UTG Recon Flex BIPOD Owner’s Manual

MUB032012003

ICEYl10a-MOUNT INSTALLATION INSl’RUC110NS

- Hold the Keymod Nut in place and loosen the screw by turning it counterclockwise with the included 3/32″ Allen Wrench. Be sure not to unscrew too far as to allow the keymod to free spin or detach. Do this to both of Keymod Nuts on each bipod leg.

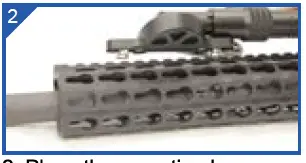

- Place the mounting base so that the Keymod Nuts insert into the desired slots of the handguard through the slot’s larger opening. Make sure the towards the muzzle of the firearm. Carefully look at each determine which one is already setup for the 3 or 9 o’clock positions of the handguard.

- Once the Keymod Nuts are seated in the larger opening of the slot, carefully slide the mounting base forward towards the muzzle until it fully seats into and engages the handguard.

- Reti9hten the Keymod Nuts by turning the Allen Wrench clockwise until securely tightened while holding the mounting base in place. Recommended torque value: 20in-lbs.

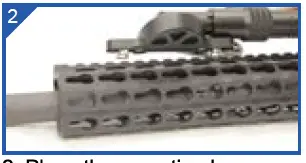

M-LOK® MOUNT INSTALLATION INSTRUCTIONS

- Hold the T-Nut in place and loosen the screw by turning it counterclockwise with the included 1/8″ Allen Wrench until the gap between the T-Nut and the bipos’s mounting base(T-Nut Gap) is slightly larger than the thickness of the handguard. Measuring the thickness of the handguard directly or use the edge of the handguard as a gauge. Do this to both of T-Nuts on each bipod leg.

- Place the mounting base so that the T-Nuts insert into the desired slots of the handguard. The bottom of the mounting base must sit flush with the mounting surface of the handguard. “Bias’ the mounting base towards the muzzle by applying lateral pressure until contact is made with that side of the slot.

- Once seated and the “biased”, hold the mounting base in place and retighten the T-Nuts by turning the Allen Wreanch clockwise until securely tightened. Recommended torque value: 35in-lbs.

- ~ 4. Pay special attention that the T-Nut catches on the slot and rotates the T-Nut to a 90 degree perpendicular ali9nment in relation to the slot . This

can often be seen within the first 1 /4″ tum of the screw if the T-Nut Gap was adjusted properly earlier on.

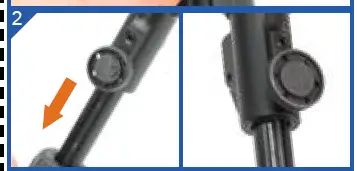

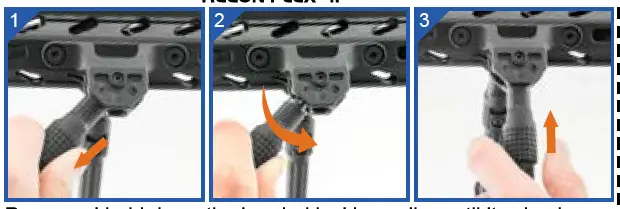

BIDIRECTIONAL 5 POSITION FOLDING INSTRUCT ONS RECON FLEX• II

Press and hold down the knurled locking collar until its circular locking lug clears the 5 position mount. Turn the bipod leg along its axis to the desired position, releasing the locking collar once done to lock the bipod leg in place.

Pull and hold down the spring-loaded slide locking ring. Turn the bipod leg along its axis to the desired position, releasing the slide locking ring once done to lock the bipod leg in place.

LEG EXTENSION/RETRACTION INSTRUCTIONS

- Unlock the locking thumb wheel by turning it all the way counterclockwise.

- Press the tab above the locking thumb wheel to automatically deploy the leg extension to its full length. If at full length the desired center height is achieved, lock the thumb wheel of each bipod leg by turning clockwise until tightened.

- At full extension, press the tab once while simultaneously pushing the leg extension back in to traverse through the shorter, lengths. The notches in the leg extension will lock with the tab each time you reach, a preset length. Lock the thumb wheel of each bipod leg by turning clockwise until tightened once the desired center height is achieved.

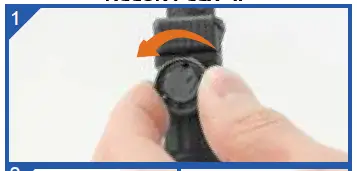

RECON FLEX

- Make sure the Locking Thumb Wheel is fully released by turning it counter-clockwise

.

. - Extend the bipod leg by pulling it out of the leg housing. Set it at any of the pre-cut extension notches. Or, extend to any location in between notches. Tighten the Locking Thumb Wheel by turning it clockwise to lock the leg.

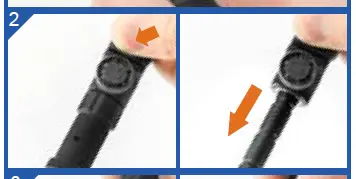

- To retract the bipod leg, loosen the Locking Thumb Wheel first. Press down the Leg Retraction Clamp before you push the extended leg upward into the housing.