INSTALLATION INSTRUCTIONS

INTERACTIVE PDF | DOWNLOAD FOR THE BEST EXPERIENCE

Simple, easy-to-follow instructions for the handy DIYer.

SIMPLE

Start to finish, everything you need to know to install your SMARTCORE floor like a professional.

TECHNICAL

If you’ve printed these instructions, use qr code to view the installation video.

INSTALLATION 101

Follow these simple steps for an easy DIY installation with quick, professional results.

- Gather your supplies

- Make sure your space is clean, flat, dryand structurally sound.

- Choose your starting wall (work from left to right).

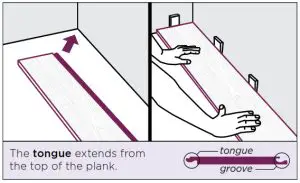

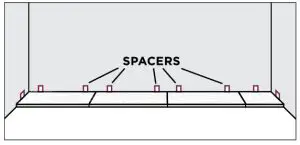

- Place tongue of the first plank side in the starting corner and add 1/4″ spacers.

- Use several 1/4″ spacers to maintain ¼” expansion gap along the walls.

- Lock the short ends together by inserting the tongue into the groove at an angle and drop in place. Continue to end of the first row.

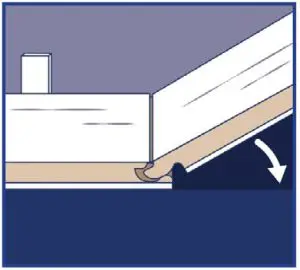

- Use a leftover plank from the first row to start the second. Stagger planks by at least 8in between end joints on adjacent rows.

- Use a leftover plank from the first row to start the second. Stagger planks by at least 8in between end joints on adjacent rows.

- For the second plank in the second row, lock the long edge of the plank by inserting the tongue into the groove of the plank in the previous row. Slide flooring toward end of previously installed flooring until the tongue just touches the groove.

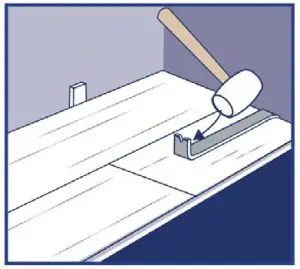

- Use a rubber mallet and tapping block to tap long edge of plank to ensure a tight fit. ANY GAPPING CAN COMPROMISE THE LOCKING SYSTEM!

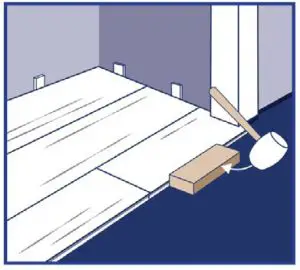

- Attach a scrap piece of floor to bridge the gap between the ends of planks.

- Tap the end of the plank with a rubber mallet and tapping block to lock ends together. Remove bridge and continue

until you reach your final row.

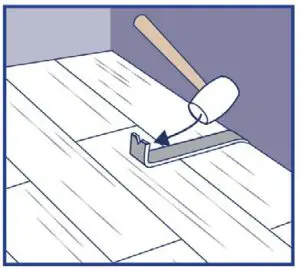

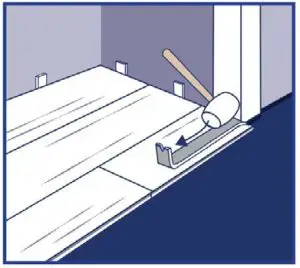

- Use a rubber mallet and pull bar to lock the final piece in each row. Insert spacers at end of row and continue to the final row.

- On the final row, use a rubber mallet and pull bar to lock long edges of the flooring.

- Remove the 1/4″ spacers and install your SMARTCORE coordinating trims

- Enjoy your new floor!

Need SMARTCORE coordinating trim to finish your flooring installation? Order today at Lowes.com!

INSTALLING UNDERNEATH DOOR JAMBS:

- Undercut space under door jamb to allow the flooring to slide freely. Tap long edge with a rubber mallet and tapping block to lock the long edge of the plank

- Use a rubber mallet and pull bar to lock the short end of the planks together.

