SKAL

Beer Dispenser

10030663

10032176

COOKINGCO www.klarstein.com

www.klarstein.com

Dear Customer,

Congratulations on purchasing this equipment. Please read this manual carefully and take care of the following hints to avoid damages. Any failure caused by ignoring the items and cautions mentioned in the instruction manual is not covered by our warranty and any liability. Scan the QR code to get access to the latest user manual and other information about the product:

TECHNICAL DATA

| Item number | 10030663 10032176 |

| Power supply | 220-240 V ~ 50 Hz |

| Volume | 5 litre keg |

| Cooling capacity | 2-12 °C |

| Size (W x H x D) | 27.2 x 47 x 48 cm |

| Weight | 6,4 ± 0,3 kg |

Note: This is a household beer cooler, equipped with a CO₂ cartridge pressure system to keep the beer fresh. It brings the beer to the best temperature for cold storage (0 to 4℃) within 19-21 hours. The beer cooler will keep the 5 L Keg cool for an almost indefinite period. We do, however, suggest that you initially cool your beer keg for at least 12 hours in your refrigerator before placing it into the beer cooler.

SAFETY INSTRUCTIONS

- Read all safety and operating instructions before using the device. Keep the operating instructions in a safe place for future reference.

- Check that the power cord is intact before use. If this is not the case, contact customer service.

- If the power cord is damaged, it must be replaced by Customer Service to avert danger.

- Before use, check that the plug fits the outlet. If this is not the case, contact Customer Service.

- Do not handle the power plug with wet hands when plugging in or unplugging it.

- Place the appliance on a dry and level surface.

- To ensure adequate ventilation around the unit, leave at least 12 cm of free space around the unit.

- Place the unit in direct sunlight.

- Do not cover the device with objects when it is in operation.

- The device must be installed in an area that is protected from environmental influences such as wind, rain and water splashes.

- Disconnect the device from the power supply before cleaning it. Failure to do so may result in electric shock or death.

- Do not immerse the product in water or any other liquid.

- Do not use coarse cloths or abrasive cleaners to clean the product.

- Do not take the keg out of the dispenser if the beer has not been fully drawn.

- Do not remove the CO₂ cartridge until it is empty.

- Do not use CO₂ cartridges if the room temperature exceeds 49°C. Failure to follow this warning may result in explosion and death.

- Do not allow children to operate, play with or crawl into the system.

- Children must be supervised so that they do not play with the equipment.

- Do not store explosive materials such as spray cans of flammable propellants in this appliance.

- This appliance is intended for use in the home and similar establishments, such as kitchenettes in shops, offices and other working environments in manor houses, hotels, motels and other non-business catering facilities.

PRODUCT OVERVIEW

|

1 Top cover 2 CO₂ cartridge sheath 3 Tap handle 4 Tap 5 Keg lifter 6 Drain switch 7 Drip tray 8 CO₂ pressure relief valve/ knob 9 LED display Drain switch/ Digital control button Drip tray 10 Door lock button 11 Rear cover 12 Power cord & plug 13 AC power switch |

COMMISSIONING

Installation

- Take out the beer cooler from its package. Place the beer cooler on a steady and horizontal surface, and make sure the beer cooler is at least 5 inches/10 cm away from other appliances or wall on each side so as to allow correct ventilation on the appliances to get better performance.

- Install the tap handle connect the tap, make sure both end fit together perfectly.

- Set the water drip tray into the notch provided.

- Plug the beer cooler.

Note: Do not connect or disconnect the electric plug when your hands are wet. Before use it, make sure the voltage is in conformity with plug mark, and check whether the power cord is well connected or not; if not, please don’t use it, and call service center. - Put 800ml water into the cooling cavity or pour the water to the max mark (It can work without water, but it can’t display the best performance).

Note: Make sure the drain switch is at “Off” position, and no extra objects in the cooling cavity

HOW TO SELECT A KEG

- Sealed 5L universal keg and Heineken keg applies only

- Pay close attention to safety and storage messages about the keg / on the keg.

