TRUPER DES-430 , DES-520 Gas Brushcutter

Product Information

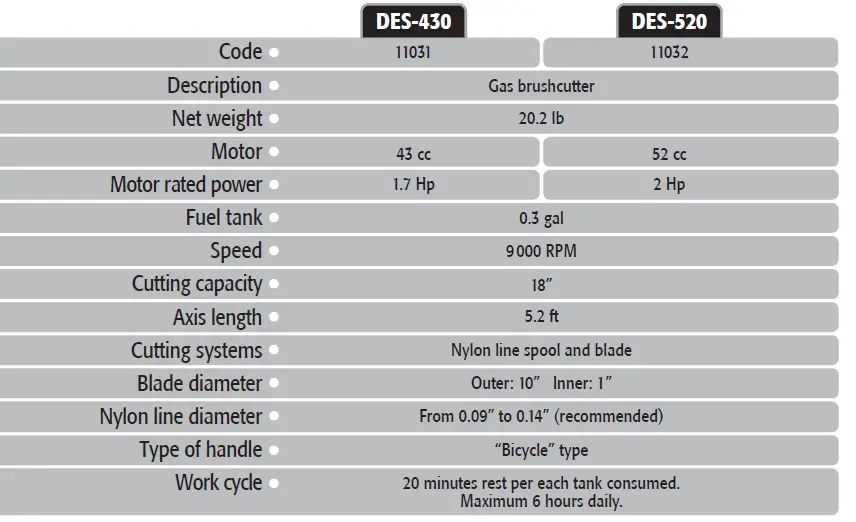

The Gas Brushcutter is a powerful tool designed for cutting through dense foliage and vegetation. It comes in two models – DES-430 and DES-520 with motor sizes of 43 cc and 52 cc respectively. The brushcutter has a fuel tank capacity of 0.3 gallons and can operate at a maximum speed of 9,000 RPM. It has a cutting capacity of 5.2 feet and comes with nylon line spool and blade options. The brushcutter has a bicycle-type handle and requires periodic maintenance to ensure optimal performance. It weighs 20.2 lbs and comes with safety warnings for motor tools and brushcutters for safe usage.

Product Usage Instructions

Before operating the Gas Brushcutter, it is essential to read and understand the user manual thoroughly. Follow the below guidelines to use the tool safely:

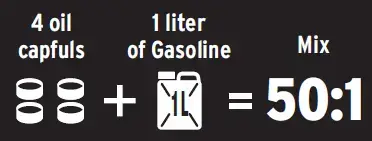

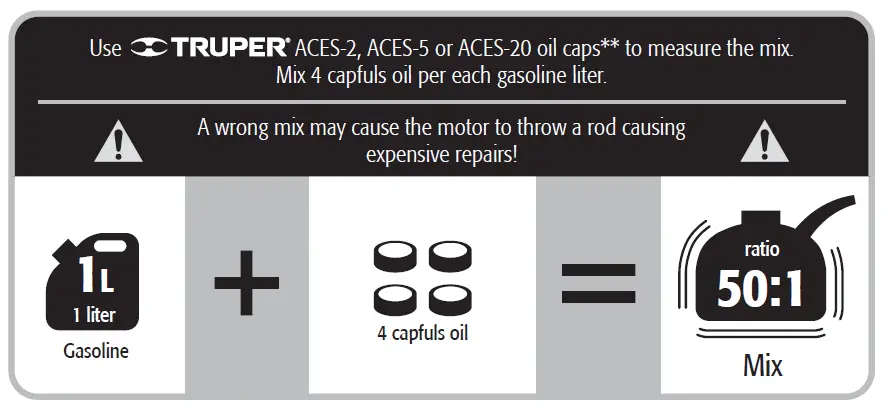

- Use gasoline mixed with 2-STROKE motor OIL in the ratio of 50:1. A wrong mix may cause the brushcutter to throw a rod, causing repairs. Mix 4 oil capfuls per liter of gasoline.

- Do not use fuel mix that has been stored for more than 15 days.

- Always use the guard and operate the brushcutter at maximum power with the trigger fully tightened.

- Use thread with diameter from 3/32 to 9/64.

- Perform periodic maintenance to your machine as per instructions on page 11.

- Keep your work area clean, tidy, and well-lit to avoid accidents.

- Never use the brushcutter in explosive areas or in the presence of flammable liquids.

- Keep the brushcutter at least 9 meters (30 feet) away from the fill-up area before starting the motor.

- Keep children and passersby at a safe distance while operating the brushcutter to avoid accidents.

- Avoid contact with power lines and circuits and stay alert while using the brushcutter.

WARNING

To gain the best performance of the tool, prolong the duty life, make the Warranty valid if necessary, and to avoid hazards of fatal injuries please read and understand this Manual before using the tool.

Keep this manual for future references.

The illustrations in this manual are for reference only. They might be different from the real tool.

Use and care recomendations

- Use gasoline mixed with 2-STROKE motor OIL. A wrong mix may cause the brushcutter to throw a rod, causing expensive repairs!

- Do not use a fuel MIX that has been stored longer than 15 days.

- ALWAYS USE the GUARD. USE THREAD with diameter from 3/32” to 9/64”

- ALWAYS operate your brushcutter at MAXIMUM POWER with the trigger FULLY tightened

- Perform periodic MAINTENANCE to your machine (page 11).

