ADVANCED FEATURES FOR MAXIMUM DRIVE PERFORMANCE

Plain-English LED/LCD Interface Startup Wizard allows for

quick, user-friendly programming and easy modification of the

expanded parameter set. The keypad is able to store parameter

sets, which allows the user to set up multiple drives using these

saved parameters. In addition, a built-in fault-logging chip

records faults in the keypad memory. These records contain

time and date stamps as well as detailed information about

operating conditions at the time of the fault.

My Function, Toshiba’s Proprietary Programming Feature,

allows the user to utilize logic-type programming without the

expense of a micro PLC. The user is able to read all analog and

digital inputs and outputs as well as to monitor and compare

data. When programmed in a user-defined logic sequence, the

use of this data will allow for a higher level of process control

not normally seen in an adjustable speed drive. These functions,

along with timers, counters, and comparators, allow the G9® to

help meet the user’s performance expectations.

Eight Digital Inputs & Three Digital Outputs are an integral part

of the G9’s versatility. Each digital input/output is individually

programmable with more than 60 possible functions. When used

in conjunction with My Function programming, the capabilities

of these terminals are virtually limitless. Additionally, the G9 is

setting a new industry standard by providing an isolated analog

input (4 to 20 mA) on its standard terminal strip.

A Built-In Proportional/Integral/Derivative (PID) Control

Algorithm provides regulation of critical processes. High and

low speed limits, deviation limits, online switching, and a builtin

sleep function are included to enhance the flexibility and

reliability of PID process control.

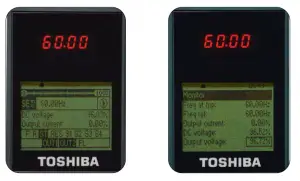

Toshiba’s Proprietary Windows®-Based ASD Pro Software

is available at no additional cost. This easy-to-use software is

designed to provide a full range of programming and monitoring

tools for the G9. ASD Pro Software offers trending and logging

features that allow the user to save and transfer parameters and

to export data and graphs to an electronic file. Parameter groups

and trending data can be easily converted into spreadsheets or

graphs for field and validation reports.

ASD Pro Main Control Screen ASD Pro Real-Time Monitoring Screen

A LOOK INSIDE THE G9 ASD

- High Visibility LED Display

- Rotary Encoder

- Discrete Input

& Output Status - Single Retaining Screw

for Easy Terminal Board

Removal - Selectable Voltage or

Current Analog Output - Isolated Voltage or

Current Input - Half/Full Duplex RS485

- Stackable Option

Cards Available - Parameter Storage

Available in

Removable EOI - Built-In

Real-Time Clock - Backlit Character

Display for Monitoring &

Programming - Eight Programmable

Discrete Inputs - 24 VDC Input for External

Control Power - NEMA 1

Conduit Box - One Form-C

& Two Form-A

Programmable Relays - One Isolated Voltage

or Current Input

ADDITIONAL OPTIONS

The G9 can be customized with additional options to best suit

a user’s specific needs. Options include:

- DeviceNet®

- Ethernet/IP

- Modbus® Plus

- Modbus® TCP/IP

- Profibus DP

- Profinet® IO

- Extended Terminal Cards

- Encoder Feedback Cards

- 120 VAC Discrete Inputs

- AC Line & Load Reactors

- DV/DT Long-Lead Filters

- Harmonic Filters

- Remote-Mountable

Keypads

OTHER SPECIAL FEATURES

The G9 includes several standard top-of-the-line features.

Options include:

- Dynamic Braking

Transistor - UL Type-1/NEMA 1

Enclosure - 100 or 200 KAIC Rating

- UL® Listed & Labeled

- NEC Motor Overload

Retention (No External

Motor Overloads Required)

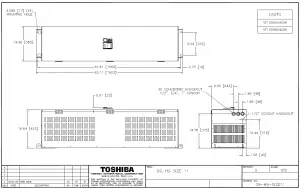

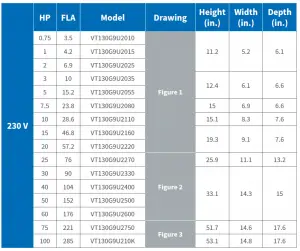

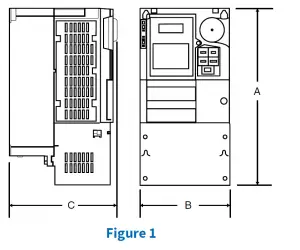

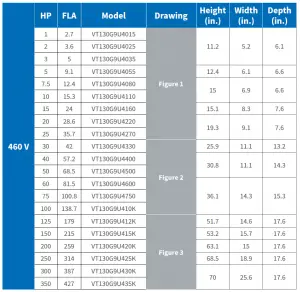

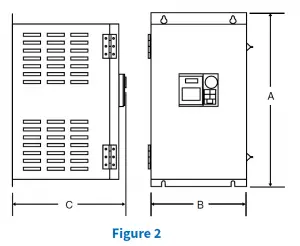

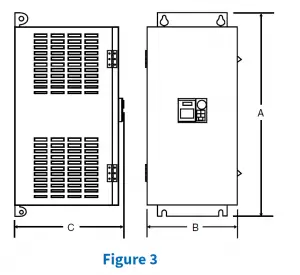

DIMENSIONS

A POWERFUL

DRIVE SOLUTION

The G9 low voltage adjustable speed

drive is a severe duty drive offered

by Toshiba. Designed with the enduser

in mind, this drive combines a

rugged proven power platform with

the an advanced micro-processor to

provide users with a smarter, stronger

and more reliable drive with flexible

application control.

G9 EXTREME DURABILITY FOR GENERAL PURPOSE

Powerful performance separates the G9 from the competition. This drive offers one of the toughest overload ratings in the industry.

On ratings up to 100 HP at 460 V and 50 HP at 230 V, the G9 provides a continuous overload rating of 115% of its full-load amp and 150%

for up to two minutes. Above these frames, the drive is rated for 110% of its full-load amp rating for continuous operation and 150% for

up to one minute.

Superior control allows the user ultimate flexibility. The G9 can operate using open or closed-loop vector control volts/hertz patterns.

Toshiba’s advanced vector-control algorithm offers speed regulation of 0.1% sensorless and 0.02% with motor encoder feedback. While

operating in the feedback vector control mode, the G9 can generate 100% torque at zerospeed to hold the shaft stationary while the

motor is stopped. The G9 drive also offers advanced torque control operation with high torque accuracy and the ability to switch on-thefly

between speed and torque modes.

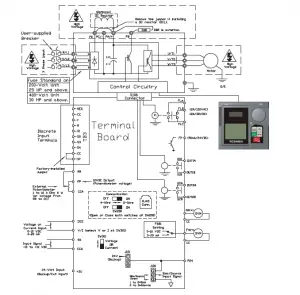

Typical Connection Diagram

Figure 20

Note: When connecting multiple wires to any of ASD terminals, do not

connect a solid wire and a stranded wire to the same terminal.

. The G9 ASD Typical Connection Diagram

Note: The AM, FM, and the +SU analog terminals are referenced to CC.

Note: The PP, RR, RX, and the P24 analog terminals are referenced to CCA.

Note: The isolated V/I analog terminal references IICC.