to on. This feature automatically turns on the garage door opener lights when motion is sensed. The lights will come on for the set period of time, then shut off. If using the garage door opener light as a work light disable the motion sensor, otherwise the light will turn off automatically if you are beyond the range of the sensor.

Light Feature

The lights will turn on when someone enters through the open garage door and the safety reversing sensor infrared beam is broken.

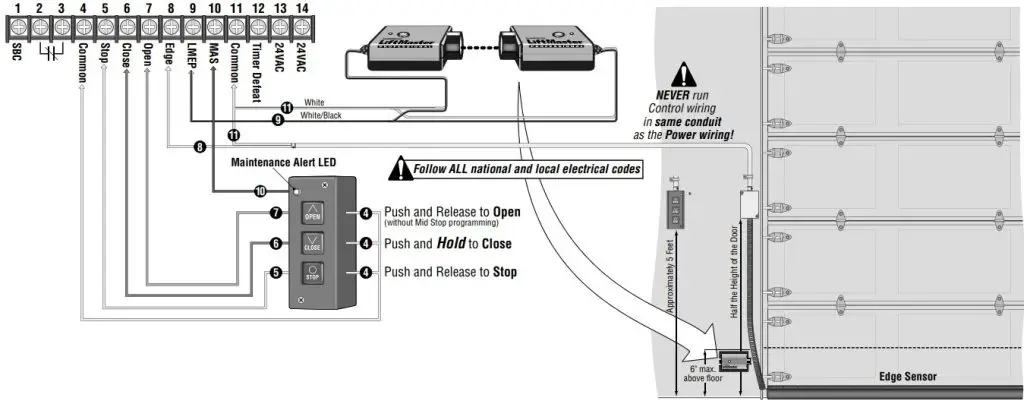

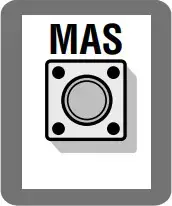

MAINTENANCE ALERT SYSTEM (MAS)

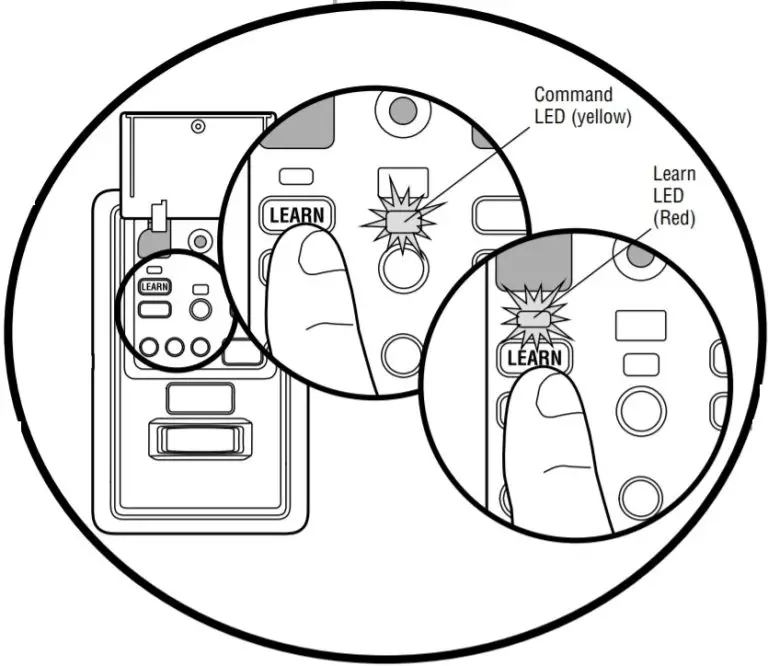

This feature assists the homeowner in ensuring the garage door opener system stays in good working condition. When the garage door opener needs to be serviced (approximately 4500 garage door opener cycles) the command (yellow) and service (red) LEDs will begin to alternately flash back and forth. The factory setting for the MAS feature is off and can be activated at the time of installation. Contact your installing dealer for service.

Programming – Motion-Detecting Control Panel

Features

Lock:

NOTE: Your remote controls will NOT work when LOCK mode is active however your keyless entry will still allow access to your garage. Activate: Press and hold the LOCK button for 2 seconds. The command LED will flash as long as the lock feature is activated and your handheld remote control will not operate your door at this time. Deactivate: Press and hold the LOCK button gain for 2 seconds. The command LED will stop flashing and normal operation will resume.

Light:

To change the amount of time the garage door opener lights will stay on:

Press and hold the LOCK button until the garage door opener lights flash.* The time interval is indicated by the number of flashes.

NUMBER OF TIMES GARAGE DOOR OPENER LIGHTS FLASH 1:2:3:4

TIME THE GARAGE DOOR OPENER LIGHT STAYS ON 1 ½ Minutes: 2 ½ Minutes: 3 ½ Minutes: 4 ½ Minutes

To cycle through the time intervals repeat the step above.

Deactivate: Press and hold the LIGHT button until the garage door opener lights turn on, then off again.*

Activate: Start with the garage door opener lights on. Press and hold the LIGHT button until the garage door opener lights turn off, then on again.*

* Approximately 10 seconds

Motion Sensor: Activate/Deactivate: Slide the motion sensor switch ON or OFF.

To Program a Remote Control or Keyless Entry:

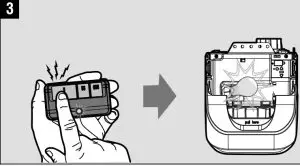

- Press the LEARN button on the door control to enter Programming Mode.

- Press the LEARN button again, the LED will fl ash once.

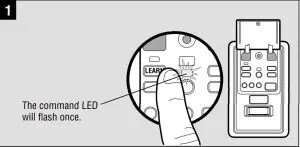

- Remote Control: Press the button on the remote control that you wish to operate your garage door.

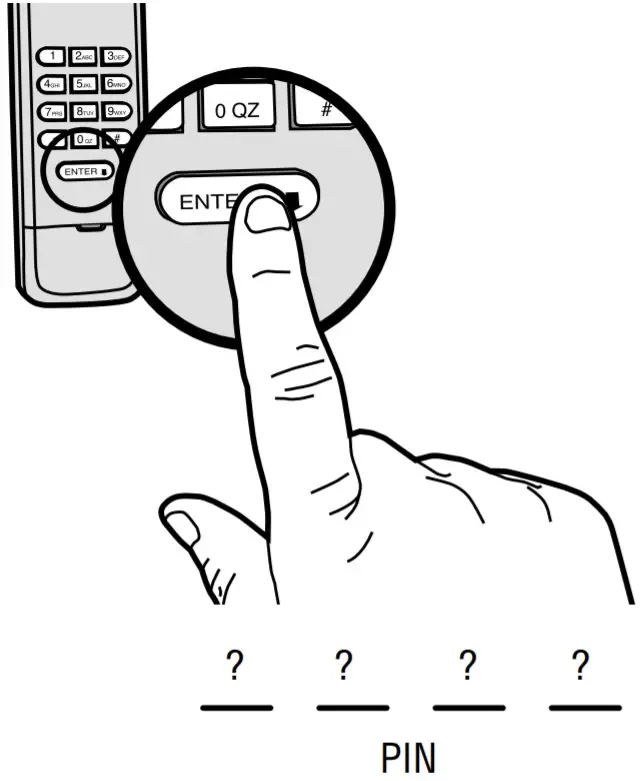

Keyless Entry: Enter a 4-digit personal identifi cation number (PIN) of your choice on the keyless entry keypad. Then press the ENTER button.

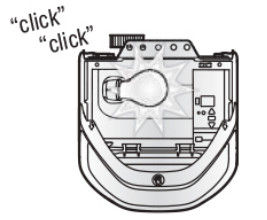

The garage door opener lights will fl ash (or two clicks will be heard) when the code has been programmed. If programming is unsuccessful, repeat steps 1-3 or program the remote using the learn button on the garage door opener.

Maintenance Alert System (MAS):

Activate/Deactivate

Press and hold the LEARN button. Then press the LIGHT button. The service LED will fl ash the status; Active is 2 fl ashes and deactivated is 3 fl ashes.

Programming – Remote Controls

Your garage door opener has been programmed at the factory to operate with your remote control. Older LiftMaster remote controls are NOT compatible. Programming can be done through the door control or the Learn button on the garage door opener. To program additional remote controls refer to the instructions provided with the additional remote controls or visit www.liftmaster.com. If your vehicle is equipped with a Homelink®, you may require an external adapter depending on the make, model, and year of your vehicle. Visit www.homelink.com for additional information.

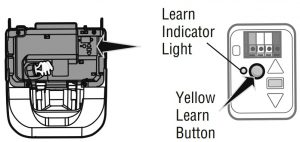

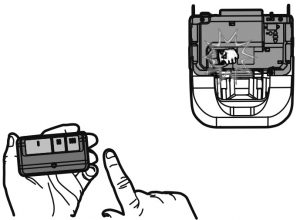

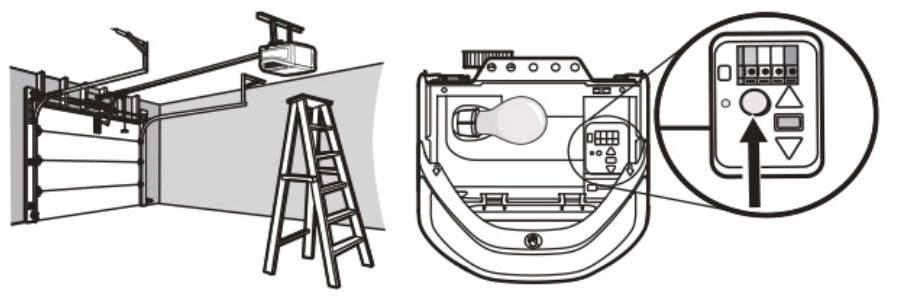

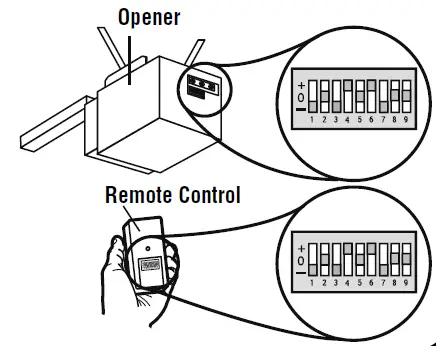

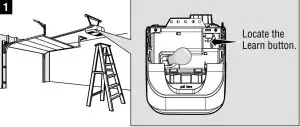

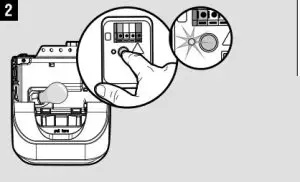

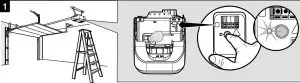

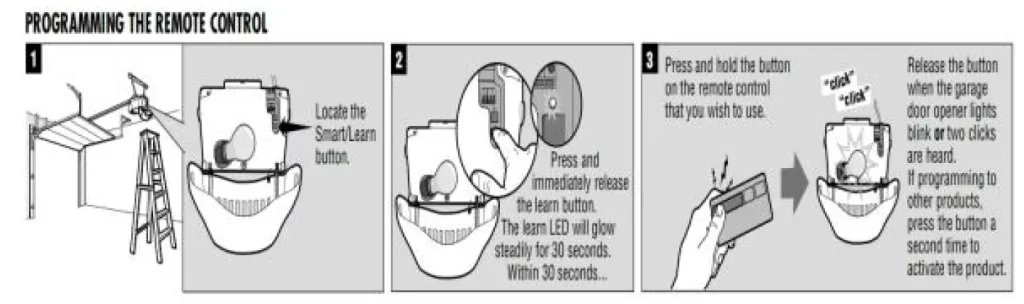

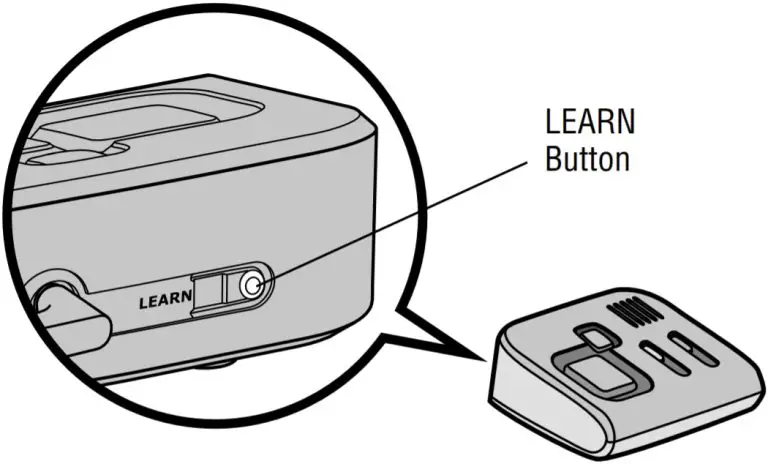

PROGRAM A REMOTE USING THE LEARN BUTTON ON THE GARAGE DOOR OPENER

- Press and release the Learn button on the garage door opener. The Learn indicator light will glow steadily for 30 seconds.