Technical data

Fuel specifications

- The brushcutter has an air-cooled 2-cycle motor using a mix of unleaded gasoline and high quality self-propulsion oil for air-cooled two-cycle motors.

- The motor is certified to run with unleaded gasoline for vehicles with 87 or more ([R+M]) octane level.

- Do not use any type of gasoline premixed with oil bought in service stations such as gasoline for motorcycles.

- Do not use automotive oil or oil for 2-cycle outboard motors oil.

- The mix ratio should be 50 parts gasoline per 1 part oil (50:1 ratio). Prepare the mix in a gasoline-approved container. Always mix thoroughly before pouring in the motor tank.

- CAUTION Do not use fuel mix stored longer than 15 days. Make small amounts of mix.

WARNING ver smoke near fuel, the gasoline filling up area or where the oil mix is being prepared or when operating the tool. - WARNING Any attempt to start the brushcutter with no oil added to the fuel mix will damage to the brushcutter.

To prolong the useful life of the motor use two-cycle synthetic motor oil.

* 1 gallon = 3.78 liter

** Not included

Safety warnings for motor tools

- Keep your work area clean, tidy and well lit.

Cluttered and dark areas may cause accidents. - Never use the brushcutter in explosive areas or in the presence of flammable liquids.

Before starting the motor keep the brushcutter at least 9 meters (30 feet) away from the fill up area. - Keep children and passersby at a safe distance while operating the brushcutter.

Distractions could cause loosing control and cause accidents. - Avoid contact with power lines and circuits.

Find and avoid power lines and circuits, especially hidden wiring as well as any grounded object. - Stay alert, use care and common sense.

Familiarity with the brushcutter operation could lead to distractions. It could cause accidents. - Refrain from using the brushcutter if tired or under the influence of drugs, alcohol or medication.

Being momentarily distracted while using the brushcutter could cause severe personal injury. - Operate the brushcutter with guards and protection devices in place and in good working condition.

Failure to comply with this warning is a hazard of severe personal injury. - Do not force the brushcutter.

Working within the tool’s working design assures a better and safer job. - Keep the brushcutter in a safe place and out of the reach of children.

Motor powered tools are dangerous to inexperienced people. - Wear proper clothes.

Loose clothes, jewelry or long hair could get caught in the mobile parts. - Keep hands away from rotating and/or mobile parts.

Failure to comply with this warning is a hazard of severe personal injury. - Do not operate the brushcutter in enclosed areas.

Avoid breathing accumulated carbon monoxide, a potentially deadly odorless toxic gas. - Wear adequate protective safety accessories.

Wear eye protection, dust mask, non-skid safety shoes, helmet and ear plugs. These safety gears reduce the risk of injury. - Turn off the brushcutter before adjusting, changing accessories or storin.

Double check the brushcutter switch is in the off position. - Refrain from operating the brushcutter if the switch is not working or is not properly assembled.

Failure to complain with this warning is a hazard of personal injury. Immediately send it to a Authorized Service Center. - Do not overreach.

Good balance and support lead to better controlling the tool in unexpected situations. - Avoid the brushcutter to unintentionally start.

Double-check the brushcutter motor is off before maintenance or putting it away. - Remove brackets before turning on the brushcutter.

Additional tools or vices installed in a rotating part could cause severe personal injury. - Service the brushcutter and double-check it is in good working conditions before operating.

Carefully check mobile parts, alignment and assembly. Do it periodically. Look for any damaged element or part not working properly. Repair immediately in a Authorized Service Center. - Accessories.

Use only accessories or spare parts indicated in this Manual or certified by . - Never leave a running brushcutter unattended.

Turn off and disconnect the brushcutter after using. Set it in a safe position to avoid severe injury. - Never smoke in the proximity of fuel.

Do not smoke in the proximity of the fuelling area or when using the brushcutter.

Safety warnings for brushcutters

Fuel handling

- Never smoke near fuel or where gasoline is supplied. Or where the oil mix is prepared or while operating the brushcutter.

- Handle fuel with care to reduce risk of fire or burns. Fuel is very flammable.

- Do not allow gasoline or oil getting contact with your skin.

- Protect your eyes. Avoid spilling oil or gasoline. In the event of accidental contact, wash eyes immediately with clean water. If irritation persists, see a doctor.

- Mix and store fuel in a labeled container.

WARNING

- Mix fuel outdoors away from flames or sparks.

- Before refueling the brushcutter turn off the motor. Set the brushcutter in the ground in a clear surface. Wait for the motor to cool down.

CAUTION

- Verify there are no leaks. If so, correct them before using the brushcutter to prevent fire or burns.

- Move the brushcutter at least 30 feet away from the fuel filling up site before starting the motor.

- Under no circumstance burn spilled fuel.

- Under no circumstance, use any other type of fuel different from the specified in this Manual.

Before operating the brushcutter

- Wear the right clothes to operate the brushcutter. Tight fitting clothes, strong pants, anti-skid safety boots, heavy-duty protecting gloves and safety glasses with side protection complying with ANSI Z87.1. Standard.

- Remove any accessory or loose clothes that could get caught by the moving cutter head. Fasten your long hair above your shoulders.

