H-3530

BOSTITCH®ROLL FEED PNEUMATIC STAPLER

1-800-295-5510

uline.com

OPERATION

1. LOADING THE MAGAZINE

Disconnect from the air supply.

WARNING! When loading the stapler, never place a hand or any part of the body in the fastener discharge area of the stapler. Never point the stapler at anyone. Do not pull the trigger or depress the trip as accidental actuation may occur, possibly causing injury.

WARNING! When loading the stapler, never place a hand or any part of the body in the fastener discharge area of the stapler. Never point the stapler at anyone. Do not pull the trigger or depress the trip as accidental actuation may occur, possibly causing injury.

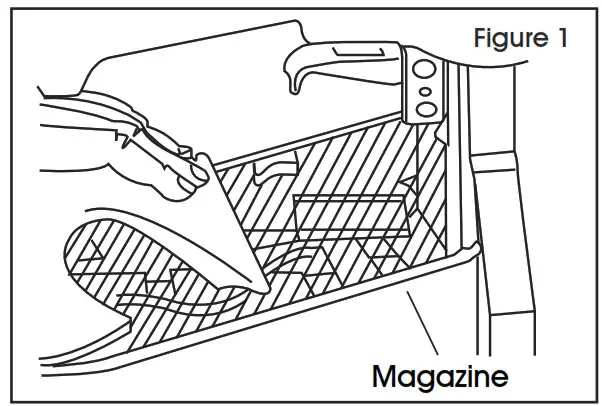

2. Open the magazine Press cover slightly to unlatch from magazine and swing cover open (See Figure 1).

3. Check Staple Leg Length -Adjustment is provided in the H-3530 for different staple leg lengths. Spacers must be changed to use 1/2″ (13mm) staples.

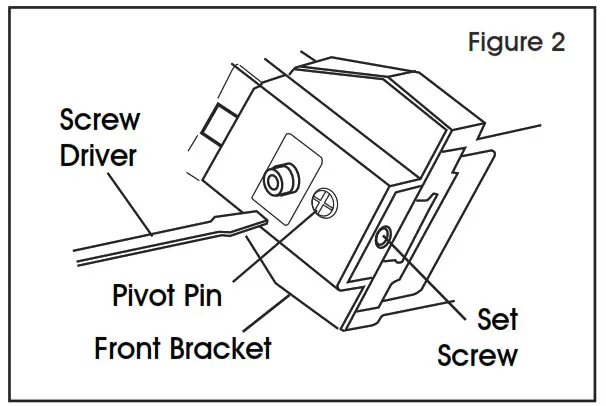

a. To adjust the machine for leg length, loosen set screw and turn the pivot pin 180º with a screwdriver to the desired adjustment as noted. Tighten set screw (See Figure 2).

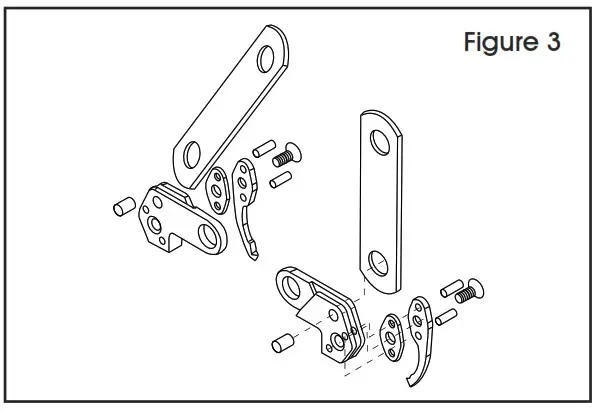

b. To change shallow clinchers (see specifications chart for part numbers), remove screws and front bracket to provide access to clinchers. Change one at a time to prevent reversing parts. Also, part #45 (See Figure 3) will need to be changed to a specified spacer in the table.

b. To change shallow clinchers (see specifications chart for part numbers), remove screws and front bracket to provide access to clinchers. Change one at a time to prevent reversing parts. Also, part #45 (See Figure 3) will need to be changed to a specified spacer in the table.

