INSTRUCTION MANUAL

24/26 inch Two Stage Gas Snow Thrower

Model # PSSAM24BS/PSS2260BS

|

PROBLEMS? QUESTIONS? DO NOT RETURN TO THE STORE CALL OUR CUSTOMER HELPLINE (800)791-9458 Mon-Fri 9-5 EST |

Have product questions or need technical support? Please feel free to contact us!

Website: www.PowerSmartUSA.com

Toll free: 1-800-791-9458 Mon-Fri 9-5 EST

Email: [email protected]

TECHNICAL DATA

| 24-inch Two-Stage Electric Start Snow Thrower | 26-inch Two-Stage Electric Start Snow Thrower | |

| Model # | PSSAM24BS | PSS2260BS |

| Engine: | 208cc snow engine | 250cc snow engine |

| Engine oil Capacity: | 20.29 fl. oz | 20.29 fl. oz |

| Fuel Tank Capacity: | 0.8 Gallon | 0.71 Gallon |

| Start System: | 120V Electric / Recoil | 120V Electric / Recoil |

| Clearing Width: | 24 in. | 26 in. |

| Clearing Height: | 20 in. | 20 in. |

| Chute Rotation Angle: | 180° | 180° |

| Speed: | Forward&Reverse | Forward&Reverse |

| Tire Size: | 13 in. snow tire | 13 in. snow tire |

| Overall Dimensions: | 32.3×24.8×23.63in. | 31.9×27.2x24in. |

| Weight: | 147.731bs | 147.91bs |

Thank you for purchasing PowerSmart products.

It is crucial and highly recommended that you read this instruction manual in its’ entirety, as this is an invaluable tool and reference point in understanding the operation of your unit.

Please register your unit online at www. Amerisuninc.com. This process will allow us to track your warranty information and update our records regarding your unit accordingly.

Important: Our company does not provide email or personal information to any third party for any reason. For any questions check our website or call customer service at (800)791 9458.

INTRODUCTION,

Thank you for purchasing a PowerSmartt Product. This manual provides detailed information regarding the safe operation and maintenance of this product. Every effort has been made to ensure the accuracy of the information in this document. PowerSmartt reserves the right to change this product and specifications at any time without prior notice.

Please keep this manual available to all users during the entire life of the product.

This manual contains special messages to bring attention to potential safety concerns, product damage as well as helpful operating and servicing information. Please read all the information carefully to avoid injury and machine damage.

This manual contains special messages to bring attention to potential safety concerns, product damage as well as helpful operating and servicing information. Please read all the information carefully to avoid injury and machine damage.

QUESTIONS? PROBLEMS?

To answer questions and resolve issues in the most efficient and timely manner, please contact Customer Service at (800) 791-9458, Mon-Fri 9 am-5 pm EST or email: [email protected].

NOTICE REGARDING EMISSIONS

Engines that are certified to comply with U.S. EPA emission regulations for SORE (Small Off-Road Equipment), are certified to operate on regular unleaded gasoline and may include the following emission control systems: (EM) Engine Modifications and (TWC) Three-Way Catalyst (if so equipped).

SAFETY INFORMATION

This symbol points out important safety instructions which, if not followed, could endanger the personal safety and or property of yourself and others. Read and follow all instructions in this manual before attempting to operate this machine. Failure to comply with these instructions may result in personal injury.

This symbol points out important safety instructions which, if not followed, could endanger the personal safety and or property of yourself and others. Read and follow all instructions in this manual before attempting to operate this machine. Failure to comply with these instructions may result in personal injury.

WARNING! This machine was built to be operated according to the safe operation practices in this manual. As with any type of power equipment, carelessness or error on the part of the operator can result in serious injury. This machine is capable of amputating fingers, hands, toes, and feet and throwing foreign objects. Failure to observe the following safety instructions could result in serious injury or even a fatal occurrence.

WARNING! This machine was built to be operated according to the safe operation practices in this manual. As with any type of power equipment, carelessness or error on the part of the operator can result in serious injury. This machine is capable of amputating fingers, hands, toes, and feet and throwing foreign objects. Failure to observe the following safety instructions could result in serious injury or even a fatal occurrence.

It is your responsibility to restrict the use of this power machine to persons who read, understand, and follow the warnings and instructions in this manual and on the machine.

ROTATING PARTS! Only use a clean-out tool to clear blockages. NEVER use your hands.

ROTATING PARTS! Only use a clean-out tool to clear blockages. NEVER use your hands.

NEVER direct discharge towards persons or property that may be injured or damaged by thrown objects.

NEVER direct discharge towards persons or property that may be injured or damaged by thrown objects.

Keep people away from the unit while operating. Keep children out of the work area and under the watchful care of a responsible adult.

Keep people away from the unit while operating. Keep children out of the work area and under the watchful care of a responsible adult.

TRAINING

Read, understand, and follow all instructions on the machine and in the manual(s) before attempting to assemble and operate. Keep this manual in a safe place for future and regular reference.

- Be familiar with all controls and their proper operation. Know how to stop the machine and disengage them quickly.

- Never allow children under 14 years of age to operate this machine. Children 14 and over should read and understand the instructions and safe operation practices in this manual and on the machine and be trained and supervised by an adult

- Never allow “non-trained” adult personnel to operate this machine without proper instruction.

- Thrown objects can cause serious personal injury. Plan and map out your snow-throwing pattern to avoid discharge of material toward roads, bystanders, and the like.

- Keep bystanders, pets, and children at least 75 feet from the machine while it is in operation. Stop the machine if anyone enters the area.

- Exercise caution to avoid slipping or falling, especially when operating in reverse.

PREPARATION

Thoroughly inspect the area where the equipment is to be used. Remove all doormats, newspapers, sleds, boards, wires, branches, and other foreign objects, which could be hazardous and damage the auger system.

- Always wear safety glasses or eye shields during operation and while performing an adjustment or

repair to protect your eyes, as thrown objects can ricochet and cause serious injury to the eyes. - Do not operate without wearing adequate, winter outer gannets. Do not wear jewelry, long scarves, or other loose clothing, which could become entangled in moving parts, and wear footwear that will improve footing on slippery surfaces.

- Use a grounded “three-wire” extension cord and receptacle for all machines with electric start

- Adjust skid shoe and/or housing height to clear gravel or crushed rock surfaces.

- Disengage all control levers before starting the engine.

- Never attempt to make any adjustments while the engine is running, except where specifically recommended in the instruction manual.

- Let engine and machine adjust to outdoor temperature before starting to clear snow.

PERSONAL SAFETY

- Engine exhaust and certain vehicle components contain or emit chemicals known to cause cancer, birth defects, or other reproductive harm.

- Read, understand and follow all instructions on your snow thrower unit and in this instruction manual before attempting to assemble and operate your machine.

- Keep this instruction manual in a safe place for future and regular reference. If replacement parts are needed, refer to the Panel, Chute, Frame, and Housing Diagrams and Parts’ Listings on pages 25-30.

- Stay alert, watch what you are doing, and use common sense when operating your snow thrower unit.

- Do not use your snow thrower unit while you are tired or under the influence of drugs, alcohol, A moment of inattention while operating the snow thrower may result in severe bodily injury.

- NEVER LEAVE YOUR RUNNING SNOW THROWER UNATTENDED. Stop the engine!

- Do not leave your snow thrower unit until it has come to a complete stop.

- When stepping backward, be cautious about any obstacles beneath your feet or behind you to avoid

SERVICE

- Stop the engine before making any adjustments. Check for misalignment, breakage, or binding of moving parts, and any other conditions that may affect operation.