- Verify the brushcutter is in perfect working conditions. Do not turn on is not properly adjusted or fully assembled to work in a safe manner, or if the fuel tank shows leakage or loose screws.

- Verify the cutter head stops moving when the throttle trigger is released. If it does not stop shut off the brushcutter. Go to a Authorized Service Center to solve the problem.

- Verify the brushcutter is clean, dry and free of oil or fuel.

- Double-check the work area is in an open area and is well ventilated.

- Check the work area. Remove stones, pieces of broken glass, nails, wire or rope. They could be soot out or be tangled in the brushcutter.

- In extreme temperatures verify there are no ice

When operating the brushcutter

- Keep passersby, children and animals away no less than 50 feet away.

- Verify the cutter head is not making contact with any object before starting the motor.

- Keep both feet firmly set on the ground and both hands holding the brushcutter by the handles. Never operate the brushcutter single-handed. Otherwise the operator and any other person present may be injured.

- Keep all your body away from the cutter head when the motor is running.

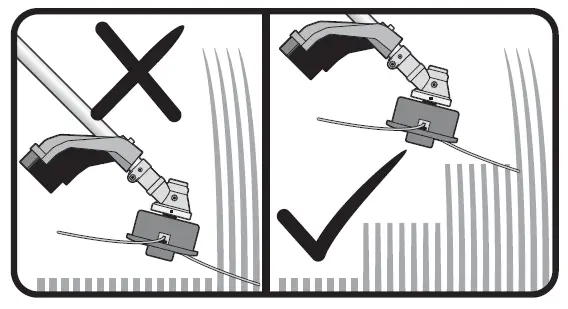

- Always keep the cutting head pointed downwards, below your waist level. Never raise it above 2.4 feet from the ground.

- Keep all your body parts away from the muffler. Otherwise severe burns can occur.

- Keep the brushcutter away from flammable materials.

- The blades are designed to cut grass and vines no thicker than 0.5” in diameter.

- Do not use the brushcutter to cut woody shrubs.

- Be alert to surrounding risks. The brushcutter noise could prevent you from noticing them.

DANGER

- If making jobs near traffic roads, stop cutting until there are no vehicles in sight. The brushcutter could shoot particles towards the moving vehicles and produce a severe accident.

- After operating the brushcutter

WARNING

- Do not try to stop the cutter head rotating movement in any other way than releasing the switch. Wait for the cutter head stop after shutting off the brushcutter. It will take a couple of seconds.

- Always carry the brushcutter with the motor off and the muffler away from your body. Before putting the brushcutter in a vehicle, drain the fuel tank.

- Turn off the motor before idling the brushcutter. DO NOT leave the motor running unattended. Wait for the brushcutter to cool off before storing.

- Highly trained personnel of a Authorized Service Center should only carry out service and repairs.

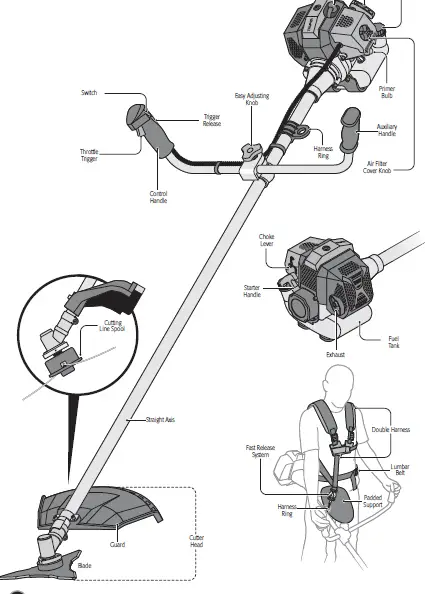

Parts

WARNING

Do not try to modify the brushcutter or manufacture not recommended accessories. Otherwise, the user may suffer severe injuries and will make the warranty void.

WARNING

When assembling parts, always disconnect the motor spark plug cable to prevent an accidental start up causing severe personal injuries.

Assembly

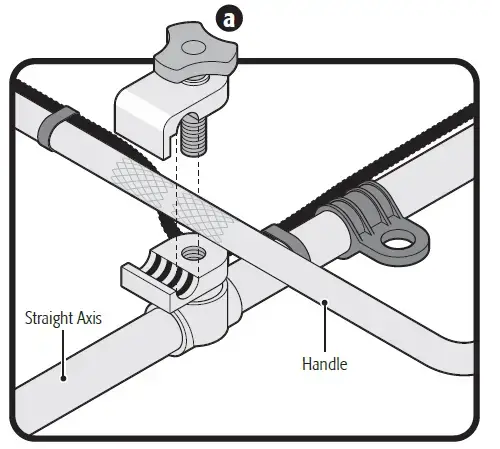

Handle

- Separate the hinge bracket from the straight axis frame loosening the easy adjusting knob (a).

- Set the handle in the straight axis frame.

- Secure the handle in place and tighten the easy adjusting knob firmly.

- To rotate the handle, loosen the easy adjusting knob and turn the handle (b) 90°. This is useful to store and transport the brushcutter.