TECHNICAL INSTRUCTIONS

RESILIENT INSTALLATION GUIDELINES FOR WPC PRODUCTS

GENERAL INFORMATION

These installation guidelines apply to the WPC products only. Al instructions and recommendations should be Jo/bowed for a satisfactory installation.

- Acclimation of material prior to installation is not required: however, the floor covering should be installed in a climate-controlled environment with an ambient temperature range between 55°F – 85°F (13°C-29°C) or average temperature of 70°F (21.1°C).

- For installations involving 3 season scenarios, meaning, the dwelling or installed space is without climate control for extended periods during certain seasons of the year, the post-installation temperature range allowed an ambient room temperature between 32°F and 100°F (0°C- 37.7°C). This allowance is for floating floors only and does not apply to glue-do ‘n installations.

- Avoid exposure to direct sunlight for prolonged periods, doing so may result in During peak sunlight hours, the use of crapes or binds is recommended. Excess temperature due to direct sunlight can result in ti thermal expansion and UV faring.

- Install product after all other trades have completed work that could damage the flooring.

- If cabinets are to be installed on top of the flooring (including islands) that area of material must fully adhere to the subfloor (ncluck–ig an additional 2′ beyond the cabinets and islands)

- To minimize shade variation, mix and install flooring from several cartons.

- Inspect all flooring for damage before installing. If you have any concerns about the product fit or finish, call Shaw Information Services at 1-8W-441-7429. Claims wl not be accepted fa flooring that has been cut to size and/or installed.

- Use cementitious patching and leveling compounds that meet or exceed maximum moisture level and pH requirements. Use of gypsum-based patching and/or living compounds that contain Portland or high alumina cement and meet or exceed the compressive strength of 3,000 psi is acceptable.

- Installation Methods: Floating (on, above or below grade) / Glue Down (on, above or below grade)

- Required perimeter expansion spacing for Floating or Glue Down installation is as follows:For areas less than 2500 sq. ft. use 1/4′ gapFa areas larger than 25W sq. ft. use 1/2′ gap.

- WPC flooring is waterproof and reliably secures the flooring panels on all four sides. However, excessive moisture in the subfloor could promote mold, mildew, and other moisture related issues Ike the trapping of moisture emissions under the floor:1g, which may contribute to an unhealthy indoor environment.

- An additional layer of 6 mil poly film or equal vapor retarder with a perm rating of 1 or less may be used as an additional layer of Protection.

- A second underlayment is allowed under any currently sold WPC product with attached underlayment in a residential If installed over a second underlayment, this underlayment cannot be greater than 3 mm thick. IIC (ASTM E49209) and STC (ASTM E90-09) lab testing on certain WPC products tested with and without a second layer of underlayment, to date, does not indicate that a second underlayment will provide additional acoustic benefit.

SUBFLOOR INFORMATION

All subfloors must be clean, flat, dry, and structurally sound. The correct preparation of the subfloor is a major part of a successful installation. Subfloor must be flat: 3/16′ in 10′ a 1/8″ in 6′.

Installation

WOOD SUBFLOORS

Do not install material over wood subfloors that by directly on concrete or over-dimensional lumber or plywood used over concrete. Refer to ASTM F1482 for panel underlayment recommendations.

- Do not apply sheet plastic over wood subfloors.

- Basements and crawl spaces must be Use of a 6 mil black polyethylene is required to cover 100% of the crawl space earth. Crawl space clearance from ground to underside of the joist is to be no less than 18″ and perimeter vent spacing should be equal to 1.5% of the total square footage of the crawl space area to provide cross ventilation. Where necessary, local regulations prevail.

- DO NOT install over sleeper construction subfloors or wood subfloors applied directly over

- All other subfloors – Plywood, OSB, particleboard, chipboard, wafer board, must be structurally sound and must be installed following their manufacturer’s recommendations. Local bulking codes may only establish minimum requirements of the flooring system and may not provide adequate rigidity and support for proper installation and performance.

