ZIPPER Generator

Dear Customer!

This manual contains information and important instructions for the installation and correct use of the ZIPPER generators ZI-STE1100IV. Following the usual commercial name of the machine (see cover) is substituted in this manual with the name “machine”.

This manual is part of the product and shall not be stored separately from the product. Save it for later reference and if you let other people use the product, add this instruction manual to the product.

Please read and obey the security instructions!

Due to constant advancements in product design, construction pictures and content may diverse slightly. However, if you discover any errors, inform us please.

Technical specifications are subject to changes!

Please check the product contents immediately after receipt for any eventual transport damage or missing parts. Claims from transport damage or missing parts must be placed immediately after initial product receipt and unpacking before putting the product into operation. Please understand that later claims cannot be accepted anymore.

Copyright

© 2018 This document is protected by international copyright law. Any unauthorized duplication, translation or use of pictures, illustrations or text of this manual will be pursued by law.

Court of jurisdiction is the Landesgericht Linz or the competent court for 4707 Schlüsslberg, AUSTRIA.

Customer Support

ZIPPER MASCHINEN GmbH

Gewerbepark 8, 4707 Schlüsslberg

AUSTRIA

Tel.: +43 7248 61116-700

Fax: +43 7248 61116–720

Mail: [email protected]

SAFETY

This section contains information and important notices for safe commissioning and handling of machine. For your own safety, read these operating instructions carefully before putting the machine into operation. This will enable you to handle the machine safely and prevent misunderstandings as well as possible damage to property and persons. Also observe the symbols and pictograms used as well as the safety instructions and hazard warnings!

Intended use of the machine

The machine is intended exclusively for the following activities: This power unit is designed exclusively for operating electric devices whose max. performance is within the specifications for the generator. A higher starting current of inductive loads must be considered. The generator is designed to operate from conventional resistive and inductive loads, such as Lights, electric hand tools (drills, electric chain saws, compressors) determined. When connecting to stationary systems such as heating, house supply, air conditioning or for the power supply of mobile homes, an electrician and the heating manufacturer must be consulted regarding the connection and grounding.

ZIPPER-MASCHINEN assumes no responsibility or warranty for any other use or use beyond this and for any resulting damage to property or injury.

Technical Restrictions

The machine is intended for use under the following ambient conditions:

Relative humidity: max. 65 %

Temperature (for operation) +5° C bis +40° C

Temperature (for storage and/or transport) -20° C bis +55° C

Prohibited Use / Forseeable Misuse

- Operation of the machine without adequate physical and mental aptitude

- Operating the machine without appropriate knowledge of the operating instructions (machine + motor).

- Changes in the design of the machine

- Operating the machine in wet and rainy conditions

- Operating the machine in a potentially explosive environment

- Operating the machine indoors or in closed areas

- Operation of the machine without functioning or missing guards

- Remove the safety markings attached to the machine.

- Modify, circumvent or disable the safety devices of the machine.

The prohibited/hazardous use or disregard of the information and instructions presented in this manual will result in the voiding of all warranty and damage claims against Zipper Maschinen GmbH.

User Requirements

The physical and mental suitability as well as knowledge and understanding of the operating instructions are prerequisites for operating the machine. Persons who, because of their physical, sensory or mental abilities or their inexperience or ignorance, are unable to operate the machinery safely must not use it without the supervision or instruction by a responsible person.

Please note that local laws and regulations may determine the minimum age of the operator and restrict the use of this machine! Put on your personal protective equipment before working on the machine. Work on electrical components or equipment may only be carried out by a qualified electrician or carried out under the guidance and supervision of a qualified Electrician.

Safety instructions

In order to avoid malfunctions, damage and health hazards when working with this machine, in addition to the general rules for safe working, the following measures in particular must be observed UNCONDITIONALLY:

- Check that the machine is in perfect condition before each use. Ensure that all guards are in place and working properly and that all nuts, bolts, etc. are securely tightened. Do not take the machine into operation if you notice that parts are missing or damaged!

- Ensure sufficient lighting conditions in the working and surrounding areas of the machine.

- Keep hands and feet away from moving machine parts and always ensure a safe stand when working.

