Rigol DM3058 Digital Multimeter Instructions

Data logger device for DM3058 digital multi meter

Suggested workflow for using the data logger is to set up measurements type and range using multimeter controls. Then choose measurements logging rate on the data logger and start recording. Each recording session is saved as file that can be retrieved by connecting the data logger to PC as USB flash disk.

This manual consists of following sections:

- Data logger controls.

- Measurements logging mode.

- Connecting the data logger and starting measurements recording.

- Using USB disk mode and managing measurement files.

- Additional notes on some measurement types.

Data logger controls

LCD screen and four control buttons are located on front side of the data logger.

- START / STOP button is used to start and stop recording and also to CONFIRM some actions.

- UP and DOWN buttons are used to change measurements logging interval and scroll through files.

- MODE / SELECT button is used to change logging mode and also to choose additional settings.

- Status led lights up while measurement is requested and also to indicate other activity.

Other inputs and controls are on left side and back of the data logger. - Power On button is used to turn on data logger. There is no power off option. Data logger will stay on until multimeter is turned off.

- Micro USB port is used to connect device to PC as USB flash disk to retrieve saved measurements. Data logger will turn on while connected to USB.

- Recessed firmware update button can be used while connecting device to PC as USB device to perform firmware updates.

- RJ45 port connects to serial port of DM3058 multimeter. Use cable provided with the data logger. Additional USB-A type connection provides power to data logger while it is connected to multimeter. USB port in front of DM3058 multimeter can be used for this purpose.

Another USB power adapter can be used if it provides reasonably stable 5V supply. In this case data logger will stay on while external 5V supply available even if multimeter is turned off.

Measurements logging mode

Based on how DM3058 measurements loop works there are two measurements logging modes used by the data logger interval mode and continuous mode. In interval mode measurements logging period can be set from 1 second to 120 seconds. Data logger triggers and records measurements at this selected rate. Continuous mode adjusts to internal measurements clock of the multimeter. It is suited for logging fast continuous measurements at uniform rate. It is not, however, possible to choose any arbitrary recording period in continuous mode as DM3058 measurements cycle depends on selected rate (fast, medium, slow) and measurements type. Multimeter is triggered to take measurements continuously and by logging every reading or skipping some readings uniform measurements logging rate is achieved. Another benefit for continuous mode measurements is that all changing values can be observed on multimeter while just some are logged to file. Measurements at FAST rate can be recorded at 24 ms period (or multiples of 24 ms); measurements at MEDIUM rate can be recorded at about 50 ms period (or multiples of that); measurements at SLOW rate can be recorded at about 400 ms period (or multiples of that). There are some exceptions based on measurements type. Data logger detects actual measurement rate and saves that information with every file.

Connecting the data logger and starting measurements recording

Before using data logger it is necessary to change serial baud rate setting on DM3058 multimeter. This is done by pressing  button on multimeter and selecting “I/O” “RS232” “Baud” and choosing value of 57600. “Parity” setting should be left at default state “None”. Baud rate setting will remain until changed or settings of multimeter are reset to defaults. Press

button on multimeter and selecting “I/O” “RS232” “Baud” and choosing value of 57600. “Parity” setting should be left at default state “None”. Baud rate setting will remain until changed or settings of multimeter are reset to defaults. Press  again to exit this screen.

again to exit this screen.

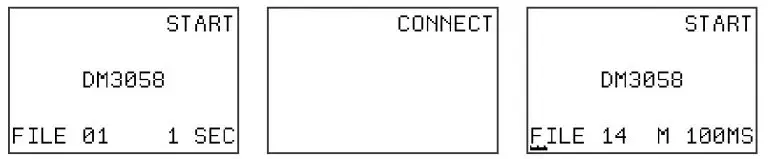

Connect cable provided with data logger to serial port at the back of multimeter and additional USB connection to USB port at the front of multimeter. Don’t forget to fix serial port connection using screws as it might get loose easily. Connect RJ45 connector to data logger. Turn on multimeter if it is not powered already and turn on data logger by pressing Power On button. If 5V supply is available LCD screen turns on and data logger queries multimeter using serial connection. Multimeter should change to remote control mode indicated by “Rmt” on top right corner of multimeter display. If DM3058 or DM3058E multimeter model is detected data logger shows startup screen with measurements logging interval set to 1 second.

If multimeter was not detected by querying serial commands data logger displays single CONNECT prompt. This is most likely caused by wrong RS232 baud rate setting on multimeter. Connection can be re-checked by pressing START/STOP button.

To change measurement settings using multimeter controls it is necessary to exit remote control mode. This is done by pressing  button on multimeter. Local control mode is indicated by “Lcl” on multimeter display. Set up desired measurement type using multimeter controls.

button on multimeter. Local control mode is indicated by “Lcl” on multimeter display. Set up desired measurement type using multimeter controls.

