veratron MARINE Link Up Gateways Series Link Up Resistive

INTRODUCTION

PACKAGING CONTENT

- 1 Link Up Gateway- Resistive B000422

- 1 Safety Manual B000100

- 1 Veratron Card B000101

THE LINKUP GATEWAY CONCEPT

The resistive-type Link Up gateway provides an easy method to convert vessel and engine information to NMEA 2000®.

Compatible sensors are for example, but not only, liquid levels, temperature, or pressure senders.

Easily installed, the Link Up gateway replaces the original wiring, delivering power to both the Link Up device and sensor from the NMEA 2000® backbone while still being compliant with the NMEA 2000® certification requirements.

The data are then available for being displayed on any Ocean Link, Acqua Link, or more in general on any glass cockpit NMEA 2000® display device.

Configuring Link Up gateways is simple using a mobile device and the companion Link Up Configurator App for Android or iOS.

Each device has a built-in passive NFC antenna, so the parameters of the sensor are wirelessly configured to type, instance and warning threshold on the mobile device which is then “tapped” against the Link Up device for instant data download.

DESIGN AND FUNCTION

The Link Up gateway has a simple yet effective design. The potted housing allows the unit to be installed in engine rooms, making it compliant to the ISO 8846:1990 as requested by the directive 2013-53(EC).

The standard NMEA 2000® M12 plug allows for a plug-and-play installation to the network backbone.ؔ

The sensor connection happens though an AMP Super Seal plug, which perfectly matches the veratron level sensors, without the need of additional wiring.

SAFETY INFORMATION

WARNING

- No smoking! No open fire or heat sources!

- The product was developed, manufactured, and inspected according to the basic safety requirements of EC Guidelines and state-of-the-art technology.

- The instrument is designed for use in grounded vehicles and machines as well as in pleasure boats, including non-classified commercial shipping.

- Use our product only as intended. Use of the product for reasons other than its intended use may lead to personal injury, property damage or environmental damage. Before installation, check the vehicle documentation for vehicle type and any possible special features!

- Use the assembly plan to learn the location of the fuel/hydraulic/compressed air and electrical lines!

- Note possible modifications to the vehicle, which must be considered during installation!

- To prevent personal injury, property damage or environmental damage, basic knowledge of motor vehicle/shipbuilding electronics and mechanics is required.

- Make sure that the engine cannot start unintentionally during installation!

- Modifications or manipulations to Veratron products can affect safety. Consequently, you may not modify or manipulate the product!

- When removing/installing seats, covers, etc., ensure that lines are not damaged and plug-in connections are not loosened!

- Note all data from other installed instruments with volatile electronic memories.

SAFETY DURING INSTALLATION

- During installation, ensure that the product’s components do not affect or limit vehicle functions. Avoid damaging these components!

- Only install undamaged parts in a vehicle!

- During installation, ensure that the product does not impair the field of vision and that it cannot impact the driver’s or passenger’s head!

- A specialized technician should install the product. If you install the product yourself, wear appropriate work clothing. Do not wear loose clothing, as it may get caught in moving parts. Protect long hair with a hair net.

- When working on the on-board electronics, do not wear metallic or conductive jewelry such as necklaces, bracelets, rings, etc.

- If work on a running engine is required, exercise extreme caution. Wear only appropriate work clothing as you are at risk of personal injury, resulting from being crushed or burned.

- Before beginning, disconnect the negative terminal on the battery, otherwise you risk a short circuit. If the vehicle is supplied by auxiliary batteries, you must also disconnect the negative terminals on these batteries! Short circuits can cause fires, battery explosions and damages to other electronic systems. Please note that when you disconnect the battery, all volatile electronic memories lose their input values and must be reprogrammed.

- If working on gasoline boat motors, let the motor compartment fan run before beginning work.

- Pay attention to how lines and cable harnesses are laid so that you do not drill or saw through them!

- Do not install the product in the mechanical and electrical airbag area!