- Ensure that the area to be tamped does not contain any electric cables, gas or water lines which could be damaged by vibration.

- Remove the adjustment tool from the machine before operation.

- Ensure that unauthorised persons maintain a safe distance from the machine and keep children away from the machine.

- The machine may only be operated, serviced or repaired by persons who are familiar with it and who have been informed of the dangers arising during this work.

- Always wear suitable personal protective equipment (eg. ear protection,.., etc.)!

- Do not work with the machine if you are tired, not concentrated or under the influence of medication, alcohol or drugs!

- Never operate the unit in the presence of flammable liquids or gases (danger of explosion!).

- Carry out maintenance, adjustment and cleaning work only when the engine is switched off.

- Only use spare parts and accessories recommended by Zipper machines.

Special safety instructions for the operation of the machine

- Do not use the generator if it is raining, wet or has high humidity. RISK OF ELECTRIC SHOCK. DANGER OF LIFE!.

- Place the generator at least 1m away from buildings and the equipment connected to it.

- Place the generator in a secure, level position. Do not turn, tip or change the generator’s position while it is working.

Safety instructions for machines with combustion engine

- Do not touch the engine and/or muffler during operation or immediately after switching off! These areas become hot during operation and can cause burns.

- Do not touch the spark plug connector when the engine is running (electric shock!).

- Do not operate the unit in closed areas or in poorly ventilated rooms unless there is adequate ventilation through exhaust fans or hoses. (Risk of suffocation from carbon monoxide!)

- Do not smoke while the machine is in operation.

- Do not smoke when refuelling the machine.

- Refuel the machine only in a well ventilated area.

- Do not refuel the machine when the engine is running or the machine is still hot.

- Do not refuel the machine near naked flames.

- Do not spill fuel when refuelling.

- Do not crank a gas flooded engine as long as the spark plug is removed- fuel in the cylinder sprays out of the spark plug opening.

- Do not carry out an ignition spark test on engines if the engine is flooded or gas can be smelled. A stray spark could ignite the vapours.

- Do not use fuel to clean machine parts, especially indoors. Vapours from fuels may explode.

- Always keep the area around the muffler free of foreign substances such as leaves, paper, cardboard, etc. A hot muffler could ignite these substances and cause a fire.

- Close the filler cap after refuelling.

- Check the fuel line and tank regularly for leaks and cracks. Do not operate the machine if leaks in the fuel system are known.

- Store fuel only in designated and approved containers.

Hazard warnings

Despite intended use, certain residual risks remain.

- Risk of burns:

Touching the mufflers, exhaust and other machine components which can be hot after prolonged continuous operation or when the engine is hot cause severe burns. - Risk of fire and explosion:

- Gasoline is highly flammable and explosive under certain conditions.

- NEVER refuel fuel or engine oil while the machine is in operation or is hot.

- When refueling and at places where fuel is stored not smoke or allow open flames or sparks.

- Do not overfill the fuel tank and avoid the spillage of gasoline during refueling. If fuel is spilled make sure the area is completely dry and cleaned before starting the engine.

- Make sure that the filler cap is tightly closed again after refueling safely.

- Chemical risks

Never use or refuel a gasoline or diesel engine in a closed area without adequate ventilation. Carbon monoxide emissions from the internal drive units of the engine can cause in confined spaces through inhalation health effects and death. Therefore use the machine only in well-ventilated rooms or outdoors in operation. Liquid fuels can cause serious damage on the skin and the environment.

- Risk of electric shock

Direct electrical contact may cause electric shock. Never touch the unit with wet hands. Provide adequate grounding. - Hearing damage

A longer stay in the immediate vicinity of the running unit may cause hearing damage. Wear ear protectors! Due to the design and construction of the machine, hazardous situations may occur which are identified as follows in these operating instructions:

DANGER

A safety instruction designed in this way indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

Such a safety instruction indicates a potentially hazardous situation which, if not avoided, may result in serious injury or even death.

CAUTION

A safety instruction designed in this way indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

NOTICE

A safety note designed in this way indicates a potentially dangerous situation which, if not avoided, may result in property damage.