- If damaged, have the snow thrower unit serviced by an authorized service center using only specified, manufactured replacement parts. This will ensure that the safety of the snow thrower unit is maintained.

SAFE HANDLING OF GASOLINE

To avoid personal injury or property damage use extreme care in handling gasoline. Gasoline is extremely flammable and the vapors are explosive. Serious personal injury can occur when gasoline is spilled on yourself or your clothes which can ignite, therefore wash your skin and change clothes immediately.

- Use only an approved gasoline container.

- Extinguish all cigarettes, cigars, pipes, and other sources of ignition.

- Never fuel the snow thrower unit’s engine indoors.

- Never remove the gas cap or add fuel while the engine is hot or running.

- Allow the engine to cool at least two minutes before refueling.

- Never overfill the fuel tank.

- Replace the gasoline cap and tighten securely.

- If gasoline is spilled, wipe it off the engine and equipment. Move the machine to another Wait 5 minutes before starting the engine.

- Never store the machine or fuel container inside where there is an open flame, spark, or pilot light (e.g. furnace, water heats, space heater, clothes dryer, etc.).

- Allow the machine to cool at least 5 minutes before storing.

- Never fill containers inside a vehicle or on a truck or trailer bed with a plastic liner. Always place containers on the ground away from your vehicle before filling.

- If possible, remove gas-powered equipment from the truck or trailer and refuel it on the ground.

- If this is not possible, then refuel such equipment on a trailer with a portable container, rather than from a gasoline dispenser nozzle.

- Keep the nozzle in contact with the rim of the fuel tank or container opening at all times until fueling is complete. Do not use a nozzle lock open device.

OPERATION

- Do not put hands or feet near rotating parts, in the auger impeller housing or chute assembly. Contact with the rotating parts can amputate hands and feet.

- The auger (impeller) control lever is a safety device. Never bypass its operation. Doing so makes the machine unsafe and may cause personal injury.

- The control levers must operate easily in both directions and automatically return to the disengaged (vertical) position when released.

- Never operate with a missing or damaged chute assembly. Keep all safety devices in place and

- Never run an engine indoors or in a poorly ventilated Engine exhaust containing carbon monoxide, an odorless and deadly gas.

- Do not operate the machine while under the influence of alcohol or dings.

- Muffler and engine become hot and can cause burning. Do not touch. Keep children away.

- Exercise extreme caution when operating on or crossing gravel surfaces. Stay alert for hidden hazards or traffic.

- Exercise caution when changing direction and while operating on slopes.

- Plan your snow-throwing pattern to avoid snow discharge towards windows, walls, cars, etc., thus avoiding possible property damage or personal injury caused by ricocheting debris.

- Never direct discharge at children, bystanders, and pets or allow anyone in front of the machine.

- Do not overload machine capacity by attempting to clear snow at too fast of a rate… Remember! Slow and steady operation is best to avoid clogs of snow being impelled too rapidly.

- Never operate this machine without good visibility or light. Always be sure of your footing and keep a firm hold on the handles. Walk, never run.

- Disengage power to the auger system (auger/impeller) by releasing the auger control (lever) when transporting or not in use.

- Never operate machines at high transport speeds on slippery surfaces. Look down and behind and use care when backing up.

- If the machine should start to vibrate abnormally, stop the engine, disconnect the spark plug wire, and ground it against the engine. Inspect thoroughly for damage. Repair any damage before starting and operating.

- Disengage all (drive and auger) control levers and stop the engine before you leave the operation position (behind the handles).

- Wait until the auger /impeller comes to a complete stop before unclogging the chute assembly, making any adjustments or inspections.

- Never put your hand in the discharge or collector openings. Always use the clean-out tool provided to unclog the discharge opening. Do not unclog chute assembly while the engine is running. Shut off the engine and remain behind handles until all moving parts have stopped before unclogging.

- Use only attachments and accessories approved by the manufacturer (e.g. wheel weights, tire chains, cabs, etc.).

- When starting the engine, pull the cord slowly until resistance is felt, then pull rapidly, Rapid retraction of starter cord (kickback) will pull hand and arm toward engine faster than you can let go. Broken bones, fractures, bruises, or sprains could result.

- If situations occur which are not covered in this manual, use care, and good judgment to contact customer support for assistance.

MAINTENANCE

- Never tamper with safety devices. Check their proper operation regularly. Refer to the maintenance and adjustment sections of the manual.

- Before cleaning, repairing, or inspecting the machine disengage all control levers and stop the engine.

- Wait until the auger impeller comes to a complete stop. Disconnect the spark plug wire to prevent unintended starting.

- Check bolts and screws for proper tightness (every time before & after use) as engine vibration could cause hardware to loosen.

This process will keep the machine in safe working condition. Also, visually inspect the machine for any damage.

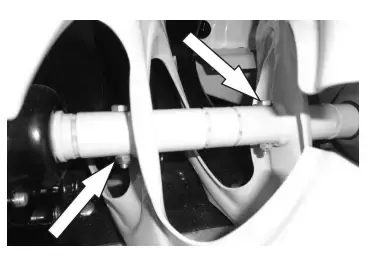

- Verify that the auger gearbox, located between your right and left auger blades, has substantial lubricant in the casing.

The gearbox fill and drain plugs (bolts) are the only “vertical” plugs (bolts) on the gearbox assembly when viewed in the standing position. The top plug (bolt) is used for filling…the bottom plug (bolt) is for draining. Simply remove the top plug (bolt) for verification of lubricant, as it should be inside. To drain, simply remove the bottom plug (bolt).

- Do not change the engine governor setting or over-speed the engine. The governor controls the maximum safe operating speed of the engine.

- Snow thrower auger belts, shave plates, shear pins and skid shoes are subject to wear and damage, therefore it is expected that the owner assumes personal responsibility for the maintenance (removal & installation) of these items.

- For your safety protection, frequently check all components and replace them with original equipment manufacturers (OEM) parts only. Use of parts that do not meet the original equipment specifications may lead to improper performance and compromise safety.

- Check (drive & auger) control lever (handles) and cables periodically to verify they engage and disengage properly and adjust, if necessary. Refer to the adjustment section in this operator’s manual for instructions.

- Maintain or replace safety and instruction labels, as necessary.

- Observe proper disposal laws and regulations for gas, oil, etc. to protect the environment.

- Prior to storing, run the machine for a few minutes to clear snow from the machine and prevent freeze-up of auger impeller and completely wipe down unit, while inspecting for frozen components.

- Never store the machine or fuel container inside where them is an open flame, spark, or pilot light such as water heater, furnace, clothes dryer, etc.

- Always refer to the operator’s manual for proper instructions on off-season storage.

- Check fuel line, tank, cap, and fittings frequently for cracks or leaks. Replace if necessary.

- Do not crank engine with spark plug removed.

- Have the machine inspected annually by an authorized service dealer to ensure that all mechanical and safety systems are working properly and have not worn excessively*? Failure to do so can result in accidents, injuries, or death.

*Please note that an annual inspection is not covered within the warranty program…only REPAIR service.

CLEANING

- To clean your Snow Thrower, use a damp cloth and mild detergent on the surfaces only. Never get soap or water inside the working mechanisms of your Snow Thrower. Do not clean with water. Water will freeze due to low temperature and damage the machine.

- Clean the Snow Thrower of snow and ice buildup before storing or transporting. Be sure to secure the unit while transporting.

- Inspect the Snow Thrower carefully for worn, loose, or damaged parts. Check connections and screws and tighten if necessary.

