Chek-Mate Air Sampling Calibrator

Product Information: Sampling Train

The Sampling Train is an essential equipment for sampling

airborne contaminants. It is used to determine airborne

concentrations with accurate knowledge of the volume of air

sampled. The constancy of flow rate and equipment reliability are

two important factors that affect air volume.

The Sampling Train requires the following equipment:

- A personal sampling pump

- A sampling medium as specified in the method

- Any additional equipment specified in the method

- CalChek Communication Cable Cat. No. 375-200 for CalChek

calibration, for use with chek-mate Calibrator with CalChek and

AirChek TOUCH and Leland Legacy Sample Pumps - Pulsation Dampener Cat. No. 375-150, required for calibration

of high flow pumps and CalChek automatic calibration (High Flow

chek-mate Calibrator with CalChek used with Leland Legacy Sample

Pump)

Refer to the method and to the related Sample Setup Guide for

preparing a sampling train: Pre-filter and Tube Publication 1164,

Impingers Publication 1165, Filters and Cyclones Publication 1166,

Air Sample Bags Publication 1167, Single Sorbent Sample.

Product Usage: Calibrating a Pump Using a chek-mate

To calibrate an air sampling pump using the chek-mate

Calibrator, follow the below instructions:

- Setting Up the Electronic Calibrator

- Turn on the chek-mate Calibrator by pressing the on/off

button. - If a sampler does not have a calibration adapter, attach the

sampler/medium to the chek-mate inlet using the shortest length of

tubing possible and the sample pump to the chek-mate outlet

(suction port). - If using the High Flow chek-mate Calibrator, place Pulsation

Dampener Cat. No. 375-150 in line between calibrator and pump. - Setting Up the Calibration Train

- Use a second length of tubing to connect the sample medium

outlet to the pump inlet. Use the shortest length possible to avoid

kinks and bends. - If CalChek single-point calibration is performed with a sample

medium in line but also requires Pulsation Dampener Cat. No.

375-150 in line with the High Flow chek-mate Calibrator and Leland

Legacy Pump.

- Use a second length of tubing to connect the sample medium

- Setting Up the Sampling Train

- When ready to begin sampling, remove the calibrator (and

pulsation dampener if used) and representative sampling medium from

the calibration train. - If CalChek was used, remove the CalChek Communication

Cable. - Place a new unexposed sampling medium of the same type into the

train.

- When ready to begin sampling, remove the calibrator (and

- Sampling

- Attach the sampling medium to a worker’s clothing in the

breathing zone and the pump to the worker’s belt. - Run the pump and note sampling start time.

View Fullscreen

Sampling Train — Calibrating a

Pump Using a chek-mate Calibrator

Personal sampling pumps are essential equipment for sampling airborne contaminants. However, determining airborne concentrations requires accurate knowledge of the volume of air sampled. Constancy of flow rate and equipment reliability are two important factors that affect air volume.

Some sample pumps feature a built-in rotameter, which is not a precision instrument and can provide only an approximation of pump flow rate. Other pumps have an electronic flow sensor built in, which can provide a more accurate flow rate. No matter how accurately the pump displays the flow rate, the flow rate through the sampling train should be measured with an electronic calibrator or a precision rotameter before and after sampling. The performance of any such calibrator should be traceable to a primary standard; periodic calibration by an accredited laboratory is recommended. Some electronic calibrators, such as CalChek®, provide advanced calibration options. The CalChek feature of the SKC chek-mate® Calibrator with CalChek (medium and high flow models) provides direct communication with CalChek-ready sample pumps such as the SKC AirChek TOUCH and Leland Legacy for automatic calibration. This Sample Setup Guide describes Calibrating a Pump Using a chek-mate Calibrator. For calibration with a film flowmeter (non-electronic), refer to Publication 1163.

Required Equipment 1. An air sampling pump capable of sampling at the recommended flow rate with the sampling medium in line, such as: · SKC Pocket Pump TOUCH · SKC AirChek® Series (low flow applications require the All-in-One Low Flow Single/Adjustable Holder Cat. No. 224-27 or Constant Pressure Controller Cat. No. 224-26CPC and the Cat. No. 224-26 Series Adjustable Multiple-tube Low Flow Holder) · SKC AirLite (low flow applications require theAll-in-One Low Flow Single/Adjustable Holder Cat. No. 224-27 or Constant Pressure Controller Cat. No. 224-26 Series Adjustable Multiple-tube Low Flow Holder) · SKC Leland Legacy® · SKC QuickTake® 30

2. SKC chek-mate Calibrator, such as: · Low Flow chek-mate Calibrator Cat. Nos. 375-00205N, 375-00205, and 375-00205S · Medium Flow chek-mate Calibrator with CalChek Cat. Nos. 375-0550N, 375-0550, and 375-0550S · High Flow chek-mate Calibrator with CalChek Cat. Nos. 375-50300N, 375-50300, and 375-50300S

3. Sampling medium as specified in the method*

4. Any additional equipment specified in the method*

5. CalChek Communication Cable Cat. No. 375-200 for CalChek calibration, for use with chek-mate Calibrator with CalChek and AirChek TOUCH and Leland Legacy Sample Pumps

6. Pulsation Dampener Cat. No. 375-150, required for calibration of high flow pumps and CalChek automatic calibration (High Flow chek-mate Calibrator with CalChek used with Leland Legacy Sample Pump)

* Refer to the method and to the related Sample Setup Guide for preparing a sampling train: Pre-filter and Tube Publication 1164, Impingers Publication 1165, Filters and Cyclones Publication 1166, Air Sample Bags Publication 1167, Single Sorbent Sample

Introduction This Sample Setup Guide provides general information about calibrating an air sampling pump using the chek-mate Calibrator. For details about the operation of a particular calibrator or sample pump, refer to the individual operating instructions.Publication 1366 Rev 221108

1. Setting Up the Electronic Calibrator

Turn on the chek-mate Calibrator by pressing the on/off button (Figure 1).Jarless calibration method (chek-mate Calibrator only): If a sampler does not have a calibration adapter, attach the sampler/medium to the chek-mate inlet using the shortest length of tubing possible and the sample pump to the chek-mate outlet (suction port). See Figure 3. Note: If using the High Flow chek-mate Calibrator, place Pulsation Dampener Cat. No. 375-150 in line between calibrator and pump. Proceed with calibration per the instructions in Step 2 and pump operating instructions.

