RYOBI RY143011 Electric Pressure Washer

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

- Read and understand all instructions. Failure to follow all instructions listed below may result in electric shock, fire, and/or serious personal injury.

- When using this product basic precautions should always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS PRODUCT - To reduce the risk of injury, close supervision is necessary when a product is used near children.

- Be thoroughly familiar with controls. Know how to stop the product and release pressure quickly.

- Stay alert and exercise control. Watch what you are doing and use common sense. Do not operate the product when you are tired. Do not rush.

- Do not operate the product while under the influence of drugs, alcohol, or any medication.

- Keep the area of operation clear of all persons, particularly small children, and pets.

- Don’t overreach or stand on a ladder, rooftop, or other unstable support. Keep proper footing and balance at all times.

- Follow the maintenance instructions specified in this manual.

- This product is provided with a ground fault circuit interrupter built into the power cord plug. If replacement of the plug or cord is needed, use only identical replacement parts.

- WARNING: Risk of injection or injury – Do not direct discharge stream at persons.

GROUNDING INSTRUCTIONS

This product must be grounded. If it should malfunction or break down, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This prod-uct is equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

DANGER: Improper connection of the equipment-grounding conductor can result in a risk of electrocution. Check with a qualified electrician or service personnel if you are in doubt as to whether the outlet is properly grounded. Do not modify the plug provided with the product – if it will not fit the outlet, have a proper outlet installed by a qualified electrician. Do not use any type of adaptor with this product.

GROUND FAULT CIRCUIT INTERRUPTER PROTECTION

This pressure washer is provided with a ground-fault circuit-interrupter (GFCI) built into the plug of the power supply cord. This device provides additional protection from the risk of electric shock. Should replacement of the plug or cord become necessary, use only identical replacement parts that include GFCI protection.

EXTENSION CORDS

See Figure 1.

Use only 3-wire extension cords that have 3-prong grounding-type plugs and 3-pole cord connectors that accept the plug from the product. Use only extension cords that are intended for outdoor use. These extension cords are identified by a marking “Acceptable for use with outdoor appliances; store indoors while not in use.” Use only extension cords having an electrical rating not less than the rating of the product. Do not use damaged extension cords. Examine the extension cord before using and replace if damaged. Do not abuse the extension cord and do not yank on any cord to disconnect. Keep cord away from heat and sharp edges. Always disconnect the extension cord from the receptacle before disconnecting the product from the extension cord.

WARNING: To reduce the risk of electrocution, keep all connections dry and off the ground. Do not touch plug with wet hands.

To avoid the possibility of the product plug or outlet getting wet, the operator should arrange a “drip loop” in the cord connecting the product to the outlet. The “drip loop” is that part of the cord below the level of the outlet, or the connector if an extension cord is used, to prevent water from traveling along the cord and coming in contact with the outlet.

- A – Pressure washer power cord

- B – Drip loop

- C – Extension cord

SPECIFIC SAFETY RULES

- Use caution when positioning the pressure washer for use. Warm air from the motor could cause discolored spots on grass.

- Know your product. Read the operator’s manual carefully. Learn the machine’s applications and limitations as well as the specific potential hazards related to this product.

- To reduce the risk of injury, keep children and visitors away. All visitors should wear safety glasses and be kept a safe distance from the work area.

- Use the right product. Don’t force a product or attachment to do a job it was not designed for. Don’t use it for a purpose not intended.

- Dress properly. Wear long pants and long sleeves. Do not wear loose clothing, neckties, or jewelry. They can get caught and draw you into moving parts. Rubber gloves and nonskid footwear are recommended when working outdoors. Also wear protective hair covering to contain long hair.

- Do not operate the equipment while barefoot or when wearing sandals or similar lightweight footwear. Wear protective footwear that will protect your feet and improve your footing on slippery surfaces.

- Exercise caution to avoid slipping or falling.

- syawlA wears eye protection with side shields marked to comply with ANSI Z87.1. Following this rule will reduce the risk of serious personal injury.

- Use only recommended accessories. The use of improper accessories may cause a risk of injury.

- Check damaged parts. Before further use of the product, a guard or other part that is damaged should be carefully checked to determine that it will operate properly and perform its intended function. Check for alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or other part that is damaged must be properly repaired or replaced by an authorized service center to avoid risk of personal injury.

- Never leave the product running unattended. Turn the power off. Don’t leave the product until it comes to a complete stop.

- Keep the motor free of grass, leaves, or grease to reduce the chance of a fire hazard.

- Follow the manufacturer’s recommendations for safe loading, unloading, transport, and storage of the machine.

- Keep the product dry, clean, and free from oil and grease. Always use a clean cloth when cleaning. Never use brake fluids, gasoline, petroleum-based products, or any solvents to clean products.

- Check the work area before each use. Remove all objects such as rocks, broken glass, nails, wire, or string which can be thrown or become entangled in the machine.

- Do not use the product if the switch does not turn it off. Has the switch been replaced by an authorized service center?

- Avoid dangerous environments. Don’t expose to rain. Keep work area well lit.

- Do not abuse the cord. Never use the cord to carry the product or to disconnect the plug from an outlet. Keep cord away from heat, oil, sharp edges, or moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric shock.