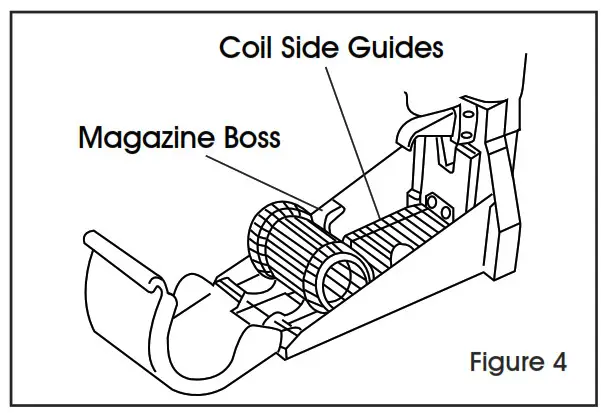

c. To adjust coil guides, loosen 4 screws (See Figure 4). Coil Side Guides

- For 1/2″ (13mm) staples: push guides forward and in as far as they go; tighten screws.

- For 5/8″ (16mm) staples: push guides to rear with screws in the center of the slot; tighten screws.

- For 3/4″ (19mm) staples: push guides forward and outwards as far as they go; tighten screws.

LOADING THE MAGAZINE CONTINUED

4. Load the coil of staples Place coil of staples into the magazine. Feed the front end of the coil into the side and top guides. Push forward until it stops. Swing cover opens and slightly squeeze to enlarge magazine bosses. Check positive engagement.

5. Clinch Adjustment Turn the special nut clockwise to tighten the clinch and counterclockwise to loosen the clinch. Use a tool to fit a 1/8″ (3mm) hole (See Figure 5).

NOTE: Remove adjusting tool after adjustment.

NOTE: Remove adjusting tool after adjustment.

6.Depth Adjustment – Loosen front screw and adjust to the desired length (See Figure 6). When the top edge of the adjustment plate is at the highest setting (#4), the clinches are at their shallowest If set at the lowest setting (#1), the clinchers are at their deepest penetration.

NOTE: Tighten screw after adjusting stapler.

NOTE: Tighten screw after adjusting stapler.

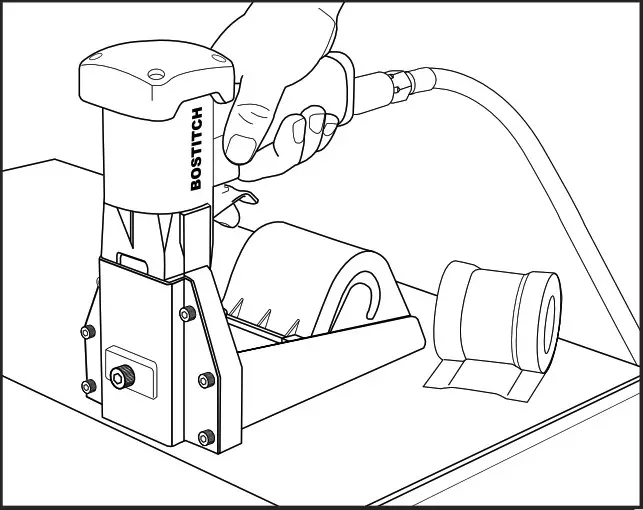

USING THE STAPLER

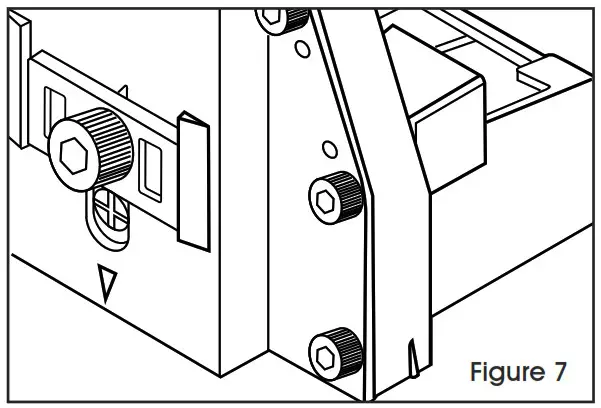

Stapling – Grasp handle with one hand. Position on the box in line with the desired staple location. There is a small projection on either side of the frame as an aid in locating the position of the staple (See Figure 7). Press trigger. The strongest closure requires end staples close to end of box. Check packaging requirements. Check staple clinching in a sample of the board being used. Adjust clinch for depth of penetration and tightness.