DO NOT MODIFY THE ENGINE

To avoid serious injury or death, do not modify the engine in any way. Tampering with the governor setting can lead to a runaway engine and cause it to operate at unsafe speeds. Never tamper with the factory setting of the engine governor.

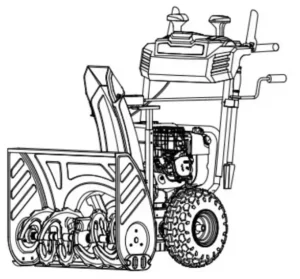

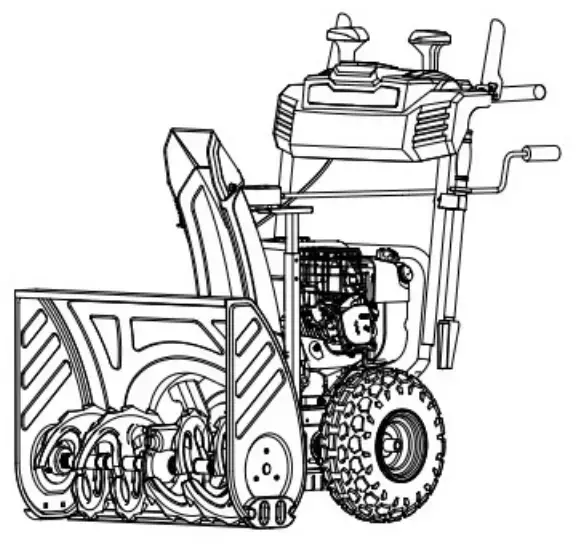

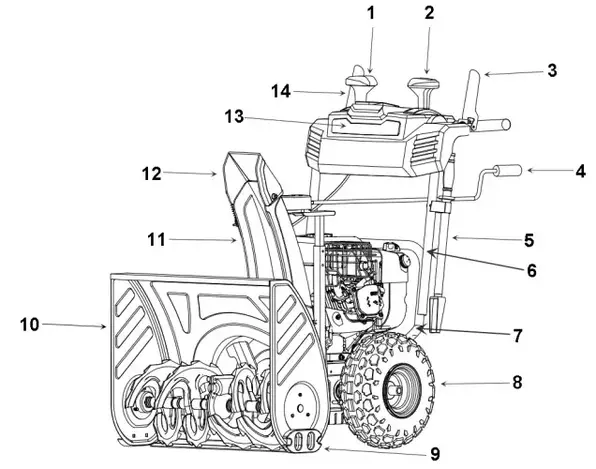

KNOWING YOUR SNOW THROWER

Use the illustrations below to become familiar with the locations and functions of the various components and controls of this snow thrower.

| 1 Chute Deflector Control Lever 2 Speed Control Lever 3 Auger Control Trigger 4 Chute Rotation Handle 5 Clean Out Tool 6 Upper Handle 7 Lower Handle |

8 Tire 9 Skid Shoe 10 Auger Housing 11 Discharge Chute 12 Discharge Chute Deflector 13 Light 14 Drive Control Trigger |

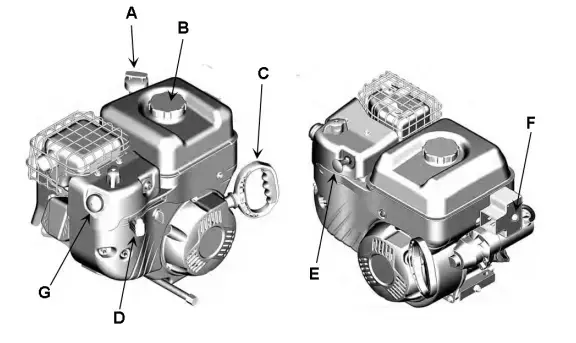

| A Dipstick/Oil Fill B Fuel Tank and Cap C Starter Cord Handle |

D Throttle Control (if equipped) E-Safety Key (if equipped) F Push Button Electric Start G Primer |

Drive Control Trigger

Located on the right side of the upper handle, the Drive Control Handle is used to engage and disengage the drive wheels. Squeeze the Drive Control Handle against the upper handle to engage the wheels; release to disengage.

Drive Speed Control Lever

The Speed Control is located at the center of the panel and is used to set the drive speed and direction of travel. The speeds include forward and reverse.

Auger Control Trigger

Located on the left side of the upper handle, the Auger Control Handle is used to engage and disengage the augers. Squeeze the Auger Control Handle to engage the augers; release to disengage the augers.

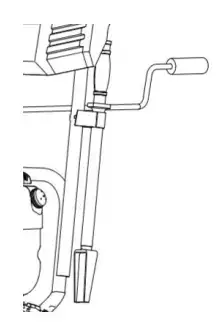

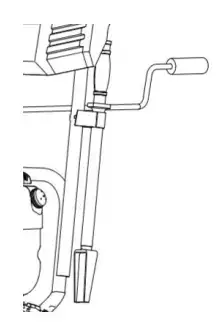

Chute Rotation Handle

To adjust snow discharge direction, rotate the handle clockwise or counter-clockwise…. should rotate 180 degrees.

Skid Shoe

Position the shoes based on the surface conditions. Adjust upward for hard-packed snow. Adjust downward when operating on gravel or crushed rock surfaces.

Auger Blade and Impeller

When engaged, the auger blades rotate to cut snow and direct it into the auger/impeller housing to be discharged out the chute.

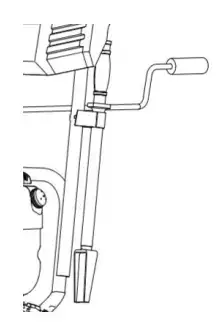

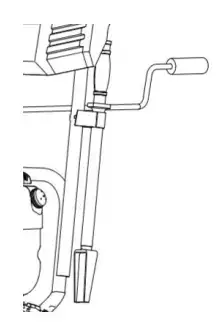

Clean-out Tool

The chute Clean-out Tool is conveniently fastened to the rear of the auger housing with a mounting clip. It is used to clean the chute assembly and chute opening when snow and ice become lodged. WARNING! Never use your hands to clear a clogged chute assembly. Shut off the engine and remain behind handles until all moving parts have stopped before unclogging.

Wheel

13-inch snow tire

LED Light

Located on the front of the panel, this feature provides extra light for increased visibility.

Heated Handle

Open the switch on the back of the panel, handles began to heat up.

One-Hand Operation

When you activate the drive control trigger and auger control trigger at the same time, the auger control trigger will be temporarily locked. Release the auger control trigger(left hand)and the auger switch trigger will remain engaged. This feature allows you to adjust the auger speed, self-propelling speed, and discharging direction of the snow while the auger rotates. To stop the auger, release the drive control trigger and both the auger and the self-propel function will stop.

SNOWTHROWER PREPARATION,

ADD OIL

The snow thrower is shipped without oil. The user must add the proper amount of oil before operating the snowblower for the first time. The oil capacity of the engine crankcase is 20.29 fl. oz. For general use, we recommend 5W-30, 4-stroke engine oil.

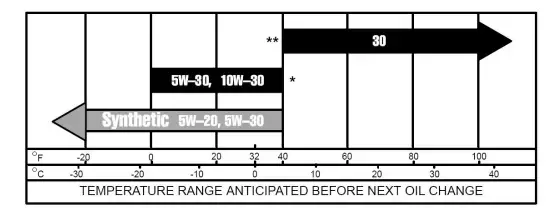

ENGINE OIL RECOMMENDATIONS

Select good quality detergent oil bearing the American Petroleum Institute (API) service classifications SJ, SL, or SM (synthetic oils may be used). Use the ASE viscosity grade of oil from the following chart that matches the starting temperature anticipated before the next oil changes.