- Ground Fault Circuit Interrupter (GFCI) protection should be provided on the circuit(s) or outlet(s) to be used for the product. Receptacles are available having built-in GFCI protection and may be used for this measure of safety.

- This pressure washer is not recommended for use with an extension cord. If an extension cord must be used, please make sure it is in good condition. When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. A wire gauge size (A.W.G.) of at least 12 is recommended for an extension cord 25 feet or less in length. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the cord. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating.

- WARNING: Use outdoor extension cords marked SW-A, SOW-A, STW-A, STOW-A, SJW-A, SJTW-A, or SJTOWA. These cords are rated for outdoor use and reduce the risk of electric shock.

- Inspect extension cords periodically and replace if damaged. Keep handles dry, clean, and free from oil or grease.

- Never direct a water stream toward people or pets, or any electrical device.

- Before starting any cleaning operation, close doors and windows. Clear the area to be cleaned of debris, toys, outdoor furniture, or other objects that could create a hazard.

- Do not use acids, alkalines, solvents, flammable material, bleaches, or industrial-grade solutions in this product. These products can cause physical injuries to the operator and irreversible damage to the machine.

- WARNING: High-pressure jets can be dangerous if subject to misuse. The jet must not be directed at persons, animals, electrical devices, or the machine itself.

- Keep the motor away from flammables and other hazardous materials.

- Check bolts and nuts for looseness before each use. A loose bolt or nut may cause serious motor problems.

- Before storing, allow the motor to cool.

- When servicing use only identical replacement parts. Use of any other parts may create a hazard or cause product damage.

- ONLY use cold water.

- Never pick up or carry the machine while the motor is running.

- Never start the machine if ice has formed in any part of the equipment.

- Make sure a minimum clearance of 3 feet is maintained from combustible materials.

- Never spray close to the surface to be cleaned, as you can damage the surface.

- After stopping the motor, always pull the trigger on the trigger handle to relieve stored pressure in the high-pressure hose. Failure to do so could result in serious personal injury.

- Ensure the high-pressure hose is properly connected before using the product.

- Connect pressure washer only to an individual branch circuit.

- Hold the trigger handle securely with both hands. Expect the trigger handle to move when the trigger is pulled due to reaction forces. Failure to do so could cause loss of control and injury to yourself and others.

- For outdoor use only.

- Save these instructions. Refer to them frequently and use them to instruct other users. If you loan someone this product, loan them these instructions also.

SYMBOLS

| The following signal words and meanings are intended to explain the levels of risk associated with this product. | ||

| SYMBOL | SIGNAL | MEANING |

|

DANGER: | Indicates a hazardous situation, which, if not avoided, will result in death or serious injury. |

|

WARNING: | Indicates a hazardous situation, which, if not avoided, could result in death or serious injury. |

|

CAUTION: | Indicates a hazardous situation, that, if not avoided, may result in minor or moderate injury. |

|

NOTICE: | (Without Safety Alert Symbol) Indicates information considered important, but not related to a potential injury (e.g. messages relating to property damage). |

| Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the product better and safer. | |||

| SYMBOL | NAME | DESIGNATION/EXPLANATION | |

|

Safety Alert | Indicates a potential personal injury hazard. | |

|

Read Operator’s Manual | To reduce the risk of injury, user must read and understand the operator’s manual before using this product. | |

|

Eye Protection | Always wear eye protection with side shields marked to comply with ANSI Z87.1. | |

|

Wet Conditions Alert | Do not expose to rain or use in damp locations, and never direct a water stream toward any electrical device. | |

|

Risk of Injection | To reduce the risk of injection or injury, never direct a water stream towards people or pets or place any body part in the stream. Leak- ing hoses and fittings are also capable of causing injection injury. Do not hold hoses or fittings. | |

|

Risk of Explosion | Do not spray flammable liquids. Flammable liquids and their vapors are explosive and can cause severe burns or death. | |

|

Kickback | To reduce the risk of injury from kickback, hold the spray wand securely with both hands when the machine is on. | |

|

Electric Shock | Do not use near electric power lines or receptacle outlets. | |

|

Chemical Burns | To reduce the risk of injury or damage, DO NOT USE ACIDS, ALKALINES, BLEACHES, SOLVENTS, FLAMMABLE MATERIAL,

OR INDUSTRIAL GRADE SOLUTIONS in this product. |

|

| Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the product better and safer. | ||

| SYMBOL | NAME | DESIGNATION/EXPLANATION |

| V | Volts | Voltage |

| A | Amperes | Current |

| Hz | Hertz | Frequency (cycles per second) |

| W | Watt | Power |

|

Alternating Current | Type of current |

| no | No Load Speed | Rotational speed, at no load |

| …/min | Per Minute | Revolutions, strokes, surface speed, orbits etc., per minute |

ELECTRICAL

EXTENSION CORDS

When using a power tool at a considerable distance from a power source, be sure to use an extension cord that has the capacity to handle the current the product will draw. An undersized cord will cause a drop in line voltage, possibly resulting in overheating, loss of power, and/or circuit breaker or GFCI tripping. Use the chart to determine the minimum wire size required in an extension cord. Only round jacketed cords listed by Underwriter’s Laboratories (UL) should be used.

When working outdoors with a product, use an extension cord that is designed for outside use. This type of cord is designated with “WA” or “W” on the cord’s jacket.