To start measurements logging in interval mode desired logging period can be set using UP and DOWN buttons on data logger. Holding UP and DOWN button will continue to change set value. Pressing MODE button next to displayed interval value switches to continuous measurements logging mode and data logger queries multimeter for measurement rate. Measurements period value next to MODE button changes to some value in ms or seconds with decimal digits according to detected measurements type. Desired measurements logging period can be changed using UP and DOWN buttons. Pressing MODE button once again switches back to interval mode where measurements logging period can be set in whole seconds.

Measurements logging is started by pressing START / STOP button. While measurements are logged light on  and

and  buttons should turn off as multimeter is set to external triggering mode. Following information is displayed on data logger screen:

buttons should turn off as multimeter is set to external triggering mode. Following information is displayed on data logger screen:

Measurement type (like VOLTAGE DC, CURRENT DC, 2 WIRE RES, 4 WIRE RES, DIODE, etc.); Received measurement value in scientific format (two values in dual measurements mode); Current file number; Measurements counter.

Pressing MODE button while measurements logging is active changes display to measurements interval information screen.

In interval logging mode this will show seconds counter until next measurement will be triggered. Seconds counter is not displayed if measurement interval is set to one second. Although interval mode measurements are triggered at exact time when counter elapses measurement will be processed according to internal clock cycle of DM3058 multimeter.

In continuous logging mode measurements interval display will show actual interval between logged measurements in ms or seconds with decimal digits. Interval between logged measurements depends on internal measurements clock of multimeter and selected measurements rate. Rate set with data logger controls acts as multiplier for measurement cycle of DM3058 multimeter. Actual measurements interval will not be exactly same as selected while setting desired interval in continuous mode. Measurements interval is detected and included in data file.

Press MODE button again to show last received measurement instead of measurements interval information.

Blue status led lights while measurement is requested from multimeter. Measurements triggering is indicated also by green/yellow led on back side of data logger. In interval mode multimeter performs single measurement when seconds counter is elapsed. Two measurements are done in dual measurements mode. In continuous logging mode data logger triggers measurements continuously but measurement value is requested and logged according to selected logging interval.

Pressing UP or DOWN button while measurements logging is active changes display backlight dimming.

Measurements logging is stopped by pressing START / STOP button. Measurement file is closed and file counter advanced. Multimeter is set to Single triggering mode. To use any control on multimeter it is necessary to exit remote control mode indicated by “Rmt” on multimeter display. It is done by pressing  button on multimeter. Free running measurements can then be resumed by pressing

button on multimeter. Free running measurements can then be resumed by pressing  button or any other settings can be changed using multimeter controls.

button or any other settings can be changed using multimeter controls.

Using USB disk mode and managing measurement files

Measurement files are retrieved by connecting the data logger to computer using micro USB port. In USB mode data logger mounts as standard USB flash disk. No additional driver files are necessary. Data logger can be disconnected from multimeter using RJ45 connector. It is not necessary to turn off multimeter before unplugging RJ45 connector but measurements logging should not be active when disconnecting. It is also possible to leave data logger connected both to computer USB and multimeter or connect and disconnect USB connection as needed.

At first USB connection flash disk mode of the data logger takes priority. USB disk can then be is dismounted by unplugging micro USB connection or data logger controls can be used to switch between USB disk and data logging mode quickly.

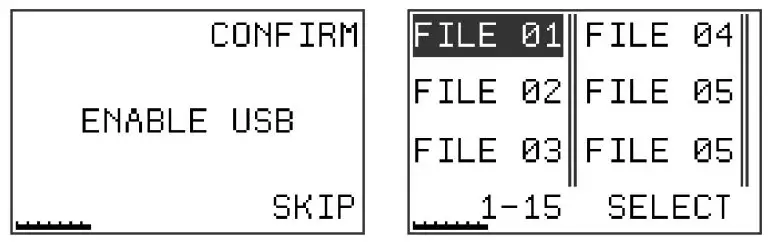

Pressing and holding MODE button while data logger is in data logging mode but measurements logging is not active opens saved measurement files list. If USB connection is detected ENABLE USB prompt will show with CONFIRM and SKIP options. Pressing CONFIRM activates USB disk mode and SKIP proceeds to files list screen. If USB connection is not detected files list will open without additional prompts.

Use UP or DOWN button to scroll through files list. Pressing and holding UP or DOWN button advances to next few files and if files list exceeds one screen first or last file is selected. This can be used to move to the end or beginning of files list quickly.