- Check the keg is neither damaged nor beer out-of-date before purchasing.

- Protect the top surface from being damaged. Otherwise it could be difficult of accession for the suction tube.

- Keep the keg in a rather cold for 12 hours but not too cold place (e.g. refrigerator) until next use.

- Never shake the keg before use

- Never put the beer keg under the sunlight

Beer keg sealant

All 5 Liter beer keg with the below various appearance sealants can apply to the beer cooler, however, you should follow the information as below.

The sealants with code No. 20 and 21 can be pierced simply by the cooler piercing pin.

The sealants with code No. 22 need to be removed off the marking ring from the sealant and pierce the keg by cooler piercing pin.

The difference between code No 23 and 24 is the safety clasp quantity. Pull up the safety clasp carefully, turn around and take it out from the keg; replaced it by the sealant (like code No 20 sealant) provided in the beer cooler, attach it to the beer keg, and pierce it by cooler piercing pin.

Note: Important: Before replacing the sealants or piercing the cooler kit, you must always follow the instructions marked on the keg to eliminate the excess gas and ensure that the keg has rested long enough to avoid foam coming out through the cooler piercing pin /tap faucet. And it is no need to release the gas and replace the seal rubber if you use Heineken keg, because Heineken keg has its own CO₂ pressure inside, and no need to be provided from outer CO₂ pressure system.

Universal 5 L beer keg

- Before piercing the plug on the top of the keg, you must always follow the instructions marked on the keg to eliminate the excess gas and ensure that the keg has rested long enough to avoid foam coming out through the tap faucet.

- Uprightly direct the piercing pin against the sealant on the upper center of the keg (maybe you need to tear off the marking ring or change a proper sealant), press the piercing pin/keg lifter to poke the sealant and then push the piercing pin all immerse in the keg quickly. To assemble the tap mechanism until you hear a “Ka” sound that will indicate the tap mechanism fixes on the beer keg.

- Open the beer cooler with 30-40 N strength and place the well-assembled keg into the cooling cavity; Connect the CO₂ connector tube and beer outlet tube with the keg lifter tube connector. Note: make sure all connection of tap mechanism is well connected, and without damage. And make sure tap valve is on close status, and the CO₂ pressure regulator knob is at “Off” status.

- Loosen the CO₂ bottle sheath (Show as figure 15), insert a 16 gram CO₂ cartridge in the sheath (Figure 16), and screw the sheath tightly until you will hear a “Click”(Figure 17), which indicates that the cartridge seal has been pierced and the CO₂ gas can flow into the keg freely. Make us the bottle sheath is fixed tightly to avoid the CO₂ leakage. Then put CO₂ bottle sheath into the top cover.

Note: Turn off the CO₂ knob when cooling the beer, turn off when the beer flow is paused, turn off when changing the CO₂ cartridge. If the beer cannot be tapped out (there is still beer in the keg), or beer foams are not enough, turn the knob to „+“ position for 5 seconds then turn it off again. - Close the top cover of the beer cooler; When pouring out the beer, the turn the knob on the top cover to “+” position to release the CO₂, and turn it to “-“position when pause or stop pouring beer to close the CO₂. Please refer to the notice label on the top cover.

- Turn on the power switch to “I” position to power on the beer cooler. (While “0”position is to power it off). Note: Please make sure your hands are dry when you operate the beer cooler, to avoid electric shock.

- It will take 19-21 hours to cool the beer to 0-4 °C at 22-24 °C ambient temperature. And it can keep the temperature as set and displayed on the LED.