Before using any extension cord, inspect it for loose or exposed wires and cut or worn insulation.

It is possible to tie the extension cord and power cord in a knot to prevent them from becoming disconnected during use. Make a knot, then connect the plug end of the power cord into the receptacle end of the extension cord. This method can also be used to tie two extension cords together.

NOTE:

This pressure washer is not recommended for use with an extension cord. If using an extension cord, arrange a drip loop to avoid the possibility of the tool plug getting wet (see page 2).

USE ONLY THIS SIZE EXTENSION CORD WHEN USING THIS PRODUCT:

| Cord Length | Wire Size (A.W.G.) |

| 25 ft. | 12 |

| 50 ft. | Not Allowed |

WARNING:

- Keep the extension cord clear of the working area. Position the cord so that it will not get caught on lumber, tools, or other obstructions while you are working with a power tool. Failure to do so can result in serious personal injury.

- Check extension cords before each use. If damaged replace it immediately. Never use the product with a damaged cord since touching the damaged area could cause electrical shock resulting in serious injury.

ELECTRICAL CONNECTION

This product has a precision-built electric motor. It should be connected to a power supply that is nominal 120V/60Hz AC (typical U.S. household circuit). Do not operate this product on direct current (DC). A substantial voltage drop will cause a loss of power and the motor will overheat. If the product does not operate when plugged into an outlet, double-check the power supply.

GROUNDING INSTRUCTIONS

This product must be grounded. In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This product is equipped with an electric cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet, have the proper outlet installed by a qualified electrician.

WARNING:

Improper installation of a grounded plug increases the risk of electric shock. When repair or replacement of the cord or plug is required, take the tool to an authorized service center.

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood, or if in doubt as to whether the product is properly grounded.

Repair or replace a damaged or worn cord immediately.

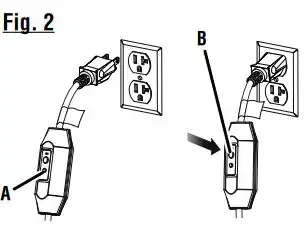

This product is for use on a nominal 120 V circuit and has a grounding plug similar to the plug illustrated in figure 2. Only connect the product to an outlet having the same configuration as the plug. Do not use an adapter with this product.

GROUND FAULT CIRCUIT INTERRUPTER

See Figure 2.

This unit is equipped with a Ground Fault Circuit Interrupter (GFCI), which guards against the hazards of ground fault currents. An example of a ground-fault current is the current that would flow through a person who is using an appliance with faulty insulation and, at the same time, is in contact with an electrical ground such as a plumbing fixture, wet floor, or earth.

GFCI plugs do not protect against short circuits, overloads, or shocks.

- A – Test button

- B – Reset button

NOTE:

To ensure readiness for use, press the reset button each time you connect the pressure washer to the power supply.

The GFCI plug can be tested with the TEST and RESET buttons.

To test:

- Press the TEST button. You will hear a “click” sound and the LED light will go out.

- To restore power, press the RESET button. The LED light will illuminate to indicate power has been restored.

Perform this test monthly to ensure proper operation of the GFCI. - To reduce the risk of electric shock the supervisory circuit must be operated before an appliance is plugged into any receptacle on the device.

FEATURES

PRODUCT SPECIFICATIONS

- Maximum Pounds Per Square Inch* 3000 psi

- Maximum Gallons Per Minute. 1.1 GPM

- Input nominal 120V/60Hz AC only, 13.5 Amps

KNOW YOUR PRESSURE WASHER

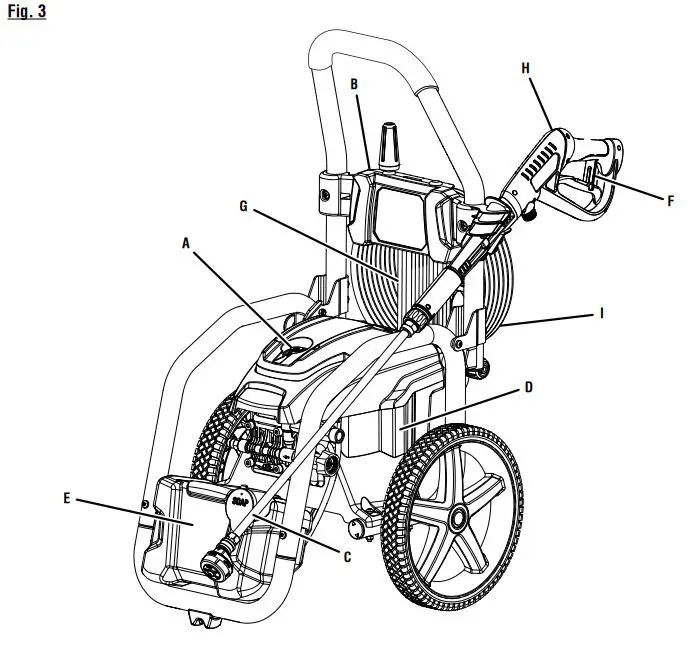

See Figure 3.

The safe use of this product requires an understanding of the information on the product and in this operator’s manual as well as a knowledge of the project you are attempting. Before use of this product, familiarize yourself with all operating features and safety rules.