- If needed add an additional layer of APA rated underlayment, fasten and secure according to the underlayment manufacturer’s

- Resilient flooring is not recommended directly over fire-retardant-treated plywood or preservative-treated plywood. An additional layer of APA rated 1/4″ thick underlayment should be insttaled.

CONCRETE SUBFLOORS

NEW AND EXISTING CONCRETE SUBFLOORS SHOULD MEET THE GUIDELINES OF THE LATEST EDITION OF ACI 302 AND ASTM F 710, “STANDARD PRACTICE FOR PREPARING CONCRETE FLOORS TO RECEIVE RESILIENT FLOORING” AVAILABLE FROM THE AMERICAN SOCIETY FOR TESTING AND MATERIALS, 100 BARR HARBOR DRIVE, WEST CONSHOHOCKEN, PA 19428; 610-832-9585; HTTP://WWW.ASTM.ORG.

- Floors shal be smooth, permanently dry, clean, and free all foreign material such as dust, wax, solvents, paint, grease, oils, and old adhesive residue. The surface must be hard and dense, and free from powder or flaking.

- Concrete slabs must be dry with no visible moisture.

- Required Moisture Testing – maximum moisture level per ASTM 1869 CCI is 8 and ASTM 2170 In-situ Relative Humidity 90% per 1000 sq.ft. in 24 hours.

- Do not install over concrete with a history of high moisture or hydrostatic Excessive moisture in the subfloor could promote mold, mildew, and other moisture-related issues like the trapping of moisture emissions under the flooring, which may contribute to an unhealthy indoor environment. Shaw Industries does not warrant nor is responsible for damage to floor covering due to moisture-related issues.

- the pH level of concrete should be between 7-10.

- The final responsibility for determining if the concrete is dry enough for installation of the flooring lies with the floor covering installer.

NOTE: IT MAY NOT BE THE FLOOR COVERING INSTALLER’S RESPONSIBILITY TO CONDUCT THESE TESTS. IT IS, HOWEVER, THE FLOOR COVERING INSTALLER’S RESPONSIBILITY TO MAKE SURE THESE TESTS HAVE BEEN CONDUCTED, AND THAT THE RESULTS ARE ACCEPTABLE PRIOR TO INSTALL THE FLOOR COVERING. WHEN MOISTURE TESTS ARE CONDUCTED, IT INDICATES THE CONDITIONS ONLY AT THE TIME OF THE TEST.

LIGHTWEIGHT CONCRETE

All recommendations and guarantees as to the suitability and performance of lightweight concrete under resilient flooring are the

responsibility of the lightweight concrete manufacturer. The installer of the lightweight product may be required to be authorized or certified by the manufacturer. Correct on-site mixing ratios and properly functioning pumping equipment are critical. To ensure proper mixture, slump testing is recommended.

- Lightweight aggregate concretes having dry densities greater than 90 lbs. per cubic foot may be acceptable under resilient flooring.

- Concrete slabs with heavy static and/or dynamic loads should be designed with higher strengths and densities to support such loads.

- The surface must be permanently dry, clean, smooth, free of all dust, and structurally sound.

- Perform Bond testing to determine the compatibility of adhesive to the substrate. Shaw 9050 primer (or equivalent /comparable product) can be utilized to promote adhesion.

Three internal relative humidity tests should be conducted for areas up to 1000 sq. ft. One additional test, for each additional 1000 sq. ft.

Radiant Heating: Radiant-heated subfloor systems can be concrete, wood or a combination of both.

The heating systems components must have a minimum of 1/2″ separation from the flooring product. The system must be on and operational for at least 2 weeks prior to installation to reduce residual moisture. Three days prior to installation lower the temperature to 65°F, after installation gradually increase the temperature in increments of 5°F to avoid overheating. Maximum operating temperature

should never exceed 85°F. Use of an in-floor temperature sensor is recommended to avoid overheating. Contact the manufacturer of your radiant heating system for further recommendations.