Check Oil Level

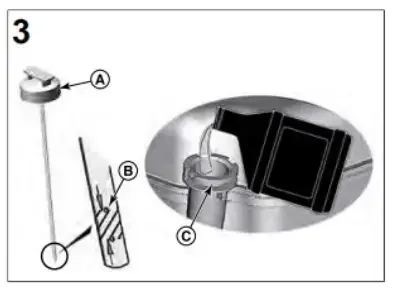

- Remove the dipstick (A, Figure 3) and wipe with a clean cloth.

- Install and tighten the dipstick (A, Figure 3).

- Remove the dipstick and check the oil level. Correct oil level is at the top of the full indicator (B, Figure 3) on the dipstick.

Add Oil

- If the oil level is low, slowly add oil into the engine oil fill (C, Figure 3). Do not overfill. After adding oil, wait one minute and then check the oil level.

- Reinstall and tighten the dipstick (A, Figure 3).

ADD GASOLINE

Use fresh (within 30 days from purchase), lead-free gasoline with a minimum of 87 octane rating. Do not mix oil with gasoline.

To add gasoline, follow these steps:

- Make sure the snow thrower is on a level surface.

- Unscrew the fuel tank cap and set it aside. NOTE: The fuel cap may be tight and hard to unscrew.

- Slowly add unleaded gasoline to the fuel tank. Be careful not to overfill. The capacity of the fuel tank is 0.8gallons for model#PSSAM24BS; 0.71gallons for model#PSS2260BS.

NOTE: Do not fill the fuel tank to the very top. Gasoline will expand and spill over during use even with the fuel cap in place. - Reinstall the fuel cap and wipe clean any spilled gasoline with a dry cloth.

IMPORTANT:

- Never use an oil/gasoline mixture.

- Never use old gasoline.

- Avoid getting dirt or water into the fuel tank.

- Gasoline can age in the tank and make starting difficult. Never store snow throwers for extended periods of time with fuel in the tank or the carburetor.

NOTE: After completing the above preparation, the engine is ready to be started.

WARNING! Keep the area of operation free from foreign objects that can be thrown by the auger and/or impeller blades. Perform a thorough inspection of the area since some objects may be hidden from view by surrounding snow. If the snow thrower hits an obstruction or picks up a foreign object during use, stop the snow thrower immediately, remove the obstruction, and inspect it for damage. Repair or replace any damaged parts before restarting and operating your snow thrower.

- Keep children, pets, and bystanders away from the area of operation. Be aware that the normal noise of the snow thrower when turned on may make it difficult for you to hear approaching people.

- Start your clearing path by throwing snow in a back and forth motion. To clear in the opposite direction, stop your snow thrower and pivot it on its’ wheels to face the opposite direction. Make sure to overlap clearing paths.

- Determine the direction of the wind. If possible, move in the same direction as the wind so that the snow is not thrown against the wind, back into your face, and on the just cleared path.

WARNING! DO NOT USE YOUR HANDS TO UNCLOG THE CHUTE. Stop the motor before removing debris. Use the supplied Clean-out tool to unclog the chute. Do not walk in front of your running snow thrower. Do not direct discharged snow towards bystanders.

- Do not apply additional man-made load to the engine since this may damage the engine.

- Some parts of your snow thrower may freeze under extreme temperature conditions. Do not attempt to operate your snow thrower with frozen parts. If the parts freeze while your snow thrower is in use, stop the unit and inspect it for frozen parts. Thaw all parts before restarting and operating your snow Never force parts or controls that are frozen. Never use an open flame of any sort to thaw frozen parts.

Pre-operation Inspection – IMPORTANT!!!

Before using your snow thrower for the first time, check the following:

- Have you read and followed all setup and operation procedures for the engine as outlined?

- Has the engine been filled with oil and gasoline to the proper level?

- Are all snow thrower components properly attached and assembled?

- Are there any broken or damaged parts?

- Are all fasteners tight?

- Are the tires inflated to the proper pressure?

NOTICE: If you are unsure about the assembly or condition of any of your snow thrower parts, please call our customer service department at (800)791 9458.

AUGER AND DRIVE CONTROLS

- To engage the auger (blades), press down on the auger control lever (left side handle).

- To engage the drive, press down on the drive control lever (right side handle). The machine should start moving in the direction and speed for the respective setting on the speed/gear control.

When finished clearing a snow path, release the auger control lever (handle) and the drive control lever (handle)Attention: Release (disengage) the auger and drive control lever (handles) before adjusting the drive speed control lever. NEVER change the drive/gear speed while your snow thrower is in motion, as it will damage the drive mechanism and void the warranty.

DRIVE SPEED CONTROL

Move the drive speed control lever to the desired speed. There are forward and reverse speeds.

CHUTE DISCHARGE DIRECTION ADJUSTMENT

WARNING – Never direct the snow discharge chute at the operator, bystanders, vehicles, or nearby windows. Discharged snow and foreign objects accidentally picked up by the Snow Thrower can cause serious damage and severe bodily injury. Always point the discharge chute in the opposite direction from potential hazards.

WARNING – Never direct the snow discharge chute at the operator, bystanders, vehicles, or nearby windows. Discharged snow and foreign objects accidentally picked up by the Snow Thrower can cause serious damage and severe bodily injury. Always point the discharge chute in the opposite direction from potential hazards.

The discharge chute can be adjusted 180° by rotating the chute rotation handle. Rotate the chute rotation handle clockwise to move the discharge chute to the right; counterclockwise to move the chute to the left.

SKID SHOE ADJUSTMENT

Adjustment of the skid shoes sets the height above the ground at which the auger shave plate operates. For clearing snow from concrete, asphalt, and other smooth surfaces, set the auger shave plate so that the bottom of the plate is just above the ground.

For clearing snow from gravel, dirt, and other rough surfaces set the auger shave plate slightly above the ground to avoid dirt and gravel from entering the auger.

The optimal height of the plate will vary depending on the type of surface being cleared. Surfaces with larger gravel or stones require a higher shave plate setting.

- Move the snow thrower to a solid, smooth, and level surface.

- Place a spacer board on the ground underneath the auger shave plate between the skid shoes. The thickness of the board should die the same as the height above the ground you wish to raise the auger shave plate. The skid shoes should not touch the board.

With the two nuts, loose allows the skid shoe to slide to the ground then tighten the nuts to secure the skid shoe.

OPERATING YOUR SNOW THROWER

MANUAL START THE ENGINE

To manual start the engine, perform the following steps:

- Check the engine oil. See the Check Oil Level

- Make sure equipment drive controls, if equipped, are disengaged.

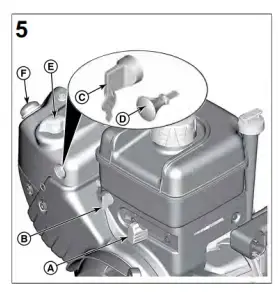

- Move the throttle control (A, Figure 5), if equipped, to the fast Operate the engine in the fast position.

- Move the fuel shut-off (B, Figure 5), if equipped, to the open

- Insert the key (C, Figure 5), and turn to the on position.

- Move the choke control (E, Figure 5) to the choke position. Note: Choke is usually unnecessary when restarting a warm engine.

- Push the primer (F, Figure 5) two times.

Note: Priming is usually unnecessary when restarting a warm engine. - Rewind Start, if equipped: Finely hold the starter cord handle. Pull the starter cord handle slowly until resistance is felt, then pull rapidly.

ELECTRIC START THE ENGINE

Connect the extension cord to the power cord receptacle 120V and then into a wall receptacle. Depress the push button. After you start the engine, disconnect the extension cord from the wall receptacle and then from the power cord receptacle.