- A – On/off switch

- B – Nozzle storage

- C – Spray wand

- D – Motor

- E – Soap tank

- F – Trigger with lock-out

- G – Power cord

- H – Trigger handle

- I – High pressure hose

5-IN-1 CHANGE OVER NOZZLE

The 5-in-1 Change-over Nozzle makes it easy to change spray patterns.

AUTOMATIC SOAP INJECTION SYSTEM

Pour pressure washer detergent into the soap tank to apply detergent quickly and easily to your cleaning project. Use of the soap nozzle will activate the soap injector at a 20:1 dilution ratio.

GFCI PLUG

The pressure washer is equipped with a GFCI plug to guard against the hazards of ground fault currents. This plug does not protect against short circuits, overloads, or shocks.

ON/OFF SWITCH

This switch turns the pressure washer on and off.

TRIGGER HANDLE

The trigger handle has a gripping surface that provides added control of the spray wand and helps reduce fatigue.

TRIGGER WITH LOCK-OUT

Pulling the trigger releases a stream of water for high-pressure cleaning. The lock-out provides protection against unauthorized use.

ASSEMBLY

UNPACKING

This product requires assembly.

- Carefully remove the product and any accessories from the box. Make sure that all items listed in the packing list are included.

WARNING:

Do not use this product if any parts on the Packing List are already assembled to your product when you unpack it. Parts on this list are not assembled to the product by the manufacturer and require custom installation. Use of a product that may have been improperly assembled could result in serious personal injury. - Inspect the product carefully to make sure no breakage or damage occurred during shipping.

- Do not discard the packing material until you have carefully inspected and satisfactorily operated the product.

- If any parts are damaged or missing, please call 1- 800-525-2579 for assistance.

PACKING LIST

- Electric Pressure Washer Trigger Handle

- Spray Wand

- 35 ft. High-Pressure Hose 5-in-1 Change Over Nozzle Turbo Nozzle

- Wheel (2)

- Axle (2)

- Hitch Pin (2)

- Washer (2)

- Operator’s Manual

WARNING:

- If any parts are damaged or missing do not operate this product until the parts are replaced. Use of this product with damaged or missing parts could result in serious personal injury.

- Do not attempt to modify this product or create accessories not recommended for use with this product. Any such alteration or modification is misused and could result in a hazardous condition leading to possible serious personal injury.

- Do not connect to the power supply until assembly is completed. Failure to comply could result in accidental starting and possible serious personal injury.

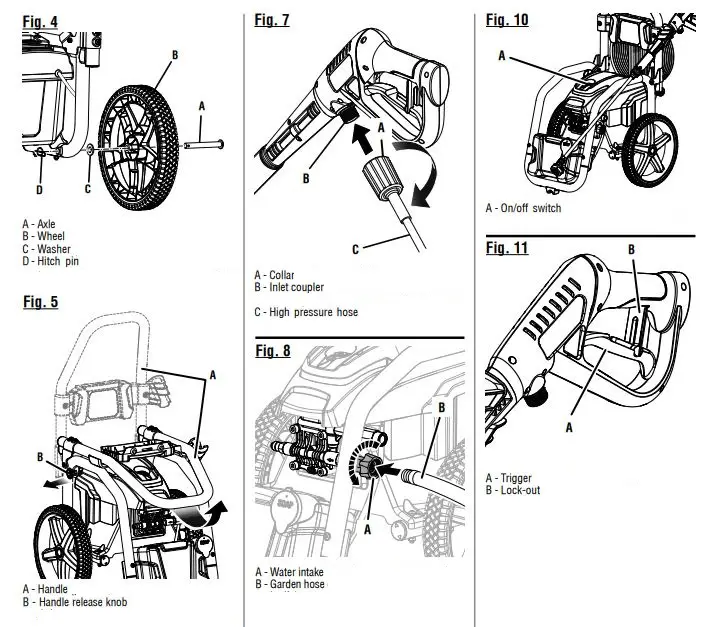

INSTALLING THE WHEELS

See Figure 4.

- Locate the axles, hitch pins, washers and wheels.

- Slide the axle through the hole in the center of the wheel.

- Slide the washer onto the axle.

- Lift the machine and slide the axle into the wheel mount- ing hole in the machine base as shown.

- Push the hitch pin into the hole on the end of the axle to secure the wheel assembly.

NOTE: The hitch pin should be pushed into the axle until the center of the pin rests on top of the axle.

RAISING AND LOWERING THE HANDLE

See Figure 5. - To raise the handle: pull the handle up until the handle release knob snaps through the locking hole to secure the handle in place.

- To lower the handle: pull the handle release knob out then lower the handle to the position shown in figure 5.