NOTE: Always disconnect air supply: 1. Before making adjustments; 2. When servicing the stapler; 3. When clearing a jam; 4. When stapler is not in use; 5. When moving to a different work area, as accidental actuation may occur, possibly causing injury.

NOTE: Always disconnect air supply: 1. Before making adjustments; 2. When servicing the stapler; 3. When clearing a jam; 4. When stapler is not in use; 5. When moving to a different work area, as accidental actuation may occur, possibly causing injury.

REMOVING STUCK STAPLES

WARNING! Always disconnect air supply: 1. When servicing the stapler; 2.When clearing the jam; 3. When stapler is not in use; 4. When moving to a different work area, an accidental actuation may occur.

WARNING! Always disconnect air supply: 1. When servicing the stapler; 2.When clearing the jam; 3. When stapler is not in use; 4. When moving to a different work area, an accidental actuation may occur.

- Jams can be cleared by pulling the jam release lever to a 90º position (See Figure 8). At this position, hold a coil of staples to prevent movement and use either a long nose plier or a screwdriver to clear the jam.(See Figure 8)

- Carefully release lever to prevent staples from being trapped between anvil and blade.

SAFETY WARNINGS

OPERATION

WARNING! Always handle the stapler with care: 1. Never engage in horseplay. 2. Never pull the trigger unless the nose is directed toward the work. 3. Keep others at a safe distance from the stapler while in operation as accidental actuation may occur, possibly causing injury.

WARNING! Always handle the stapler with care: 1. Never engage in horseplay. 2. Never pull the trigger unless the nose is directed toward the work. 3. Keep others at a safe distance from the stapler while in operation as accidental actuation may occur, possibly causing injury.

WARNING! Keep hands and body away from the discharge area of the stapler.

WARNING! Keep hands and body away from the discharge area of the stapler.

WARNING! Do not drive fasteners on top of other fasteners or with the stapler at an overly steep angle as this may cause deflection of fasteners which could cause injury.

WARNING! Do not drive fasteners on top of other fasteners or with the stapler at an overly steep angle as this may cause deflection of fasteners which could cause injury.

WARNING! This stapler produces SPARKS during operation. NEVER use the stapler near flammable substances, gases or vapors including lacquer, paint, benzene, thinner, gasoline, adhesives, mastics, glues, or any other material that is – or vapors which are – flammable, combustible or explosive. Using the stapler in any such environment could cause an EXPLOSION resulting in personal injury or death to users and bystanders.

WARNING! This stapler produces SPARKS during operation. NEVER use the stapler near flammable substances, gases or vapors including lacquer, paint, benzene, thinner, gasoline, adhesives, mastics, glues, or any other material that is – or vapors which are – flammable, combustible or explosive. Using the stapler in any such environment could cause an EXPLOSION resulting in personal injury or death to users and bystanders.

CAUTION: Remove all fasteners from the stapler before performing a stapler operation check.

CAUTION: Remove all fasteners from the stapler before performing a stapler operation check.

TRIGGER-OPERATED STAPLER

a.With the finger off the trigger, hold the stapler with a firm grip on the handle.

b. Place the nose of the stapler against the work.

c. Pull the trigger to drive.

WARNING! This is a full-cycle stapler. The stapler will cycle each time the trigger is pulled! Clinchers will discharge and retract.

WARNING! This is a full-cycle stapler. The stapler will cycle each time the trigger is pulled! Clinchers will discharge and retract.

EYE PROTECTION

WARNING! Eye protection which conforms to ANSI specifications and provides protection against flying particles from both the FRONT and the SIDES should always be worn by the operator and others in the work area when connecting to air supply, loading operating, or servicing this stapler. Eye protection is required to guard against flying fasteners debris which could cause severe eye injury.