As the engine warms up, move the choke control (E, Figure 5) to the run position.

CLEARING SNOW

Start the engine once your snow thrower has been running outside for several minutes, it is now ready for use. Make sure the path in front of your Snow Thrower is free from people, animals, objects, and all other obstructions except for the snow.

Adjust the chute outlet to the desired direction.

Turn the chute rotation handle clockwise or counter-clockwise until the desired position is reached.

WARNING! Never direct the chute outlet toward people or animals. While snow may seem harmless, it can contain rocks or other debris that can cause serious injury when projected through the chute.

- Engage/depress the auger control lever (handle) to start the augers and impeller turning.

- Set the desired direction and speed using the speed/gear control lever.

- Engage/depress the drive control lever (handle) and direct the snow thrower into the snow to be cleared.

NOTICE: NEVER change speed/gear positions while the drive control lever (handle) is engaged. Disengage the drive control handle BEFORE changing speeds or directions. If the snow is deeper than the height of the auger, remove it in several steps taking narrower swaths. Make several passes with the auger overlapping the cleared areas and reduce forward speed.

For the best clearing efficiency, clear snow before it melts refreezes, and hardens. Hard-packed and wet snow can be very difficult to clear.

Clearing wet heavy snow can be a challenge, depending on ambient temperature, humidity levels, and overall climate conditions including actual snow conditions, there may be no 100% solution as snow may be too wet or compacted to move or throw. Wet snow will tend to clog and stick more to the augers and chute. Keep the auger engaged as much as possible when clearing wet snow to help prevent clogging.

WARNING! If snow is filled with foreign material, damage to the snow thrower may result. Avoid snow with foreign materials.

STOPPING

When finished using your snow thrower, perform the following steps to shut it down.

- Engage the auger and impeller for 30 seconds to clear any remaining snow inside your snow thrower

- Stop the auger blade rotation by releasing the (left) auger control lever (handle).

- Key, if equipped: Turn the key (C, Figure 5) to the off position. Remove the key and keep it in a safe place out of the reach of children.

- After the engine stops, move the fuel shut-off (B, Figure 5), if equipped, to the closed position.

- Remove snow from all snow thrower surfaces including the auger housing and chute areas.

CLEARING RESTRICTIONS

If the snow discharge chute or auger housing becomes clogged, STOP the engine. Remove the Engine Safety key and make sure that all rotating parts have come to a complete stop. Use the supplied snow clean-out tool to clear the obstruction. After unclogging, wipe the tool clean, and place it in the holder on top of the auger housing.

MAINTENANCE

TIRE INFLATION

Before each use of your Snow Thrower, check the tire pressure. The pressure in each tire should be in the range of 20-24 psi for the best performance. The pressure can be checked using an ordinary tire pressure gauge. Fill the tires using a small or pressure-regulated air compressor.

WARNING! DO NOT OVER–INFLATE THE TIRES. Over-inflating could cause a tire to burst and cause severe bodily injury.

SHAVE PLATE REPLACEMENT

Remove both skid shoes and hardware including carriage bolts and nuts which attach shave plate to snow thrower housing. Reassemble new shave plate, making sure heads of the carriage bolts are to the inside of the auger housing.

AUGER OR IMPELLER JAMS

WARNING! The auger and impeller rotate at fast speeds which can cause harm or even amputation to a person’s body parts. Even if you do not see the auger or impeller rotating, it may start at any time if the engine is running. Remove the Safety Key before cleaning the jams. The chute clean-out tool is fastened to the upper tube with mounting clips.

- Always turn OFF the engine before attempting to clear any clogs or jams.

- Keep hands and feet away from rotating parts while the engine is running.

- Do not wear loose-fitting clothing that can become entangled in rotating parts.

- Wait until the auger and impeller have come to a full stop.

- Clear any visible jams using the clean-out tool attached to your machine.

WARNING! DO NOT try to clear jams with your hands or feet.

AUGER SHEAR PINS REPLACEMENT

Shear pins are used to attach the auger shaft to the auger blades. Stop the engine by removing the safety key. A clog or jam in the augers may cause one or multiple shear pins to break. The shear pins are a safety mechanism designed to break under high load or impact and protect the auger drive system from damage. Replacement shear pins and nylon lock nuts are provided with your snow thrower.

For additional replacement shear pins, please call the customer service department at (800)791 9458.

- Turn off the engine and wait for all moving parts to come to a complete stop. Remove any remnants of the broken shear pin. It may be necessary to unscrew the nut from the broken shear pin and drive out the broken pin.

- Insert a new shear pin through the hole in the auger shaft and tighten using the shear pin nylon lock nut. Do not over-tighten the nylon lock nut.

Note: Never replace the shear pins with standard pins or fasteners. Damage may occur to the snow blower and drive systems.

NOTICE: Never replace the shear pins with standard pins or fasteners. Damage may occur to the snow blower and drive systems.

TROUBLESHOOTING

| Problem | Causes | Remedy | ||

| WARNING – Before attempting to make any inspections, repairs, or adjustments, stop the engine, wait for all moving parts to stop moving, and carefully disconnect the engine spark plug wire. If tipping or turning the snowblower is required for any inspection or repair, first, wait until the engine is cool to the touch and then drain the engine of all fuel and oil into suitable containers and store or dispose of in a proper manner. | ||||

| Engine Systems – Note: For all engine problems, see the below-troubleshooting information. | ||||

| Engine Fails to Start (Engine cranks over) | Spark plug wire disconnected | Connect a wire to spark plug | ||

| Faulty spark plug | Clean, adjust the gap, or replace the spark plug. | |||

| Engine flooded with fuel | Discontinue choke or primer use, clean, or replace the spark plug. | |||

| Safety key not inserted in engine ignition | Insert the key fully into the switch | |||

| Choke not in START position | Move to choke to START position, after the engine starts slowly move to RUN position as engine speed and operation stabilizes at the set rpm. If the engine still does not; tart mow to half choke and crank engine. | |||

| Fuel incorrect, old or stale, will not ignite | Empty and clean fuel tank & carburetor, refill with fresh, lean gasoline. (Note: Fuel may become stale after 30 Jays in some cases) | |||

| Blocked or clogged fuel system or line | Clean fuel system or line | |||

| An extension cord is not properly attached to the electric starter terminal | Re-insert extension cord into electric starter terminal. | |||

| Engine electric starter will not crank the engine | No power from the power supply, tripped breaker | Check power supply extension cord is attached to. | ||

| Extension cord wire gauge is too small, or cord is too long | Use proper rated and length extension cord | |||

| CHOKE in ON or partial ON position | Move CHOKE lever to RUN | |||

| Engine runs erratic, stalls or seems low on power | Fuel incorrect, old or stale | Empty and clean fuel tank & carburetor, refill with fresh, clean gasoline. (Note: Fuel may become stale after 30 days in some cases) | ||

| Blocked or clogged fuel system or line | Clean fuel system or line | |||

| The carburetor is in need of cleaning | Clean fuel system and carburetor | |||

| Spark plug wire lose | Connect and tighten spark plug wire | |||

| Faulty spark plug | Clean, adjust gap or replace the spark plug, see Engine Operator’s manual | |||

| Engine oil overfilled | Drain oil to the proper level. Oil should not be above the top 2 threads of the LOWER fill plug. | |||

| Engine oil level low or empty | Add oil | |||

| Drive system | ||||

| No forward or reverse drive movement when Jrive handle : gaged | Drive belt loose or damaged | Check drive belt tension pulley for damage or incorrect tension, repair as necessary. Replace drive belt. | ||