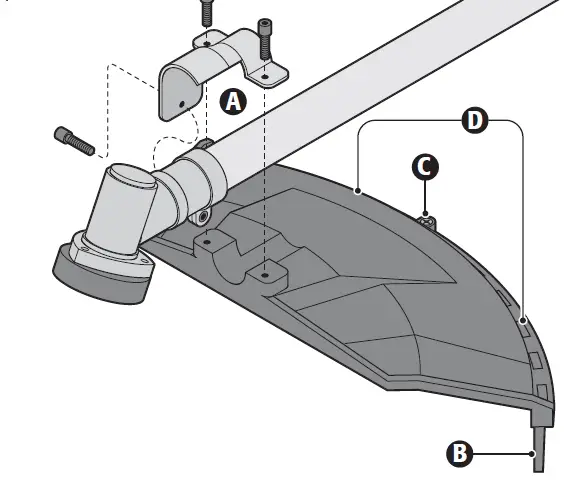

Blade installation

- Set the turn table onto the cutter head (1).

- Set the blade onto the pressed turn table making sure the turning direction of the blade is the same as the sense labeled on the guard (2).

- Set the flange onto the blade (3).

- Set the cover and the lock nut (4).

- Insert the Allen key in the pressed turn table to block the axis (5) and tighten the lock nut counterclockwise using the included wrench (6).

- Use the guard with the protection removed. See the guard section.

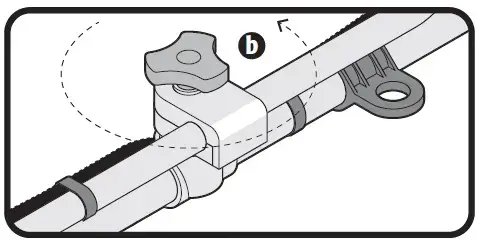

Guard

- Fasten the guard into the cutting head using the bracket and the bolts included (A).

- If using the line spool, use the guard with the protection (B) included.

- When using the blade, remove the screw in the rear of the guard (C). Press both clips (D) and remove the protection.

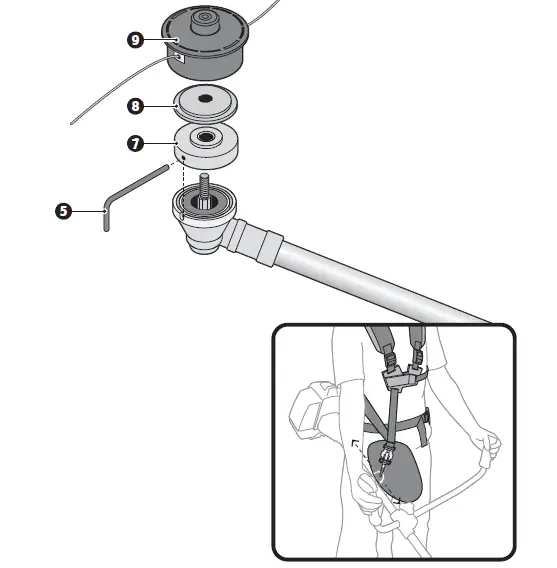

Line spool installation

- Set the pressure turn table onto the cutter head (7).

- Set the flange onto the turn table (8).

- Insert the Allen key into the turn table side to block the axis (5).

- Place the threaded spool in the axis and tighten counterclockwise using your hand (9).

- Use the guard with the protection. See the guard section.

Balancing the brushcutter

- Wear the harness and adjust to set it firmly and comfortably.

- Join the harness into the harness ring of the straight axis of the brushcutter.

- Travel the ring upwards and downwards until the brushcutter is balanced and the cutter head points down, below the user’s waist and no more than 30” away from the ground.

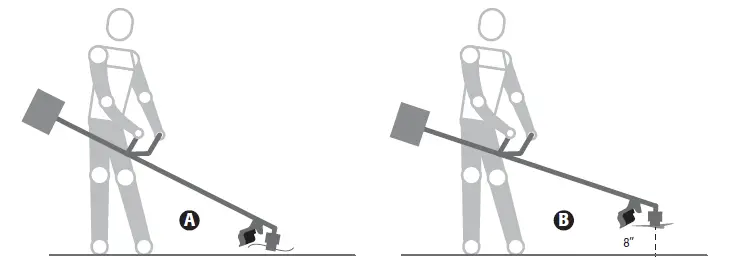

- When using the line spool, the cutter head shall touch the ground slightly (A).

- When using the blade, the cutter head shall be approximately 8” away from the ground (B).

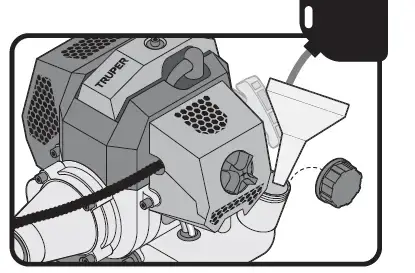

Fuel supply

- Follow the safety standards for handling fuel (page 5).

- Wait until the motor has cooled down completely before supplying fuel.

- Set the brushcutter onto a flat surface.

- Wipe clean around the fuel tank cap to prevent contamination.

- Slowly loosen the fuel tank cap.

- Use care to prevent spills. Pour the fuel mix into the tank.

- Before capping the fuel tank check and clean the joints.

- Set immediately the fuel tank cap and tighten with your hand.

- Clean all fuel spilled.

