VEVOR THHJ151551 Multifunctional Digital Heat Press Machine

HEAT PRESS MACHINE PARTS INTRODUCTION

PARTS LIST

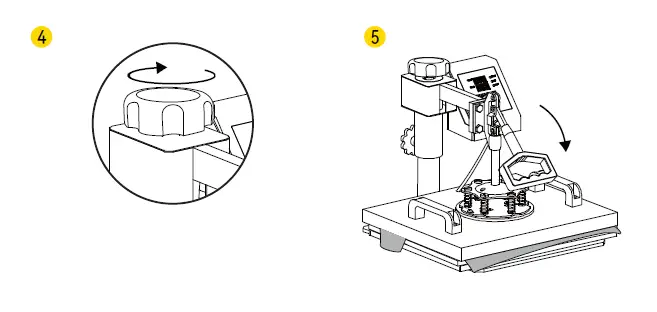

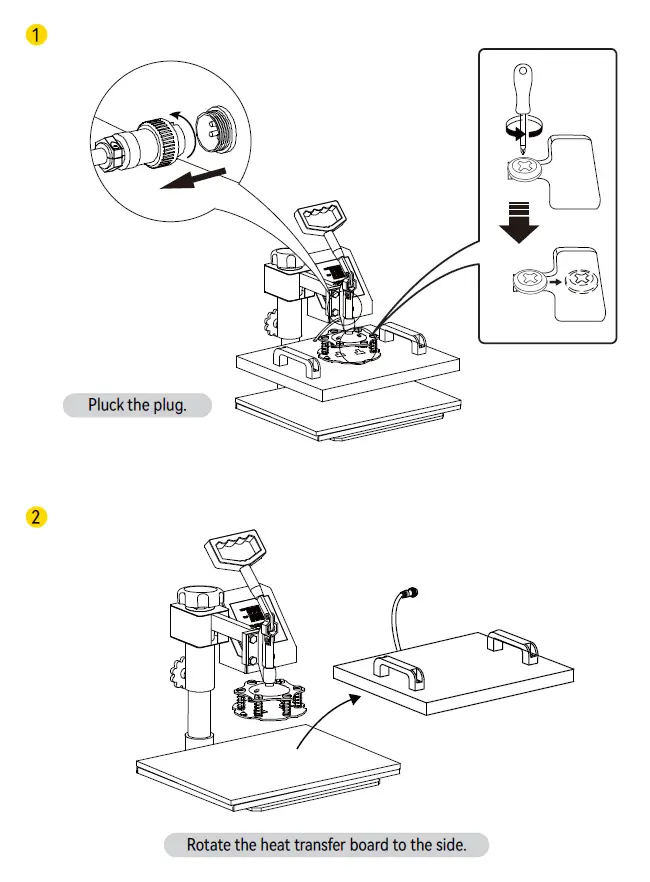

ASSEMBLY and USE STEPS

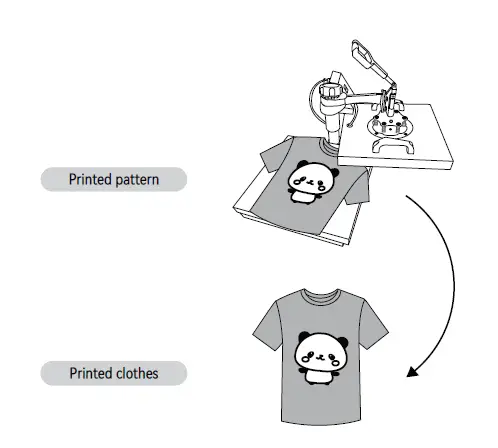

- Rotate the heat transfer board to the side.

- Pull out the mat below, place the clothes flat on the mat, and place the pattern on the clothes.

- Turn this adjustment switch to adjust the pressure.

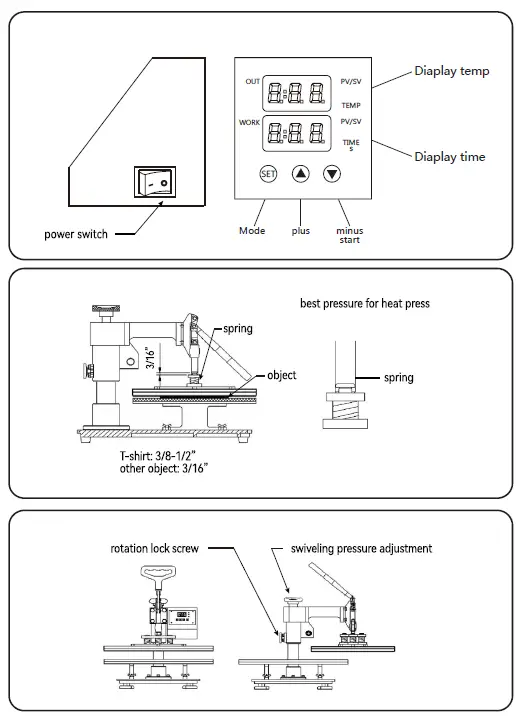

INTELLIGENT TEMPERATURE CONTROLLER OPERATION METHOD

Preparation before Using:

- Check the connection between the power plug and the electrical socket of the electrical cabinet. Be sure to operate with safe ground wire!!!

- The heat press element must be securely plugged into the machine before you switch the machine on. Plug your electrical cord into the machine. Plug the electrical socket into wall plug.Turn the power on by flipping the On/Off Switch on.( Nominal voltage:220V, Max.input power:1250W )

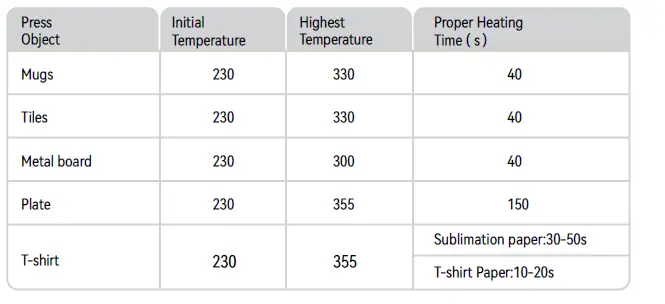

Set temperature required

Set the temperature and time according to the table below and get the specific corresponding temperature and timing setting.(Temperature is measured in Degrees Fahrenheit.)

A. Initial Temperature Setting ( Range:200-450℉)

Press the “MODE” button ONCE,see the “set light” turning red. Then press the “plus/minus key” to set the initial heating temperature.

B. Highest Temperature Setting ( Range:200-450℉)

Press the “MODE” button for THE SECOND TIME;see the “temperature light” turning red. Then press the “plus or minus key” to set the highest heating temperature.

C. Proper Heating Time Setting ( Range:0-999 sec.)

Press the “MODE” button for THE THIRD TIME;see the”time light” turning red. Then press the “plus or minus key” to set the proper heating time.

D.Finish the Setting and Stands by to Work

Press the “MODE”button for THE FOURTH TIME;finish the setting , The set light is on, and the temperature will continue to rise. When the set maximum temperature is reached, the countdown starts. After the countdown ends, the “BEEF” sound will be emitted, the indicator light will turn off, and the operation is complete.and the machine stands by to work.

- Turn off the power and pull out the mat. It is recommended to wear heat-resistant gloves when removing clothes or remove them after 2-3 minutes. Be careful of hot heat.

Note

- The machine has a self -locking function for temperature setting.

- If the starting temperature is set to 340°F,the machine will automatically limit the maximum temperature setting range from 340 to 430°F.

- Conversely,if setting the maximum temperature as 250°F at first,the machine will automatically limit the starting temperature setting range from 200 to 250°F.