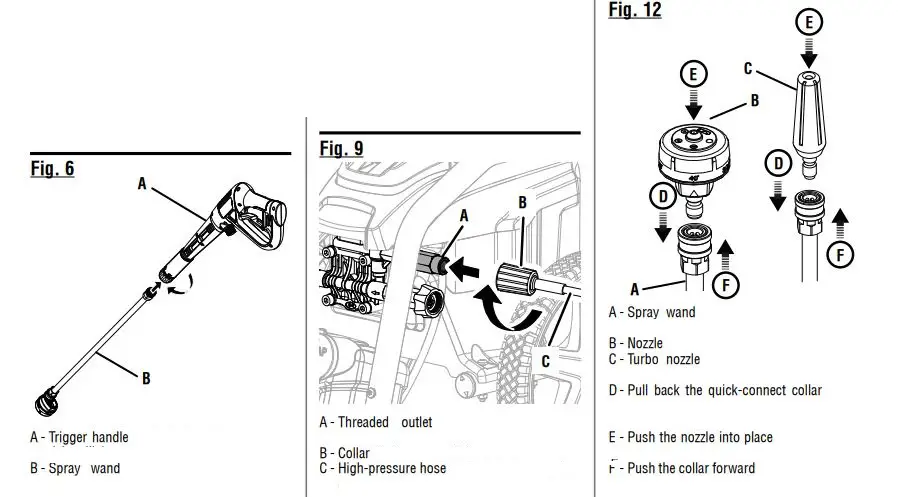

CONNECTING THE SPRAY WAND TO THE

TRIGGER HANDLE

See Figure 6. - Place the threaded end of the spray wand in the connector on the end of the trigger handle.

- Turn the connector until it stops to secure the spray wand in place.

CONNECTING THE HIGH-PRESSURE HOSE TO THE TRIGGER HANDLE

See Figure 7. - Screw the collar on the high-pressure hose onto the trigger handle inlet coupler by turning the hose collar clockwise. Tighten securely.

NOTE: Be careful to avoid cross-threading, which can cause the trigger handle to leak during use. - Pull on the hose to be certain it is properly secured.

CONNECTING THE GARDEN HOSE TO THE PRESSURE WASHER

See Figure 8. - NOTICE:

Always observe all local regulations when connecting hoses to the water main. Some areas have restrictions against connecting directly to public drinking water sup-ply to prevent the feedback of chemicals into the drinking water supply. Direct connection through a receiver tank or backflow preventer is usually permitted.

The water supply must come from water main. NEVER use hot water or water from pools, lakes, etc. Before connecting the garden hose to the pressure washer: - Run water through the hose for 30 seconds to clean any debris from the hose.

- Inspect the screen in the water intake.

- If the screen is damaged, do not use the machine until the screen has been replaced.

- If the screen is dirty, clean it before connecting the garden hose to the machine.

To connect the garden hose to the machine: - Completely uncoil the garden hose or remove it completely from reel to prevent kinks.

NOTE: There must be a minimum of 10 feet of unrestricted hose between the pressure washer intake and the hose faucet or shut-off valve (such as a “Y” shut-off connector). - With the hose faucet turned completely off, attach the end of the garden hose to the water intake. Tighten by hand.

NOTICE:

Do not run the pressure washer without a water supply connected and turned on, as this may damage the high-pressure seals and decrease pump life. Completely unwind the hose from its reel or coil and make sure the hose is not being restricted by tires, rocks, or any other objects that may lessen or prevent water flow to the pressure washer.

CONNECTING THE HIGH-PRESSURE HOSE TO THE PUMP

See Figure 9.

- Completely uncoil and straighten the high-pressure hose to prevent kinks.

NOTE: See Using the High-Pressure Hose in Operation for more information about using the high-pressure hose. - Align the collar on the hose to the threaded outlet on the pump.

- Install the high-pressure hose collar onto the threaded outlet.

- Turn the collar clockwise to tighten the hose securely to the pump.

NOTE: Be careful to avoid cross-threading, which can cause the hose to leak during use. - Pull on the hose to be certain it is properly secured.

OPERATION

WARNING:

- Do not allow familiarity with the product to make you careless. Remember that a careless fraction of a second is sufficient to inflict serious injury.

- Always wear eye protection with side shields marked to comply with ANSI Z87.1. Failure to do so could result in objects being thrown into your eyes resulting in possible serious injury.

- Do not use any attachments or accessories not recommended by the manufacturer of this product. The use of attachments or accessories not recommended can result in serious personal injury.

- Never direct a water stream toward people or pets, or any electrical device. Failure to follow these instructions could result in serious injury, electric shock, or death.

NOTICE:

Before each use, inspect the entire product for damaged, missing, or loose parts such as screws, nuts, bolts, caps, etc. Tighten securely all fasteners and caps and do not operate this product until all missing or damaged parts are replaced. Please call customer service or contact an authorized service center for assistance.

APPLICATIONS

You may use this tool around the house for cleaning most small to large horizontal or vertical exterior surfaces, smaller exterior objects and structures, and outdoor equipment and tools.* You can: - Clean or remove mold and mildew from weathered decks, driveways, patios, walkways, sidewalks, etc.

- Remove dirt from various exterior vertical surfaces such as house exteriors, siding, fences, brick, concrete or stone walls, etc.

- Wash boats, outdoor furniture, powered or non-powered garden equipment, gutters, window screens, grills, play-ground equipment, etc.

*Always test in an inconspicuous area first.

STARTING AND STOPPING THE PRESSURE WASHER

See Figure 10.

NOTICE:

Do not run the pressure washer without water supply connected and turned on, as this may damage the high-pressure seals and decrease pump life. Completely unwind the hose from its reel or coil and make sure the hose is not being restricted by tires, rocks, or any other objects that may lessen or prevent water flow to the pressure washer.

Before starting the motor: - Connect all hoses.