- Do not drill holes or ports in load-bearing or stabilizing stays or tie bars!

- When working underneath the vehicle, secure it according to the specifications from the vehicle manufacturer.

- Note the necessary clearance behind the drill hole or port at the installation location. Required mounting depth: 65 mm.

- Drill small ports; enlarge and complete them, if necessary, using taper milling tools, saber saws, keyhole saws or files. Deburr edges. Follow the safety instructions of the tool manufacturer.

- Use only insulated tools if work is necessary on live parts.

- Use only the multimeter or diode test lamps provided, to measure voltages and currents in the vehicle/machine or boat. Use of conventional test lamps can cause damage to control units or other electronic systems.

- The electrical indicator outputs and cables connected to them must be protected from direct contact and damage. The cables in use must have enough insulation and electric strength and the contact points must be safe from touch.

- Use appropriate measures to also protect the electrically conductive parts on the connected consumer from direct contact. Laying metallic, uninsulated cables and contacts is prohibited.

SAFETY AFTER INSTALLATION

- Connect the ground cable tightly to the negative terminal of the battery.

- Reenter/reprogram the volatile electronic memory values.

- Check all functions.

- Use only clean water to clean the components. Note the Ingress Protection (IP) ratings (IEC 60529).

ELECTRICAL CONNECTION

- Note cable cross-sectional area!

- Reducing the cable cross-sectional area leads to higher current density, which can cause the cable cross-sectional area in question to heat up!

- When installing electrical cables, use the provided cable ducts and harnesses; however, do not run cables parallel to ignition cables or to cables that lead to large electricity consumers.

- Fasten cables with cable ties or adhesive tape. Do not run cables over moving parts. Do not attach cables to the steering column!

- Ensure that cables are not subject to tensile, compressive, or shearing forces.

- If cables are run through drill holes, protect them using rubber sleeves or the like.

- Use only one cable stripper to strip the cable. Adjust the stripper so that stranded wires are not damaged or separated.

- Use only a soft soldering process or commercially available crimp connector to solder new cable connections!

- Make crimp connections with cable crimping pliers only. Follow the safety instructions of the tool manufacturer.

- Insulate exposed stranded wires to prevent short circuits.

- Caution: Risk of short circuit if junctions are faulty or cables are damaged.

- Short circuits in the vehicle network can cause fires, battery explosions and damages to other electronic systems. Consequently, all power supply cable connections must be provided with weldable connectors and be sufficiently insulated.

- Ensure ground connections are sound.

- Faulty connections can cause short circuits. Only connect cables according to the electrical wiring diagram.

- If operating the instrument on power supply units, note that the power supply unit must be stabilized and it must comply with the following standard: DIN EN 61000, Parts 6-1 to 6-4.

SYSTEM INSTALLATION

BEFORE THE ASSEMBLY

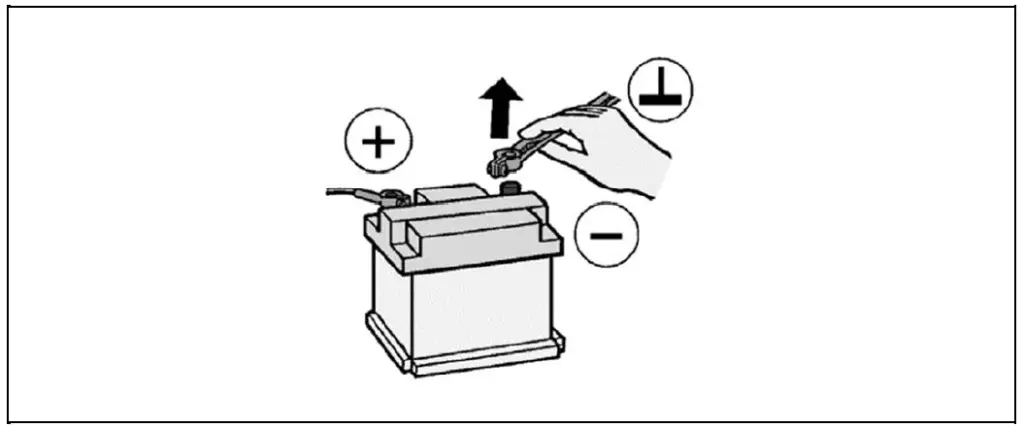

WARNING Before beginning, disconnect the negative terminal on the battery, otherwise you risk a short circuit.