- Within 30 seconds, press and hold the button on the remote control.

- Release the button when the garage door opener light blinks.

It has learned the code. If light bulbs are not installed, two clicks will be heard.

When replacing the light lens cover, ensure the antenna wires are hanging straight down.

ERASE ALL REMOTE CONTROLS AND KEYLESS ENTRIES

- Press and hold the learn button on garage door opener until the learn LED goes out (approximately 6 seconds). All remote control and keyless entry codes are now erased. Reprogram any accessory you wish to use.

ERASE ALL DEVICES

- Press and hold the learn button on garage door opener until the learn LED goes out (approximately 6 seconds).

- Immediately press and hold the learn button again until the learn LED goes out. All codes are now erased. Reprogram any accessory you wish to use.

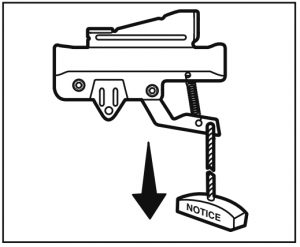

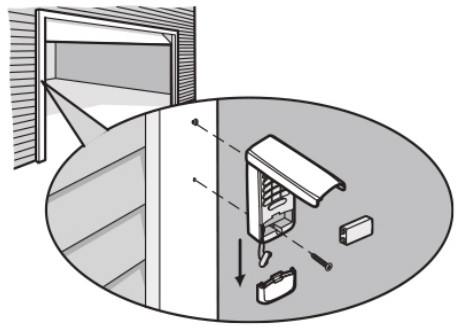

To Open the Door Manually

![]() WARNING

WARNING

To prevent possible SERIOUS INJURY or DEATH from a falling garage door:

- If possible, use emergency release handle to disengage trolley ONLY when garage door is CLOSED. Weak or broken springs or unbalanced door could result in an open door falling rapidly and/or unexpectedly.

- NEVER use emergency release handle unless garage doorway is clear of persons and obstructions.

- NEVER use handle to pull door open or closed. If rope knot becomes untied, you could fall.

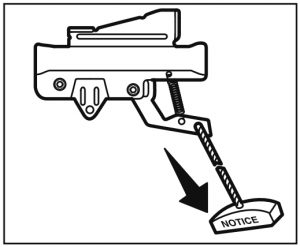

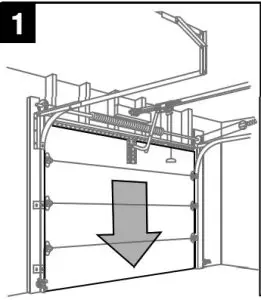

DISCONNECT THE TROLLEY

- The door should be fully closed if possible.

- Pull down on the emergency release handle.

RECONNECT THE TROLLEY

The lockout feature prevents the trolley from reconnecting automatically.

- Pull the emergency release handle down and back (toward the opener). The door can then be raised and lowered manually as often as necessary.

- To disengage the lockout feature, pull the handle straight down.

The trolley will reconnect on the next UP or DOWN operation, either manually or by using the door control or remote control.

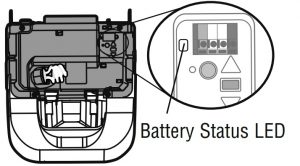

Battery Backup (If applicable)

The battery backup system allows access in and out of your garage, even when the power is out. When the garage door opener is operating on battery power, the garage door opener will run slower, the light will not function, the Battery Status LED will glow solid orange, and a beep will sound approximately every 2 seconds.

The battery charges when the garage door opener is plugged into a 110Vac electrical outlet that has power and requires 24 hours to fully charge. A fully charged battery supplies 12Vdc to the garage door opener for one to two days of normal operation during an electrical power outage. After the electrical power has been restored, the battery will recharge within 24 hours. The battery will last approximately 1 to 2 years with normal usage. Instructions for replacement are provided with the battery. To obtain maximum battery life and prevent damage, disconnect the battery when the garage door opener is unplugged for an extended period of time.

NOTE: When the garage door opener is in battery backup mode the garage door opener lights, Timer-to-Close, and Remote Close features are unavailable.

BATTERY STATUS LED

NOTE: The Battery Status LED is most visible with the garage door opener light off.

Battery does not have to be fully charged to operate the garage door opener.

GREEN LED:

All systems are normal.

- A solid green LED light indicates the battery is fully charged.

- A fl ashing green LED indicates the battery is being charged.

ORANGE LED:

The garage door opener has lost power and is in battery backup mode.

- A solid orange LED with beep, sounding approximately every 2 seconds, indicates the garage door opener is operating on battery power.

- A fl ashing orange LED with beep, sounding every 30 seconds, indicates the battery is low.

RED LED:

The garage door opener’s 12V battery needs to be replaced.

- A solid red LED with beep, sounding every 30 seconds, indicates the garage door opener needs servicing. Please call for replacement battery to allow your system to operate during a power outage.

Adjustment

WARNING: Without a properly installed safety reversal system, persons (particularly small children) could be SERIOUSLY INJURED or KILLED by a closing garage door.

- Incorrect adjustment of garage door travel limits will interfere with proper operation of safety reversal system.

- After ANY adjustments are made, the safety reversal system MUST be tested. Door MUST reverse on contact with 1-1/2″ (3.8 cm) high object (or 2×4 laid fl at) on floor.

CAUTION: To prevent damage to vehicles, be sure fully open door provides adequate clearance.

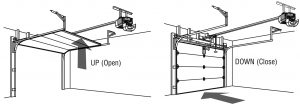

Your garage door opener is designed with electronic controls to make setup and adjustments easy. The adjustments allow you to program where the door will stop in the open (UP) and close (DOWN) position.

The electronic controls sense the amount of force required to open and close the door.

NOTE: If anything interferes with the door’s upward travel it will stop. If anything interferes with the door’s downward travel, it will reverse.

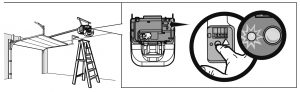

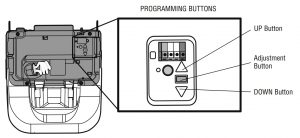

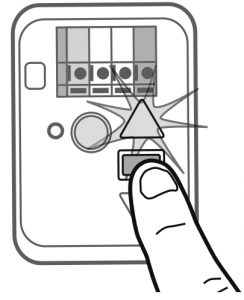

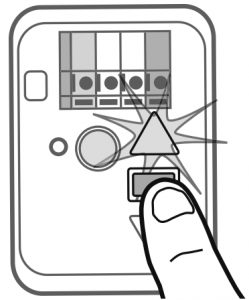

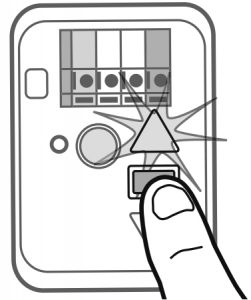

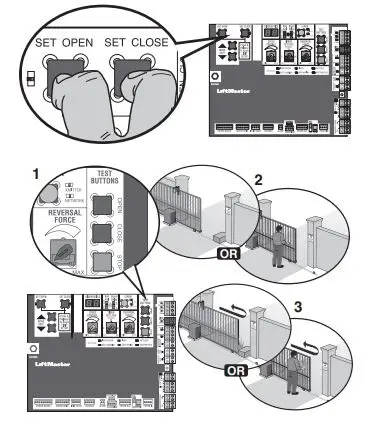

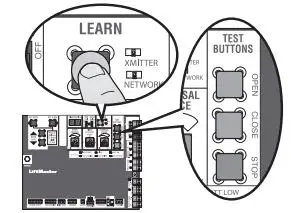

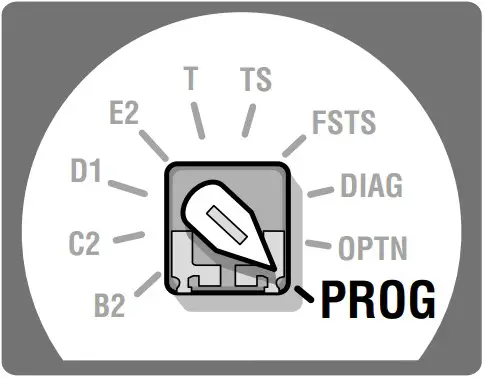

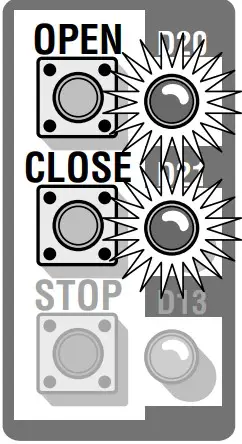

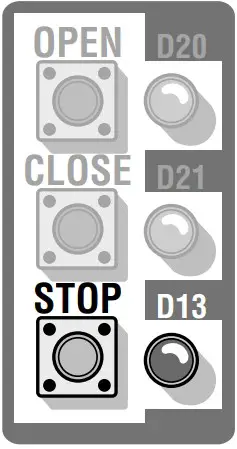

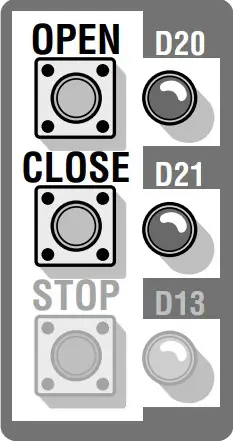

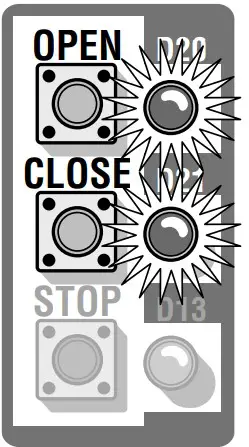

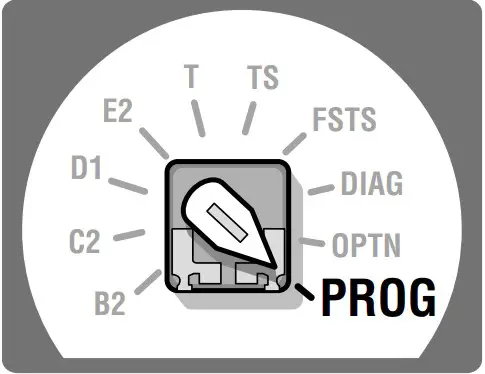

PROGRAMMING BUTTONS

The programming buttons are located on the left side panel of the garage door opener and are used to program the travel.