Turning on

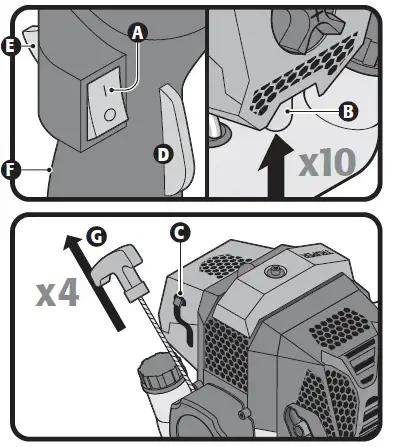

Start up with a cold motor

- Set the brushcutter on level ground where the blade or spool will not make contact with any obstacle.

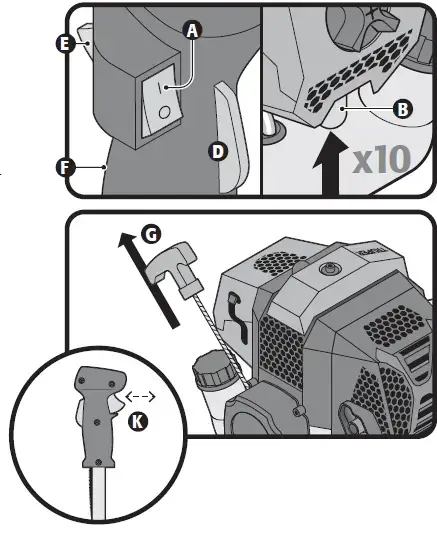

- Set the switch into the ON position (A).

- Press and release the primer bulb 10 times (B).

- Move the choke lever upwards (C).

- Press simultaneously the trigger release (D) and the throttle trigger (E). Keep the trigger depressed.

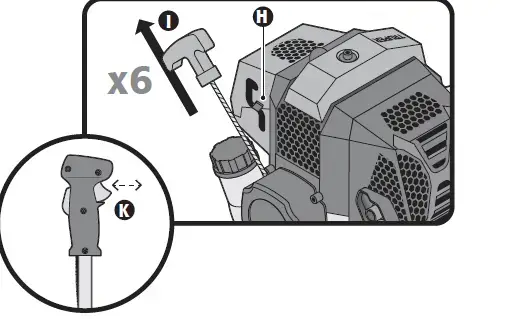

- Pull the starter handle (G) to start the motor. Do NOT pull more than 4 times to avoid flooding the motor.

- If the motor is not starting, move the choke lever downwards (H). Pull again the starter handle (I) until the motor starts. DO NOT pull more than 6 times (although in cold climate you may need to pull the starter handle more times).

- If the motor is not starting still, repeat steps from (B) and on.

- Once the motor starts, leave it running a few seconds in that position.

- Press and release the throttle trigger to set the motor idle (K).

- The brushcutter is now ready to operate. Hold both handles using both hands and lift it to start the job.

Start up with a hot motor

- Set the brushcutter on level ground where the blade or spool will not make contact with any obstacle.

- Set the switch into the ON position (A).

- Press simultaneously the trigger release (D) and the throttle trigger (E).Keep the trigger depressed.

- Pull the starter handle (G) to start the motor.

- Press and release the throttle trigger to set the motor idle (K).

Turning off

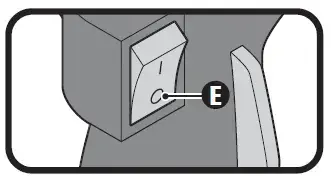

- Press and hold the switch into the OFF position (E) until the motor stops.

CAUTION

- Remember, you as the brushcutter operator is responsible of your own safety as well as people close to the work area. Follow all safety warnings (pages 4 and 5) before operating the brushcutter.

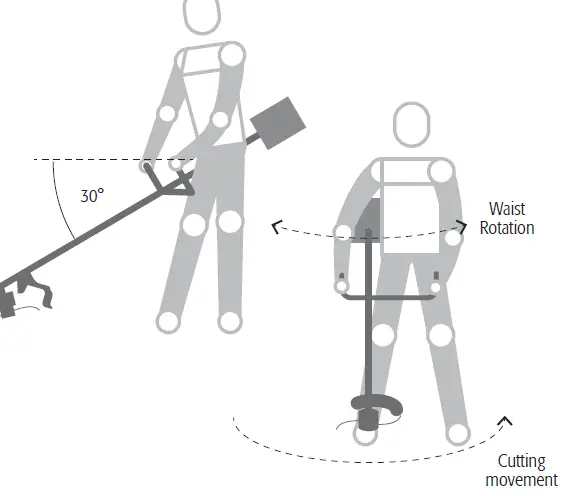

- Keep a balanced stance with both feet firmly set onto the ground.

- Hold the brushcutter firmly in front of you; one hand holds the handle and the other holds the auxiliary handle so that the brushcutter is aligned to your body and pointing the cutter head 30° downwards, away from your feet.

DANGER

- Do not start the brushcutter in a different position.

- Turn ON the brushcutter and cut from left to right rotating your waist and keeping the brushcutter position.

- As the cut is performed, the cutting line wears out and will be detached. To release more line from the spool, press the brushcutter slightly downwards. The ground will depress the retention cap against the spool and will release more line. The guard blade will cut the remaining line. Then, stop pushing the brushcutter against the ground to save line lengths.