If the vehicle is supplied by auxiliary batteries, you must also disconnect the negative terminals on these batteries! Short circuits can cause fires, battery explosions and damages to other electronic systems. Please note that when you disconnect the battery, all volatile electronic memories lose their input values and must be reprogrammed.

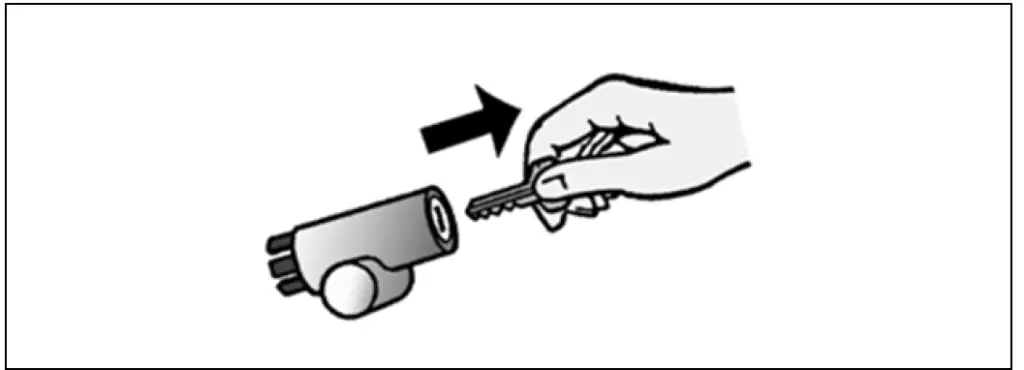

- Before beginning, turn off the ignition and remove the ignition key. If necessary, remove the main circuit switch

- Disconnect the negative terminal on the battery. Make sure the battery cannot unintentionally restart.

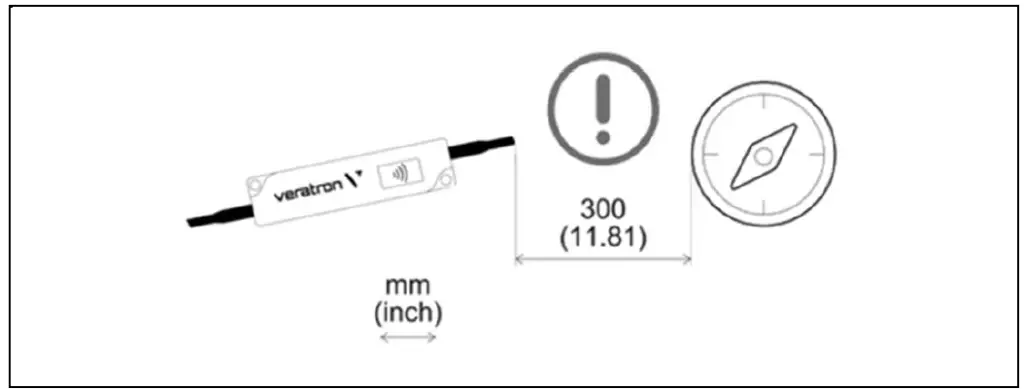

- Place the device at least 300 mm away from any magnetic compass.

CONNECT THE SENSOR

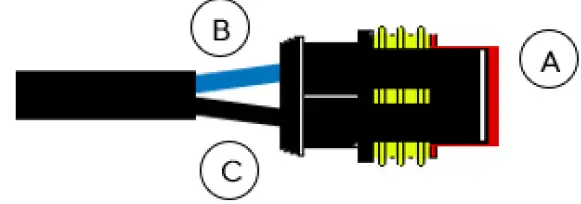

Depending on the sensor to be configured, connect the Link Up plug to the sensor according to the following pin assignment.