1. Program the Travel

Without a properly installed safety reversal system, persons (particularly small children) could be SERIOUSLY INJURED or KILLED by a closing garage door.

* Incorrect adjustment of garage door travel limits will interfere with proper operation of safety reversal system.

* After ANY adjustments are made, the safety reversal system MUST be tested. Door MUST reverse on contact with 1-1/2″ (3.8 cm) high object (or 2×4 laid flat) on floor.

1.1 Press and hold the Adjustment Button until the UP Button begins to fl ash and/or a beep is heard.

1.2 Press and hold the UP Button until the door is in the desired UP position.

NOTE: The UP and DOWN Buttons can be used to move the door up and down as needed.

1.3 Once the door is in the desired UP position press and release the Adjustment Button. The garage door opener lights will flash twice and the DOWN Button will begin to flash.

1.4 Press and hold the DOWN Button until the door is in the desired DOWN position.

NOTE: The UP and DOWN Buttons can be used to move the door up and down as needed.

1.5 Once the door is in the desired DOWN position press and release the Adjustment Button. The garage door opener lights will flash twice and the UP Button will begin to flash.

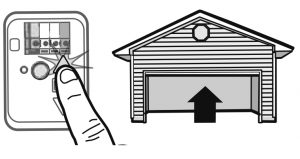

1.6 Press and release the UP Button. When the door travels to the programmed UP position, the DOWN Button will begin to flash.

1.7 Press and release the DOWN Button. The door will travel to the programmed DOWN position. Programming is complete.

* If the garage door opener lights are flashing 5 times during the steps for Program the Travel, the programming has timed out. If the garage door opener lights are fl ashing 10 times during the steps for Program the Travel, the safety reversing sensors are misaligned or obstructed. When the sensors are aligned and unobstructed, cycle the door through a complete up and down cycle using the remote control or the UP and DOWN buttons. Programming is complete. If you are unable to operate the door up and down, repeat the steps for Programming the Travel.

2. Test the Safety Reversal System

![]() WARNING

WARNING

Without a properly installed safety reversal system, persons (particularly small children) could be SERIOUSLY INJURED or KILLED by a closing garage door.

- Safety reversal system MUST be tested every month.

- After ANY adjustments are made, the safety reversal system MUST be tested. Door MUST reverse on contact with 1-1/2″ high (3.8 cm) object (or 2×4 laid flat) on the floor.

2.1 With the door fully open, place a 1-1/2 inch (3.8 cm) board (or a 2×4 laid flat) on the floor, centered under the garage door.

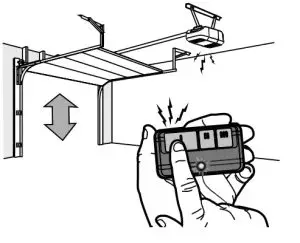

2.2 Press the remote control push button to close the door. The door MUST reverse when it makes contact with the board.

If the door stops and does not reverse on the obstruction, increase the down travel (refer to Adjustment Step 1).

Repeat the test. When the door reverses upon contact with the 1-1/2 inch board, remove the board and open/close the door 3 or 4 times to test the adjustment.

If the test continues to fail, call a trained door systems technician.

3. Test the Protector System ®

![]() WARNING: Without a properly installed safety reversing sensor, persons (particularly small children) could be SERIOUSLY INJURED or KILLED by a closing garage door.

WARNING: Without a properly installed safety reversing sensor, persons (particularly small children) could be SERIOUSLY INJURED or KILLED by a closing garage door.

3.1 Open the door. Place the garage door opener carton in the path of the door.

3.2 Press the remote control push button to close the door. The door will not move more than an inch (2.5 cm), and the garage door opener lights will flash 10 times.

The garage door opener will not close from a remote control if the LED in either safety reversing sensor is off (alerting you to the fact that the sensor is misaligned or obstructed).

If the garage door opener closes the door when the safety reversing sensor is obstructed (and the sensors are no more than 6 inches [15 cm] above the fl oor), call for a trained door systems technician.

Maintenance

EVERY MONTH

- Manually operate door. If it is unbalanced or binding, call a trained door systems technician.

- Check to be sure door opens and closes fully. Adjust if necessary.

- Test the safety reversal system. Adjust if necessary.

EVERY YEAR

- Oil door rollers, bearings and hinges. The garage door opener does not require additional lubrication. Do not grease the door tracks.

- (If applicable) Test the battery backup and consider replacing the battery to ensure the garage door opener will operate during an electrical power outage.

Testing the Battery Backup:

- Unplug the garage door opener. The battery status LED will either glow solid orange indicating opener is operating on battery power or will fl ash indicating low battery power.

- Open and close the door using the remote control or door control.

NOTE: The garage door opener may run slower if the battery is not fully charged. The battery will take 24 hours to fully charge. - Plug in the garage door opener. Verify the battery status LED is fl ashing green, indicating the battery is charging.

EVERY TWO TO THREE YEARS

- Use a rag to wipe away the existing grease from the garage door opener rail. Reapply a small layer of white lithium grease to the top and underside of the rail surface where the trolley slides.

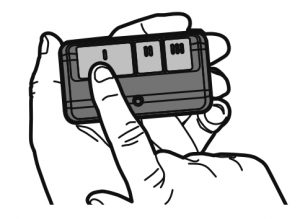

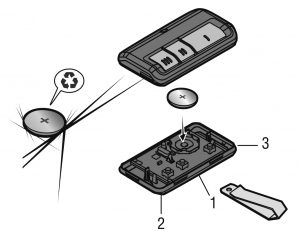

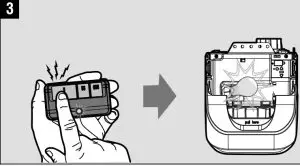

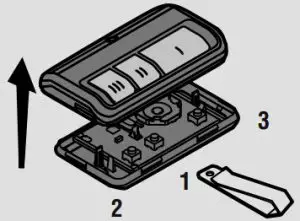

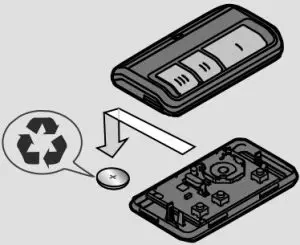

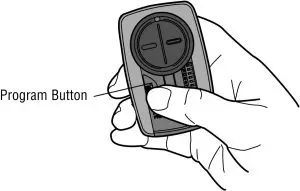

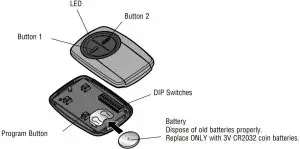

The Remote Control Battery

WARNING: To prevent possible SERIOUS INJURY or DEATH:

- NEVER allow small children near batteries.

- If the battery is swallowed, immediately notify a doctor.

To reduce risk of fire, explosion or chemical burn:

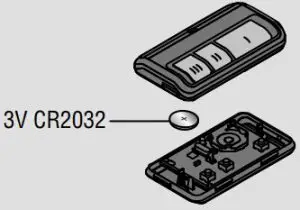

- Replace ONLY with 3V2032 coin batteries.

- DO NOT recharge, disassemble, heat above 212°F (100°C) or incinerate.

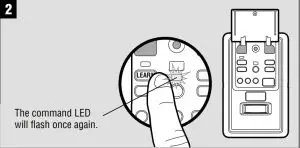

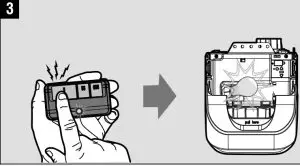

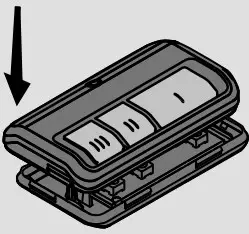

The lithium batteries should produce power for up to 5 years. If the battery is low, the remote control’s LED will not flash when the button is pressed. To replace the battery, pry open the case first in the middle (1), then at each side (2 and 3) with the visor clip. Insert battery positive side up.

Replace the batteries with only 3V2032 coin cell batteries. Dispose of old batteries properly.

NOTICE: To comply with FCC and/or Industry Canada (IC) rules, adjustment or modifications of this transceiver are prohibited. THERE ARE NO USER SERVICEABLE PARTS. Any changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment.

This device complies with Part 15 of the FCC rules and IC RSS-210. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

This Class B digital apparatus complies with Canadian ICES-003.

Troubleshooting

Diagnostic Chart

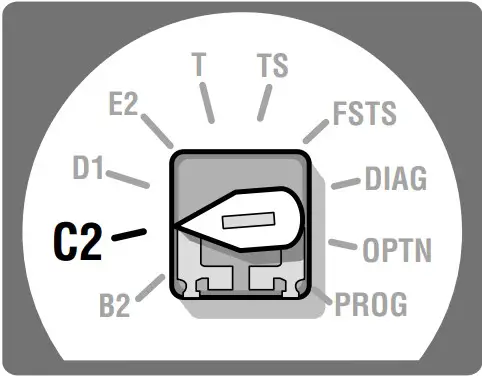

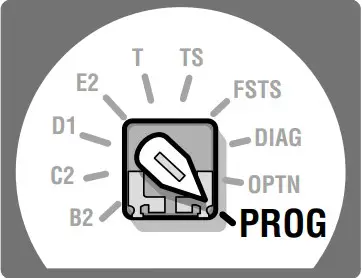

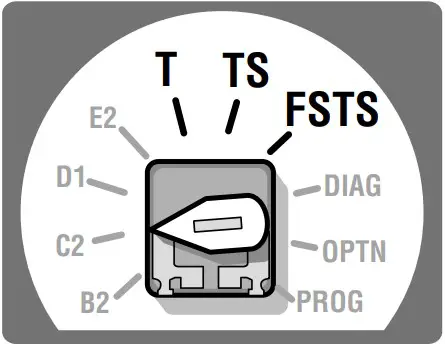

Your garage door opener is programmed with self-diagnostic capabilities. The UP and DOWN arrows on the garage door opener will fl ash the diagnostic codes.

DIAGNOSTIC CODE:

SYMPTOM:

SOLUTION

Up arrow Flash(es); Down arrow Flash(es)

1; 1: The garage door opener will not close and the light bulbs flash.:

Safety sensors are not installed, connected, or wires may be cut. Inspect sensor wires for a disconnected or cut wire.

1; 2:

The garage door opener will not close and the light bulbs flash.

There is a short or reversed wire for the safety sensors. Inspect safety sensor wire at all staple and connection points, replace wire or correct as needed.

1; 3:

The door control will not function.:

The wires for the door control are shorted or the door control is faulty. Inspect door control wires at all staple and connection points, replace wire or correct as needed.

1; 4:

The garage door opener will not close and the light bulbs flash.:

Safety sensors are misaligned or were momentarily obstructed. Realign both sensors to ensure both LEDs are steady and not fl ickering. Make sure nothing is hanging or mounted on the door that would interrupt the sensor’s path while closing;.

1; 5:

Door moves 6-8″ stops or reverses.:

Manually open and close the door. Check for binding or obstructions, such as a broken spring or door lock, correct as needed. Check wiring connections at travel module and at the logic board. Replace travel module if necessary.

No movement, only a single click.:

Manually open and close the door. Check for binding or obstructions, such as a broken spring or door lock, correct as needed. Replace logic board if necessary.:

Opener hums for 1-2 seconds no movement.:

Manually open and close the door. Check for binding or obstructions, such as a broken spring or door lock, correct as needed. Replace motor if necessary.