| The friction drive wheel is worn or damaged | Replace friction drive wheel | |||

| Friction drive wheel wet or slipping | Allow snowblower to dry and or warm-up or adjust drive cable tension as necessary. | |||

| Drive speed control stuck in gear or won’t change gears | Speed control lever lose or damaged, not moving speed control cables | Check speed control lever and cables for damage or loose or missing parts. Repair or replace parts as needed, ensure pivot stud spring tension is correct, adjust pivot nut spring tension as needed. | ||

| Speed control cables lose, damaged, or binding | Repair, adjust, or replace as necessary | |||

| Drive speed control allows only I

direction |

Speed control cables misadjusted, loose, damaged, or binding | Check speed control lever and cables for damage or loose or missing parts. Repair or replace parts as needed. Adjust drive speed control cables, see Drive Speed Control Cables Adjustment | ||

| Drive engaged when drive control handle released | Drive control cable binding, won’t release Repair, replace cable as necessary | Repair, replace cable as necessary | ||

| Friction drive wheel return spring broke or missing | Replace spring, adjust cable as necessary | |||

| Auger System | ||||

| Auger not rotating when the auger control handle engaged or Not blowing snow or Poor snow blowing performance | Chute assembly clogged | Clean chute and inside of auger housing with a clean-out tool | ||

| Auger shear pins broken | Replace shear pins. Check each auger blade shear pin. | |||

| Foreign object in auger or impeller causing auger to stop without shearing pins | Remove object from auger or impeller areas | |||

| Auger belt loss, slipping, worn, or damaged | Replace auger belt | |||

| Auger belt tension cable lose, damaged, or binding | Repair, adjust, or replace as necessary | |||

| Auger blade(s) damaged or bent | Replace auger blade(s) | |||

| Auger gearbox mechanical damage, auger drive system not rotating freely (binding) | Check bearings, bushings, and all system parts for damage or mechanical binding. Repair or replace as necessary using proper lubrication | |||

| Impeller damaged | Replace impeller | |||

| Impeller not connected to impeller shaft, impeller or shear pins broken | Replace shear pins or impeller as necessary | |||

| Forward speed too fast while blowing snow, overload | Allow the engine to maintain its speed. | |||

| Auger belt is broken or repeated failure | Auger tension pulley arm return spring broken nr missing | Replace tension arm return spring | ||

| Auger tension pulley arm stuck or binding | Repair or replace tension arm as necessary | |||

| Auger tension pulley arm or pulley misaligned or damaged tece scary | Repair, replace, or align tension arm and or pulley as | |||

| Foreign material on pulleys and belts, oil, rase, dirt, etc. | Clean belt and pulleys as necessary, replace the belt if necessary | |||

| Auger pulleys misaligned, loose, damaged, or ent | Replace or align pulleys as necessary | |||

| Incorrect or damaged auger belt | Replace with the correct size and type belt | |||

| Auger belt guide pin not adjusted | Adjust belt guide pin to within 1/8 to 3/16 in. from the pulley. (Guide pin keeps the belt in pulley when disengaged) | |||

| Auger rotating when the auger control handle released | Auger tension pulley arm return spring broken or missing | Replace tension arm return spring | ||

