Munters Green RTU G5 Serial Transmitter Module Installation Guide

Green RTU G5 Serial Transmitter

Module

User Manual

Revision: N.1.1 of 06.2020

Product Software: N/A

This manual for use and maintenance is an integral part of the apparatus together with the attached technical documentation.

This document is destined for the user of the apparatus: it may not be reproduced in whole or in part, committed to computer memory as a file or delivered to third parties without the prior authorization of the assembler of the system.

Munters reserves the right to effect modifications to the apparatus in accordance with technical and legal developments.

1 Introduction

1.1 Disclaimer

Munters reserves the right to make alterations to specifications, quantities, dimensions etc. for production or other reasons, subsequent to publication. The information contained herein has been prepared by qualified experts within Munters. While we believe the information is accurate and complete, we make no warranty or representation for any particular purposes. The information is offered in good faith and with the understanding that any use of the units or accessories in breach of the directions and warnings in this document is at the sole discretion and risk of the user.

1.2 Introduction

Congratulations on your excellent choice of purchasing a Green RTU G5 Serial Transmitter Module. In order to realize the full benefit from this product it is important that it is installed, commissioned and operated correctly. Before installation or using the device, this manual should be studied carefully. It is also recommended that it is kept safely for future reference. The manual is intended as a reference for installation, commissioning and day-to-day operation of the Munters Controllers.

1.3 Notes

Date of release: May 2020

Munters cannot guarantee to inform users about the changes or to distribute new manuals to them.

NOTE All rights reserved. No part of this manual may be reproduced in any manner whatsoever without the expressed written permission of Munters. The contents of this manual are subject to change without notice.

2 Serial Transmitter Module Installation

This guide relates to the installation and setup of the Green RTU G5 Serial Transmitter Module used in Point to Multi Point (PTMP) control systems. This guide applies to Green RTU G5 Serial Transmitter Modules that support 433, 868 and 915MHz license free ISM wireless bands used in various regions around the globe.

![]()

NOTE Before commencing with the installation, please read the following.

- Do not locate this equipment near high voltage power lines. Take special precautions to avoid any contact with high voltage power lines when installing this equipment.

- Avoid locating this equipment close to a roof structure.

- Avoid locating this equipment near dense foliage and vegetation.

2.1 Installing the Transmitters Antenna and the Antenna Cable

NOTE Antennae structures and designs may differ based on the frequency band being used.

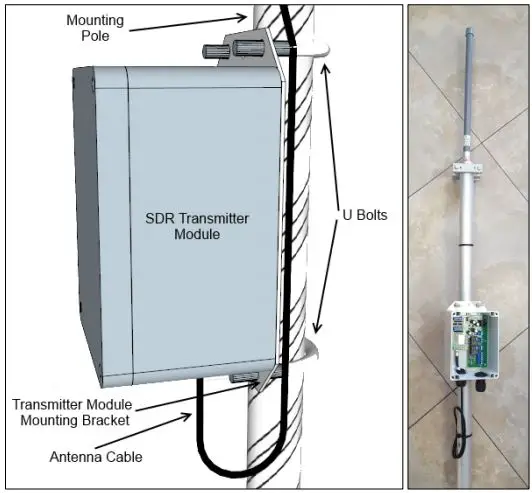

It is best practice to mount the Transmitter Module and the system Antenna on a pole in free air space. The pole should be of a rigid construction with an outside diameter of between 30 and 50mm. The equipment should be located on the pole as high as is practically possible above ground level. Different antennae can be used depending on the topography of the terrain where the system is located. For example it would be possible to make use of a stubby antenna in small scale system that only requires line of sight (LOS) coverage of a few hundred meters from the Transmitter Module. This document will focus on making use of an Omni directional dipole antennae which is the most common antennae used in point to multi point applications.

- Remove the antenna and the antenna’s “U” bolt/s or mounting clamp from the packaging.

- Install the antenna at the top of the mounting pole with the cable and or cable connection facing downwards as shown in the images below.

- Fit the washers provided with each U Bolt / Bolt and tighten the nuts accordingly without damaging the mounting pole.

- Referring to image above, connect the 1M RG58 antenna cable to the Antenna and loop the cable once (to allow for contraction and expansion) and fix the antenna cable to the post using a cable tie. Leave the other end of the cable loose for now.

2.2 Installing the Serial Transmitter Module

- Remove the module from its packaging then remove the modules lid. The lids fasteners are spring loaded and need to be pushed and turned 90° anticlockwise simultaneously to release them.

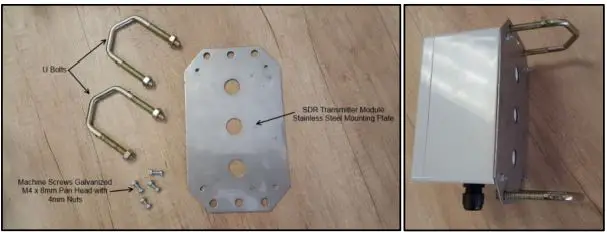

- Install the transmitter modules stainless steel mounting plate using four M4 x 8mm pan head galvanized or stainless steel machine screws and four M4 nuts. Fit the mounting plate to the transmitter module using the four mounting holes provided in the corners of the box. See the images below.

- Install the transmitter module at the top of the mounting pole, approximately 0.5m below the antenna with the cable glands facing downwards. Pass the two U Bolts around the mounting pole and through the transmitter modules mounting bracket. Fit the washers and nuts and tighten the nuts. See the images below.

- Extract the Cable Glands to be found inside the module and remove the wrapping. Install each Cable Glands into the holes provided in the base of the module as seen in the image below.

- Feed the antenna cable through the lower cable gland and fasten the SMA connector to the transmitter board as shown in the images below. Push the protection boot down through the cable gland and tighten the glands compression fitting around the boot to create a water tight connection.

- Disassemble the right hand upper cable gland by removing the compression nut, the split rubber insert and the rubber seal. Pass the one end of the Ethernet (LAN) cable through the cable glands compression nut, the rubber seal and the cable gland. Fit the split rubber insert around the Ethernet (LAN) cable and insert this into the cable gland.

- Plug the RJ45 connector on the end of the (one to one) Ethernet (LAN) cable into the socket on the transmitter modules board. Allow the Ethernet (LAN) cable to take a gradual bend then tighten the compression nut onto the cable gland to form a weatherproof seal. See the image below.

- Power to the Transmitter Module is supplied via the Ethernet (LAN) cable. Make sure the power is off to the Transmitter Module then carry out the following the dip switch settings

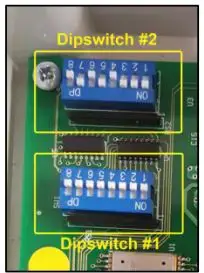

Dip Switch SW1 is used to set the System ID. This System ID must match the System ID being used by the radio receiver modules in the same control system. The System ID can be set in the range from 0 to 255 using binary. The dip switch numbers conform to the following binary numbers:

- SW1.1 = 128

- SW1.2 = 64

- SW1.3 = 32

- SW1.4 = 16

- SW1.5 = 8

- SW1.6 = 4

- SW1.7 = 2

- SW1.8 = 1

- E.g. In order to set a System ID of 119, switches 1.2 (64), 1.3 (32), 1.4 (16), 1.6 (4), 1.7 (2) and 1.8 (1) must be on and the others off. This setting is thus 64 + 32 + 16 + 4 + 2 + 1 = 119

- Systems with duplicated System ID’s should not be located within a 50km radius of each other. It is advisable to log the GPS coordinates of each system installed for future record keeping.

- If the number of outputs being used by this Transmitter Module exceeds 128 (as set using Dip Switch 2.1, 2.2 and 2.3) a second ID which is one value greater will automatically be set in the module for all outputs greater than 129. For example if the system ID is set as 119 on Dip Switch 1, the next system ID for output 129 and greater will be set to 120. Radio receivers that belong to this second system will need to be set to system ID 120 and valve outputs numbers would be set from 1 to 128. Output 1 in system with ID 120 is in fact output 129, output 2 would therefore be 130 and so on.

- Dip Switch SW2 is used to set the number of outputs to be controlled by the 915MHz Transmitter Module, the Serial Data Baud Rate and the Radio Channel to be used.

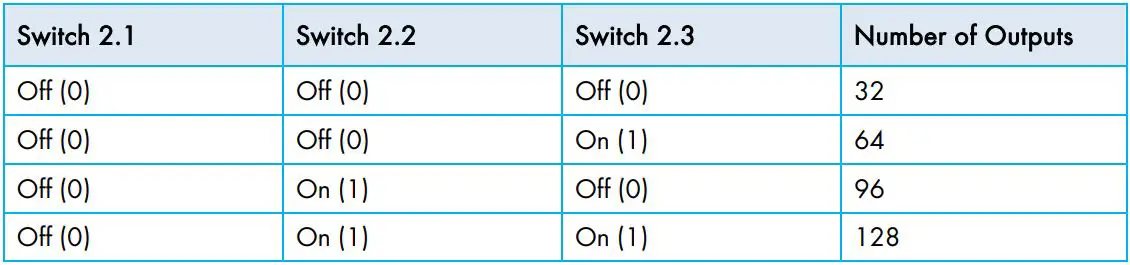

- Switches 2.1, 2.2 and 2.3 are used to set the Number of Outputs the Transmitter Module will service as set out in the table below:

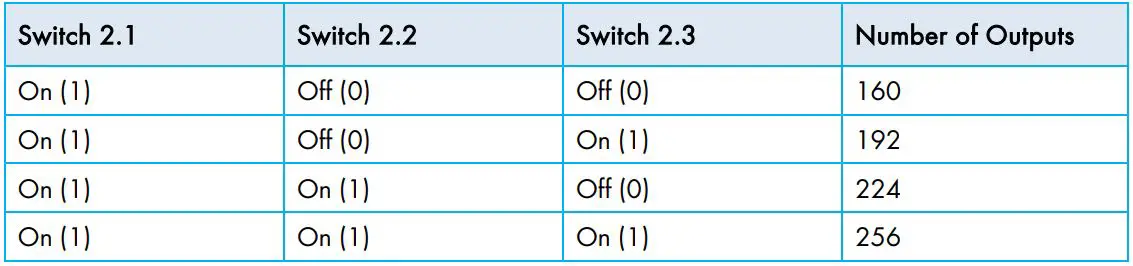

Switch 2.4 is used to set the Serial Data Communications Baud Rate the Transmitter Module requires for communication with other control devices. Switch settings are set out in the table below:

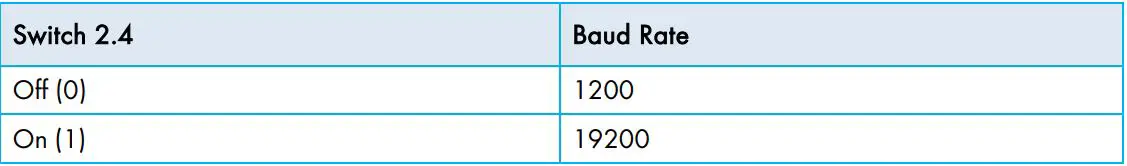

Switch 2.5, 2.6, 2.7 and 2.8 are used to set the Radio Channel the system will make use of. Switch settings are set out in the table below:

NOTE When using the 915MHz transmitter module a total of 15 channels (0 to 14) are available. This is restricted to a maximum of 10 channels (0 to 9) when using 868 or 433MHz transmitter modules.

- This module is now ready for testing and field operation.

2.3 General Notes

- Do not drop either of the modules as this could lead to permanent damage to the module enclosures or sensitive electronic components.

- Keep the components in the original packaging until they are on site and ready to be installed. This provides optimum protection to the equipment during the transport process.

- Avoid exposing the equipment to high vibration and or shock as this can lead to permanent damage to the equipment.

- Do not attempt to modify the equipment or the electronics as this will deem the warranty void and may lead to permanent damage of the equipment.

3 Warranty

Warranty and technical assistance

Munters products are designed and built to provide reliable and satisfactory performance but cannot be guaranteed free of faults; although they are reliable products they can develop unforeseeable defects and the user must take this into account and arrange adequate emergency or alarm systems if failure to operate could cause damage to the articles for which the Munters plant was required: if this is not done, the user is fully responsible for the damage which they could suffer.

Munters extends this limited warranty to the first purchaser and guarantees its products to be free from defects originating in manufacture or materials for one year from the date of delivery, provided that suitable transport, storage, installation and maintenance terms are complied with. The warranty does not apply if the products have been repaired without express authorization from Munters, or repaired in such a way that, in Munters’ judgement, their performance and reliability have been impaired, or incorrectly installed, or subjected to improper use. The user accepts total responsibility for incorrect use of the products.

The warranty on products from outside suppliers fitted to Green RTU G5 Serial Transmitter Module, (for example cables, attends, etc.) is limited to the conditions stated by the supplier: all claims must be made in writing within eight days of the discovery of the defect and within 12 months of the delivery of the defective product. Munters has thirty days from the date of receipt in which to take action, and has the right to examine the product at the customer’s premises or at its own plant (carriage cost to be borne by the customer).

Munters at its sole discretion has the option of replacing or repairing, free of charge, products which it considers defective, and will arrange for their dispatch back to the customer carriage paid. In the case of faulty parts of small commercial value which are widely available (such as bolts, etc.) for urgent dispatch, where the cost of carriage would exceed the value of the parts, Munters may authorize the customer exclusively to purchase the replacement parts locally; Munters will reimburse the value of the product at its cost price.

Munters will not be liable for costs incurred in demounting the defective part, or the time required to travel to site and the associated travel costs. No agent, employee or dealer is authorized to give any further guarantees or to accept any other liability on Munters’ behalf in connection with other Munters products, except in writing with the signature of one of the Company’s Managers.

WARNING: In the interests of improving the quality of its products and services, Munters reserves the right at any time and without prior notice to alter the specifications in this manual.

The liability of the manufacturer Munters ceases in the event of:

- dismantling the safety devices;

- use of unauthorized materials;

- inadequate maintenance;

- use of non-original spare parts and accessories.

Barring specific contractual terms, the following are directly at the user’s expense:

- preparing installation sites;

- providing an electricity supply (including the protective equipotential bonding (PE) conductor, in accordance with CEI EN 60204-1, paragraph 8.2), for correctly connecting the equipment to the mains electricity supply;

- providing ancillary services appropriate to the requirements of the plant on the basis of the information supplied with regard to installation;

- tools and consumables required for fitting and installation;

- lubricants necessary for commissioning and maintenance.

It is mandatory to purchase and use only original spare parts or those recommended by the manufacturer.

Dismantling and assembly must be performed by qualified technicians and according to the manufacturer’s instructions.

The use of non-original spare parts or incorrect assembly exonerates the manufacturer from all liability.

Requests for technical assistance and spare parts can be made directly to the nearest Munters office. A full list of contact details can be found on the back page of this manual.

Munters Israel

18 HaSivim Street

Petach-Tikva 49517,

Israel Telephone: +972-3-920-6200

Fax: +972-3-924-9834

Australia Munters Pty Limited, Phone +61 2 8843 1594, Brazil Munters Brasil Industria e Comercio Ltda, Phone +55 41 3317 5050, Canada Munters Corporation Lansing, Phone +1 517 676 7070, China Munters Air Treatment Equipment (Beijing) Co. Ltd, Phone +86 10 80 481 121, Denmark Munters A/S, Phone +45 9862 3311, India Munters India, Phone +91 20 3052 2520, Indonesia Munters, Phone +62 818 739 235, Israel Munters Israel Phone +972-3-920-6200, Italy Munters Italy S.p.A., Chiusavecchia, Phone +39 0183 52 11, Japan Munters K.K., Phone +81 3 5970 0021, Korea Munters Korea Co. Ltd., Phone +82 2 761 8701, Mexico Munters Mexico, Phone +52 818 262 54 00, Singapore Munters Pte Ltd., Phone +65 744 6828, South Africa and Sub-Sahara Countries Munters (Pty) Ltd., Phone +27 11 997 2000, Spain Munters Spain S.A., Phone +34 91 640 09 02, Sweden Munters AB, Phone +46 8 626 63 00, Thailand Munters Co. Ltd., Phone +66 2 642 2670, Turkey Munters Form Endüstri Sistemleri A., Phone +90 322 231 1338, USA Munters Corporation Lansing, Phone +1 517 676 7070, Vietnam Munters Vietnam, Phone +84 8 3825 6838, Export & Other countries Munters Italy S.p.A., Chiusavecchia Phone +39 0183 52 11