1; 6:

Door coasts after it has come to a complete stop.:

Program travel to coasting position or have door balanced by a trained door systems technician.

2; 1-5:

No movement, or sound.:

Replace logic board.

3; 2:

Unable to set the travel or retain position.

Check travel module for proper assembly, replace if necessary.

3; 3:

The battery status LED* is constantly fl ashing green.:

Battery backup* charging circuit error, replace the logic board.

*If applicable.

4; 1-4:

Door is moving stops or reverses.:

Manually open and close the door. Check for binding or obstructions, such as a broken spring or door lock, correct as needed. If the door is binding or sticking contact a trained door systems technician. If door is not binding or sticking attempt to reprogram travel.

4; 5:

Opener runs approximately 6-8″, stops and reverses.:

Communication error to travel module. Check travel module connections, replace travel module if necessary.

4; 6:

The garage door opener will not close and the light bulbs flash.:

Safety sensors are misaligned or were momentarily obstructed. Realign both sensors to ensure both LEDs are steady and not fl ickering. Make sure nothing is hanging or mounted on the door that would interrupt the sensor’s path while closing.

My garage door opener beeps:

The garage door opener can beep for several reasons:

- Garage door opener has been activated through a device or feature such as Timer-to-Close, garage door monitor or LiftMaster Internet Gateway.

- Operating on battery power or the 12Vdc battery needs to be replaced (if applicable).

My remote control will not activate the garage door:

- Verify the lock feature is not activated on the door control.

- Reprogram the remote control.

- If the remote control will still not activate the door check the diagnostic codes to ensure the garage door opener is working properly.

My door will not close and the light bulbs blink on my motor unit:

The safety reversing sensor must be connected and aligned correctly before the garage door opener will move in the down direction.

- Verify the safety sensors are properly installed, aligned and free of any obstructions.

My garage door opener light(s) will not turn off when the door is open:

The garage door opener is equipped with a feature that turns the light on when the safety reversing sensors have been obstructed or when the motion sensor on the door control detects movement in the garage. These features can be disabled using the door control.

My neighbor’s remote control opens my garage door:

Erase the memory from your garage door opener and reprogram the remote control(s).

My vehicle’s Homelink® is not programming to my garage door opener:

Depending on the make, model, and year of your vehicle an external adapter may be required. Visit www.homelink.com for additional information.

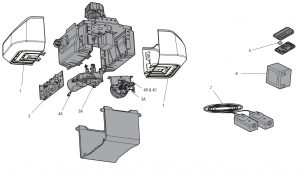

Repair Parts

NOTE: For additional parts not shown, visit www.liftmaster.com to download or print the full owner’s manual.

DESCRIPTION: PART NUMBER

1 Light Lens: 41A7562

2 Receiver Logic Board – Model 8350 & 8360: 45DCT

Receiver Logic Board – Model 8355 & 8365: 45ACT

3A Travel Module – Model 8350 & 8360: 41A7114-7

3B Travel Module – Model 8355 & 8365: 41D7742-7

4A Motor w/Travel Module – Model 8350 & 8360: 41D1739-1

4B Motor w/Travel Module – Model 8355: 41D7442

4C Motor w/Travel Module – Model 8365: 41D7440

5 3V2032 Lithium Battery (Remote Control): 10A20

6 Backup Battery (if applicable): 485LM

7 Safety Sensor Kit with receiving and sending sensors with 3 feet (.9 m) 2-conductor wire: 41A5034

Warranty

LIFTMASTER® ONE YEAR LIMITED WARRANTY LIFETIME MOTOR AND BELT* LIMITED WARRANTY ONE YEAR LIMITED WARRANTY FOR THE BATTERY BACKUP SYSTEM*

The Chamberlain Group, Inc. (“Seller”) warrants to the first retail purchaser of this product, for the residence in which this product is originally installed, that it is free from defects in materials and/or workmanship for a period of one year from the date of purchase, except that the motor and belt* are warranted to be free from defects in materials and/or workmanship for the lifetime of the product while you own your residence, and the Battery Backup System* is warranted to be free from defects in materials and/or workmanship for a period of one year from the date of purchase. The proper operation of this product is dependent on your compliance with the instructions regarding installation, operation, and maintenance and testing. Failure to comply strictly with those instructions will void this limited warranty in its entirety.

If, during the limited warranty period, this product appears to contain a defect covered by this limited warranty, call 1-800-528-9131, toll free, before dismantling this product. You will be advised of disassembly and shipping instructions when you call. Then send the product or component, pre-paid and insured, as directed to our service center for warranty repair. Please include a brief description of the problem and a dated proof-of purchase receipt with any product returned for warranty repair. Products returned to Seller for warranty repair, which upon receipt by Seller are confirmed to be defective and covered by this limited warranty, will be repaired or replaced (at Seller’s sole option) at no cost to you and returned pre- paid. Defective parts will be repaired or replaced with new or factory-rebuilt parts at Seller’s sole option. [You are responsible for any costs incurred in removing and/or reinstalling the product or any component.]

ALL IMPLIED WARRANTIES FOR THE PRODUCT, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO THE APPLICABLE LIMITED WARRANTY PERIOD SET FORTH ABOVE FOR THE RELATED COMPONENT(S), AND NO IMPLIED WARRANTIES WILL EXIST OR APPLY AFTER SUCH PERIOD. Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you. THIS LIMITED WARRANTY DOES NOT COVER NON DEFECT DAMAGE, DAMAGE CAUSED BY IMPROPER INSTALLATION, OPERATION OR CARE (INCLUDING, BUT NOT LIMITED TO ABUSE, MISUSE, FAILURE TO PROVIDE REASONABLE AND NECESSARY MAINTENANCE, UNAUTHORIZED REPAIRS OR ANY ALTERATIONS TO THIS PRODUCT), LABOR CHARGES FOR REINSTALLING A REPAIRED OR REPLACED UNIT, REPLACEMENT OF CONSUMABLE ITEMS (E.G., BATTERIES IN REMOTE CONTROL TRANSMITTERS AND LIGHT BULBS), OR UNITS INSTALLED FOR NON RESIDENTIAL USE. THIS LIMITED WARRANTY DOES NOT COVER ANY PROBLEMS WITH, OR RELATING TO, THE GARAGE DOOR OR GARAGE DOOR HARDWARE, INCLUDING BUT NOT LIMITED TO THE DOOR SPRINGS, DOOR ROLLERS, DOOR ALIGNMENT OR HINGES. THIS LIMITED WARRANTY ALSO DOES NOT COVER ANY PROBLEMS CAUSED BY INTERFERENCE. UNDER NO CIRCUMSTANCES SHALL SELLER BE LIABLE FOR CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES ARISING IN CONNECTION WITH USE, OR INABILITY TO USE, THIS PRODUCT. IN NO EVENT SHALL SELLER’S LIABILITY FOR BREACH OF WARRANTY, BREACH OF CONTRACT, NEGLIGENCE OR STRICT LIABILITY EXCEED THE COST OF THE PRODUCT COVERED HEREBY. NO PERSON IS AUTHORIZED TO ASSUME FOR US ANY OTHER LIABILITY IN CONNECTION WITH THE SALE OF THIS PRODUCT.

Some states do not allow the exclusion or limitation of consequential, incidental or special damages, so the above limitation or exclusion may not apply to you. This limited warranty gives you specific legal rights, and you may also have other rights, which vary from state to state.

]]>

LiftMaster Wireless Keyless Entry 878MAX

LiftMaster Wireless Keyless Entry 878MAX

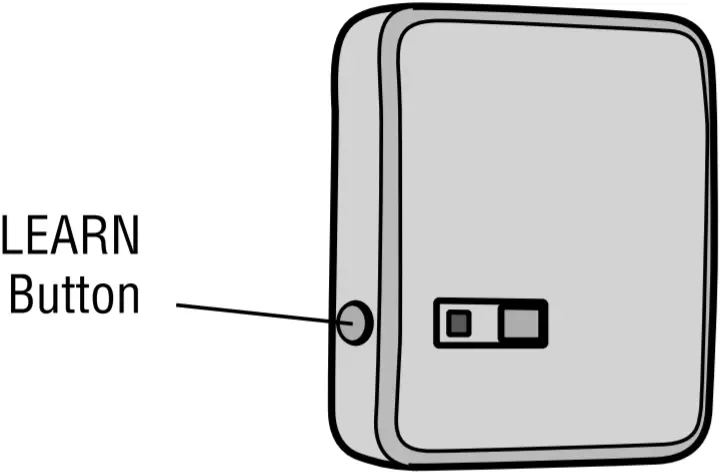

BEFORE YOU START Your wireless keyless entry is compatible with 315 MHz or 390 MHz garage door openers manufactured starting January 1, 1993, and have a LEARN button.

Read instructions thoroughly BEFORE beginning. If you are using this product with residential door openers, this product must be used only with door openers manufactured starting January 1, 1993, that use photoelectric sensors located near the bottom of the door track.

IMPORTANT: The keypad will activate your door or gate during programming. Be sure the door is clear of ALL obstructions. Start with the garage door closed. Make sure the garage door opener has a working light because it is a programming indicator.

Install the battery and program the wireless keyless entry prior to installation.

WARNING: This product can expose you to chemicals including lead, which is known to the State of California to cause cancer or birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

WARNING: This product can expose you to chemicals including lead, which is known to the State of California to cause cancer or birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

WARNING

WARNING

To prevent possible SERIOUS INJURY or DEATH from a moving gate or garage door:

- Install Wireless Keyless Entry within sight of the garage door, out of reach of children at a minimum height of 5feet (1.5 m), and away from ALL moving parts of the door.

- ALWAYS keep remote controls out of reach of children. NEVER permit children to operate, or play with remote controls.

- Activate gate or door ONLY when it can be seen clearly, is properly adjusted, and there are no obstructions to door travel.

ALWAYS keep gate or garage door in sight until completely closed. NEVER permit anyone to cross the path of the moving gate or door.

INSTALLATION

- Select a location to mount the wireless keyless entry at a minimum height of 5′ (1.5 m) out of the reach of children.

- Remove the battery cover and battery to show mounting

- Mark the top mounting hole and drill l/8′ (3.2mm) pilot

- Install the top screw, allowing 1/W (3.2mm) to protrude above the surface. Position the wireless keyless entry over the top screw.

- Mark the bottom hole and drill 1/W (3.2 mm) pilot hole. Install the bottom Do not overtighten to avoid cracking the plastic housing.

- Reinstall the battery and replace the cover.

PROGRAM THE INITIAL PIN

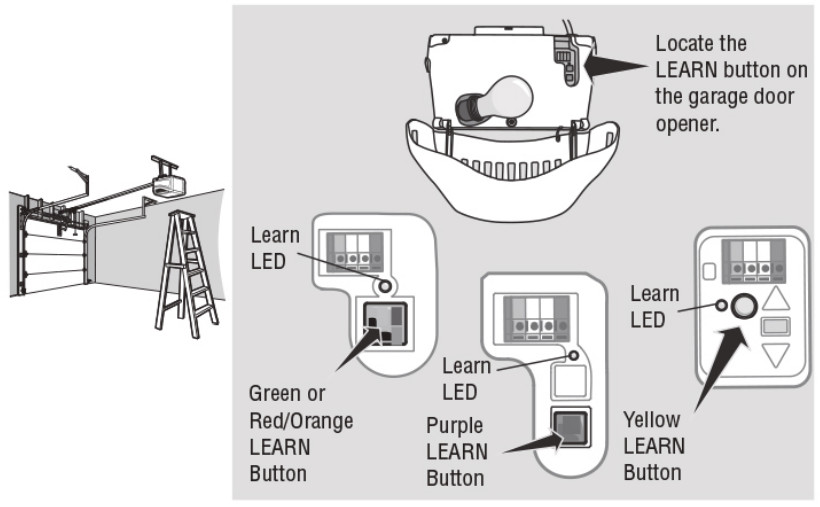

The wireless keyless entry is pre-programmed to work with a LiftMaster garage door opener with a yellow LEARN button. Locate the LEARN button on the garage door opener. If the LEARN button is YELLOW, see Method A. Otherwise, see Method B for other colored LEARN buttons.