EXPLODED VIEW AND PART LIST

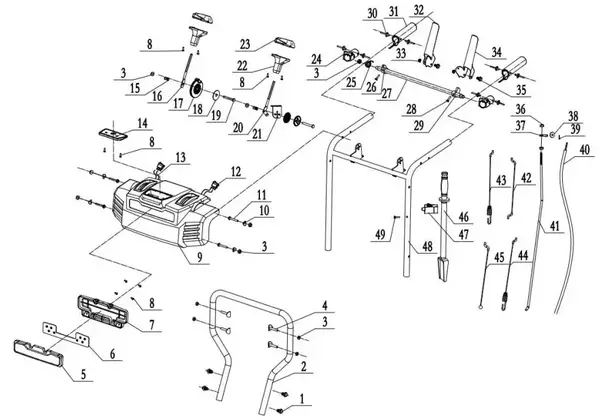

PANEL ASSEMBLY

| Item | Stock# | Description | OW |

| 1 | 303020240 | Hex Flange Screw | 4 |

| 2 | 303160909 | Lower Handle | 1 |

| 3 | 303030077 | Flange Lock Nut M8 | 11 |

| 4 | 303020154 | Bolt M8×40 | 4 |

| 5 | 203050729 | Lampshade | 1 |

| 6 | 301013054 | Lamp board | 1 |

| 7 | 203050730 | Lampshade cover | 1 |

| 8 | 303010026 | Screw | 10 |

| 9 | 203050728 | Panel | 1 |

| 10 | 303043010 | Concave pad | 4 |

| 11 | 303020275 | Bolt | 4 |

| 12 | 301100037 | Switch | 2 |

| 13 | 301040130 | Connecting line | 3 |

| 14 | 306040055 | Driving board | 1 |

| 15 | 303130074 | Compression spring | 2 |

| 16 | 303071528 | Control lever | 1 |

| 17 | 303071343 | Gear plate | 2 |

| 18 | 203020380 | Tooth pad | 4 |

| 19 | 303020072 | Bolt | 2 |

| 20 | 303071527 | Travel control lever | 1 |

| 21 | 303071536 | Travel control panel | 1 |

| 22 | 203050740 | Lower cover | 2 |

| 23 | 203050739 | Upper cover | 2 |

| 24 | 203050682 | Self-locking seat | 2 |

| 25 | 303071499 | Self-locking torsion spring | 1 |

| 26 | 303060158 | Right self-locking cam | 1 |

| 27 | 303170030 | Shaft | 1 |

| 28 | 303160790 | Screw M5’18 | 2 |

| 29 | 303060157 | Left self-locking cam | 1 |

| 30 | 306110038 | Rivet | 8 |

| 31 | 203070005 | Heated handle | 2 |

| 32 | 303071520 | Right control trigger | 1 |

| 33 | 303030025 | Nut | 2 |

| 34 | 303071518 | Left control trigger | 1 |

| 35 | 303020486 | Hex Flange Screw | 2 |

| 36 | 303030076 | Flange Normal Nut M8 | 2 |

| 37 | 303123034 | Connection Rod Pin | 1 |

| 38 | 303042023 | Flat Washer | 1 |

| 39 | 303160845 | Dowel Pin | 1 |

| 40 | 3010401366 | Connecting line | 1 |

| 41 | 303071442A | Speed Control Connection Rod | 1 |

| 42 | 303200060A | Upper Auger Cable | 1 |

| 43 | 303200130 | Upper Drive Cable | 1 |

| 44 | 303200012 | Lower Auger Cable | 1 |

| 45 | 303200050 | Lower Drive Cable | 1 |

| 46 | 203050057 | Clean Out Tool | 1 |

| 47 | 203050512 | Rocker Seat | 1 |

| 48 | 303181339 | Upper Handle Welding | 1 |

| 49 | 303010164 | Screw M6x20 | 1 |

CHUTE ASSEMBLY

| Item | Stock # | Description | Qty |

| 1 | 203050514 | Chute | 1 |

| 2 | 303030087 | Locknut M8 | 1 |

| 3 | 303071344 | Cable seat | 1 |

| 4 | 303020244 | Hex Flange Bolt M6×35 | 1 |

| 5 | 303200117 | Chute cable | 1 |

| 6 | 303030077 | Locknut M8 | 2 |

| 7 | 303020622 | Bolt M8X20 | 2 |

| 8 | 203050515 | upper Chute | 1 |

| 9 | 203021301 | Steering gear | 1 |

| 10 | 303042019 | Flat washer | 2 |

| 11 | 303010026 | Screw | 2 |

| 12 | 306110029 | Rivet | 3 |

| 13 | 303071053 | Steering dead plate | 1 |

| 14 | 303020655 | Hex Bolt | 2 |

| 15 | 303041022 | spring washer | 2 |

| 16 | 303042023 | Flat washer | 2 |

| 17 | 303181010 | Chute Support tube welding | 1 |

| 18 | 303020503 | Hex Flange Bolt M6x35 | 2 |

| 19 | 303030087 | Hex Flange Lock Nut M6 | 2 |

| 20 | 303181164 | Small Support Tube Welded | 1 |

| 21 | 303030077 | Locknut M8 | 1 |

| 22 | 303130369 | Pressure spring | 1 |

| 23 | 303071056A | Locating plate | 1 |

| 24 | 303030087 | Locknut M8 | 2 |

| 25 | 303160865 | Cable rod | 1 |

| 26 | 303020655 | Bolt M8X45 | 1 |

| 27 | 303020246 | Bolt M6X16 | 2 |

| 28 | 303030032 | Locknut M6 | 2 |

| 29 | 303060131A | Steering pinion | 1 |

| 30 | 203010818 | Steering gear seat | 1 |

| 31 | 203010817 | Steering gear cover | 1 |

| 32 | 303010026 | Screw 4X12 | 2 |

| 33 | 303043058 | Flat washer | 1 |

| 34 | 303050044 | Shaft Ring | 1 |

| 35 | 303160845 | Dowel Pin | 1 |

| 36 | 303160755A | Z-long rocker | 1 |

| 37 | 303042004 | Flat washer | 2 |

| 38 | 203020384 | Rocker lever | 1 |

| 39 | 303050029 | Shaft Ring | 1 |

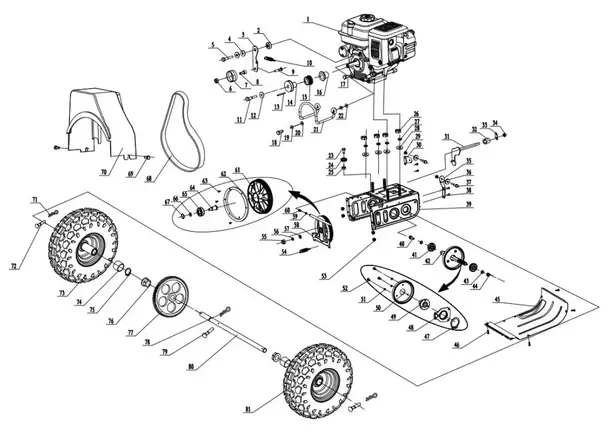

FRAME ASSEMBLY FOR MODEL#PSSAM24BS

FRAME ASSEMBLY FOR MODEL#PSS2260BS

| Item | Stock # | Description | Qty |

| 1 | 303190341 | Engine MCC for monet#P9SAM2499 | 1 |

| 1 | 303190342 | Engine 250CC for modeltiPSS2260BS | 1 |

| 2 | 303160192 | Spacer bush | 1 |

| 3 | 303070202 | Small tension plate | 1 |

| 4 | 303042005 | Flat washer | 2 |

| 5 | 303020664 | Outer hexagonal flange facing bolt | 1 |

| 6 | 303030077 | Flange locknut M8 | 1 |

| 7 | 203100004 | Tension wheel assembly | 1 |

| 8 | 303160195A | Bushing | 1 |

| 9 | 303020154 | Step bolt | 1 |

| 10 | 303130094 | Friction wheel bracket spring | 1 |

| 11 | 303020667 | Flange hexagonal bolt | 1 |

| 12 | 303042005 | Flat washer | 1 |

| 13 | 9141960501 | Flat key | 1 |

| 14 | 303160152A | V-belt wheel | 1 |

| 15 | 303060041 | Synchronous pulley wheel | 1 |

| 16 | 303060040 | Adjustable pad | 1 |

| 17 | 303160527 | Screw | 1 |

| 18 | 303020664 | Outer hexagonal flange facing bolt | 1 |

| 19 | 303041022 | Spring Washer 08 | 1 |

| 20 | 303042023 | Flat washer | 2 |

| 21 | 303081251 | Belt stop lever for modellePSSAM24 BS | 1 |

| 21 | 303080144 | Belt stop lever for modeltIPSS2260BS | 1 |

| 22 | 303043016 | External teeth lock washer | 1 |

| 23 | 303160177 | Guide pulley Screw | 1 |

| 24 | 203020364 | Guide pulley | 1 |

| 25 | 303030032 | Locknut | 1 |

| 26 | 303030066 | Nut | 4 |

| 27 | 303041022 | Spring washer | 4 |

| 28 | 303042023 | Flat washer | 4 |

| 29 | 303030032 | Locknut M6 | 2 |

| 30 | 303070418A | Guide Wheel Plate | 1 |

| 31 | 303181227 | Gear Shift Fork Welded | 1 |

| 32 | 303160308 | Friction wheel support shaft sleeve tube | 1 |

| 33 | 303160830A | Shift Pick | 1 |

| 34 | 303030077 | Flange Lock Nut M8 | 1 |

| 35 | 303071243 | Guide wheel plate | 1 |

| 36 | 203020364 | Guide pulley | 2 |

| 37 | 303160177 | Guide pulley Screw | 2 |

| 38 | 303020444 | Flange hexagon bolt | 4 |

| 39 | 303181006 | Chassis welded | 1 |

| 40 | 303020239 | Hex Flange Bolt | 1 |

| 41 | 303100051 | Grooved deep groove ball bearing | 2 |

| 42 | 303160799 | Six square axis | 1 |

| 43 | 303042004 | Flat Washer | 2 |

| 44 | 303343043 | Locknut M10 | 1 |

| 45 | 303525287 | Big raft | 1 |

| 46 | 303120561 | Triangular head bolt | 4 |

| 47 | 303050027 | Shaft ring 030 | 1 |

| 48 | 303210036 | Fork riveting | 1 |