NOTE: Make sure the pressure washer’s water intake screen is in place and unclogged before connecting garden hose. - Turn on the garden hose then pull the trigger to relieve air pressure; hold the trigger until a steady stream of water appears.

NOTE: Make sure the faucet is turned on fully and that there are no kinks or leaks in the hose.

To start the motor: - With the on/off switch in the OFF position, connect the pressure washer to the power supply.

NOTE: If using an extension cord, make sure to arrange a drip loop as described on page 2.

WARNING:

To reduce the risk of electrocution, keep all connections dry and off the ground. Do not touch plug with wet hands. - Press the reset button on the pressure washer’s plug to make sure the unit is ready for operation.

- Put the on/off switch in the ON position to start the motor.

NOTICE:

Routinely make a visual inspection of the pump and motor during use. If you notice any lubricant leaking around the pump or motor seals, stop using the pres-sure washer immediately. Contact customer service or a qualified service center for repair. Failure to do so may cause property damage.

To stop the motor: - Put the on/off switch in the OFF position.

- Pull trigger to release water pressure.

NOTE: The pressure washer may be on and the system may have pressure even when the pump and/or motor cannot be heard running. Always use caution around the pressure washer. Shutting off the motor will not relieve pressure in the system.

USING THE TRIGGER HANDLE

See Figure 11.

WARNING:

Hold the trigger handle securely with both hands. Expect the trigger handle to move when the trigger is pulled due to reaction forces. Failure to do so could cause loss of control and injury to yourself and others. - Pull back and hold the trigger to operate the pressure washer.

- Release the trigger to stop the flow of water through the nozzle.

To engage the lockout: - Push up on the lock out until it clicks into the slot.

To disengage the lockout: - Push the lockout down and into its original position.

Start with the nozzle 1–2 ft. away from the cleaning surface and carefully approach the surface just until the desired level of cleaning is achieved. If the spray is too close it can damage the cleaning surface.

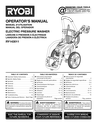

USING THE 5-IN-1 CHANGE OVER NOZZLE

See Figure 12.

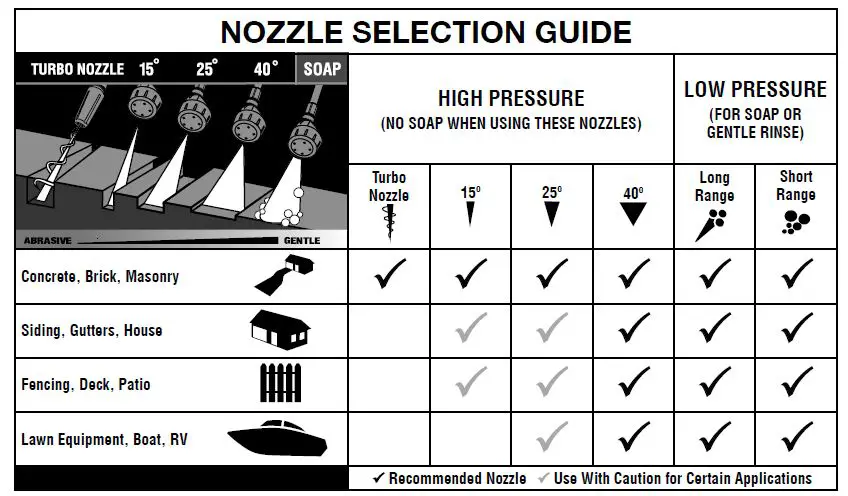

There are five spray pattern settings located on the 5-in-1 Change-over Nozzle. To select a spray pattern, rotate the spray selector to the desired setting. Refer to the Nozzle Selection Guide for more information about which setting to choose.

NOZZLE SELECTION GUIDE

WARNING:

NEVER remove nozzles without first turning off the motor, disconnecting from the power supply, relieving the water pressure in the trigger handle, and locking the lock out on the trigger handle. NEVER point the nozzle at your face or at others. The quick-connect feature contains small springs that could eject the nozzle with some force. Failure to follow these instructions could result in an eye injury or other serious personal injury.

To connect a nozzle to the spray wand:

- Turn off the pressure washer, disconnect from the power supply, and shut off the water supply. Pull the trigger to release water pressure.

- Engage the lock-out on the trigger handle by pushing up on the lock-out until it clicks into the slot.

- Pull back the quick-connect collar.

- Push the nozzle into place in the spray wand.

- Push the collar forward so that the nozzle is secured properly. Check to see that the nozzle is secure.

To disconnect a nozzle from the spray wand once the cleaning job is complete: - Turn off the pressure washer, disconnect from the power supply, and shut off the water supply. Pull trigger to release water pressure.

- Engage the lock-out on the trigger handle by pushing up on the lock-out until it clicks into the slot.

- Pull back and hold the quick-connect collar.

- Remove the nozzle by pulling it from the quick-connect collar. Place nozzle in the nozzle storage area on the top of the machine.

USING THE HIGH-PRESSURE HOSE

WARNING:

Injection hazard. Fully unwrap and straighten high pres-sure hose prior to and during each use and do not allow it to become kinked. The high-pressure hose features an outer covering that provides strength to the hose. If the outer covering becomes damaged, stop using the hose and replace it immediately. A kinked or damaged hose can develop a high-pressure leak and result in a possible injection or another serious personal injury.