- Electric Radiant Floors: consist of electric cables (or) mats of electrically conductive materials mounted on the subfloor below the floor covering. Mesh systems are typically embedded in thin-set. When embedding the system components, use cementitious patching and leveling compounds that meet or exceed Shaw’s maximum moisture level and pH requirements.

Use of gypsum-based patching and/or leveling compounds that contain Portland or high alumina cement and meet or exceed the compressive strength of 3,000 psi is acceptable. - Hydronic Radiant Floors: pump heated water from a boiler through tubing laid in a pattern under the flooring. Typically installed in channels under a wooden subfloor (or) embedded in concrete slabs. Requires the installer to follow a specific nailing pattern to avoid penetration of the heating system.

EXISTING FLOOR COVERINGS

Flooring can be installed over most existing hard-surface floor coverings, provided that the existing floor surface is fully adhered, clean, flat, dry, structurally sound and free of deflection.

- Existing sheet vinyl floors should not be heavily cushioned and not exceed more than one layer in thickness. Soft underlayment and soft substrates will compromise the product’s locking ability as well as diminish its indentation resistance.

- Installation is NOT allowed over any type of carpat.

- Do NOT install over wood floors adhered to concrete.

- Never use solvents or citrus adhesive removers to remove old adhesive Solvent residue left in and on the subfloor may affect the new floor covering.

- This product can be installed over existing ceramic/porcelain tile products with up to a 1/4 inch wide grout If the grout joint width exceeds 1/4 inch, a cementitious patching compound should be used to fill the grout joint to make it smooth with the surface of the tile.

RAISED ACCESS PANEL SUBFLOORS

- Raised access panels must be stable, level, flat, free and clean of existing adhesives

- 24″ x 24″ panels are recommended.

- Up page (variation of height) between of panels must not exceed 0.295″ (0.75 mm)

- Gaps between panels must not exceed 0.039″ (1 mm)

- There should be no deflection of the individual panels – Concave less than 0.0295″ (0.75 mm)

- Flatness 1/8″ in 10′

- Stagger the flooring tiles/planks to overlap the access panels

- Telegraphing of access panel seams may be visible and is not considered a product defect nor warranted by the flooring manufacturer.

If needed, overlay the panels with a 1/4″ (6 mm) plywood and properly fasten to the access panels prior to the installation of the floor covering. Prior to underlayment installation, repair any loose or unstable panels. Use the appropriate installation methods for the product.

INSTALLATION

Tools: Tape Measure, Utility Knife, Jigsaw, Tapping Block or Rubber Mallet, Pull Bar, ¼” Spacers, T-Square, Safety Glasses, Broom or Vacuum and, if necessary, tools for subfloor repair.

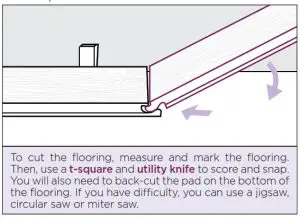

To cut the flooring, simply measure and mark the flooring. Then, use a t-square and utility knife to np score and snap. You will also need to back-cut the underpad (if applicable) on the bottom of the flooring. If you have difficulty using this method. you can use a jigsaw, circular saw or miter saw.

To cut the flooring, simply measure and mark the flooring. Then, use a t-square and utility knife to np score and snap. You will also need to back-cut the underpad (if applicable) on the bottom of the flooring. If you have difficulty using this method. you can use a jigsaw, circular saw or miter saw.

FLOATING INSTALLATION

WPC flooring is designed to be installed utilizing the floating method. Proper expansion space 1/4” (6.35 mm) is required. Undercut all doorjambs. Do not fasten wall moldings and or transition strips to the flooring.