Pressing MODE button at files list screen cycles through file information such as: measurements type, measurements count and selected file DELETE prompt. While file DELETE prompt is active pressing START / STOP button changes DELETE prompt to CONFIRM. Pressing START / STOP button once again deletes selected file. Remaining files will be renumbered sequentially and file count updated. (It is also possible to delete files in USB disk mode without using data logger controls.) Changing selected file with UP or DOWN button clears DELETE or CONFIRM prompt and advances to next or previous file. Pressing and holding MODE button exits files list and returns to initial screen with interval logging mode set.

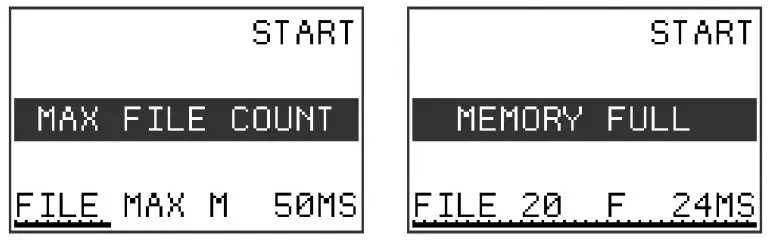

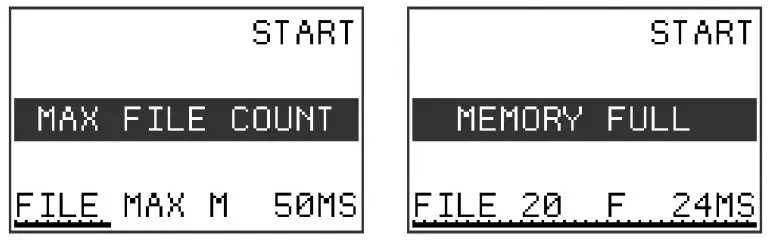

Flash memory pages used by measurements are indicated by ruler type progress bar along the bottom side of data logger screen. There are 4096 pages of 130 measurement records available that can be used by 30 files. When file count limit is reached current file number will change to FILE MAX and further measurements logging will not be possible until file is deleted although free memory pages might be available. If all internal flash memory pages are used MEMORY FULL message is displayed until any file is deleted.

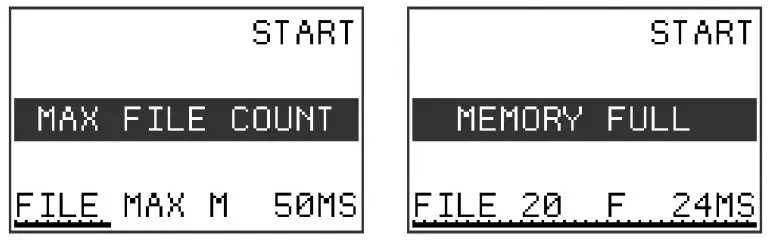

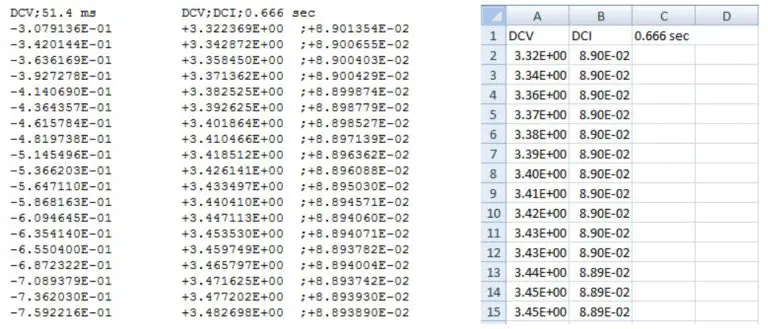

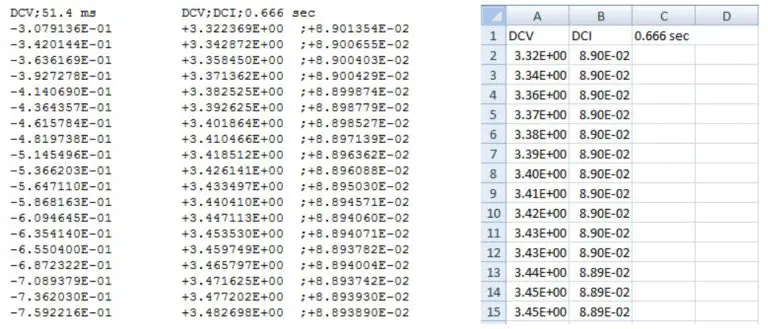

Measurement files in USB disk are formatted as csv text files. First line of each file shows measurement type and detected interval between measurements in continuous mode or seconds between measurements in interval mode. Remaining lines contain measurement values in scientific format. Dual mode measurements shows two measurement types in first line and two measurement values separated by semicolon in remaining lines. Measurement interval in dual measurement mode is time of one complete measurement cycle that consists of two measurements.