To prevent damage to the outer covering:

- Inspect the hose before every use.

- Fully unwrap and straighten the hose before use.

- Do not allow the high-pressure hose to be kinked.

- Keep hose away from hot surfaces and sharp edges.

- Do not pull the unit by a high-pressure hose.

- Do not allow the hose to be crushed or wrapped around objects.

WASHING WITH DETERGENT

See Figures 13-14.

As sold, this unit is designed for use with “downstream” pres-sure washer detergents. To convert for use with “upstream” detergents, contact customer service or an authorized service center for more information.

NOTICE:

USE ONLY DETERGENTS DESIGNED FOR PRESSURE WASHERS. Do not use household detergents, acids, alkalines, bleaches, solvents, flammable material, or industrial-grade solutions, which can damage the pump or cause property damage. Many detergents may require mixing prior to use. Prepare cleaning solution as instructed on the solution bottle. Always test in an inconspicuous area before beginning.

- Disconnect the pressure washer from the power supply.

- Pour detergent in the soap tank. Use a funnel, if needed, to prevent accidental spilling of the detergent outside the tank. If any detergent is spilled during the filling process, make sure the unit is cleaned and dried before proceeding.

NOTE: The machine setting of this unit is 20:1, which usually allows the use of 1-gallon pressure washer detergent without further dilution. Check your detergent instructions to be sure additional dilution is not necessary. - Install 5-in-1 Change-over Nozzle (if necessary). Rotate the spray selector on the nozzle to either the blue short-range detergent or blue long-range detergent setting.

- Connect unit to the power supply and turn the pressure washer on.

- Squeeze the trigger and wait approximately 5 seconds for the detergent to appear.

- Spray the detergent on a dry surface using long, even, overlapping strokes. To prevent streaking, do not allow detergent to dry on the surface.

For long-range detergent application:

With the nozzle installed on the spray wand and the engine shut off, rotate the spray selector to the long-range detergent setting.

For short-range detergent application:

With the nozzle installed on the spray wand and the engine shut off, rotate the spray selector to the short-range deter-gent setting.

Before shutting off the motor: - Fill the soap tank with clean water.

- Spray the clear water through the spray wand until the tank is empty.

- If any detergent remains in the spray, repeat with the second tank of clean water.

- Shut off the motor.

NOTE: Shutting off the motor will not relieve pressure in the system. Pull trigger to release water pressure.

RINSING WITH THE PRESSURE WASHER - Turn off the pressure washer and shut off the water supply. Pull the trigger to release water pressure.

- Engage the lockout on the trigger handle by pushing up on the lock out until it clicks into the slot.

- Remove the soap nozzle and place it in the nozzle storage area on the machine.

- Select the right nozzle for the job. See the chart shown earlier in the manual to select the appropriate nozzle.

- Start at the top of the area to be rinsed and work down, overlapping the strokes.

USING PUMP PROTECTOR

See Figure 15.

Regular use of a commercially available pump protector prolongs the life of the pressure washer by removing hard water mineral deposits, lubricating pump seals and pistons, and preventing freeze damage. Pump protector should be added to the unit after every use and before storage. A pump protector can be purchased at the retailer where you purchased your pressure washer, or by calling customer service.

The instructions that follow are typical for adding a pump protector but you should always verify the specific instructions provided by the manufacturer of the pump protector used. - Turn off the pressure washer motor and shut off the water supply. Pull the trigger to release water pressure.

- Disconnect the garden hose and high-pressure hose.

- Unscrew the threaded top from the pump protector bottle and remove the paper seal from the bottle. Reinstall top on the bottle and tighten securely.

NOTE: The rubber seal should remain inside the threaded top. If it comes out, be sure to replace it before reinstalling the top. - Remove the bottle cap and attach the threaded end of the bottle securely to the pressure washer pump water intake.

- Squeeze the bottle to inject contents into the pump.

- The pump is protected when the protector fluid exits the pump outlet.

MOVING THE PRESSURE WASHER

See Figure 16.

NOTE: Never lift or carry this product using the handle and never place the unit in any position other than upright on its wheels. - Turn the pressure washer off. Point nozzle in a safe direction and pull the trigger to release water pressure.

- Tilt the machine toward you slightly until it balances on the wheels then roll the machine to the desired position. Do not tilt forward or sideways when moving.

- DO NOT attempt to move the unit by pulling on any of the hoses.

MAINTENANCE

WARNING:

- Before inspecting, cleaning, or servicing the machine, shut off motor, wait for all moving parts to stop, disconnect unit from the power supply, and pull the trigger to release water pressure. Failure to follow these instructions can result in serious personal injury or property damage.

- Always wear eye protection with side shields marked to comply with ANSI Z87.1. Failure to do so could result in objects being thrown into your eyes, resulting in possible serious injury.

- When servicing, use only identical replacement parts. Use of any other parts could create a hazard or cause product damage.

NOTICE:

Periodically inspect the entire product for damaged, missing, or loose parts such as screws, nuts, bolts, caps, etc. Tighten securely all fasteners and caps and do not operate this product until all missing or damaged parts are replaced. Please call customer service or contact an authorized service center for assistance.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from various types of commercial solvents and may be damaged by their use. Use clean cloths to remove dirt, dust, oil, grease, etc.