If the sensor is not equipped with the matching connector, it is possible to either crimp a male counterpart on it (see “Technical Data”), or simply cut-off the sensor plugs on the Link Up and manually connect the wires.

Veratron level sensors are already designed with the matching AMP connector for a plug-and-play installation.

The contacts must audibly lock into place.

- A. TE AMP Super Seal 1.5 series female plug

- B. Blue wire – Sensor input

- C. Black wire – Sensor ground

SUPPORTED SENSORS

- Fuel Level

- Freshwater Level

- Wastewater Level

- Trim Level

- Rudder Angle

- Coolant Temperature

- Boost Pressure

- Oil Temperature

- Oil Pressure

- Gear Oil Pressure

- Gear Oil Temperature

- Trim Tabs

CONNECT TO THE NMEA 2000® NETWORK

- Once the sensor installation is complete you can interface the Link Up gateway to the NMEA 2000® backbone through the dedicated plug.

- Please ensure to tighten the M12 connector by screwing it onto its counterpart, so to preserve the water tightness.

- A drop cable is not needed unless the total length of the Link Up device is not enough to reach the NMEA 2000® backbone. In this case it is possible to extend the total length by using one of the accessory drop cables.

- Please note that NMEA 2000® does not allow drop cables longer than 6 meters.

- Refer to the NMEA 2000® standard for a proper network design.

- If power from the NMEA 2000® network is received, the green LED on the Link Up housing will start flashing (see “LED notifications”).

CONFIGURATION

LINKUP CONFIGURATOR APP

To configure the sensor, some parameters like sensor type, its calibration or warning threshold, must be calibrated through the Link Up gateway.

- Launch the “Link Up Configurator” App and read the actual configuration of the Link Up device by “tapping” the smartphone onto the Link Up wireless area (indicated by the NFC symbol) The readout is necessary before you can write new configurations on the Link Up

NOTE: The antenna position on the smartphone depends on the model.

Please refer to the smartphone manufacturer manual

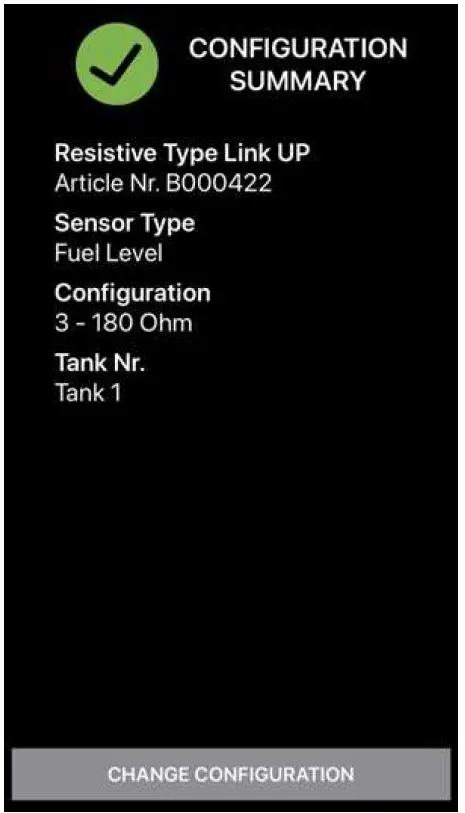

- After the readout, the App will show the

“Configuration Summary”, which displays all the current settings of the device.