Method A – Yellow LEARN Button

- Press and release the LEARN button on the garage door opener. The learn LED will light.

- Enter a 4-digit personal identification number (PIN) of your choice.

- Press the ENTER button until the opener light bulb blinks or two clicks are heard.

- Test by pressing in the PIN you just programmed, and then press the ENTER The garage door opener will activate.

Method B – Yellow LEARN/Security+ 2.08 and Other LEARN Buttons

- Press and hold the * and # buttons until the lights on the keypad stop blinking.

- Enter a 4-digit personal identification number (PIN) of your choice. Then press the # button. You will use this PIN in step 6.

- Press and release the ENTER button the number of times that corresponds with the garage door opener type:

- Press and release the 0 buttons.

# of Presses Garage Door Opener Type 1 Yellow LEARN Button (Security+ 2.00) 2 Purple LEARN Button (315 MHz Security+0) 3 Red/Orange LEARN Button (390 MHz Security+0) 4 Green LEARN (390 MHz Billion Code) - Press and releas the LEARN button one time on the garage door opener. The Learn LED will light.

- Enter the 4-digit PIN from step 2, then press and release the ENTER button until the garage door opener lights flash or two clicks are heard.

- Test by pressing in the PIN you just programmed, and then press the ENTER button. The garage door opener will activate. Add more openers by repeating steps 1 through 7 using a new PIN for each.

HOW TO USE THE WIRELESS KEYLESS ENTRY

The garage door opener activates when you press the personal identification number (PIN) and ENTER button. The keypad will blink for 15 seconds. During that time the ENTER button can be used to stop, start or reverse the door.

If the wrong PIN number is accidentally pressed, press the correct PIN then ENTER button. The wireless keyless entry will transmit only the last four digits that were pressed before the ENTER button.

ONE BUTTON CLOSE FEATURE: This feature allows you to CLOSE your garage door by pressing just the ENTER button instead of your 4-digit PIN.

NOTE: This feature ONLY closes and is not available on garage door openers manufactured prior to 2006 or an external receiver.

To deactivate the one-button close feature:

- Press and hold the 1 and 9 buttons for 10 seconds. The keypad will blink four times when the one-button close feature is deactivated.

To activate the one button close feature:

- Press and hold the 1 and 9 buttons for 10 seconds. The keypad will blink twice when the one-button close feature is actuated.

PROGRAM A TEMPORARY PIN

NOTE: This feature is not available on garage door openers that have a green LEARN button or an external receiver.

A temporary 4-digit personal identification number (PIN) can be programmed to allow access to visitors. Each programmed PIN can program one temporary PIN. The temporary PIN can be set for a number of hours or a number of door openings. The temporary PIN cannot be the same as any previously programmed PIN.

- Press any programmed PIN, then press and hold the * button until the garage door opener light blinks three times.

- Press the temporary 4-digit PIN of your choice, then press the ENTER button. The light blinks 4 times.

- Enter the temporary PIN limit of use by:

| Number of Hours PIN Will Work | Number of Openings PIN Will Work | |

| Press the number of hours the temporary PIN will work (up to255), then press the * button. The opener light blinks once. | OR | Press the number of openings the temporary PIN will work ( up to 255), then press the # button. The opener light blinks once. |

- Test by pressing in the temporary P N you just programmed, and then press the ENTER button. The garage door opener activates. The test uses up one Clear the temporary PIN by repeating steps 1 through 4, and set the number of hours or openings to 0 at step 3.

CHANGE AN EXISTING PIN*

- Enter the programmed PIN you want to change.

- Press and hold the # button until the garage door opener light blinks twice.

- Enter the new 4-digit PIN of your choice and press the ENTER button. The opener light will blink once.

- Test by entering the PIN you just programmed, and then press the ENTER The garage door opener will activate.

*You cannot change an existing PIN for an opener with a green LEARN button or an external receiver. You MUST repeat ‘Program the Initial PIN’ to change the PIN number.

ERASE ALL REMOTE CONTROL AND KEYLESS ENTRY PROGRAMMING FROM THE OPENER

The following steps will erase ALL remote controls and any keyless entries from your opener.

- Press and hold the LEARN button on the garage door opener until the Learn LED turns off (approximately 6 seconds).

- Test by pressing the buttons on the remote control and keyless entry to ensure they no longer activate the opener.

- Follow programming steps to reprogram each remote control and keyless entry you wish to use.

For more information and support, go to: support.chamberlaingroup.com.

REPLACE THE BATTERY

WARNING

WARNING

To prevent possible SERIOUS INJURY or DEATH:

- NEVER allow small children near batteries.

- If the battery is swallowed, immediately notify the doctor.

Replace the battery when the keypad becomes dim or does not light after a button is pressed. Slide the cover-up, remove the battery cover, and replace the battery. Dispose of the old battery properly.

ONE YEAR LIMITED WARRANTY

The Chamberlain Group, Inc. warrants to the first consumer purchaser of this product that it is free from defects in materials and/or workmanship for a period of 1 year from the date of purchase.

NOTICE: This device complies With part 15 of the FCC rules and Innovation, Science and Economic Development Canada license-exempt RSS. Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

My changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment

This device must be installed to ensure a minimum 20 cm (8 in.) distance is maintained between users/bystander rs and the device.

This device has been tested and –found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC rules and Industry Canada ICES standard. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy and, it not installed and used in accordance with the instructions may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment of and on, the user is encouraged to try to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/technician for help.

For more information, please visit www.devancocanada.com or call toll free at 855-931-3334

HOW TO ORDER REPAIR PARTS

DEVANCO CANADA

19192 HAY ROAD, UNIT Q SUMMERSTOWN, ON K0C 2E0

TOLL-FREE: 855-931-3334

www.devancocanada.com

WHEN ORDERING REPAIR PARTS PLEASE SUPPLY THE FOLLOWING INFORMATION:

√ PART NUMBER

√ DESCRIPTION

√ MODEL NUMBER

How do I program my LiftMaster Wireless Keyless Entry?

LiftMaster Wireless Keyless Entry is programmed by using the Learn Button on the garage door opener. Press and hold the Learn Button for 5 seconds. Release button. The LED will flash rapidly, indicating that it is ready to learn.

Can I use my LiftMaster Wireless Keyless Entry with a LiftMaster garage door opener?

Yes, as long as your garage door opener was manufactured after January 1, 1993.

How many codes can I program on my LiftMaster Wireless Keyless Entry?

You can program up to 4 codes on the LiftMaster Wireless Keyless Entry. Each code can be used to operate one garage door or gate opener.

How do I change the code on my LiftMaster Wireless Keyless Entry?

To change the code, press and hold the Learn Button for 5 seconds. Release button. The LED will flash rapidly, indicating that it is ready to learn. Press and release any button on the keypad to change the code. Repeat until you have entered a new code for each button you want to change. When finished, press and hold any button for 2 seconds to save new code(s). The LED will flash once per second, indicating that it has saved new code(s). If you want to erase all of your codes at once, press and hold any button for 5 seconds until the LED flashes twice per second (approximately 10 seconds). The keypad will then be in programming mode and all codes will be erased when a new code is programmed into any button(s).

Where is the Learn button on my LiftMaster?

Learn buttons that are red, orange, green or purple will be large, square buttons located under the light lens on the back panel of your garage door opener. To program a new garage door remote, press and quickly release your learn button to trigger the machine’s programming mode

How do you program a wireless garage door opener?

Hold the star and hash tag buttons until the lights on the keypad begin to flash. And then stop flashing do not pause longer than five seconds between keystrokes.

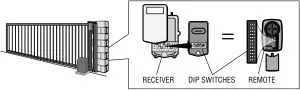

What if my garage door opener doesn’t have a Learn button?

If there is no learn button, examine the inside of the old remote by popping the back off of it. If there is a series of small switches, only big enough to be slid one way or another by the end of a pencil, you have a DIP switch unit. Make sure you purchase a universal remote with internal DIP switches

How do I reset my garage door keypad without learning button?

Remove the cover from the garage door opener remote control to reveal the switches within. What is this? Press the * and # pound button at the same time followed by red light blinking a couple of times. Once the blinking light stops the password has been reset

How do I connect to Liftmaster to WiFi?

Inside your garage your wi-fi password. And then you’ll want to enable bluetooth on your phone. And you’ll also need to enable location.

What is yellow button on LiftMaster?

Notes: Openers with a GREEN, RED, ORANGE or PURPLE learn/program button stay in accessory programming mode the 30 seconds, after 30 seconds the learn/program LED will turn off. Units with a YELLOW learn/program button stay in accessory programming mode for up to 3 minutes

Can I open my LiftMaster garage door with my phone?

You can, when you buy a brand new garage door opener from LiftMaster that has MyQ® technology. With a mere touch of your finger, you can open and close your garage door from anywhere in the world, using your Apple, Blackberry or Android phone.

How do I sync my garage door opener to my phone?

Connect with Android mobile device

Tap Garage Door Opener with Wi-Fi Ceiling Installed on the Device Setup screen. Review information on the What You Need screen and then tap Next. Note: Tap each checkbox after you review the information. You can then tap I’m Ready to continue.

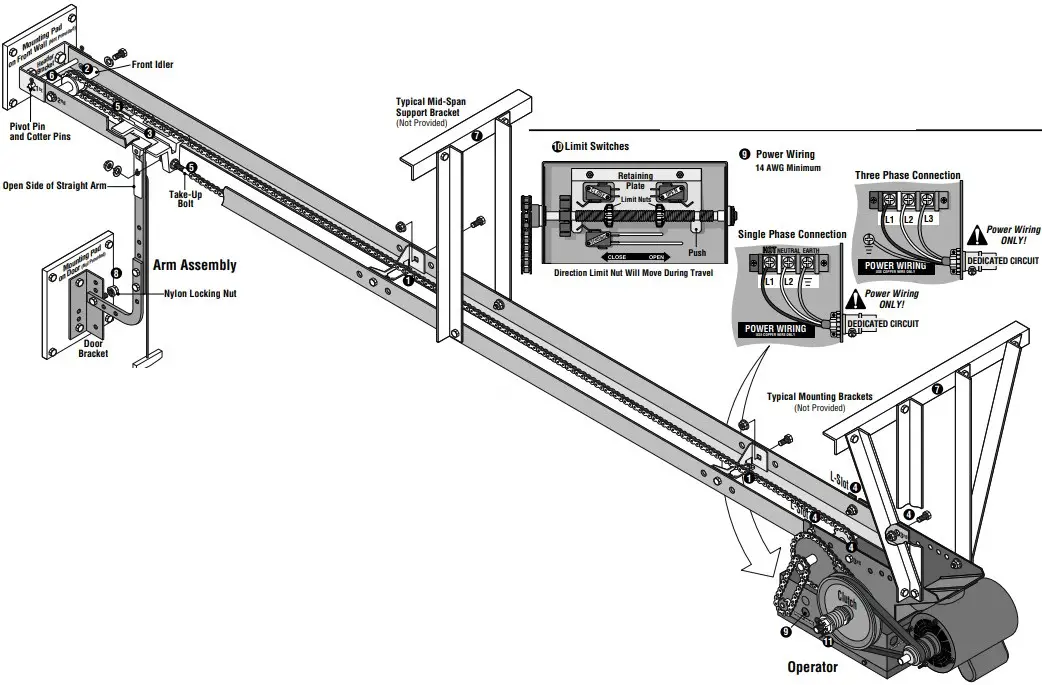

LiftMaster INSL24UL Sliding-Gate Opener

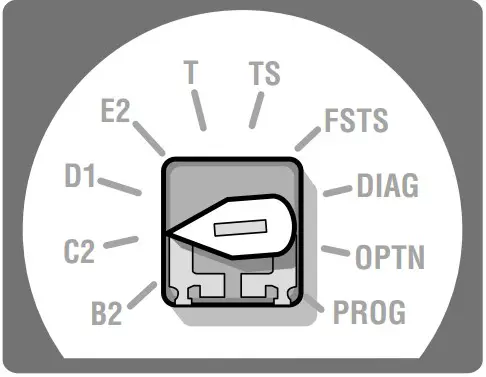

Adjust the Limits

After both limits are set and the operator is ready to run, one limit can be adjusted independently from the other by following steps 1-3 of the Initial Limit and Force Adjustment section.