Glue Down Installation: WPC products are approved for glue-down installation over approved wood and concrete substrates. Follow adhesive label application instructions. Install flooring into wet adhesive to achieve a permanent bond. Maintain 1/4” (6.35 mm) perimeter expansion space. Refer to adhesive label for moisture limits of the adhesive. Roll flooring immediately after installation with a 100 lbs. 3‐section roller.

Recommended Adhesive(s): Shaw 200 (or equivalent/comparable adhesive).

If alternative adhesives are used, a bond test should be performed to ensure compatibility.

Flooring patterns must be installed in a staggered (offset) pattern.

LAYOUT

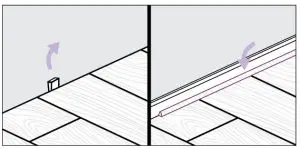

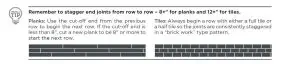

Step 1: Begin installation working from left to right. Insert spacers at ends and edges where the flooring meets the wall. Step 2: Lock short end of the flooring by inserting the tongue into the groove at an angle and drop in place. At end of the row, measure and cut the flooring to complete the row. Install the cut edge closest to the wall.

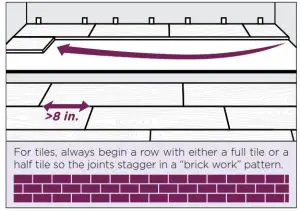

Step 2: Lock short end of the flooring by inserting the tongue into the groove at an angle and drop in place. At end of the row, measure and cut the flooring to complete the row. Install the cut edge closest to the wall. Step 3: Use leftover flooring from first row as a starter for the second row. There must be at least 20cm between flooring end joints on adjacent rows. FOR TILE INSTALLATIONS: The distance between end joints should be for equal to 30cm proper appearance.

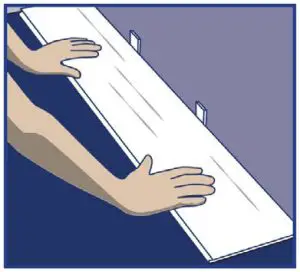

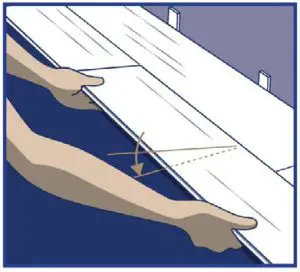

Step 3: Use leftover flooring from first row as a starter for the second row. There must be at least 20cm between flooring end joints on adjacent rows. FOR TILE INSTALLATIONS: The distance between end joints should be for equal to 30cm proper appearance. Step 4: Lock long edge of the flooring by inserting the tongue into the groove at an angle and drop in place. Slide flooring toward end of previously installed flooring until the tongue just touches the groove.

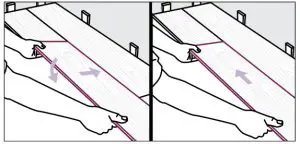

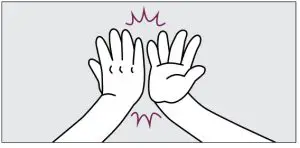

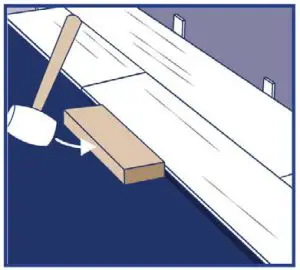

Step 4: Lock long edge of the flooring by inserting the tongue into the groove at an angle and drop in place. Slide flooring toward end of previously installed flooring until the tongue just touches the groove. Step 5: IMPORTANT! Use a hammer and tapping block to tap the long edge of the plank to ensure a tight fit. ANY GAPPING CAN COMPROMISE THE LOCKING SYSTEM!