WARNING! Eye protection which conforms to ANSI specifications and provides protection against flying particles from both the FRONT and the SIDES should always be worn by the operator and others in the work area when connecting to air supply, loading operating, or servicing this stapler. Eye protection is required to guard against flying fasteners debris which could cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection equipment must conform to the requirements of the American National Standards Institute ANSI Z87.1 and provide both frontal and side protection.

The employer and/or user must ensure that proper eye protection is worn. Eye protection equipment must conform to the requirements of the American National Standards Institute ANSI Z87.1 and provide both frontal and side protection.

NOTE: Non-side shielded spectacles and face shields do not provide adequate protection.

NOTE: Non-side shielded spectacles and face shields do not provide adequate protection.

AIR SUPPLY AND CONNECTIONS

WARNING! Do not use oxygen, combustible gases or bottled gases as a power source for this stapler, as the stapler may explode, possibly causing injury.

WARNING! Do not use oxygen, combustible gases or bottled gases as a power source for this stapler, as the stapler may explode, possibly causing injury.

WARNING! Do not use supply sources that can potentially exceed 200 psig as the stapler may burst, possibly causing injury.

WARNING! Do not use supply sources that can potentially exceed 200 psig as the stapler may burst, possibly causing injury.

WARNING! The connector on the stapler must not hold pressure when air supply is disconnected. If a wrong fitting is used, the stapler can remain charged with air after disconnecting and thus will be able to drive a fastener even after the air line is disconnected, possibly causing injury.

WARNING! The connector on the stapler must not hold pressure when air supply is disconnected. If a wrong fitting is used, the stapler can remain charged with air after disconnecting and thus will be able to drive a fastener even after the air line is disconnected, possibly causing injury.

WARNING! Do not pull the trigger or depress the contact arm while connected to the air supply as the stapler may cycle, possibly causing injury.

WARNING! Do not pull the trigger or depress the contact arm while connected to the air supply as the stapler may cycle, possibly causing injury.

WARNING! Always disconnect air supply.

WARNING! Always disconnect air supply.

In addition to the other warnings contained in this manual, observe the following for safe operation:

- Use the Bostitch® pneumatic stapler only for the purpose for which it was

- Never use this stapler in a manner that could cause a fastener to be directed toward the user or others in the work

- Do not use the stapler as a

- Always carry the stapler by the Never carry the stapler by the air hose.

- Do not alter or modify this stapler from the original design or function without approval from Bostitch Inc.

- Always be aware that misuse and improper handling of this stapler can cause injury to yourself and

- Never leave unattended with the air hose

- Do not operate this stapler if it does not have a legible WARNING

- Do not continue to use a stapler that leaks air or does not function Notify Uline if your stapler continues to experience functional problems.

MAINTENANCE

REPLACEMENT PARTS

- Bostitch replacement parts are Do not use modified parts or parts which will not give equivalent performance to the original equipment.

ASSEMBLY PROCEDURE FOR SEALS

- When repairing a stapler, make sure the internal parts are clean and Use Parker O-LUBE or equivalent on all O-Rings. Coat each O-Ring with O-Lube before assembling. Use a small amount of oil on all moving surfaces and pivots. After reassemble add a few drops of Bostitch Air Tool Lubricant through the airline fitting before sealing.

AIR SUPPLY – PRESSURE AND VOLUME

- Air volume is as important as air The air volume supplied to the stapler may be inadequate due to undersized fittings and hoses or from the effects of dirt and water in the system. Restricted airflow will prevent the stapler from receiving an adequate volume of air even though the pressure reading is high. The result will be a slow operation, misfeeds, or reduced driving power. Before evaluating stapler problems for these symptoms, trace the air supply from the stapler to the supply source for restrictive connectors, swivel fittings, low points containing water or anything else that would prevent full volume flow of air to the stapler.

SPECIFICATIONS

STAPLER SPECIFICATIONS

| ULINE PART NO. | MFG. PART NO. | LENGTH | HEIGHT | WIDTH | WEIGHT | ROLL CAPACITY |

| H-3530 | D62ADC | 9″ (228mm) | 8.625″ (219mm) | 4.5″ (115mm) | 5.9 lbs. (2.5 kg) | 1,000 |

FASTENER SPECIFICATIONS

| ULINE PART NO. | LEG LENGTH | STAPLE SERIES | WIRE SIZE | CROWN WIDTH | FASTENER RANGE |

| S-2724 | 5/8″ (16mm) | SWC | .074 x 0.37″

(1.88 x 94mm) |

1-3/8″

(35mm) |

1/2″ – 3/4″

(12-19mm) |

| S-2725 | 3/4″ (19mm) | SWC | .074 x 0.37″

(1.88 x 94mm) |

1-3/8″

(35mm) |

1/2″ – 3/4″

(12-19mm) |

PARTS/STAPLE CHART

| CLINCHERS | Standard/Flat | Shallow/Flat | ||

| A01900601(L.H.) | A01900501(R.H.) | D60065(R.H.) | D60066(L.H.) | |

| SPACERS | A02300801 | A02300801 | 175497 | 175497 |

| STAPLE LENGTHS | 5/8″ (16mm) | 3/4″ (19mm) | 1/2″ (13mm) | 5/8″ (16mm) |

| DIAL POSITION | ||||

STAPLER AIR FITTING

This stapler must use a male free-flow connector plug, 1/4″ N.P.T. The minimum inside diameter should be .300″ (8mm). Fitting must be capable of discharging stapler air pressure when disconnected from the air supply.

OPERATING PRESSURE

The operating pressure of the stapler is 70 to 100 psi (5 to 7 kg/cm2). Select the operating pressure within this range for the best fastener performance.

CAUTION: Do not exceed the recommended operating pressure.

AIR CONSUMPTION

AIR CONSUMPTION

Model H-3530 requires 4.0 cubic feet per minute (.113 cubic meters) of free air to operate at the rate of 100 fasteners per minute, at 80 psi (5.66kg/cm2). Take the actual rate at which the stapler will be run to determine the amount of air required. For instance, if your fastener usage averages 50 fasteners per minute, you need 50% of the stapler’s cfm of free air which is required for running at 100 fasteners per minute.

TROUBLESHOOTING

| OPERATING ISSUE | CAUSES | RECOMMENDATIONS |

| Trigger valve housing leaks air Trigger valve stem leaks air | O-Ring cut or cracked O-Ring/seals cut or cracked |

Replace O-Ring Replace trigger valve assembly |

| Frame/piston rod leaks air | O-Ring | Replace O-Ring |

| Frame/cap leaks air | Damaged O-Ring Loose cap screws Broken piston | Replace O-Ring Tighten and recheck Replace piston |

| Lack of power; slow to cycle | Tool dry, lacks lubrication Trigger assembly work, leaks Dirt/tar buildup on driver Air pressure too low |

Use Bostitch Air Tool Lubricant Replace O-Rings/seals Check bumper, head valve spring Replace trigger assembly Disassemble nose/driver to clean Check air supply equipment Adjust adjustment nut or replace adjustment lever |

| Skipping fasteners | Tar/dirt in driver channel Air restriction/inadequate airflow through quick disconnect socket and plugWorn piston O-Ring/piston Tool dry, lacks lubrication Low air pressure Loose magazine nose screws Leaking head cap gasket Trigger valve O-Ring cut/worn Broken/chipped driver Worn anvil/pusher Broken pusher spring Worn former Dry/dirty magazine |

Disassemble and clean nose and driver Replace quick disconnect fittings Replace O-Ring/piston Use Bostitch Air Tool Lubricant Check air supply system to tool Tighten all screws Tighten screws/replace gasket Replace O-Ring Replace driver (check piston O-Ring) Replace anvil/pusher Replace pusher spring Replace former Clean/lubricate use Bostitch Air Tool Lubricant |

| Fasteners jam in the stapler | Driver channel worn Wrong size fasteners Bent fasteners Loose magazine nose screws Broken/chipped driver Worn former Worn anvil/pusher |

Replace nose/check door Use only recommended fasteners Discontinue using these fasteners Tighten all screws Replace driver Replace former Replace pusher |

1-800-295-5510

1-800-295-5510