- To cut brush or grass, cut gradually. Do not try to cut in one movement from the base because the residues may clog the cutting head or can go out of control from the operator.

Maintenance

Before inspecting, cleaning or servicing the tool turn the motor off, wait for all the mobile parts to stop, disconnect the spark plug cable and set it away from the spark plug. Otherwise, the operator may suffer severe burns and / or damage the tool.

General cleansing

- Using a brush or compressed air, clean and clear the ventilation slots from the starter unit when necessary.

- Likewise, clean periodically the motor cylinder and fan blades to remove debris. Otherwise the motor may get damaged do to overheating.

- Air filter cleansing

- Remove the air filter cover loosening the cap knob.

- Remove the air filter.

- Depending on how long the machine is used, you may clean the filter by superficially tapping it lightly against a flat surface to displace most of the particles.

- You may also use compressed air on both sides of the filter to blow away dirt.

- For a more thorough cleansing clean the air filter in soapy water. Rinse and let it dry completely before installing it back into the brushcutter.

- Set back the filter. Verify it is flush in place.

- Clean the air filter as frequently as necessary to keep it always clean. Otherwise the motor efficiency may lessen.

Fuel filter

- Check the gasoline filter frequently.

- If the filter is dirty, replace it.

- If the gasoline tank is dirty inside, rinse with gasoline.

Blade

- Check and maintain the blade always in the best condition.

- Sharpen if necessary with a flat file. Use care not to change the blade profile and the sharpness to assure the best performance of the brushcutter.

Carburetor adjustment

- It is recommended to carry out the carburetor adjustment Authorized Service Center.

- A faulty adjustment can damage the motor and makes warranty void.

Spark plug replacement

- The motor runs with a NGK BPMR7A spark plug with 0.025” electrode gap. Replace the spark plug once a year with and identical spark plug.

- With the motor totally cold, loosen the worn spark plug towards the left using a spark plug wrench and remove it.

- Insert the new spark plug and using your hand tighten towards the right.

DANGER

- Use care not to damage the spark plug thread. Otherwise it can damage the motor.

- Give the spark plug half-a turn more using the spark plug wrench included.

Muffler and exhaust cleansing

- The muffler and exhaust can get clogged with carbon deposits dependent of type of fuel, amount of oil used and / or conditions of the use of the brushcutter. If there is power loss, deposits shall need to be removed to improve performance. Go to a Au-thorized Service Center to carry out the service.

- The muffler is built with a spark-arrest screen inside the muffler. After long periods of use the screen gets dirty and the muffler needs replacement. Go to a out the replacement.

DANGER

- Check often that the muffler has the fasteners perfectly secured and that there is no damage or corrosion. In the event of leaks stop the brushcutter and take it immediately to a Authorized Service Center to repair.

Lubrication

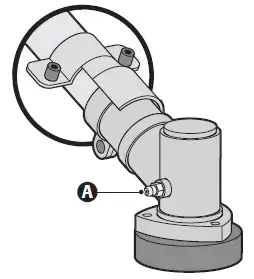

- The inside of the cutting head gearbox is lubricated with lithium-based multiple use grease. Add grease every 25 hours use.

- To add grease set the grease device into the nipple (A) and pump twice.

Gas Brushcutter Storage

In the event of storing the Gas Brushcutter for one month or longer, bear in mind the following considerations:

- Drain all the fuel tank contents into an approved gasoline container. All the remaining fuel can be re-used in another tool that uses 2-stroke motor with a 50:1 ratio.

- Start the motor until the rest of fuel is consumed and the motor shuts down. This will eliminate the fuel residues and will prevent gum formations that damage the fuel system.

- Clean the Gas Brushcutter thoroughly.

- Store the unit in a well-ventilated space, away from corrosive agents such as garden chemical products or de-icing salts. And away from children’s reach.

- Observe all the government rulings concerning safety in management and storing fuel.

| Regular maintenance | Every use | Every 25 h of use | Every 50 h of use | Every 150 h of use | Every 250 h of use |

| General cleaning |  |

||||

| Air filter cleaning | |||||

| Cutterhead Gearbox Lubrication | |||||

| Carburetor cleaning * | |||||

| Spark plug inspection and adjustment * | |||||

| Fuel tank cleaning ** | |||||

| Fuel filter change ** | |||||

| Fuel chamber replacement ** | |||||

| Combustion chamber cleaning ** | |||||

Problem: Cause: Solution

- The motor does not start.

- There is no spark.

- Check the spark. Remove the motor cover. Remove the spark plug from the cylinder. Connect the spark plug cable and set it onto the motor cylinder, with the metal part touching the cylinder. Pull the jack-line and observe the spark in the spark plug electrode. If there is no spark, repeat the test using a new spark plug.

- There is no fuel.

- Press the starter choke until fuel is visible in the bulb. If fuel is not visible, it means the primary system in the fuel supply is blocked. Contac a

- Authorized Service Center. If the starter choke is filled with fuel, the motor is flooded.

- The motor is flooded.

- With the switch off, remove the spark plug. Move the choke lever downwards and pull the jack-line 15 to 20 times to eliminate excessive fuel from the motor. Clean the spark plug and set it back in place. Follow the normal starting procedure (see page 9). If the motor is not starting, repeat the procedure using a new spark plug.