Irrespective of all safety regulations, their sound common sense and corresponding technical suitability/training are and remain the most important safety factor in the error-free operation of the machine. Safe working depends first and foremost on you!

OPERATION

Please check the product contents immediately after receipt for any eventual transport damage or missing parts. Claims from transport damage or missing parts must be placed immediately after initial machine receipt and unpacking before putting the machine into operation. Please understand that later claims cannot be accepted anymore.

Pre-operation check

Check engine oil

NOTICE

The generator is delivered without engine oil and fuel! Engine oil 15W40 must be filled before first use!

See capture maintenance => engine oil change

Check fuel

- Place the machine on a firm and flat surface.

- Open the fuel cap.

- Check the fuel filter.

- Never refuel without fuel filter!

- Fuel must be unleaded gasoline

NEVER REFUEL IF THE ENGINE IS RUNNING!!

Operation instructions

NOTICE

- Always place the machine on a firm and flat surface! No turning, tilting or moving during the engine is running

- Always check oil and fuel level before starting

- Do not connect the appliance before the unit is running at full speed. Disconnect the appliance before turning the unit off.

- Connected devices must be in perfect condition.

- Keep the cable length to the consumer as short as possible.

Operation

Start

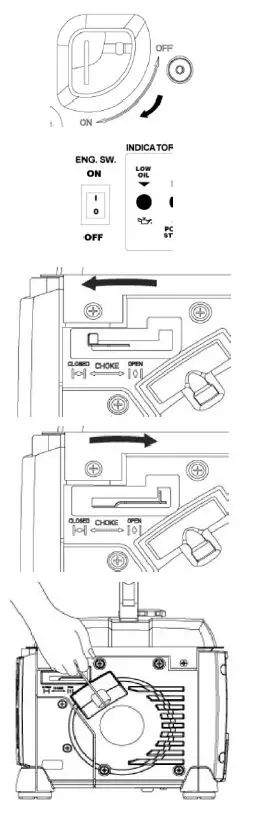

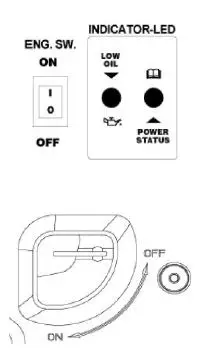

Turn the fuel cock to position „ON“ Switch the ON-OFF switch to position „I“ ON.

Switch the ON-OFF switch to position „I“ ON.

At cold start pull the choke to position „CLOSED“. At worm start (the engine was running and is still warm) pull choke to Position „OPEN“. If the generator fails to start after 5 attempts, pull choke to position “CLOSED” and try again.

After the engine starts pull the choke to position „OPEN“ after 20 s. Start the engine with the recoil starter: Grip the handle and pill the recoil starter. If the engine does not start, try again. Normally start: 3-4 attempts.

When starting with the recoil starter, the motor may recoil suddenly as it starts up, resulting in hand injuries!

Stop

In normal circumstances switch off the generator as follows:

Shut down the connected devices and disconnect them from the generator. To cool down let the engine running for a while without any loads. Switch off the generator by putting the ON-OFF switch to position „0“ OFF

At longer breaks:

To cool down let the engine running for a while without any loads. Thereafter close the fuel cock by turning to position „OFF“. The engine runs until the remaining fuel is consumed in the carburetor. Switch off the generator by putting the ON-OFF switch to position „0“ OFF

In case of emergency stop the generator directly with the ON-OFF switch.

MAINTENANCE

WARNING

No cleaning, upkeep, checks or maintenance when machine is running! Shut off the machine and let it cool down before start servicing!

The machine does not require intense maintenance. However, to ensure a long lifespan, we strongly recommend following the upkeep and maintenance plan. Repairs must be carried out by specialists! Use original ZIPPER parts only!

NOTICE

Only a properly maintained equipment may be a satisfactory tool. Care and maintenance deficiencies can cause unpredictable accidents and injuries. Repairs should be performed only by authorized service centers. Improper operation may damage the equipment or endanger your safety.