To modify the configuration, press the “Change Configuration” button

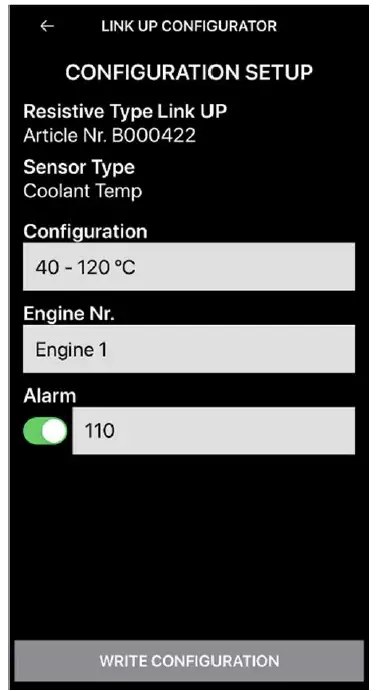

- Select the sensor type to be configured among the list shown in the App (e.g. Fuel Level).

Then choose the calibration for the selected sensor (e.g. 3-180 Ω) and its instance (e.g. Tank 2) so that the Link Up gateway will correctly transmit the value over NMEA 2000®.

For some sensors (see list) it is possible to also set up an alarm, with its related threshold.

Once the settings are completed, press the “Write Configuration” button to prepare the download.

- To upload the configuration, simply “tap” the smartphone again onto the Linkups wireless area, as described in step 1.

The configuration is instantaneously transferred to the device, and the new “Configuration Summary” is displayed.

SUPPORTED CONFIGURATION

| Sensor Type | Calibrations** | Alarm available | NMEA 2000® PGN |

|

Fuel Level |

0 – 90 Ω 3 – 180 Ω 240 – 33 Ω 90 – 4 Ω |

No | 127505 |

|

Freshwater Level |

3 – 180 Ω 90 – 4 Ω |

No | 127505 |

| Wastewater Level | 3 – 180 Ω 240 – 33 Ω 90 – 4 Ω |

No | 127505 |

| Trim Position | 167 – 10 Ω (Single station) 84 – 5 Ω (Dual station) |

No | 127488 |

| Rudder Angle | 10 – 180 Ω (Single station) 5 – 90 Ω (Dual station) |

No | 127245 |

| Coolant Temperature | 291 – 22 Ω (120 °C) 322 – 19 Ω (150 °C) |

Yes | 127489 |

| Boost Pressure | 10 – 184 Ω (2 bar) 10 – 184 Ω (5 bar) |

No | 127488 |

| Oil Pressure | 10 – 184 Ω (5 bar) 10 – 184 Ω (10 bar) |

Yes | 127489 |

| Oil Temperature | 322 – 19 Ω (150 °C) | Yes | 127489 |

| Gear Oil Pressure | 10 – 184 Ω (10 bar) 10 – 184 Ω (25 bar) 10 – 211 Ω (30 bar) |

Yes | 127493 |

| Gear Oil Temperature | 322 – 19 Ω (150 °C) | Yes | 127493 |

| Trim Tabs | 167 – 10 Ω (Single station) 84 – 5 Ω (Dual station) |

No | 130576 |

- The supported configurations may be updated at any time. Please make sure to always use the latest App version.

- There is always the option to add custom sensor curves as well.

LED NOTIFICATIONS

| LED behavior | Description |

| OFF | Device not powered. |

| ON | Device configured and in operation. |

|

Slow blink (1Hz) |

Device in operation with invalid or empty configuration. Waiting for configuration by the user (factory setting). NMEA 2000® messages are NOT transmitted. |

| Fast blink (2.5Hz) | Analogue value from the sensor out of range. NMEA 2000® messages are being set as “invalid”. |

| Very fast blink (10Hz) | Device reconfiguration in progress after wireless download |

