ridetech 11006797 Heavy Duty Universal Parallel 4-Link Instruction Manual

Recommended Tools

Major Components

…..In the box

Hardware List

…..In the box (Kit# 99010051)

The Hardware Kit contains bags to help aid in selecting the correct hardware for the component being installed. The hardware list shows how the hardware is bagged.

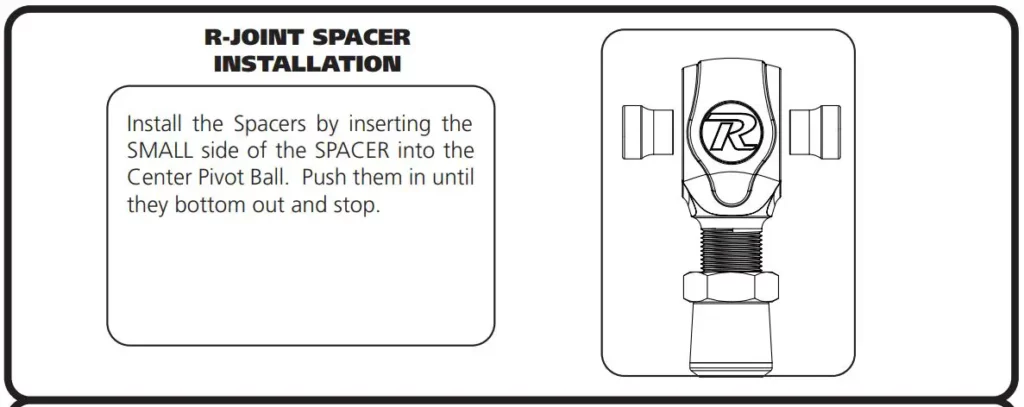

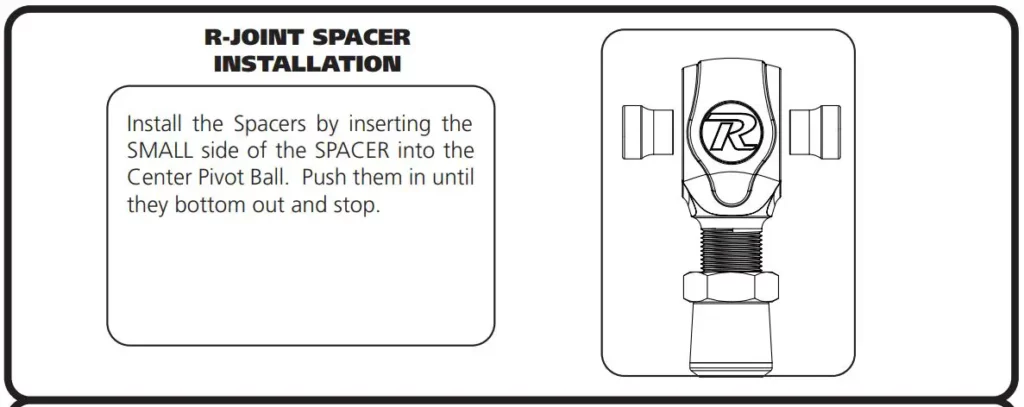

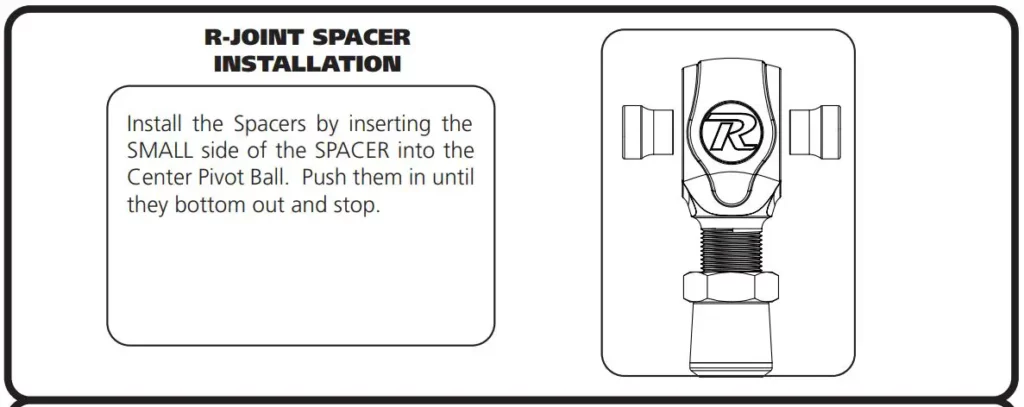

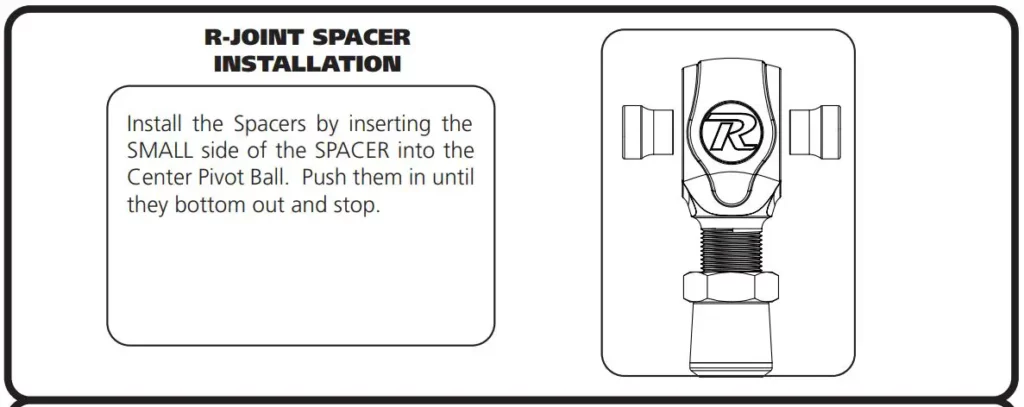

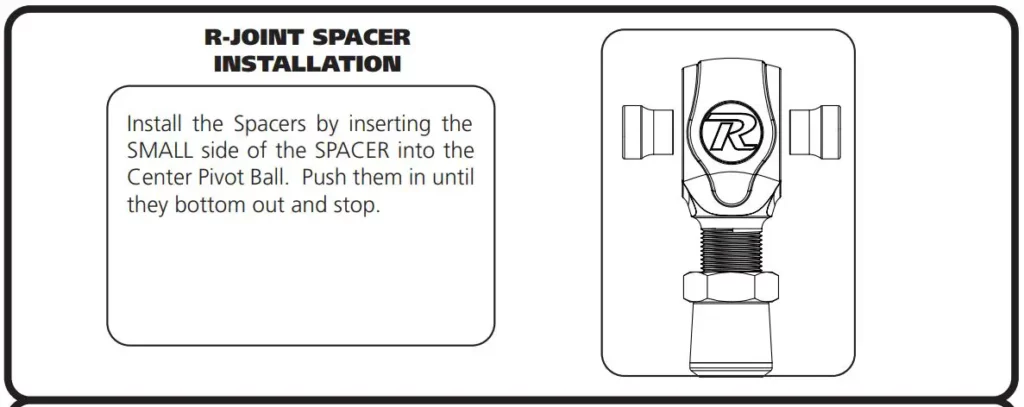

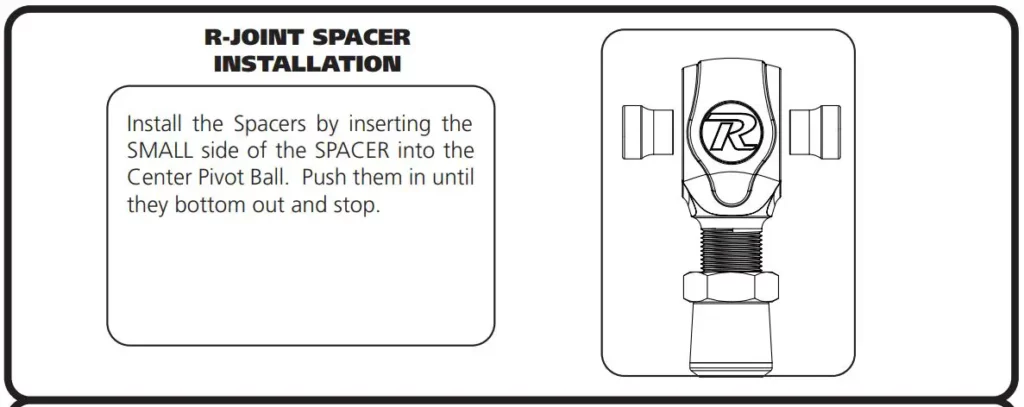

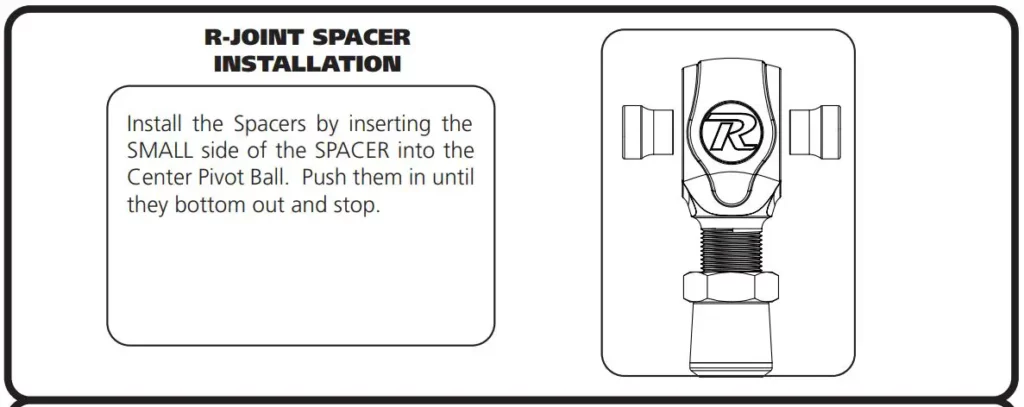

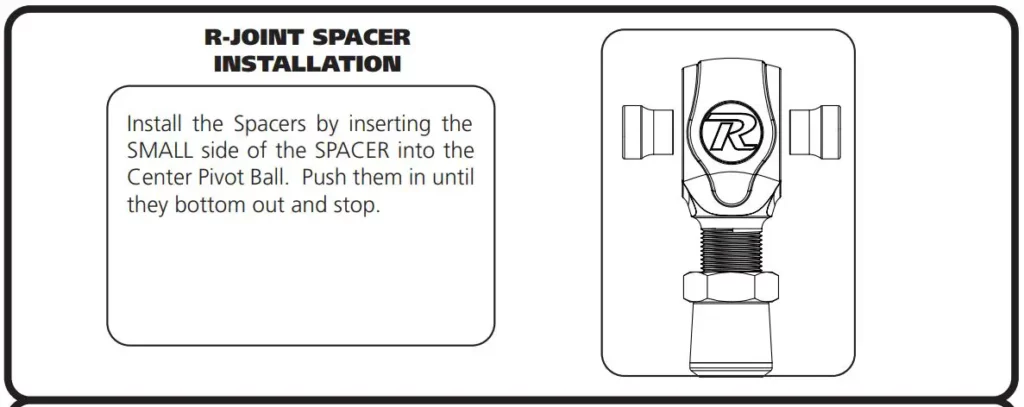

R-Joint Spacer Assembly

New R-Joints will be quite stiff (75-90 in/lbs breakaway torque) until they “break in” after a few miles of use. After the break in period they will move much more freely. Because the composite bearing race contains self lubricating ingredients, no additional lubrication