Maintenance plan

|

Servicing period |

Before any using | After: 1 month

5 HOO |

After: 3 month

25 HOO |

After: 6 month

50 HOO |

After:

12 month 100 HOO |

After:

25 month 250 HOO |

|

| Engine oil

(15W40) |

Inspection | X | |||||

| Change | X | X | |||||

| Air filter | Inspection | X | |||||

| Change | X | ||||||

| Spark plug | Inspection | X | |||||

| Change | X | ||||||

| Fuel tank / fuel filter | Inspection | ||||||

| Change | X | ||||||

Provide appropriate servicing upon the earlier of the following: in the given month or after the specified hours of operation (HOO) have expired.

Cleaning

- We recommend cleaning the machine immediately after each use.

- Keep all safety devices, air vents and the motor housing free of dirt and dust as far as possible

- Wipe the equipment with a moist cloth and some soft soap or blow it with compressed air at low pressure.

NOTICE

Do not use cleaning agents or solvents; these could attack the plastic parts of the machine!

Engine oil change

NOTICE

Waste oils are toxic and must not be released into the environment! Contact your local authorities for information on proper disposal.

NOTICE

Drain the used oil quickly and completely while the engine is still warm.

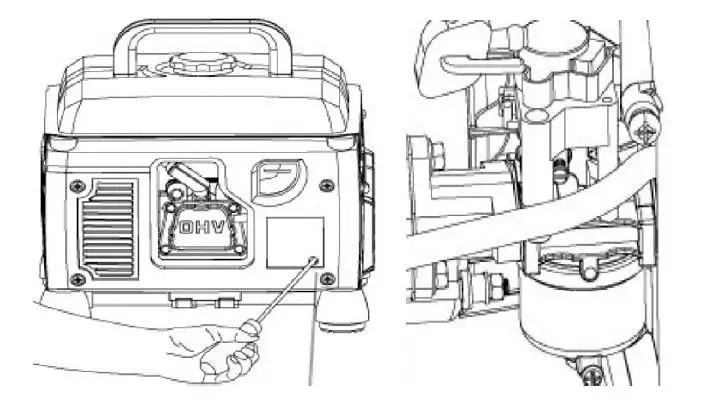

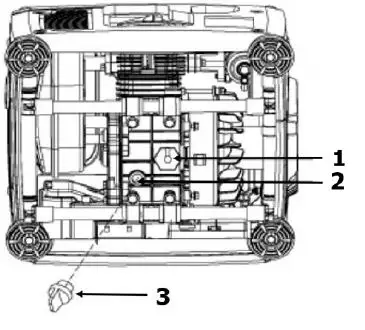

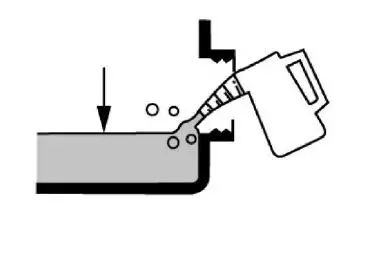

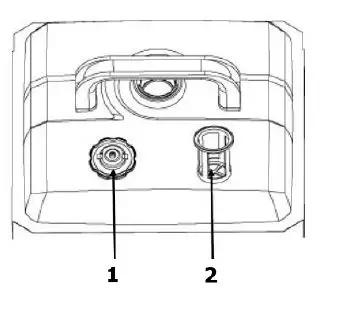

Unscrew the oil filler cap (3); tilt the machine and let the used oil run into a suitable container.

Unscrew the oil filler cap (3); tilt the machine and let the used oil run into a suitable container.- Add new engine oil (15W40, 260ml) (2) and close the oil cap.

- Clean it with a rag.

- Put the machine on an even area and start the engine. If there is sufficient oil level the oil-warning sensor (1) will be not activated.

Air cleaner

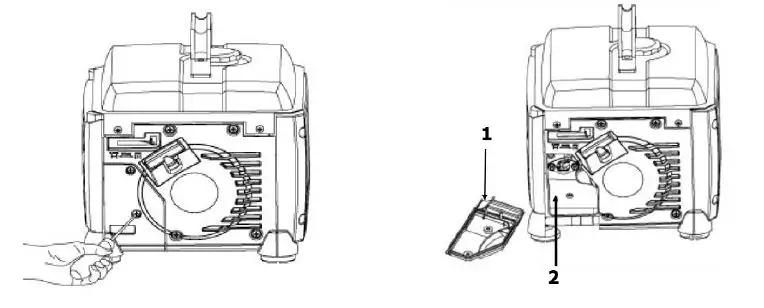

- Loosen the screws and remove the air cleaner cover (1)

- Remove the air cleaner (2)

- Clean the air filter with soapy water, then rinse with clear water and let it dry thoroughly before reassembling.