| 49 | 303160803 | Six square sleeve | 1 |

| 50 | 202170009 | Friction Wheel Assembly | 1 |

| 51 | 303041009 | Spring Washer 06 | 3 |

| 52 | 303020244 | Hex Flange Bolt M6.14 | 3 |

| 53 | 303030077 | Hex Flange Nut | 4 |

| 54 | 303130094 | Friction wheel bracket spring | 1 |

| 55 | 304315011 | Serrated nut | 1 |

| 56 | 304375759 | Elastic washer | 1 |

| 57 | 303042004 | Flat washer | 1 |

| 58 | 303181163 | Friction %Ilsel support welding | 1 |

| 59 | 304132767 | Flat washer | 1 |

| 60 | 303020244 | Outer hexagonal flange bolt | 1 |

| 61 | 303160801 | Large synchronous belt pulley | 1 |

| 62 | 304618751 | Rim | 1 |

| 63 | 304679499 | Cross recessed countersunk head screw | 3 |

| 64 | 303160802 | Large synchronous belt shaft | 1 |

| 65 | 304800995 | Deep groove ball bearing | 1 |

| 66 | 303042169 | Flat Washer | 1 |

| 67 | 303050519 | Ring 4)40 | 1 |

| 68 | 302040078 | Synchronous belt | 1 |

| 69 | 304922491 | Flange bolt M6X12 | 2 |

| 70 | 203050335 | Belt cover | 1 |

| 71 | 303160845 | Dowel Pin 1 92.5 | 2 |

| 72 | 303160815 | Dowel Pin 206 | 2 |

| 73 | 302090220 | IT Wheel assembly | 1 |

| 74 | 305165483 | Spacer bush | 2 |

| 75 | 305226231 | Shaft ring | 1 |

| 76 | 305286979 | Bushing | 2 |

| 77 | 303160876 | Big gear | 1 |

| 78 | 303160845 | Woodruff Key | 1 |

| 79 | 303160815 | Elastic cylindrical pin | 1 |

| 80 | 303160880 | Axle | 1 |

| 81 | 302090221 | 13″ Wheel assembly | 1 |

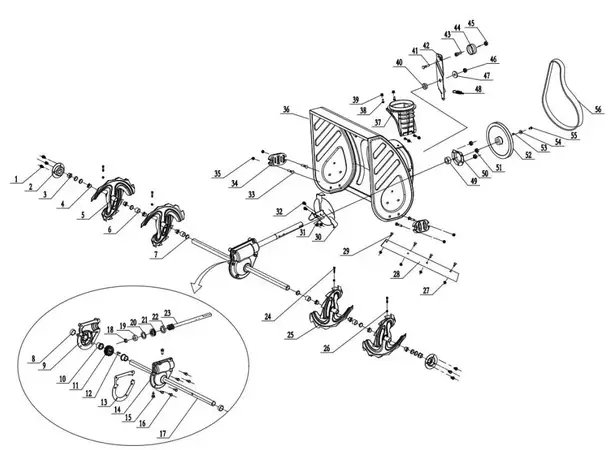

AUGER HOUSING ASSEMBLY

| Item | Stock # | Description | Qty |

| 1 | 303020245 | Hex Flange Bolt M8x14 | 6 |

| 2 | 303070234 | Bearing Block | 2 |

| 3 | 203060013 | Plastic Bearing | 2 |

| 4 | 203060012 | Auger Sleeve | 8 |

| 5 | 303180409 | Right Auger Welding | 2 |

| 6 | 203050108 | Spacer Bush 1 | 8 |

| 7 | 203050109 | Spacer Bush 2 | 6 |

| 8 | 302130005 | Skeleton seal | 2 |

| 9 | 303090032 | Worm gear Box Left | 1 |

| 10 | 303060055 | Worm Gear Shaft Sleeve | 2 |

| 11 | 303090033 | Worm Gear | 1 |

| 12 | 303110022 | Woodruff Key | 1 |

| 13 | 303070260 | Worm Gear Shaft Sleeve | 1 |

| 14 | 303090031 | Worm gear Box Right | 1 |

| 15 | 303020142 | Bolt M8x10 | 2 |

| 16 | 303020489 | Bolt M6 x 18 | 6 |

| 17 | 303160370 | 24″ Auger Axle | 1 |

| 18 | 303100030 | Deep groove ball bearing 6001Z | 1 |

| 19 | 303100035 | Deep groove ball bearing 6904Z | 1 |

| 20 | 303070179 | Worm Box Washer | 1 |

| 21 | 303100039 | Bearing 51104 | 1 |

| 22 | 302130002 | Skeleton seal | 1 |

| 23 | 303160314 | Worm | 1 |

| 24 | 303160355 | Shear Pin | 4 |

| 25 | 303180410 | Auger Welding Left | 2 |

| 26 | 303030032 | Lock Nut M6 | 4 |

| 27 | 303030076 | Flange Normal Nut M8 | 4 |

| 28 | 303071330 | 24″ Shave | 1 |

| 29 | 303020332 | Bolt M8 x 14 | 4 |

| 30 | 303181158 | Impeller | 1 |

| 31 | 303030032 | Lock Nut M6 | 2 |

| 32 | 303020442 | Hex Washer Bolt | 2 |

| 33 | 303020166 | Bolt M8 x 18 | 4 |

| 34 | 203050681 | Skid Shoes | 2 |

| 35 | 303030077 | Flange Lock Nut M8 | 4 |

| 36 | 303181159 | Auger Housing Welding | 1 |

| 37 | 203050511 | Lower chute seat | 1 |

| 38 | 303020341 | Bolt M6x16 | 4 |

| 39 | 303030087 | Flange Lock Nut M6 | 4 |

| 40 | 303160192 | Small Tension Plate Spacer | 1 |

| 41 | 303020154 | Bolt M8 x40 | 1 |

| 42 | 303071345 | Big Tension Plate | 1 |

| 43 | 303160195A | Tension Wheel Casing | 1 |

| 44 | 203100003 | Tension Wheel Assembly | 1 |

| 45 | 303030077 | Flange Lock Nut M8 | 1 |

| 46 | 303030059 | Lock Nut M10 | 1 |

| 47 | 303042078 | Flat Washer | 3 |

| 46 | 303160175 | Large Tension Plate Tension Spring | 1 |

| 49 | 303100040 | Bearing | 1 |

| 50 | 303070233 | Bearing Plate | 1 |

| 51 | 303030077 | Flange M8 | 3 |

| 52 | 303160794A | 7109 Big Pulley | 1 |

| 53 | 303110014 | Flat Key | 1 |

| 54 | 303042005 | Flat Washer | 1 |

| 55 | 303020279 | Hex Washer M8x20 | 1 |

| 56 | 302040079 | V-Belt 720mm,4LXA | 1 |

TWO (21 YEARS LIMITED WARRANTY

PowerSmart is committed to building tools that are dependable for years. Our warranties are consistent with our commitment and dedication to quality.

TWO (2) YEARS LIMITED WARRANTY OF POWER SMART PRODUCTS FOR HOME USE.

PowerSmart (“Seller”) warrants to the original purchaser only, that all PowerSmart consumer power tools will be free from defects in material or workmanship for a period of two (2) years from the date of purchase. Ninety (90) days for all PowerSmart Products, if the tool is used for professional or commercial use.

SELLER’S SOLE OBLIGATION AND YOUR EXCLUSIVE REMEDY under this Two (2) Years Limited Warranty and, to the extent permitted by law, any warranty or condition implied by law, shall be the repair or replacement of parts, without charge, which are defective in material or workmanship and which have not been misused, carelessly handled, or misrepaired by persons other than Seller or Authorized Service Center. To make a claim under this Limited Warranty, you must return the entire power tool product; transportation prepaid, to PowerSmart Include a legible copy of the original receipt, which lists the date of purchase (month and year) and the name of the company purchased from.

THIS LIMITED WARRANTY DOES NOT APPLY TO ANY ACCESSORY ITEMS INCLUDED WITH THE TOOL SUCH AS CIRCULAR SAW BLADES OTHER RELATED ITEMS OR TO ANY REPLACEMENT PARTS LISTED UNDER MAINTENANCE.

ANY IMPLIED WARRANTIES SHALL BE LIMITED IN DURATION TO TWO (2) YEARS FROM THE DATE OF PURCHASE. SOME STATES IN THE U.S. AND SOME CANADIAN PROVINCES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

IN NO EVENT SHALL THE SELLER BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES (INCLUDING BUT NOT LIMITED TO LIABILITY FOR LOSS OF PROFITS) ARISING FROM THE SALE OR USE OF THIS PRODUCT. SOME STATES IN THE U.S. AND SOME CANADIAN PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE IN THE U.S., PROVINCE TO PROVINCE IN CANADA, AND FROM COUNTRY TO COUNTRY.

For questions/comments, technical assistance, or repair parts —Please call toll free at 1-800-791-9458 (M-F 9 am — 5 pm EST) Email: [email protected]

SAVE YOUR RECEIPTS. THIS WARRANTY IS VOID WITHOUT THEM.