is needed or desired. Any additional lubrication will only serve to attract more dirt and debris to the R-Joint and actually shorten its life.

Helpful Hints

1. Determine the Axle centerline. (Do this before you remove the bed)

a. If you are getting ready to start on a driving vehicle your centerline will usually be straight up from the existing location. One thing you will want to look at is the wheel and tire location in the wheel opening, it should be centered in the opening at ride height.

b. Once the axle centerline is determined you will want to put a mark on both frame rails for reference. We like to find a common reference on both rides to measure from. Some that we use are the leaf spring hangers, hanger holes in the frame.

2. Determine Ride and Compressed Heights

a. On a HD truck you will want 3.0” to 3.5” of supension compression to achieve good ride quality. The airspring supplied with this kit has a minimum compressed height of 6.5”, you will want to run a minimum of 6.75” to keep from pinching the airspring. This will give you a useable compresson stroke of 3.75”.

b. If you are matching the existing height measure between the top of the axle (or bumpstop pad if equiped) and the frame rail and write down for later referencing.

c. If you are looking to lower the truck= Measure between the axle and frame and subtract the

amount you want to lower it. If you do not have 3.0” to 3.5” of compression travel you will need to either shoot for a taller ride height or C-notch the frame.

d. Somethings you want to keep in mind or watch out for when determining the height.

i. If you are looking to lower the truck how low can the front suspension go. You are usually more limited by the front suspension than the rear.

ii. What obsticals are above the rearend. The center of the rearend is usually the highest part of the rearend and will usually hit the bed floor or frame before the axle tube do.