WARNING: - Do not at any time let brake fluids, gasoline, petroleum-based products, penetrating oils, etc., come in contact with plastic parts. Chemicals can damage, weaken, or destroy plastic which could result in serious personal injury.

POWER SUPPLY CORD REPLACEMENT

If replacement of the power supply cord is necessary, this must be done by an authorized service center in order to avoid a safety hazard.

PUMP LUBRICATION

The pump on this unit is lubricated with a sufficient amount of high-grade lubricant for the life of the unit under normal operating conditions. Therefore, no further lubrication is required.

PUMP MAINTENANCE

Routinely make a visual inspection of the pump. If you notice any leaking of lubricant around the pump seals, take the pressure washer to an authorized service center for repair. There are no user-serviceable parts to the pressure washer pump. Any attempt to service or alter the pump may damage the pressure washer and void your product warranty.

NOZZLE MAINTENANCE

See Figure 17.

Excessive pump pressure (a pulsing sensation felt while squeezing the trigger) may be the result of a clogged or dirty nozzle.

- Turn off the pressure washer, disconnect from the power supply, and shut off the water supply. Pull the trigger to release water pressure.

- Remove the nozzle from the spray wand.

WARNING:

NEVER remove nozzles without first turning off the motor, disconnecting from the power supply, relieving the water pressure in the trigger handle, and locking the lockout on the trigger handle. NEVER point the nozzle at your face or at others. The quick-connect feature contains small springs that could eject the nozzle with some force. Failure to follow these instructions could result in an eye injury or other serious personal injury.

- To free any foreign materials clogging or restricting the nozzle, blow out or remove debris with a straightened paper clip or fine needle (not included).

- Using a garden hose, flush debris out of nozzle by back flushing (running the water through the nozzle backward or from the outside to the inside).

- Reconnect the nozzle to the spray wand.

- Turn on the water supply and start the motor.

STORING THE PRESSURE WASHER

See Figures 18 – 19.

NOTE: Regular use of pump protectors will give you better performance of the unit and increase the life of the pump.

Store in a dry, covered area where the weather can’t damage it.

It is important to store this product in a frost-free area. Al-ways empty water from all hoses, the pump, and the soap tank before storing.

- Make sure the on/off switch is in the OFF position.

- Disconnect both the high-pressure hose and the garden hose from the pump.

- Tilt the unit as shown to allow any remaining water in the pump to drain from the water outlet.

- Pull the handle release knob out and lower the handle to the down position.

NOTICE:

If the location where your pressure washer is stored will fall below 32°F, the use of a pump protector is required before storing to prevent freeze damage. Freeze damage will void your warranty. - Store the unit and accessories in an area that does not reach freezing temperatures. Do not store near furnace or other sources of heat that could dry out the pump seals.

TROUBLESHOOTING

| PROBLEM | POSSIBLE CAUSE | SOLUTION |

| The pressure washer does not start when the trigger is depressed | Power cord not connected to a power source.

The on/off switch is in the OFF position. GFCI is tripped. House/shop circuit breaker is tripped. Water pressure in hose. Receptacle is bad. |

Connect the power cord to a live 120V AC, 60 Hz AC receptacle.

Put the on/off switch in the ON position. Press the reset button on the GFCI plug. Reset house/shop breaker. Make sure the pressure washer is connected to an individual branch circuit only. If using an extension cord, make sure it is heavy enough to carry the current of the pressure washer. Squeeze trigger to relieve water pressure. Try another receptacle. |

| The pump doesn’t produce pressure | The spray selector on the 5-in-1 Change-over Nozzle is set to either the short-range detergent or long-range detergent setting.

Inadequate water supply Trigger handle or spray wand leaks The nozzle is clogged Air in line The hose is leaking Kink in hose Pump is faulty |

Rotate the spray selector on the 5-in-1 Change-over Nozzle to either the 40º, 25º or 15º setting

Provide adequate water flow Check connections and/or replace trigger handle or spray wand Clean nozzle Squeeze the trigger on the trigger handle to remove air from the line Replace the hose Eliminate kinks in the hose Contact a qualified service center |

| The machine doesn’t reach high pressure | The diameter of the garden hose is too small Water supply is restricted

Not enough inlet water The spray selector on the 5-in-1 Change-over Nozzle is set to either the short-range detergent or long-range detergent setting |

Replace with 3/4 in. garden hose

Check the garden hose for kinks, leaks, and blockages Open water source full force Rotate the spray selector on the 5-in-1 Change-over Nozzle to either the 40º, 25º, or 15º setting |

| Detergent fails to mix with a spray | The spray selector on the 5-in-1 Change-over Nozzle is set to either the 40º, 25º or 15º setting

The soap tank is empty |

Rotate the spray selector on the 5-in-1 Change-over Nozzle to either the short-range detergent or long-range detergent setting.

Add detergent to soap tank |

| Wand leaks | O-ring needs replacing. | Replace o-ring. If this does not correct the problem, contact your authorized service center to purchase a new wand. |

NOTICE: As the equipment owner, you are responsible for the performance of the required maintenance listed in the Maintenance section. It is recommended that you retain all receipts covering maintenance on your equipment. Neglecting or failing to perform the required maintenance may increase emissions, decrease fuel efficiency, degrade performance, cause irreversible engine damage and/or void your warranty.