(The LED will display the real temperature of the beer). We do, however, suggest that you initially cool your beer keg for at least 12 hours in your refrigerator before placing it into the beer cooler, especially when the ambient temperature is higher than 25 °C. - The beer cooler has 6 preset temperatures. Press and hold the „-“ key to reach the cooling temperature setting. Press the „-“ key to set a fixed value of 12 °C, 10 °C , 8 °C, 4 °C or 2 °C. The cooling temperature is set by pressing the „-“ key. You can also press and hold the „+“ button to enter the temperature setting. Then press „+“ to set a fixed value of 2 °C, 4 °C, 6 °C, 8 °C, 10 °C, or 12 °C.

The unit has a memory function that uses the last selected temperature value when you turn on the cooler. By default, the display shows the current temperature of the beer. Press and hold the „+“ key to display the set temperature. The set temperature is displayed for 3 seconds, then the current temperature is displayed again.

9. Adjust the CO₂ pressure regulator knob to “+” position, to pour the beer out by pulling down the tap mechanism, and you can adjust the pressure regulator knob to control the beer flow rate and beer bubble. Note: Clean the glass before pouring beer out; if the beer or beer cup/glass is in high temperature or the beer is not cool enough, there are many bubbles when pouring beer out.

10. When taping the beer, lean your beer glass against the pouring spout and slowly straighten it up with the beer rising, then open the tap mechanism completely to avoid much bubble; It is advisable to pour half-glass, make a short pause before continuing the rest. Notes: Never immerse the pouring spout into the beer glass to avoid much bubble; Remember to lock the tap after finishing pouring.

11. It is normal to have more bubbles when pouring the first 3 cup of beer.

12. There will be a sharp and high-speed jet when pouring the last cup of beer from keg.

Heineken Keg

Heineken kegs are pre-charged with CO₂, and do not require the use of regulator, no need to install the CO₂ cartridge. And the knob on the top cover does not work.

The Heineken connector that comes with your beer cooler can work with all Heineken 5 L kegs. However you must use a flat head screwdriver to remove the green base from

the keg in order to install the new connector, provided with the beer cooler.

When install the new connector to the Heineken keg, you must firstly install the clear beer tube one end to the connector, one end to the tap mechanism, then install the connector to the Heineken keg.

Close the lid. Perform steps 6-12 as for the universal drum. Step 9 is different.

INSERTING A NEW BEER KEG

When the beer in the keg runs out, before changing a new beer keg:

- Adjust the CO₂ pressure regulation knob to “-“ switch to shut off the CO₂ supplying and save the CO₂.

- Open the top cover of the beer cooler, pull down the tap handle to release the rest gas in the keg (maybe with some beer bubble).

- Then put the piercing pin into the new keg and put into the beer cooler. Connect the gas-tube and beer tube from the keg lifter, by pressing the white parts of keg lifter.

- Disconnect the gas-tube and beer tube from the keg lifter,

- Take out the keg by the keg lifter, and pull out the piercing pin from the keg.

- It is recommended to clean the tap mechanism when changing the beer keg each time. Please refer to the below contents about cleaning.

INSERTING A NEW CO2 CARTRIDGE

Note: not required for Heineken kegs!

Please change the CO₂ cartridge if can’t pour beer out when the CO₂ pressure knob is at “on” position and has beer in keg.

- When turn the CO₂ pressure knob to “-“ position, to close the CO₂ supplying.

- Open the top cover, loose the cartridge sheath, and take out the empty CO₂ cartridge. Insert a new 16g CO₂ cartridge in the sheath, and screw the sheath tightly until you will hear a “Click”, which indicates that the cartridge seal has been pierced and the CO₂ gas can flow into the keg freely. Make us the bottle sheath is fixed tightly to avoid the CO₂ leakage. Then put CO₂ bottle sheath into the top cover.

- Close the top cover of beer cooler.

- Turn the CO₂ pressure knob to “+“ position to turn on the CO₂ supply, and it is ready to pour beer out.

Note: Each 16 g CO₂ cartridge can pressure more than 5 L beer out.

Safety instructions:

- Please use the qualified CO₂ cartridge. The below CO₂ cartridge information for your reference. Never use Nitrogen gas cartridge in the beer cooler to avoid the explosion, because of its much higher pressure;

- New CO₂ cartridge need good reserve, any play if forbidden, or will cause hazards.

|

|||

| Net weight | 15,5-16,5 g | B | 88-89 mm |

| Volume | 20 ml | C | 21,7-22 mm |

| Gross weight | 57-58,6 g | D | 19-11 mm |

| Cartridge weight | 42-42,6 g | Pressure | 60 kgf/cm2 |

| A | 8,6-8,9 mm | Detonation pressure | 45 bar |

- Open the drain switch to drain out the water from the cavity into the drip tray. Make sure the drip tray is fit into the notch to avoid water flow to the desk; the drip tray can load 450 ml water;

- After all water drain out, close the drain switch and put 800 ml fresh water into the cavity.

- Open the drain switch (drag the switch forward to 90 degree angle), and drain out the water inside the cavity to drip tray, and need twice to drain out the water.

Note: clean water is necessary; make sure the drip tray is fit into the notch to avoid water flow to the desk; the drip tray can load 450 ml water.

CLEANING THE BEER TAP MECHANISM

The beer dispenser must meet hygienic requirements. It must be cleaned before first use and after a long period of non-use. Clean the whole machine with a dry cloth. In addition, there are 2 recommended cleaning instructions:

- Fill the cleaning set with warm water.

- Connect the end of the piercing needle. Press the water into the piercing needle to clean the inlet pipe. Press the water out of the beer hose at the other end. Repeat until the beer hose is clean. You need at least 3 bottles of warm water). Clean the dosing mechanism as shown in the picture below. Disassemble the tap when cleaning.

Dosing mechanism

- When cleaning the beer hose, open the tap.

- This connection must be connected to the cleaning cartridge.

Cleaning cartridge

Note: Never place the dosing mechanism in the washing machine or dishwasher. Never use chemical detergents to clean the parts. Use as warm, clean water as possible.

To change spare parts

| Items | Name | Picture | Qty. | Instalment |

| 1 | Connector seal |  |

3 | Regulator valve |

| 2 | Piercing pin |  |

1 | Regulator valve |

| 3 | Beer tube |  |

1 | Beer-out connector |

| 4 | Tube seal circle |  |

3 | Beer-in pipe |

| 5 | Keg seal |  |

2 | Standard keg |

| 6 | Adaptor |  |

3 | Keg with integrated pressure cartridge |

| 7 | CO₂ cartridge |  |

3 | Regulator valve assembly |

| 8 | Air bulb |  |

1 |

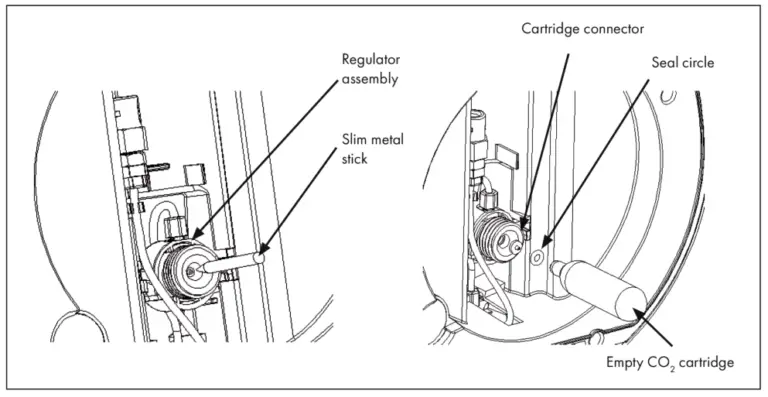

Firstly, pick out the seal washer with a tiny metal stick (Show as fi gure), and take out Cartridge pierced probe. Be careful not damage other parts of regulator.

Cartridge pierced probe and seal washer

Cartridge pierced probe and seal washer maybe damaged when wrong usage or other reasons, please replace a new one.

- Install a new cartridge pierced probe in the regulator (leave the sharp end outside toward), and install the seal washer (Show as fi gure). Don’t remove other parts of regulator in the replacing process.

WARNING

WARNING

Risk of injury! Remember to press the seal circle with empty cartridge instead of new cartridge, or will cause hazard.

To change beer tube

Please replace the beer tube if beer tube is damaged and cause beer leakage (see fi gure 26).

- Loosen the tube at connection 1 and draw out the tube. Pull down the lock setting, and draw the tube out.

- Screw out nut at connection 2, and draw the tube out.

- Replace a new beer tube, and install the beer tube according to with the reverse procedure.

Note: Don’t move other screws when processing tube replacement, otherwise it may cause the beer leakage or gas leakage.

Replace the seal circle of beer tube

Replace the new seal circle of beer tube if the connector has leakage (see figure).

- Replace the new seal circle of beer tube if the connector has leakage

- Take out the seal circle of beer tube

- Replace a new seal circle on same position

- Turn the seal circle tightly to avoid any leakage

TROUBLESHOOTING

Note: If the beer cooler does not work properly, please call the service centre. To save time and money, before you call for service, check the Troubleshooting Guide. It lists cause of minor operation problems that you can correct yourself.

| Problem | Possible Cause | Suggested Solution |

| The tap does not work /

can’t pour beer out. |

The pouring tube is in poor connection or CO₂ supplying is cut off | Well connect the pouring tube and CO₂ supplying. |

| No keg or no beer in the keg. | Change a new keg. | |

| No gas in the CO₂ cartridge. | Change a new CO₂ cartridge. | |

| The CO₂ pressure regulator knob is closed. | Turn the CO₂ pressure regulator knob on “+” position. | |

| Too much bubble pouring out. | Use a wrong way to pour beer out. | Quickly open the faucet completely.

Check and find out the correct distance from the beer mug to the tap when pouring wine. Normally to the height, the normal foam should be thick and creamy. |

| The beer temp is high (better at 3-5 °C. | Cool the beer down to 3-5 °C. | |

| The keg is shaken before usage. | Put the beer keg aside a while till no bubble inside. | |

| Almost no beer in the keg. | Change a new keg. | |

| Too much pressure in the keg. | Adjust the pressure knob to “-“ direction to decrease the pressure or close the knob. |

| Problem | Possible Cause | Suggested Solution |

| Beer fiows out too slowly | Inside CO₂ pressure isn’t high enough. | Adjust the pressure knob to release much CO₂ pressure or replace a new one. |

| The connection tube or the pouring tube has a leakage. | Check whether the tube has a leakage or not, if so replace the tube. | |

| CO₂ leaks quickly when inserting new cartridge. | CO₂ pressure regulator is not in “-“ position. | Make sure CO₂ pressure regulator is in “-“ position. |

| Connector seal broken. | Replace connector seal. | |

| Piercing pin broken. | Replace piercing pin. |

DISPOSAL CONSIDERATIONS

If there is a legal regulation for the disposal of electrical and electronic devices in your country, this symbol on the product or on the packaging indicates that this product must

If there is a legal regulation for the disposal of electrical and electronic devices in your country, this symbol on the product or on the packaging indicates that this product must

not be disposed of with household waste. Instead, it must be taken to a collection point for the recycling of electrical and electronic equipment. By disposing of it in accordance with the rules, you are protecting the environment and the health of your fellow human beings from negative consequences. For information about the recycling and disposal of this product, please contact your local authority or your household waste disposal service.

MANUFACTURER and IMPORTER (UK)

Manufacturer:

Chal-Tec GmbH, Wallstrasse 16, 10179 Berlin, Germany.

Importer for Great Britain:

Chal-Tec UK limited

Unit 6 Riverside Business Centre

Brighton Road

Shoreham-by-Sea

BN43 6RE

United Kingdom