TECHNICAL DATA

DATASHEET

| Operating voltage | 6 – 16.5 V |

| Nominal voltage | 12 V (from NMEA 2000® network) |

| Power consumption | ≤ 100 mA |

| NMEA 2000® LEN | 2 |

| Measurement range | 0 Ω – 2 kΩ |

| Protection class | IP X7 according to IEC60529 (when connected) |

| Operating temperature | -30°C to 80°C |

| Flammability | UL94-HB |

| Sensor cable length | 25 cm |

| NMEA 2000® cable length | 25 cm |

| Sensor plug | TE AMP SuperSeal 1.5 2 pins – Female Housing: 282080-1 Terminals: 282403-1 (2x) Sealing: 281934-2 (2x) |

| Counterpart for sensor plug (not included) | TE AMP SuperSeal 1.5 2 pins – Male Housing: 282104-1 Terminals: 282404-1 (2x) Sealing: 281934-2 (2x) |

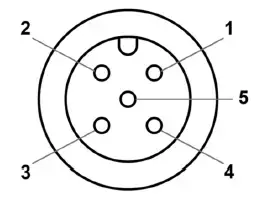

| NMEA 2000® plug | DeviceNet Micro-C M12 5 pins – Male |

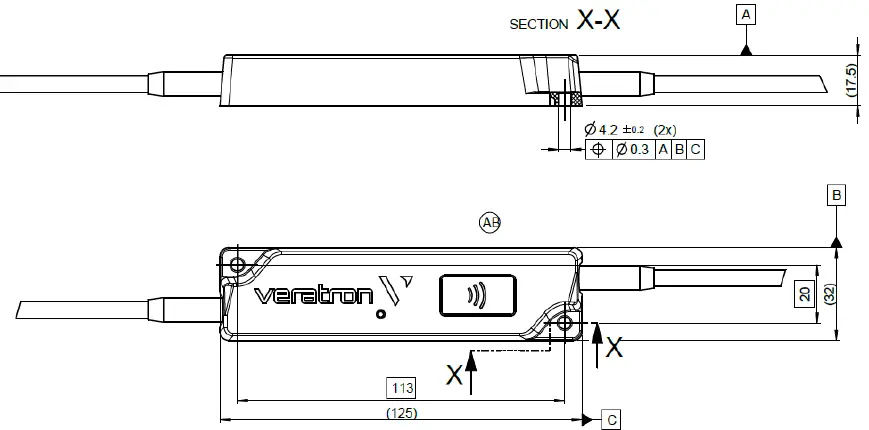

DIMENSIONS

PINOUT

| Pin No. | Description |

| 1 | Shield |

| 2 | NET-S (V+) |

| 3 | NET-C (V-) |

| 4 | NET-H (CAN H) |

| 5 | NET-L (CAN L) |

Micro-C M12 5 poles plug Male, product side view

| Pin No. | Description |

| 1 | Sensor GND |

| 2 | Sensor signal |

Sensor plug Female, product side view SUPPORTED NMEA 2000® PGNS

SUPPORTED NMEA 2000® PGNS

| Description | PGN |

| ISO Address Claim | 60928 |

| ISO Request | 59904 |

| ISO Transport Protocol, Data Transfer | 60160 |

| ISO Transport Protocol, Connection Management | 60416 |

| ISO Acknowledgment | 59392 |

| NMEA – Request group function | 126208 |

| Heartbeat | 126993 |

| Configuration Information | 126998 |

| Product Information | 126996 |

| PGN List – Received PGNs group function | 126464 |

| Rudder | 127245 |

| Fluid Level | 127505 |

| Engine Parameters, Rapid Update | 127488 |

| Engine Parameters, Dynamic | 127489 |

| Transmission Parameters, Dynamic | 127493 |

| Trim Tab Status | 130576 |

veratron AG Industriestrasse 18 9464 Rüthi, Switzerland

T +41 71 7679 111 [email protected] veratron.com

Any distribution, translation, or reproduction, partial or total, of the document is strictly prohibited unless with prior authorization in writing from veratron AG, except for the following actions:

- Printing the document in its original format, totally or partially.

- Copying contents without any modifications and stating Veratron AG as copyright owner.

Veratron AG reserves the right to make modifications or improvements to the relative documentation without notice.

Requests for authorization, additional copies of this manual or technical information on the latter, must be addressed to veratron AG.