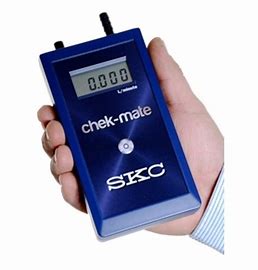

Figure 1. chek-mate Calibrator

2. Setting Up the Calibration Train

Manual Calibration (Figure 2) Allow the pump to equilibrate from one temperature to another and to run for 5 minutes before calibrating. Prepare an appropriate train as specified in the method. Ensure that the pump is in the appropriate mode (high or low flow for the desired flow rate) and that any necessary flow accessories, such as a constant pressure controller (CPC) and low flow tube holder or All-in-One, are in place. Use flexible tubing to connect the calibrator outlet or suction port to the inlet of a representative sample medium. Note: When using the High Flow chek-mate Calibrator, Pulsation Dampener Cat. No. 375-150 is required in line. See calibrator and pump operating instructions.

Use a second length of tubing to connect the sample medium outlet to the pump inlet. Use the shortest length possible to avoid kinks and bends.Figure 3. Jarless calibration train

If Using CalChek Feature AirChek TOUCH and Leland Legacy Sample Pumps (Figures 4 and 5) Allow the pump to run 5 minutes to stabilize. Prepare an appropriate train as specified in the method. Use flexible tubing to connect the calibrator outlet or suction port to the inlet of a representative sample medium (see Note below). Use a second length of tubing to connect the sample medium outlet to the pump inlet. Use the shortest length possible to avoid kinks and bends.

Note: CalChek single-point calibration is performed with a sample medium in line but also requires Pulsation Dampener Cat. No. 375-150 in line with the High Flow chek-mate Calibrator and Leland Legacy Pump.Figure 2. chek-mate Calibrator and XR5000 Sample Pump connected in a sorbent tube

AirChek TOUCH pump: CalChek calibration is performed with the pump installed on a Standard Charging Cradle or Charging e-Cradle that must be plugged into a standard wall outlet (100-240 V). Prepare the cradle by inserting the connector end of the power supply cable into the power port on the side of the cradle, and then inserting the wall cube end into a standard wall outlet (100-240 V). Align the contacts on the bottom edge of the pump with the contacts in the cradle and insert the pump in the cradle. Insert one end of the CalChek Communication Cable in the CalChek interface socket on the side of the chek-mate Calibrator with CalChek and the other end in the CalChek port on the back of the cradle.

Publication 1366 Rev 221108

Leland Legacy pump: Insert one end of the CalChek Communication Cable in the CalChek interface socket on the side of the chek-mate Calibrator with CalChek and the other end in the data port on top of the pump.

4. Setting Up the Sampling Train When ready to begin sampling, remove the calibrator (and pulsation dampener if used) and representative sampling medium from the calibration train. If CalChek was used, remove the CalChek Communication Cable. Set these items aside to verify flow after sampling. Place a new unexposed sampling medium of the same type into the train.

5. Sampling Attach the sampling medium to a worker’s clothing in the breathing zone and the pump to the worker’s belt. Run the pump and note sampling start time.

6. After Sampling At the end of the sampling period, turn off the pump and note sampling end time. Remove the sampling medium and seal it. Refer to the sampling medium operating instructions for details. Record pertinent sampling information.

Figure 4. AirChek TOUCH Sample Pump with chek-mate Calibrator in CalChek single-point calibration train

Pulsation Dampener

CalChek Interface Socket

Data Port

7. Verifying Flow Reinstate the representative sampling medium and the calibrator (and pulsation dampener if used) in the sampling train. If using an AirChek TOUCH or Leland Legacy with CalChek, reinstall the CalChek Communication Cable (see “If Using CalChek Feature” in Step 2). Take three flow readings as outlined in Step 3 and record this value as the post-sample flow rate. Do not adjust pump flow rate. Compare the pre- and post-sample flow rates. Note in sampling documentation if the values differ by more than ± 5%. Report sample time and other relevant data to the laboratory.

CalChek Communication Cable

Figure 5. Leland Legacy Sample Pump with chek-mate Calibrator in CalChek single-point calibration train

3. Calibrating the Flow Rate

Manual Calibration Ensure that the pump has run for 5 minutes before calibrating. Following operating instructions for the calibrator, adjust the flow rate on the pump until the appropriate flow rate is displayed. Take a minimum of three readings to verify flow. Do not adjust the flow any further. Record flow rate as the pre-sample flow rate.8. Transporting Samples Send the sealed sampling medium, blanks, and pertinent sampling information to a laboratory for analysis. Consult sampling medium operating instructions for details.

Copyright 1997 – 2022If Using CalChek Feature AirChek TOUCH and Leland Legacy Sample Pumps Ensure that the pump has run for 5 minutes before calibrating. Set the pump to CalChek single-point calibration (see pump operating instructions).

The calibrator will automatically calibrate the pump at a set flow.

Publication 1366 Rev 221108

- Attach the sampling medium to a worker’s clothing in the