- The starter jack-line is harder to pull than when it was new.

- Take the Gas Brushcutter to a Authorized Service Center.

- There is no spark.

- The motor starts but will not accelerate.

- The motor needs a couple of minutes to be hot.

- Allow the motor to be completely hot. If the motor will not accelerate after three minutes, contact your Authorized Service Center.

- The motor needs a couple of minutes to be hot.

- The motor starts but runs only in high speed with half a choke.

- The carburetor has to be adjusted.

- Take the Gas Brushcutter to a Authorized Service Center.

- The carburetor has to be adjusted.

- The motor is not reaching full speed and starts having smoke emissions.

- Check the oil / fuel mix.

- Use new fuel and the right oil mix for a 2-stroke motor.

- The air filter is dirty.

- Clean the air filter. See page 11.

- The spark arrest screen is dirty.

- Take the Gas Brushcutter to a Authorized Service Center.

- Check the oil / fuel mix.

- The motor starts, runs, accelerates but there is no idle speed.

- The idle screw in the carburetor need to be adjusted.

- Turn the idle screw clockwise to increase speed.

- The idle screw in the carburetor need to be adjusted.

Authorized service centers

In the event of any problem contacting a Truper Authorized Service Center, please see our webpage www.truper.com to get an updated list, or call our toll-free numbers 800 690-6990 or 800 018-7873 to get information about the nearest Service Center.

AGUASCALIENTES

DE TODO PARA LA CONSTRUCCIÓN

GRAL. BARRAGÁN #1201, COL. GREMIAL, C.P. 20030, AGUASCALIENTES, AGS. TEL.: 449 994 0537

BAJA CALIFORNIA

SUCURSAL TIJUANA

AV. LA ENCANTADA, LOTE #5, PARQUE INDUSTRIAL EL FLORIDO II, C.P 22244, TIJUANA, B.C.

TEL.: 664 969 5100

BAJA CALIFORNIA SUR

FIX FERRETERÍAS

FELIPE ÁNGELES ESQ. RUIZ CORTÍNEZ S/N, COL. PUEBLO NUEVO, C.P. 23670, CD. CONSTITUCIÓN, B.C.S.

TEL.: 613 132 1115

CAMPECHE

TORNILLERÍA Y FERRETERÍA AAA

AV. ÁLVARO OBREGÓN #324, COL. ESPERANZA

C.P. 24080 CAMPECHE, CAMP. TEL.: 981 815 2808

CHIAPAS

FIX FERRETERÍAS

AV. CENTRAL SUR #27, COL. CENTRO, C.P. 30700, TAPACHULA, CHIS. TEL.: 962 118 4083

CHIHUAHUA

SUCURSAL CHIHUAHUA

AV. SILVESTRE TERRAZAS #128-11, PARQUE INDUSTRIAL BAFAR, CARRETERA MÉXICO CUAUHTÉMOC, C.P. 31415, CHIHUAHUA, CHIH. TEL. 614 434 0052

CIUDAD DE MÉXICO

FIX FERRETERÍAS

EL MONSTRUO DE CORREGIDORA, CORREGIDORA # 35, COL. CENTRO, C.P. 06060, CUAUHTÉMOC, CDMX.

TEL: 55 5522 5031 / 5522 4861

COAHUILA

SUCURSAL TORREÓN

CALLE METAL MECÁNICA #280, PARQUE INDUSTRIAL ORIENTE, C.P. 27278, TORREÓN, COAH.

TEL.: 871 209 68 23

COLIMA

BOMBAS Y MOTORES BYMTESA DE MANZANILLO BLVD. MIGUEL DE LA MADRID #190, COL. 16 DE SEPTIEMBRE, C.P. 28239, MANZANILLO, COL.

TEL.: 314 332 1986 / 332 8013

DURANGO

TORNILLOS ÁGUILA, S.A. DE C.V.

MAZURIO #200, COL. LUIS ECHEVERRÍA, DURANGO, DGO.TEL.: 618 817 1946 / 618 818 2844

ESTADO DE

MÉXICOSUCURSAL CENTRO JILOTEPEC

PARQUE INDUSTRIAL # 1, COL. PARQUE INDUSTRIAL JILOTEPEC, JILOTEPEC, EDO. DE MÉX. C.P. 54257

TEL: 761 782 9101 EXT. 5728 Y 5102

GUANAJUATO

CÍA. FERRETERA NUEVO MUNDO S.A. DE C.V.

AV. MÉXICO – JAPÓN #225, CD. INDUSTRIAL, C.P. 38010, CELAYA, GTO. TEL.: 461 617 7578 / 79 / 80 / 88

GUERRERO

CENTRO DE SERVICIO ECLIPSE

CALLE PRINCIPAL MZ.1 LT. 1, COL. SANTA FE, C.P. 39010, CHILPANCINGO, GRO. TEL.: 747 478 5793

HIDALGO

FERREPRECIOS S.A. DE C.V.

LIBERTAD ORIENTE #304 LOCAL 30, INTERIOR DE PASAJE ROBLEDO, COL. CENTRO, C.P. 43600, TULANCINGO, HGO. TEL.: 775 753 6615 / 775 753 6616

JALISCO

SUCURSAL GUADALAJARA

AV. ADOLFO B. HORN # 6800, COL: SANTA CRUZ DEL VALLE, C.P.: 45655, TLAJOMULCO DE ZUÑIGA, JAL.