After any limit adjustment:

- Cycle the gate open and close to automatically relearn the forces.

- Perform the Obstruction Test,

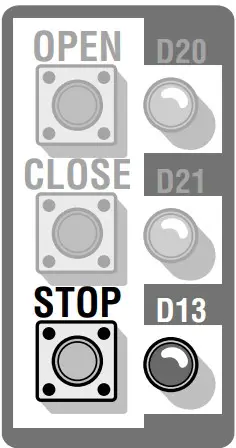

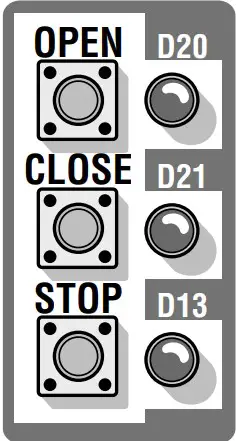

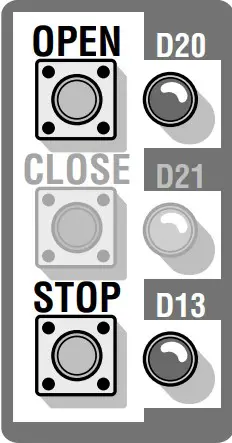

Obstruction Test

The operator is equipped with an inherent (built in to the operator) obstruction sensing device. If the gate encounters an obstruction during motion, the operator will reverse direction of the gate and then stop. The following procedure will test ONLY the inherent (built in to the operator) obstruction sensing device:

- Open and close the gate with the TEST BUTTONS, ensuring that the gate is stopping at the proper open and close limit positions.

- Either place an object between the open gate and the fixed closed catch post or obstruct the gate by hand. Make sure that any external entrapment protection devices, such as an edge or photoelectric sensor will NOT be activated by the object or by hand.

- Run the gate in the close direction. The gate should stop and reverse upon contact with the object or hand. If the gate does not reverse, reduce the force setting by turning the force control slightly counter-clockwise. The gate should have enough force to reach both the open and close limits, but MUST reverse after contact with an object or hand.

- Repeat the test for the open direction.

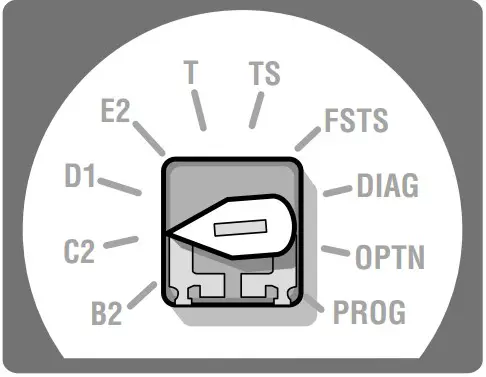

PROGRAMMING

Remote Controls (Not Provided)

A total of 50 Security+ 2.0® remote controls or KPW250 keypads and 2 keyless entries (1 PIN for each keyless entry) can be programmed to the operator. When programming a third keyless entry to the operator, the first keyless entry will be erased to allow the third keyless entry to be programmed. When the operator’s memory is full it will exit the programming mode and the remote control will not be programmed. The memory will need to be erased before programming any additional remote controls. NOTE: If installing an 86LM to extend the range of the remote controls DO NOT straighten the antenna.

There are 3 different options for programming the remote control depending on how you would like the remote control to function. Choose a programming option:

The operator will automatically exit learn mode (operator will beep and green XMITTER LED will go out) if programming is successful. To program additional Security+ 2.0® remote controls or remote control buttons, repeat the programming steps above.

| OPTION | DESCRIPTION | PROGRAMMING STEPS |

| Single button as OPEN only | Program a single button on the remote control for open only. The Timer-to-Close can be set to close the gate. | 1. Press and release the LEARN button (operator will beep and green XMITTER LED will light). NOTE: The operator will time out of programming mode after 30 seconds.

2. Press the OPEN button. 3. Press the remote control button that you would like to program. |

| Single button (SBC) as OPEN, CLOSE, and STOP | Program one remote control button as an open, close, and stop. | 1. Press and release the LEARN button (operator will beep and green XMITTER LED will light). NOTE: The operator will time out of programming mode after 30 seconds.

2. Press the remote control button that you would like to program. |

| Three separate buttons as OPEN, CLOSE, and STOP | Program each remote control button as an open, close, and stop. | 1. Press and release the LEARN button (operator will beep and green XMITTER LED will light). NOTE: The operator will time out of programming mode after 30 seconds.

2. Press the OPEN, CLOSE, or STOP button, depending on the desired function. 3. Press the remote control button that you would like to program. |

Entering programming mode using external reset button or 3-button control station:

- Make sure gate/door is closed.

- Give the operator an OPEN command.

- To put the operator into high band programming mode, give the operator an OPEN command. Within 30 seconds, when the gate is at the open limit, press the reset button three times or push the button on the control station three times. NOTE: The operator will time out of programming mode after 30 seconds.

Fcc Rules

NOTICE: This device complies with Part 15 of the FCC rules and Industry Canada’s license-exempt RSSs. Operation is subject to the following two conditions:

- this device may not cause harmful interference,

- this device must accept any interference received, including interference that may cause undesired operation.

Any changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment. This device must be installed to ensure a minimum 20 cm (8 in.) distance is maintained between users/bystanders and device. This device has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC rules and Industry Canada ICES standard. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

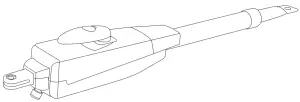

LA400EV

Automatic Gate Opener*

*For GB (UK, NI) specific information on national regulations and requirements see English part of the manual.

NOTE: The original installation and operating instructions were compiled in Germany. Any other available language is a translation of the original Germany version.

General Safety Guidelines

![]() This safety alert symbol means „Caution“ – failure to comply with such instruction involves risk of personal injury or damage to property.Please read these warnings carefully.

This safety alert symbol means „Caution“ – failure to comply with such instruction involves risk of personal injury or damage to property.Please read these warnings carefully.

![]() This gate drive mechanism is designed and tested to offer appropriately safe service provided it is installed and operated in strict accordance with the following safety rules. Incorrect installation and/or failure to comply with the following instructions may result in serious personal injury or property damage.

This gate drive mechanism is designed and tested to offer appropriately safe service provided it is installed and operated in strict accordance with the following safety rules. Incorrect installation and/or failure to comply with the following instructions may result in serious personal injury or property damage.

![]() When using tools and small parts to install or carry out repair work on a gate exercise caution and do not wear rings, watches, or loose clothing.

When using tools and small parts to install or carry out repair work on a gate exercise caution and do not wear rings, watches, or loose clothing.

![]() Installation and wiring must be in compliance with your local building and electrical installation codes. Power cables must only be connected to a properly earthed supply.

Installation and wiring must be in compliance with your local building and electrical installation codes. Power cables must only be connected to a properly earthed supply.

![]() Any entrapment possibility by the moving wing between wing & walls must be secured with safety edges or IR sensors.

Any entrapment possibility by the moving wing between wing & walls must be secured with safety edges or IR sensors.

![]() Please remove any locks fitted to the gate in order to prevent damage to the gate.

Please remove any locks fitted to the gate in order to prevent damage to the gate.

![]() After the installation, a final test of the full function of the system and the full function of the safety devices must be done.

After the installation, a final test of the full function of the system and the full function of the safety devices must be done.

![]() This drive cannot be used with a gate incorporating a wicket door unless the drive cannot be operated with the wicket door open.

This drive cannot be used with a gate incorporating a wicket door unless the drive cannot be operated with the wicket door open.

![]() It is important to make sure that the gate always runs smoothly. Gates that stick or jam must be repaired immediately. Employ a qualified technician to repair the gate, never attempt to repair it yourself.

It is important to make sure that the gate always runs smoothly. Gates that stick or jam must be repaired immediately. Employ a qualified technician to repair the gate, never attempt to repair it yourself.

![]() Keep additional accessories away from children. Do not allow children to play with pushbuttons or remote controls. A gate can cause serious injuries as it closes.

Keep additional accessories away from children. Do not allow children to play with pushbuttons or remote controls. A gate can cause serious injuries as it closes.

![]() Disconnect electric power to the system before making repairs or removing covers. A disconnecting device must be provided in the permanently-wired installation to guarantee all-pole disconnection by means of a switch (at least 3mm contact gap) or by a separate fuse.

Disconnect electric power to the system before making repairs or removing covers. A disconnecting device must be provided in the permanently-wired installation to guarantee all-pole disconnection by means of a switch (at least 3mm contact gap) or by a separate fuse.

![]() Make sure that people who install, maintain or operate the gate drive follow these instructions. Keep these instructions in a safe place so that you can refer to them quickly when you need to.

Make sure that people who install, maintain or operate the gate drive follow these instructions. Keep these instructions in a safe place so that you can refer to them quickly when you need to.

![]() The full protection against potential squeeze or entrapment must work directly when the drive arms are installed.

The full protection against potential squeeze or entrapment must work directly when the drive arms are installed.

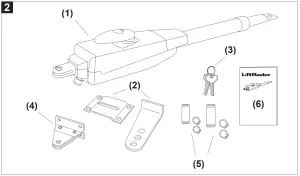

Content

- Motor LA400EV (1x)

- Postbracket (1x)

- Key (2x)

- Gate fixing bracket (1x)

- Clevis pin (2x) and rings (4x)

- Manual (1x)

BEFORE YOU BEGIN

The drive mechanism needs room to the side permitting correct installation of drive arms. Please make sure that this is available. Gates affected by high wind loads must also be protected by an (electric) lock.

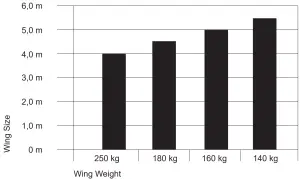

There are many factors to consider when choosing the right drive mechanism. Assuming that a gate functions properly, „startup“ is the most difficult phase, once the gate

is in motion, significantly less force is usually required to move it.

- Gate size: Gate size is a very important factor. Wind can break or distort the gate, thereby increasing the amount of force needed to move it considerably.

- Gate weight: The weight of the gate in not as relevant as the size.

- Effect of temperature: Low outdoor temperatures can make initial startup more difficult (changes in the ground, etc.) or even prevent it.