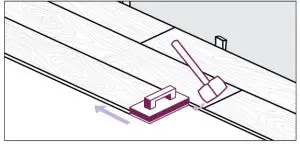

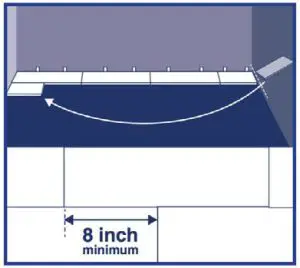

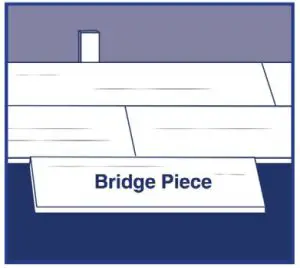

Step 5: IMPORTANT! Use a hammer and tapping block to tap the long edge of the plank to ensure a tight fit. ANY GAPPING CAN COMPROMISE THE LOCKING SYSTEM! Step 6: Attach a scrap piece of floor to bridge the gap between ends of planks.

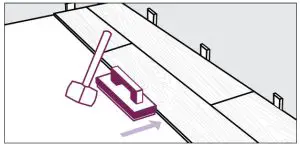

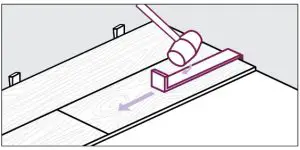

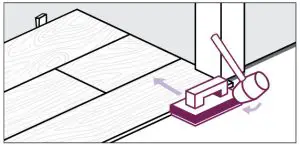

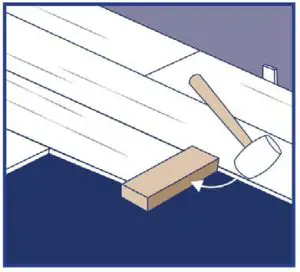

Step 6: Attach a scrap piece of floor to bridge the gap between ends of planks. Step 7: Tap end of the flooring with hammer and tapping block to lock the ends of the flooring together. Remove bridge and continue towards the wall until installing the final flooring in the row.

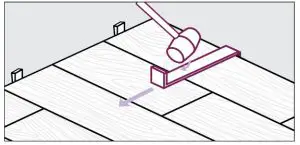

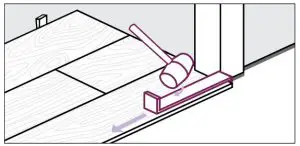

Step 7: Tap end of the flooring with hammer and tapping block to lock the ends of the flooring together. Remove bridge and continue towards the wall until installing the final flooring in the row. Step 8: Use a hammer and pull bar to lock final piece in row. Insert spacer at end of row. Continue installation to the final row.

Step 8: Use a hammer and pull bar to lock final piece in row. Insert spacer at end of row. Continue installation to the final row. Step 9: Use a hammer and pull bar to lock long edges of flooring on final row.

Step 9: Use a hammer and pull bar to lock long edges of flooring on final row.

BE SURE TO TAP ON THE EDGE OF THE VINYL SO AS NOT TO DAMAGE THE LOCKING PROFILE.

INSTALLING UNDERNEATH DOOR JAMBS:

Step 1: Undercut space under door jamb to allow the flooring to slide freely. Tap long edge with a hammer and tapping block to lock long edge.  Step 2: Use a hammer and pull bar to lock this piece of flooring.

Step 2: Use a hammer and pull bar to lock this piece of flooring. COMPLETION

COMPLETION

- Protect all exposed edges of the flooring by installing wall molding and/or transition strips. Make sure that no plank will be secured in any way to the subfloor.

- For wet areas such as bathrooms caulk the perimeter of the floor with flexible silicone caulk.

- Protect the finished flooring from exposure to direct sunlight to reduce fading and thermal expansion.

- Cutting resilient products into a fine point may lead to delamination. Use an ethyl cyanoacrylate-based glue to help fuse the resilient point together. Be sure to clean all glue from the top surface immediately. Alcohol-based glues may cause resilient products to swell.

- Adhering tape to the surface of your resilient flooring could damage the surface.

- Do not use tape to secure floor protection directly to the floor during construction or renovation. Instead, adhere the tape to the material used to protect the floor and secure it to the base molding along the wall. A material such as a ram board can also be used to protect your flooring.

For reference purposes only if printed or downloaded.