TEL.: 33 3606 5285 AL 90

MICHOACÁN

FIX FERRETERÍAS

AV. PASEO DE LA REPÚBLICA #3140-A, COL.

EX-HACIENDA DE LA HUERTA, C.P. 58050, MORELIA, MICH. TEL.: 443 334 6858

MORELOS

FIX FERRETERÍAS

CAPITÁN ANZURES #95, ESQ. JOSÉ PERDIZ, COL. CENTRO, C.P. 62740, CUAUTLA, MOR.

TEL.: 735 352 8931

NAYARIT

HERRAMIENTAS DE TEPIC

MAZATLAN #117, COL. CENTRO, C.P. 63000, TEPIC, NAY. TEL.: 311 258 0540

NUEVO LEÓN

SUCURSAL MONTERREY

CARRETERA LAREDO #300, 1B MONTERREY PARKS, COLONIA PUERTA DE ANÁHUAC, C.P. 66052, ESCOBEDO, NUEVO LEÓN, TEL.: 81 8352 8791 / 81 8352 8790

OAXACA

FIX FERRETERÍAS

AV. 20 DE NOVIEMBRE #910, COL. CENTRO, C.P. 68300, TUXTEPEC, OAX. TEL.: 287 106 3092

PUEBLA

SUCURSAL PUEBLA

AV PERIFÉRICO #2-A, SAN LORENZO ALMECATLA,

C.P. 72710, CUAUTLACINGO, PUE.

TEL.: 222 282 8282 / 84 / 85 / 86

QUERÉTARO

ARU HERRAMIENTAS S.A DE C.V.

AV. PUERTO DE VERACRUZ #110, COL. RANCHO DE ENMEDIO, C.P. 76842, SAN JUAN DEL RÍO, QRO.

TEL.: 427 268 4544

QUINTANA ROO

FIX FERRETERÍAS

CARRETERA FEDERAL MZ. 46 LT. 3 LOCAL 2, COL EJIDAL, C.P. 77710 PLAYA DEL CARMEN, Q.R.

TEL.: 984 267 3140

SAN LUIS

FIX FERRETERÍAS

AV. UNIVERSIDAD #1850, COL. EL PASEO, C.P. 78320, SAN LUIS POTOSÍ, S.L.P. TEL.: 444 822 4341

SINALOA

SUCURSAL CULIACÁN

AV. JESÚS KUMATE SUR #4301, COL. HACIENDA DE LA MORA, C.P. 80143, CULIACÁN, SIN.

TEL.: 667 173 9139 / 173 8400

SONORA

FIX FERRETERÍAS

CALLE 5 DE FEBRERO #517, SUR LT. 25 MZ. 10, COL. CENTRO, C.P. 85000, CD. OBREGÓN, SON.

TEL.: 644 413 2392

TABASCO

SUCURSAL VILLAHERMOSA

CALLE HELIO LOTES 1, 2 Y 3 MZ. #1, COL. INDUSTRIAL, 2A ETAPA, C.P. 86010, VILLAHERMOSA, TAB.

TEL.: 993 353 7244

TAMAULIPAS

VM ORINGS Y REFACCIONES

CALLE ROSITA #527 ENTRE 20 DE NOVIEMBRE Y GRAL. RODRÍGUEZ, FRACC. REYNOSA, C.P. 88780, REYNOSA, TAMS. TEL.: 899 926 7552

TLAXCALA

SERVICIOS Y HERRAMIENTAS INDUSTRIALES PABLO SIDAR #132, COL . BARRIO DE SAN BARTOLOMÉ, C.P. 90970, SAN PABLO DEL MONTE, TLAX.

TEL.: 222 271 7502

VERACRUZ

LA CASA DISTRIBUIDORA TRUPER

BLVD. PRIMAVERA. ESQ. HORTENSIA S/N, COL. PRIMAVERA C.P. 93308, POZA RICA, VER.

TEL.: 782 823 8100 / 826 8484

YUCATÁN

SUCURSAL MÉRIDA

CALLE 33 #600 Y 602, LOCALIDAD ITZINCAB Y MULSAY, MPIO. UMÁN, C.P. 97390, MÉRIDA, YUC.

TEL.: 999 912 2451

Warranty policy

Code : Model

- 11031 : DES-430

- 11032 : DES-520

Warranty. Duration: 5 year. Coverage: parts, components and workmanship against manufacturing or operating defects, except if used under conditions other than normal; when it was not operated in accordance with the instructive; was altered or repaired by personnel not authorized by Truper®. To make the warranty valid, only present the product in the establishment where you bought it or in Corregidora 35, Centro, Cuauhtémoc, CDMX, 06060, where you can also purchase parts, components, consumables and accessories. The costs of transportation of the product that derive from its fulfillment of its service network are included. Truper will not require any proof of purchase to make the warranty effective. Phone number 800-018-7873. Made in China. Imported by Truper, S.A. de C.V. Parque Industrial 1, Parque Industrial Jilotepec, Jilotepec, Edo. de Méx.

C.P. 54257, Phone number 761 782 9100.

Stamp of the business. Delivery date: