ULINE MARSH Tape Dispenser

SET-UP INSTRUCTIONS

LOADING TAPE

- Open the top cover.

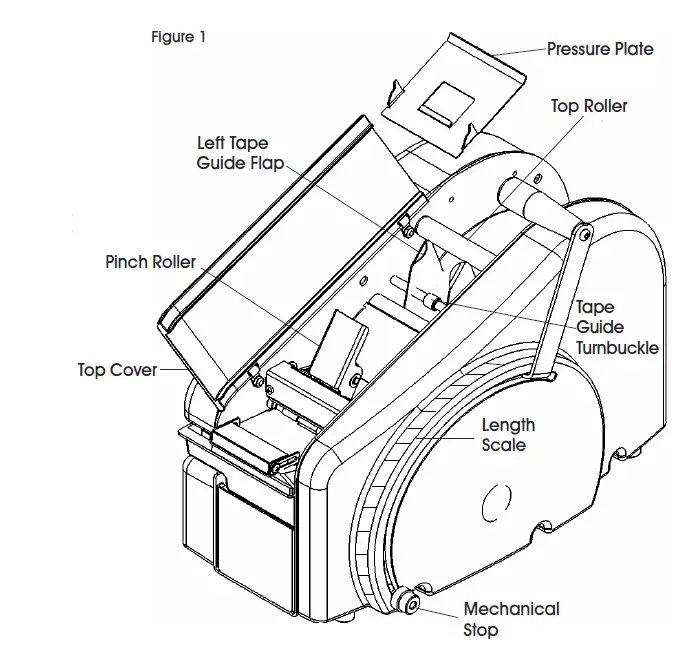

- Insert tape roll. Adjust tape guides with the tape guide turnbuckle to fit the width of the tape. Include a 1/8″ clearance on both sides of the tape roll. (See Figure 1)

- Remove the pressure plate. (See Figure 1).

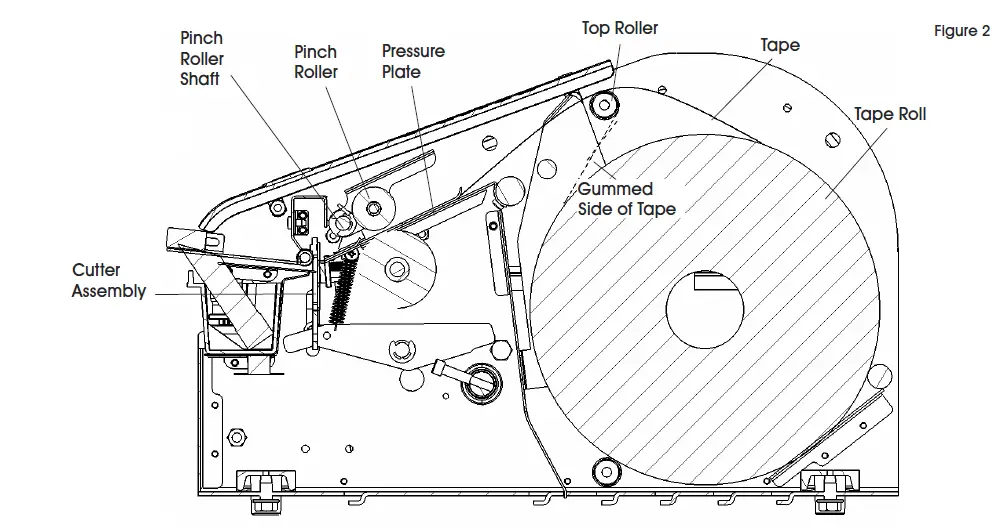

- Feed the tape, gummed side down, over the top roller, under the tape guide flaps, and under the pinch roller. (See Figure 2)

- Place the pressure plate over the tape and release the pinch roller. (See Figure 2)

- Close the top cover.

FILLING WATER BOTTLE

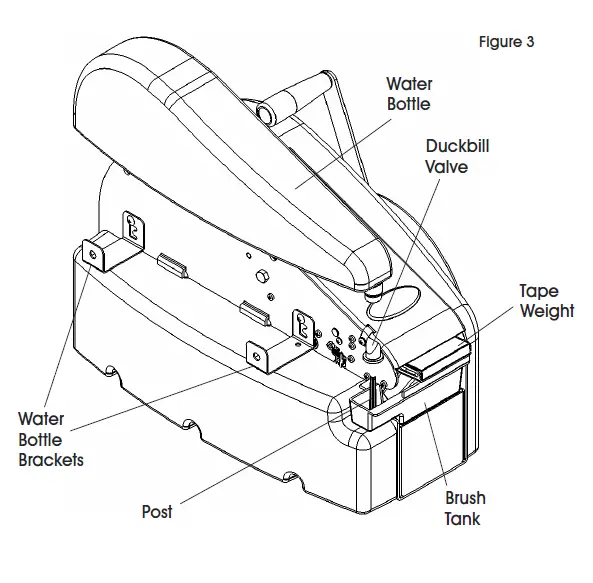

- Remove the water bottle from the dispenser. (See Figure 3)

- Remove the duckbill valve from the water bottle. Fill the water bottle with water. (See Figure 3)

- Place the duckbill valve back into the water bottle.

- Place the water bottle back onto the dispenser.

- Verify that the post in the brush tank is inserted through the duckbill valve.

ADJUSTING BRUSH TANK WATER LEVEL

- Loosen the screws on the water bottle brackets.

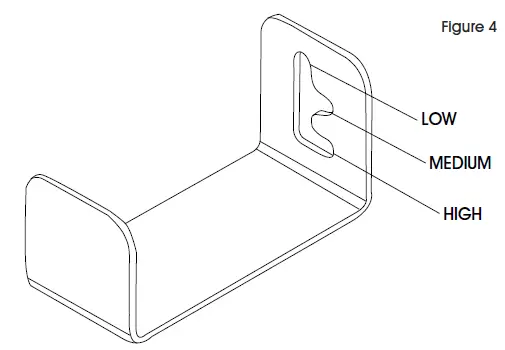

- Move the water bottle brackets to a position that will obtain the desired water level in the brush tank. Both brackets should be in the same position. (See Figure 4)

NOTE: Lightweight tapes should be adjusted to the low position, heavyweight tapes should be adjusted to the high position. - Tighten the retaining screws on the water bottle brackets.

ADJUSTING TAPE WEIGHT

- Loosen the retaining screw.

- Slide the tape weight forward to apply greater pressure. Slide the tape weight backwards to apply less pressure.

NOTE: Lightweight tapes will apply less water on the tape. Heavyweight tapes will apply more water on the tape. - Tighten retaining screw.

OPERATING INSTRUCTIONS

- Pull the operating handle to the desired length on the scale and release the handle.

- When the handle returns to resting position, the tape will be cut.

- A mechanical stop on the side of the dispenser is available if a known length will be used repeatedly.

- The mechanical stop can be moved to the desired position by loosening the knurled nut a half turn and sliding up or down in the slot. Retighten knurled nut once the desired setting has been found.

CAUTION! The knurled nut should never be removed.

MAINTENANCE

NOTE: Little maintenance is required, but regular cleaning of the brush, brush tank, cutter mechanism and tape path are important. Clean the tape dispenser when the water bottle needs refilling.

CAUTION! For units with power switch or heater: before performing any maintenance or repair procedures, turn off power switch and disconnect from power source.

CLEANING WATER FEED SYSTEM

- Clean the brush by soaking in warm, soapy water. Rinse with warm water.

- Clean the brush tank by rinsing in warm water.

- Rinse out the water bottle and duckbill valve with warm water.

CLEANING CUTTER ASSEMBLY

- Open top cover and remove pressure plate.

- Remove tape from tape path.

- Using a small amount of non-flammable lubricant, spray the cutter assembly behind the cutter guard through the gaps in front and behind the cutter guard.

- Place tape back in tape path and place pressure plate back into the machine.]

CLEANING TAPE PATH

- Open top cover and remove pressure plate.

- Remove tape from tape path.

- Using compressed air, remove all debris from the tape path

- To remove gum adhesive buildup, use a moist cloth to wipe down all sheet metal parts within tape path. This includes the tape channel, pressure plate, weighted brush tank cover and water tank holder.

- Place the tape back into the tape path and place the pressure plate back in the machine.

- Close the top cover.

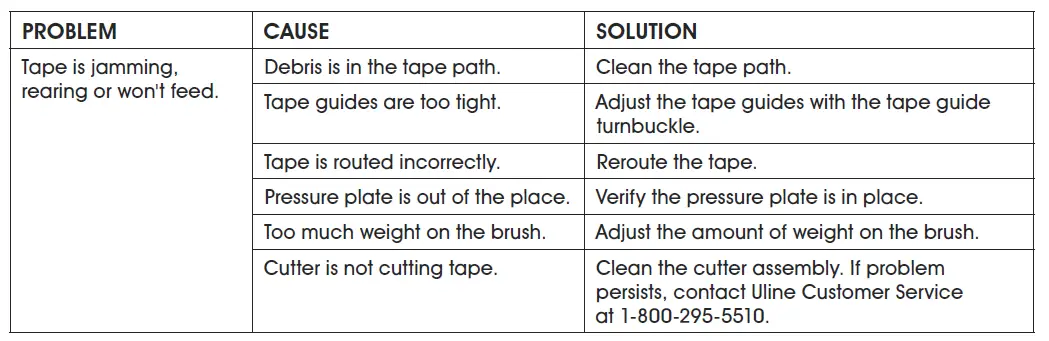

TROUBLESHOOTING

CAUTION! For units with power switch or heater: before performing any maintenance or repair procedures, turn off power switch and disconnect from power source.

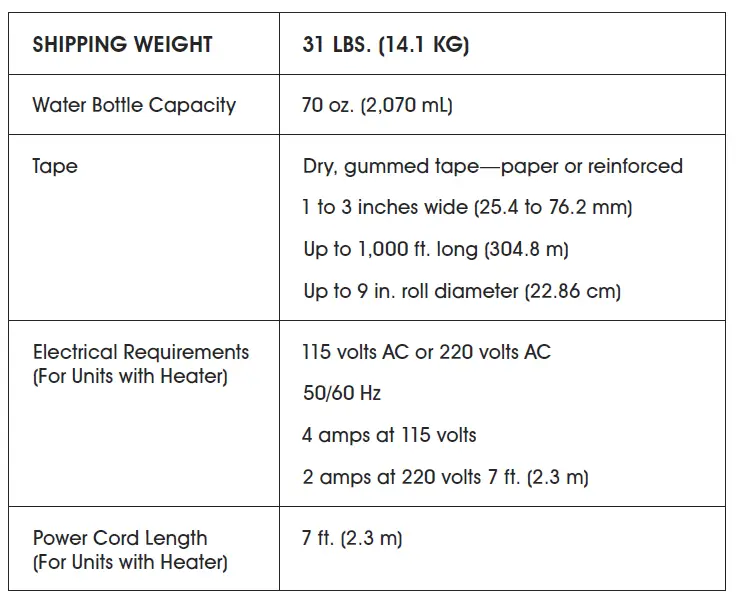

SPECIFICATIONS