- Duty cycle: 24-volt drives can run permanently.

INSTALLATION CHECKLIST – PREPARATIONS

Check the carton contents and read the instructions carefully. Make sure your gate equipment operates perfectly. The gate must run evenly and smoothly and must not stick at any point. Remember that the ground level may be several centimeters higher in winter. The gate must be stable and as free of backlash as possible in order to prevent any unwanted to and fro movement. The more smoothly the gate leaf runs, the more sensitive the force adjustment must be.

Note down any materials you still need and obtain them before starting to install. Heavy-duty plugs, bolts, gate stops, cables, distribution boxes, tools, etc.

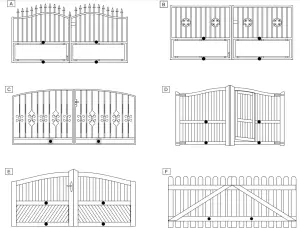

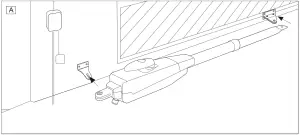

Gate Types

The gate type determines the location where the drive mechanism is installed. If the gate stop is on the ground, the drive mechanism must also be installed at a height that is as low as possible so that it cannot twist the gate. Use only parts of the gate frame for fixing purposes.

TYPE A, B, C

For steel gates, the gate fitting must be attached to the mainframe. If you are uncertain whether the available support is sufficiently stable, reinforce it.

TYPE D, E, F

In the case of wooden gates, the gate fitting must be through-bolted. It is advisable to fit a plate from the outside so that the fixing brackets cannot become loose over time. Thin wooden gates must also be reinforced in order to withstand the stresses encountered (e.g. type F).

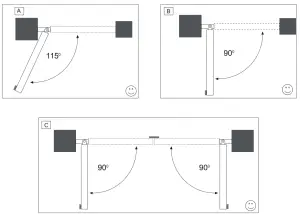

Gate Configuration

How far must the gate leaf open?

90 degrees or up to 115 degrees. An opening angle in excess of 115 degrees is possible to a limited extent but is not recommended. Reason: the drive mechanism always

runs at the same speed. The further the gate has to be opened, the faster the gate leaf must travel. Movement becomes more erratic and this subjects the fittings and gate to

extreme stresses.

For gates without limit switches: Non-identical opening angles cause one drive mechanism to reach its destination first, but continue to run, thereby forcing the gate up against the gate stop until the other motor eventually reaches its end position (see figure 4A-F).

Tip for professionals: The time taken to reach the limit stop can be controlled by deliberately selecting different A and B dimensions (left + right). However, this method of installing subjects the fittings to high stresses and can cause the gate to run erratically. It is recommended that only experienced gate installers adopt this method.

NOTE: If the gate opens towards a wall, there is a risk of entrapment. Should the distance between the wall and the open gate be less than 200 mm, this area must later be secured via a light barrier or contact strip.

Gate Stops

It is advised to use a fixed gate stop in both the open and close directions. Gate stops save wear and tear on the drive mechanism, gate, and fittings. Operating a gate without fixed limit stops results in poor performance. It is often dangerous, leads to premature wear, and voids your warranty!

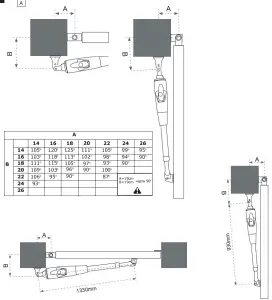

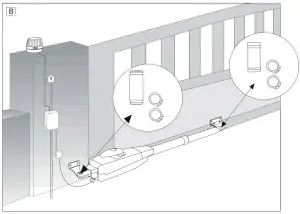

Post Fixing Bracket

Choosing the correct location for the post-fixing bracket has a decisive impact on the subsequent functioning of the system. It determines the distance between the motor‘s entre of motion and the gate‘s center of motion and hence the opening angle. These dimensions are referred to as dimension A and dimension B. Do not underestimate the effect that these dimensions have on correct functioning and running. Try and achieve the best dimension for your opening angle, as precisely as possible and suitable for all

circumstances.See Table (figure 5A) for dimensionsA/B.

If the post is not wide enough, an extension piece must be fitted to it (figure 6B). If the post is too thick, cut out part of it to make it thinner (figure 6D)or offset the gate (figure 6C).

To obtain ideal dimensions, it may be necessary to shorten or lengthen the supplied hinge plate. In the case of gates that are to be custom made, if the gate hinges are fitted on the posts appropriately, it is possible to influence dimensions A and B. Before the final mounting dimensions are determined, you should always check whether or not there is any possibility that the corner of the drive mechanism will hit the post as the gate swings.

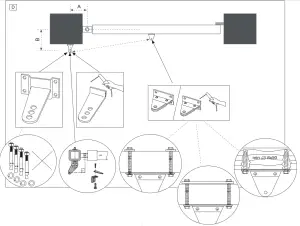

INSTALLATION: The drive mechanism exerts a considerable force against the post. Usually, acceptable mounting dimensions are obtained if the supplied hinge plate is welded directly onto the post. In the case of thick stone or concrete posts, the hinge must be welded to a base plate and attached so that the plugs cannot work loose during operation. Heavy-duty plugs where a threaded rod is bonded into the masonry stress-free are more suitable for this purpose than steel or plastic straddling plugs. In the case of brickwork pillars, bolt on a relatively large steel plate that covers several bricks and then welds the hinge plate to it. An angle plate attached over the corner of the post is also a good means of fixing the operators.

Gate Fitting

The gate fitting must be installed so that it is horizontal relative to the post bracket. The distance between the gate bracket and post bracket is referred to as the „arm span“. When the gate is closed, the drive mechanism is 99% extended. When the gate is opened, the drive mechanism is 1% extended. Fully retracting or extending the lunger/spindle in operation (with gate) damages the drive mechanism and voids the warranty. It is absolutely imperative to comply with the required arm span under all circumstances! For steel gates, fixings should be welded on or through-bolted. When bolting the gate, use large washers or a plate on the other side. The drive mechanism exerts an extremely high force on this joint. Fixings must be through-bolted for wooden gates. Wood deflects under load and the bolt will become loose. Due to movement caused by repeated loading, the wood deflects more and more until the gate no longer closes correctly and has to be repaired. Fit a reinforcing plate from the outside and one on the inside so that the wood cannot deflect and the joint cannot become loose. Thin wooden gates without a metal frame must also be reinforced in order to withstand continuous stresses (e.g. type F).

Release

The drive mechanism can be released. The gate can then be opened and operated manually (power failure). With a new drive mechanism, the release action may sometimes feel stiff/jerky. This is normal and has no effect on function.

Release: Insert the key in the cylinder lock and turn it 180 degrees. Then turn the release lever 180 degrees – done!

Engage: Turn the lever glockwise. As soon as the gate moves or the drive runs, the gear locks again. Use the lock to protect the liver against unauthorized release.

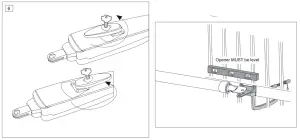

Installing The Drive Arm

Release the drive. Push the released drive onto the fittings and secure it by using the supplied bolts, nuts, and rings. „If the center or inner hole, on the hinge plate, is used to fix the post fixing bracket you MUST cut away the remaining section of the hinge plate before activating the arms. Failure to do so will result in breaking the fixing bracket“. Do not use a hammer when you mount the operator on the bracket.

Wiring

The connecting cable has 6 wires, is approx. 3 m long and is run in a curve to the control unit or to a watertight distribution box located above ground. A permanent connection is formed from the distributor box via an appropriate cable.

Connection: See control unit instructions.

Cable colors: Brown/Green/White/Yellow=sensors

Blue/Red: 24-volt motor.

ACCESSORY TIP: Extension cable LA400-JB40

Contains:

(1) 12m cable with terminals

(1) Distribution box IP65

(2) Strain relief PG 13,5

(1) Mounting material

Initial Operation

Check functionality in a disengaged state with the hand on the gate. Initial electrical operation is only possible with a suitable control unit that can be purchased as accessory. Ensure at all times that mechanical and electrical safety instructions applying to the given installation are complied with.

Should the force of the moving wing at its closing edge be higher than 400N, then additional safety facilities (light barrier, contact strip) must be used. Any safety facilities must comply with the requirements set out in EN60335-2-103

Maintenance Work

The drive mechanism is maintenance-free. Check that the gate fittings and the drive mechanism are securely fixed at regular intervals (monthly). Release the drive and check that the gate functions properly. Unless the gate runs smoothly it will not operate correctly with the drive mechanism. The drive cannot eliminate the problems caused by a gate that does not work satisfactorily.

NOTE: also see owners manual of Electronic Control

Disposal

Our electrical and electronic equipment may not be disposed of with household waste and must be disposed of after use properly in accordance with WEEE Directive EU: 2012/19/ EU; GB UK(NI): SI 2012 nr.9 on waste electrical and electronic equipment in order to ensure that materials are recycled. Collecting waste electrical equipment separately means environmentally-friendly disposal and is completely free of charge for the consumer.WEEE Reg. no. in Germany: DE66256568. Any waste packaging leftover with the end consumer must be collected separately from mixed waste, in accordance with the Directive. Packaging may not be disposed of with household waste, organic waste, or in nature. Packaging material must be separated according to its material and disposed of in the recycling containers provided and in certain council recycling bins.

Our electrical and electronic equipment may not be disposed of with household waste and must be disposed of after use properly in accordance with WEEE Directive EU: 2012/19/ EU; GB UK(NI): SI 2012 nr.9 on waste electrical and electronic equipment in order to ensure that materials are recycled. Collecting waste electrical equipment separately means environmentally-friendly disposal and is completely free of charge for the consumer.WEEE Reg. no. in Germany: DE66256568. Any waste packaging leftover with the end consumer must be collected separately from mixed waste, in accordance with the Directive. Packaging may not be disposed of with household waste, organic waste, or in nature. Packaging material must be separated according to its material and disposed of in the recycling containers provided and in certain council recycling bins.

Technical Data

| Motor Voltage | 24 Volt |

| Current consumption | 2:00 AM |

| Power consumption | 48 W |

| Max. gate width | 4,0 m |

| Max. gate weight | 250 kg |

| Protection Class | I – IP44 |

| Force (nominal) | 250 N |

| Travel Speed | variable |

| Opening time 90° | 14 sec. |

| Temperature | -20°C to + 55°C |

http://www.liftmaster.eu

Chamberlain GmbH

Saar-Lor-Lux-Str. 19

66115 Saarbrücken

Germany

WEEE-Reg.Nr. DE66256568

www.liftmaster.eu

[email protected]![]()

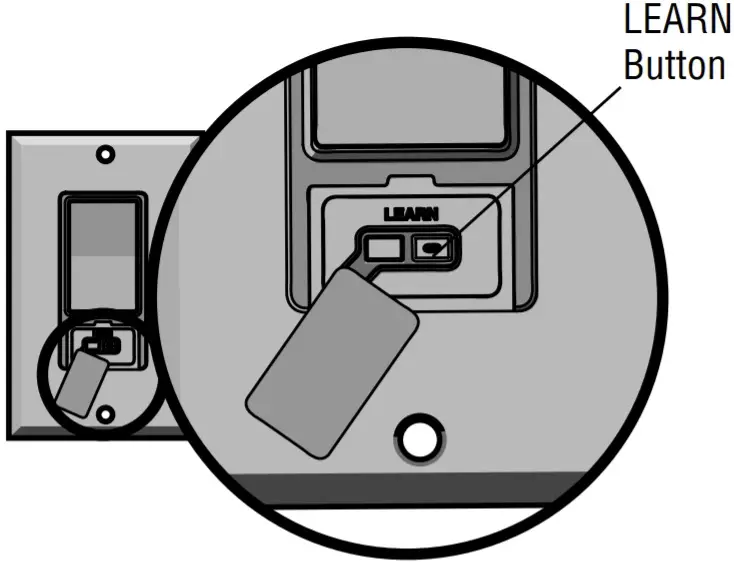

LiftMaster 387LM Universal Wireless Keyless Entry Garage Door Keypad

Read instructions thoroughly BEFORE beginning. Start with the garage door closed. Determine garage door opener type-Smart/Learn button or DIP Switch. The Smart/Learn button or DIP Switches are located on the motor unit or external receiver. Refer to the owner’s manual if necessary. LiftMaster products are intended to be used only with garage door openers manufactured after 1993 that utilize photo-eyes safety sensors. These are always located on or near the bottom of the door track. If your garage door does not have the sensors attached and working, the opener is not compliant with current federal safety regulations and should be replaced.

