GIANT Road Elite Comp Clipless Pedal

PLEASE READ INSTRUCTIONS CAREFULLY GIANT. recommends that a professional bicycle dealer install the pedals and fit the cleats.

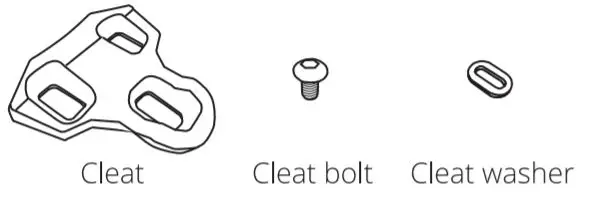

PARTS SUPPLIED

ASSEMBLY PEDALS TO CRANK ARMS

GIANT Road (lipless pedals have 9/16″ x 20T threaded spindles. The right pedal (marked R) is assembled in a clockwise direction. The left pedal (marked L) is assembled in a counter-clockwise direction.

- Lubricate spindle thread prior to assembly.

- Use a thin 15mm wrench or 6mm Allen key for assembly.

- Tighten well but avoid excessive force. Recommended torque is 34Nm (340 kgf/cm)

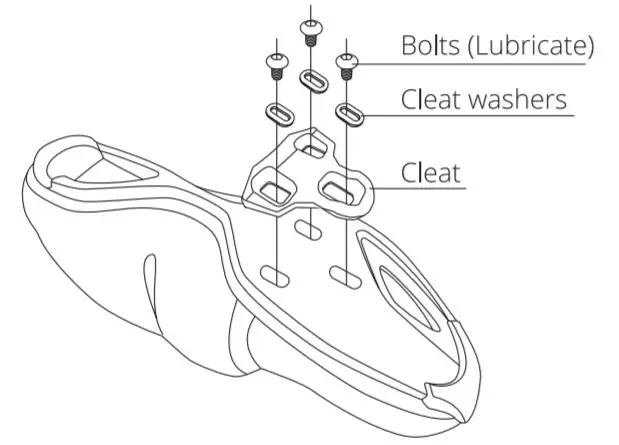

ASSEMBLY OF CLEATS TO CYCLING SHOES

The hardware and cleats supplied are compatible with 3 hole or SPD/3 hole combination style road cycling shoes. GIANT cleats, supplied with your pedals, allow 4.5° float. Left and right cleats are identical, the pointed end faces shoe toe. Use a 4mm alien tool for assembly.

- Using the bolts (lubricate prior to use), and washers supplied, attach the cleats tightly to the bolt receiver holes in the shoes.

- The lateral center line of the cleat should be aligned under the center of the ball of the foot. Adjust vertically via slots in shoe sole. Adjust horizontally via play between cleat washer and cleat. Tighten cleats very firmly. See fig. 1. Cleat position can be fine-tuned, according to personal preference after trail use. It may take some time to find your optimum cleat set-up. Refer to shoe manufacturers, instructions for more shoe-specific information.

Recommended torque: 5-16Nm / 50-160kgf/cm

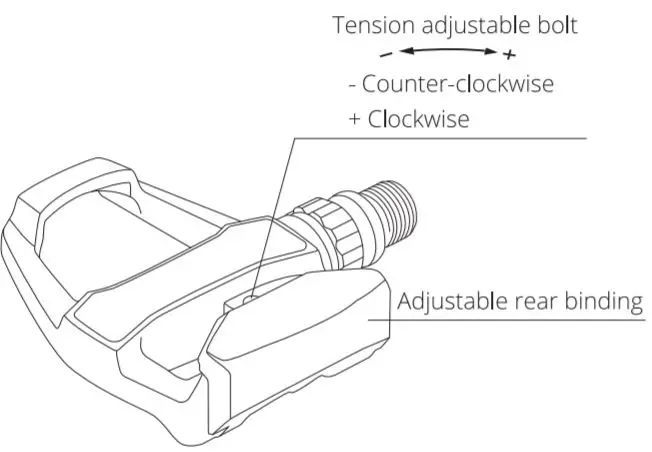

ADJUSTMENT OF PEDAL BINDING TENSION

To adjust tension of the rear binding on pedals, turn 2mm Allen key tension adjustment bolt in the spring cavity (show in fig. 2.)

- Increase tension in a clockwise direction(+) (for more secure shoe/pedal bind but more difficult engagement and disengagement)

- Decrease tension in a counter-clockwise direction(-) for less secure shoe/pedal bind easier engagement and disengagement. See fig. 2. IMPORTANT: Binding tension must be equal on both pedals to achieve a uniform effect when engaging and disengaging cleated shoes.

MINIMUM TENSION IS RECOMMENDED FOR BEGINNERS AND FOR RIDERS REQUIRING FREQUENT

CLEAT RELEASE SUCH AS IN HEAVY TRAFFIC. (SEE CAUTION)

PEDAL USE

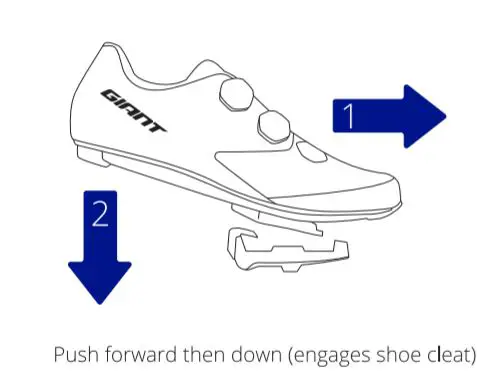

- Engage cleated shoes in pedals by pushing front of cleat into front binding then pushing heel down until rear binding engages on cleats. See fig. 3.

- Disengage by twisting heel outwards (away from bicycle). Cleat will also release by twisting heel inwards if necessary in an emergency situation. See fig. 4.

CAUTION

- It will take time to get used to your pedals and cleats. On a stationary bicycle with one foot firmly on the ground, practice engaging and disengaging cleated shoes one foot at a time with binding tension set low.

- When accustomed to these actions progress to practicing by riding in a safe, traffic-free area until engagement and disengagement become natural actions.

- Do not over tighten or over loosen tension adjustment Allen bolts (bolt will fall out if too loose, and over tightening may damage thread).

- Cleats that are badly worn or difficult to disengage should be replaced. Minimize walking in cleated shoes as this accelerates wear.

- IMPORTANT: use only pedal cleats from GIANT or other compatible cleats with your pedals. To check compatibility ask your bicycle dealer or check engagement or disengagement on a stationary bicycle.

MAINTENANCE

- To function properly, pedals and cleats must be kept clean.

- Occasional lubrication of cleat bolts will help prevent rust and seizure.

- Oil or light grease should be applied occasionally to rear binding springs.

- Pedals should be serviced every 6 months and bearing cartridges should be replaced if rotating pedal emits noise, rotation by hand feels rough or there is play in the bearings.

- Replace pedals with fractures in body or badly worn or damaged bindings.