File formatting allows files to be opened Microsoft Excel directly without data importing sequence. OpenOffice Calc can be used to open csv files as well. Semicolon should be selected as field separator and “Detect special numbers” option selected in OpenOffice Calc Text import wizard. Any other software that can parse scientific number format can be used as well. Dot symbol “.” should be used as decimal separator in corresponding regional settings of operating system or data processing software.

Unnecessary files can be deleted from USB disk while data logger is connected to computer. It deletes corresponding measurement records from internal data logger memory. Once file is deleted there is no way to revert it. Next time measurements logging mode is activated or USB disk is connected files will be renumbered sequentially so that there will be no missing file numbers in place of deleted files. Although it seems possible to copy files to mounted USB flash disk nothing is actually written to flash memory by doing so.

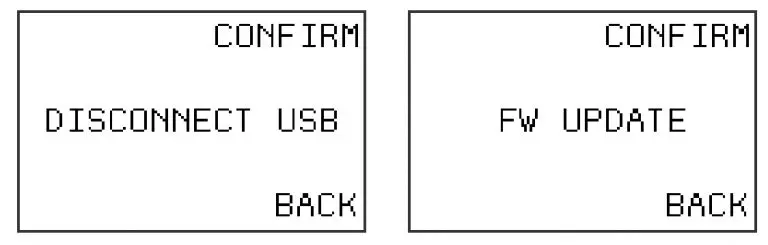

While data logger is connected to computer as USB flash disk it can be disconnected from USB by pressing and holding MODE (bottom right) button. This opens DISCONNECT USB prompt with CONFIRM and BACK options. Pressing UP or DOWN buttons changes prompt to FW UPDATE. Pressing CONFIRM activates selected choice, pressing BACK returns to USB disk mode without changes.

If DISCONNECT USB is activated USB disk dismounts and data logger queries multimeter using serial connection. Display changes to initial measurements logging screen and multimeter should go to remote control “Rmt” mode. If there is no response from multimeter CONNECT prompt is displayed. If FW UPDATE prompt is activated USB disk is disconnected, display dims with status led on and data logger enters firmware update mode enumerating as USB HID device. Firmware can be updated using additional utility. Even if FW UPDATE mode has been activated no changes to firmware are made unless update utility is used. Disconnect and power cycle data logger to clear firmware update mode.

Internal measurements record system can be reset by holding MODE button while data logger is powered on. This opens ERASE FILES prompt with CONFIRM and SKIP options. Pressing CONFIRM erases all flash memory pages and resets internal records system to blank state. Pressing SKIP proceeds with startup. ERASE FILES option can be used to delete all files quickly and to clear any internal records system error. Holding MODE button activates ERASE FILES prompt only if data logger is powered on while connected to multimeter or if unpowered data logger is connected to USB.

Additional notes on some measurement types

Useful feature of DM3058 multimeter is dual mode measurements ability to measure two types of values. There are some limitations for using it. Probably most useful mode is to measure both voltage and current of some circuit. Connections for such measurements should be made in a way that both voltage and current shares same return path. Other restriction is that secondary measurement always runs in auto range mode. Some trial and error is needed to avoid internal relays of multimeter clicking continuously while changing modes. This will break measurements timing and most likely is not recommended over longer periods. For fast changing measurement values it can be significant that both measurements are not processed at exactly same moment. At first primary measurement is done and then secondary. Time between primary and secondary measurement depends on selected measurement rate.

While testing measurement ranges and fine tuning dual mode measurements it may happen that multimeter skips some internal measurement cycle and starts to display primary measurement value in place of secondary and vice versa. Correct values are usually transmitted to data logger over serial connection. To clear this situation it is necessary to turn multimeter off and on again.

To avoid switching relays when measured value changes significantly it might help to use fixed range setting adjusting it to largest expected value. Although it is possible to mix AC and DC measurements in dual measurements mode changing from AC to DC mode will always switch internal relays.

Measurement period of capacitance varies greatly depending of capacitance value. Measurement of frequency is done at about 0.8 seconds intervals. If frequency is used as secondary measurement type it is possible to read measurements more often in continuous mode but actual frequency value is updated at about 0.8 seconds rate.

Sensor measurement mode values are reported over serial connection but not corresponding converted display values. Commands to retrieve converted sensor value are not provided in DM3058 command set. Although sensor measurements mode is detected and supported by data logger only measured value is logged without knowing what type of measurement it is and how it was converted to display value.

This manual is written by KPT for DM3058 data logger device

Licensed under Creative Commons Attribution-NoDerivatives 4.0 International License