WARNING

To prevent possible SERIOUS INJURY or DEATH from a moving gate or garage door:

- ALWAYS keep remote controls out of reach of children. NEVER permit children to operate, or play with remote controls.

- Activate gate or door ONLY when it can be seen clearly, is properly adjusted and there are no obstructions to door travel.

- ALWAYS keep the gate or garage door in sight until completely closed. NEVER permit anyone to cross the path of a moving gate or door.

- This product can expose you to chemicals including lead, which is known to the State of California to cause cancer or birth defects, or other reproductive harm. For more information go to www.P65Warnings.ca.gov

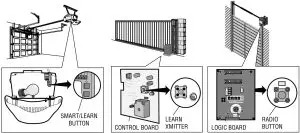

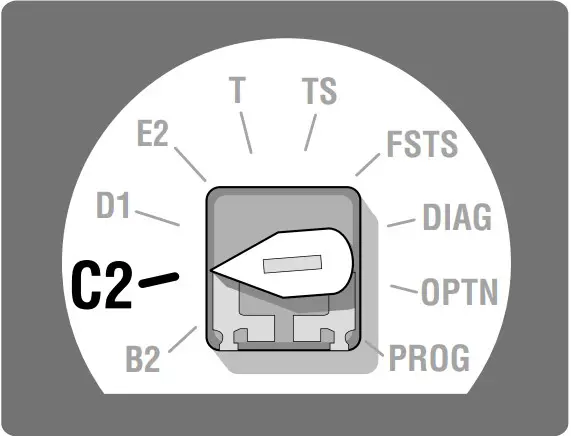

Determine Garage Door Opener Types:

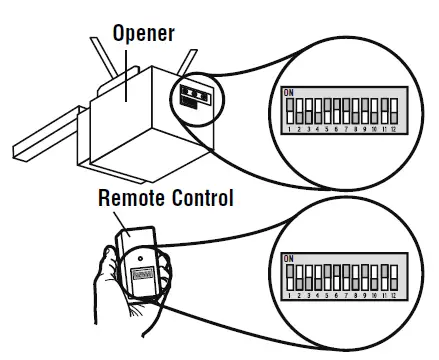

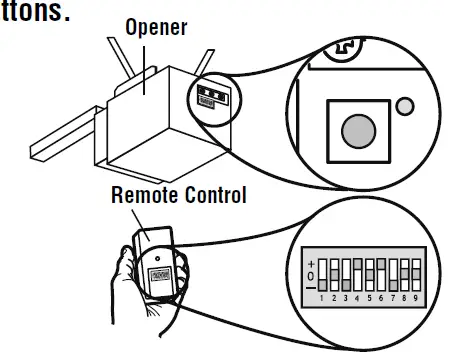

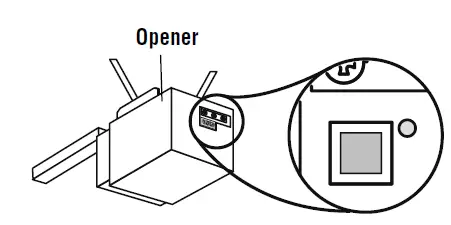

Proceed with instructions according to your garage door opener type. NOTE: Your motor unit and/or remote control may look different.

TYPE 1

Chamberlain, Sears Craftsman, LiftMaster, Master Mechanic and Do It garage door openers or receivers with 3 position DIP switches.

TYPE 2

Genie, Linear, and Moore-O-Matic garage door openers or receivers with 2 position DIP switches.

TYPE 3

Chamberlain, Sears Craftsman, LiftMaster, Master Mechanic and Do It garage door openers or receivers with Yellow, white or grey Smart/Learn buttons.

TYPE 4

Chamberlain, Sears Craftsman, LiftMaster, Master Mechanic, Do It, Genie Intellicode, Overhead Door, Stanley, Wayne Dalton or Linear garage door openers with

Smart/Learn button

Programming

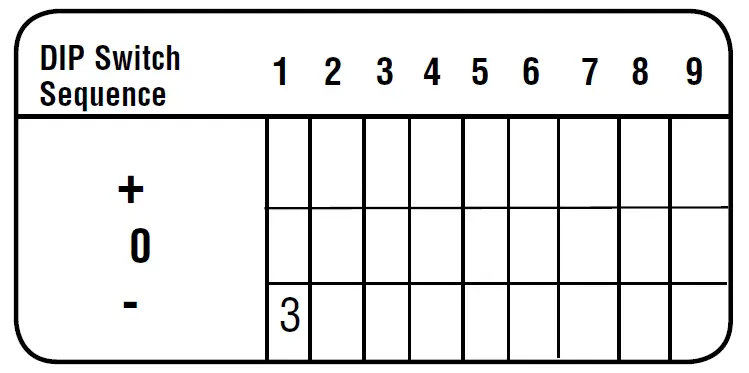

TYPE 1

- Select and write a 4-digit PIN

- Determine your opener ID using the list below. ID DIP Switch Type

- 11 = 9 DI P switch garage door openers (U.S.)

- 12 = 9 DIP switch garage door openers (Canada)

- 15 = 8 DIP switch garage door openers

- 19 = 7 DIP switch garage door openers (Write opener ID here: __ __)

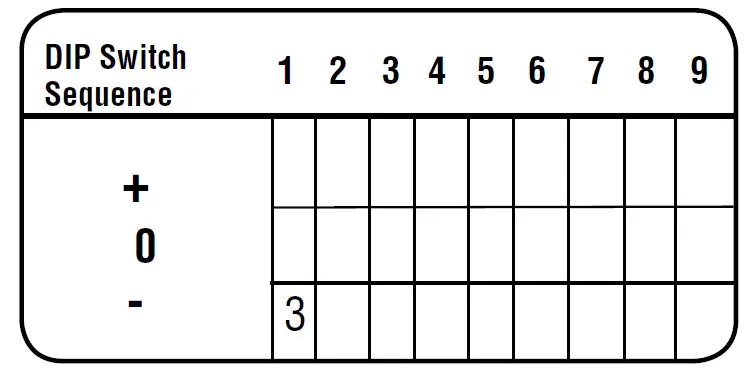

- 3. The first DIP switch must be set to the “-” position on your remote and opener. Record your DIP switch sequence for the remaining DIP switches. If the

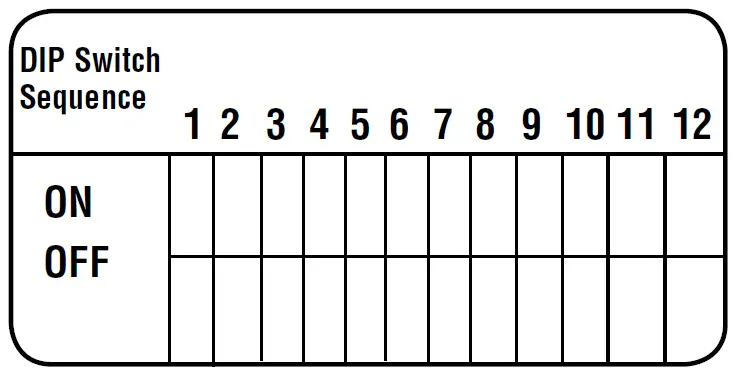

DIP switch is in the “+” position place a 1, “0” position place a 2, “-” position place a 3 in the corresponding box in the chart below:

NOTE: Leave any unused switch locations blank. Write your DIP switch sequence below:

Write your DIP switch sequence below:

- Press and # keys together until the keypad stops flashing.

- Enter the PIN from step 1, and press #.

- Enter the ID from step 2, and press #.

- Enter the DIP switch sequence from step 3 and press the # key.

- To test and use, wait until the lights turn off, enter your PIN and press the 0 key. If the opener does not function, repeat programming.

TYPE 2

- Select and write a 4-digit PIN:

- Determine your opener ID using the list below. ID DIP Switch Type

- 13 = 12 DIP switch Genie garage door openers

- 14 = 10 DIP switch Linear garage door openers

- 16 = 10 DIP switch Stanley garage door openers

- 17 = 9 DIP switch Genie garage door openers

- 18 = 8 DIP switch Linear, Moore-O-Matic garage door openers (Write opener ID here: __ __)

- Record your DIP switch sequence. If the DIP switch is in the “on” or “up” position place a 1, “off” or “down” position place a 2 in the corresponding box in the chart below:

NOTE: Leave any unused switch locations blank.

Write your DIP switch sequence below:

- Press * and # keys together until the keypad stops flashing.

- Enter the PIN from step 1, press #

- Enter the ID from step 2, and press #.

- Enter the DIP switch sequence from step 3 and press the # key.

- To test and use, wait until the lights turn off, enter your PIN and press the 0 key.

- If the opener does not function, flip DIP switches, so if a switch is “on” or “up” flip it “off” or “down” in step 3.

TYPE 3

- Select and write a 4-digit PIN:

- 2. Your opener ID is 11.

- Record your DIP switch sequence. Set your first DIP switch to “-”, your first DIP switch must be set to the “-” position on your remote and opener. If the DIP switch is in the “+” position place a 1, “0” position place a 2, “-” position place a 3 in the corresponding box in the chart below:

NOTE: Leave any unused switch locations blank.

Write your DIP switch sequence below:

- Press * and # keys together until the keypad stops flashing.

- Enter the PIN from step 1, and press #.

- Enter 11, press #.

- Enter the DIP switch sequence from step 3press #.

- Press and release the Smart/Learn button on the garage door opener.

- Enter your 4-digit PIN and press the 0 key.

- To test and use, wait until the light turns off, enter your PIN and press the 0 key. If the opener does not function, repeat programming.

TYPE 4

- Select and write a 4-digit PIN:

- Determine your opener ID using the list below.ID Garage door opener brand and manufacturing dates

- 1 = Linear garage door openers manufactured from 1997 to the present.

- 2 = Chamberlain, Sears Craftsman LiftMaster, Master Mechanic, and Do It garage door openers manufactured from 1997 to 2004 [Orange Button].

- 3 = Chamberlain, Sears Craftsman, LiftMaster, Master Mechanic, and Do It garage door openers manufactured from 2005 to the present [Purple Button].

- 4 = Chamberlain, Sears Craftsman, LiftMaster, Master Mechanic, and Do It garage door openers manufactured from 1993 to 1996 [Green Button].

- 5 = Genie Intellicode and Overhead Door garage door openers manufactured from 2005 to the present (315 MHz).

- 6 = Genie Intellicode and Overhead Door garage door openers manufactured from 1995 to the present (390 MHz).

- 7 = Stanley garage door openers manufactured in 1998-present.