- Reassemble the air cleaner in reverse order.

Spark plug

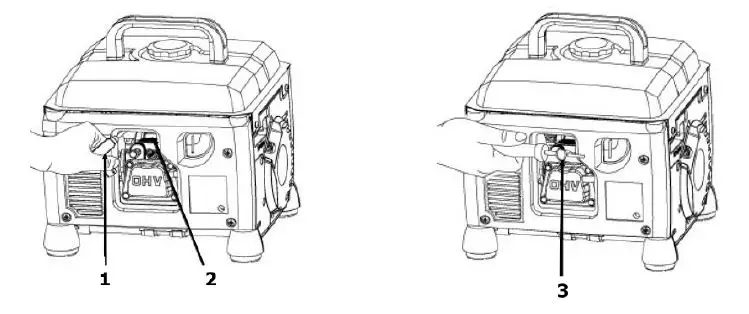

- Remove the spark plug cap (1).

- Loosen the spark plug (2) using a spark plug socket (3).

- Remove carbon deposits with a copper wire brush.

- Check electrode gap (0,6 -0,7mm)

- Reassemble the spark plug in reverse order.

Fuel tank and fuel filter

- Unscrew the fuel cap (1)

- Remove and clean the fuel filter (2)

- Check the fuel tank

- Replace the fuel filter.

Transport

- Secure the machine to prevent slipping

- Do not let the fuel spill out of the fuel tank.

- When the generator is placed on vehicle, the engine may not run.

- During transport, protect the machine from excessive heat. If longer periods in an enclosed vehicle the fuel may ignite due to overheating.

Storage

If the machine is stored for longer than 30 days:

- Wait until the engine cools down sufficiently.

- Allow the fuel from the tank into a suitable container and store the drained fuel in a suitable container.

- Clean and dry machine

- Store in a dry, out of reach of children place

- Cover the machine well and store it in a dry and clean place.

Disposal

Do not dispose the machine, machine components fuel and oil in residual waste. Contact your local authorities for information regarding the available disposal options. When you buy at your local dealer for a replacement unit, the latter is obliged to exchange your old.

TROUBLE SHOOTING

| Trouble | Possible cause | Solution |

| Engine does not start | · Incorrect starting sequence | · Observe the correct starting sequence |

| · Dirty air cleaner | · Clean/replace air cleaner | |

| · No fuel supply | · Refuel | |

| · Fault in the fuel line | · Check the fuel line for kinks or damages | |

| · Engine flooded. | · Screw off, clean and dry the spark plug. Then pull the cranking rope several times and reinstall the spark plug | |

| · Spark plug connector not placed on. | · Place on the spark plug connector | |

| · No ignition spark | · Clean/replace spark plug

· Check ignition cable |

|

| · Fuel cock closed | · Open fuel cock | |

| · Engine oil to few | · Check engine oil | |

| Engine starts and is stalled immediately | · Incorrect idle adjustment | · Contact customer service |

| Machine works with interruptions | · Carburetor incorrectly adjusted | · Contact customer service |

| · Spark plug fouled | · Clean/replace spark plug

· Check spark plug connector |

|

| Oil alarm indicator light flashes | · Check oil level | · Fill engine oil |

| Oil alarm indicator light glows | · To less or no oil | · Fill engine oil |

| Output indicator light interval flash 1x | · Low voltage protection activated | · Engine speed to low |

| Output indicator light interval flash 2x | · High temperature protection activated | · Cool down the engine |

| Output indicator light interval flash 3x | · Overload protection activated | · To big loads |

| Output indicator light interval flash 4x | · Short circuit protection activated | · Check loads |

NOTICE

Should you in necessary repairs not able to properly to perform or you have not the prescribed training for it always attract a workshop to fix the problem.