- Initial heating temperature always=<Highest heating temperature

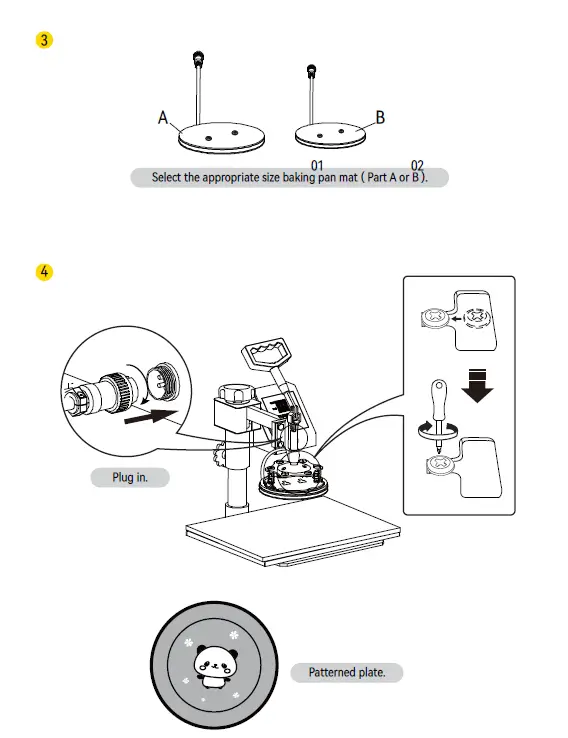

Replace Baking Tray Mat

Replace Baking Tray Mat

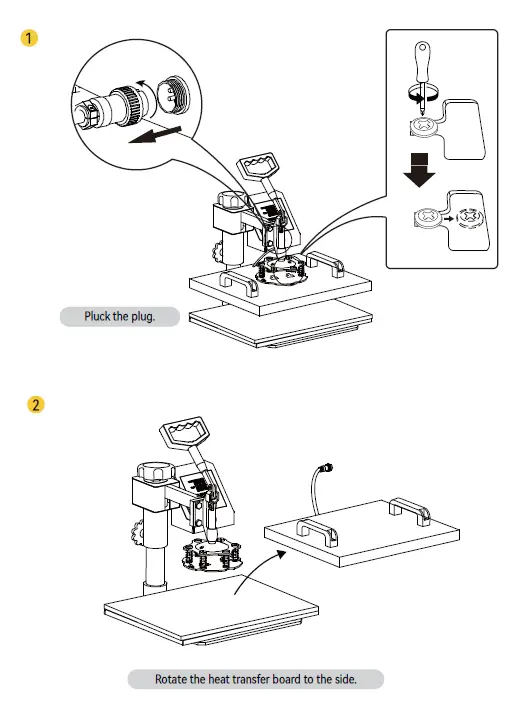

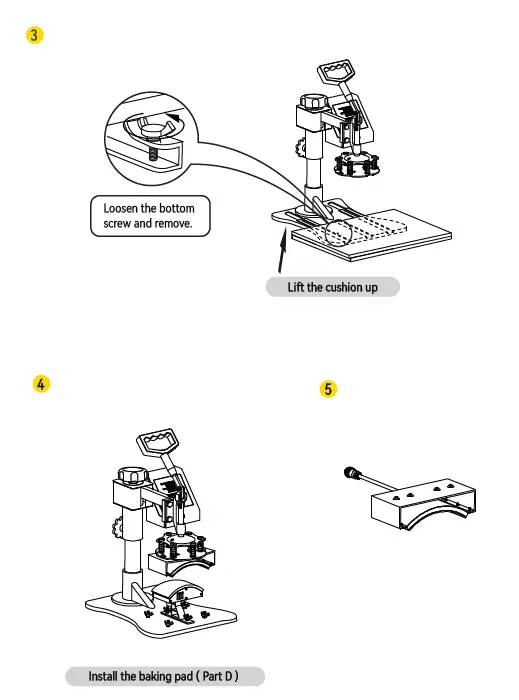

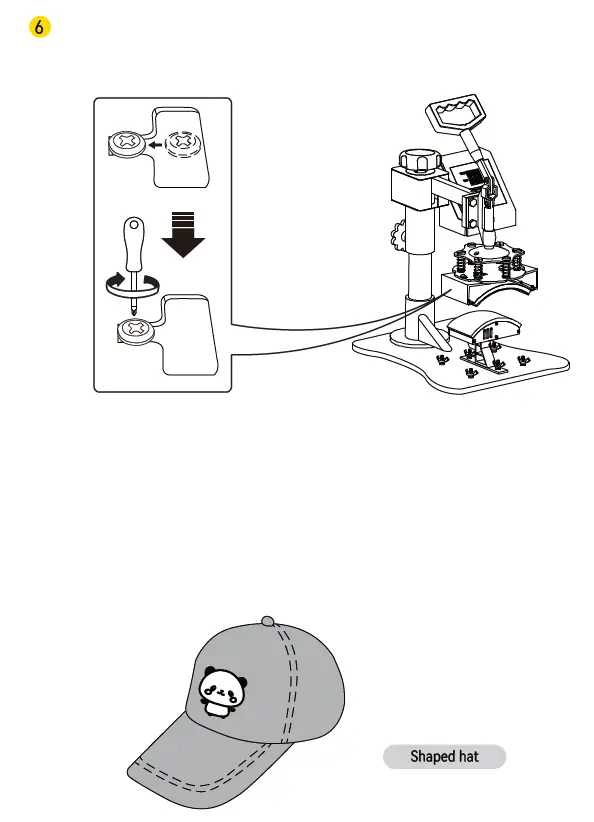

Replace Baking Cap Mat

Replace Baking Cap Mat

Replace Baking Cap Mat

- Use the screwdriver 4 to tighten the 2 screws just removed and put the cap on.

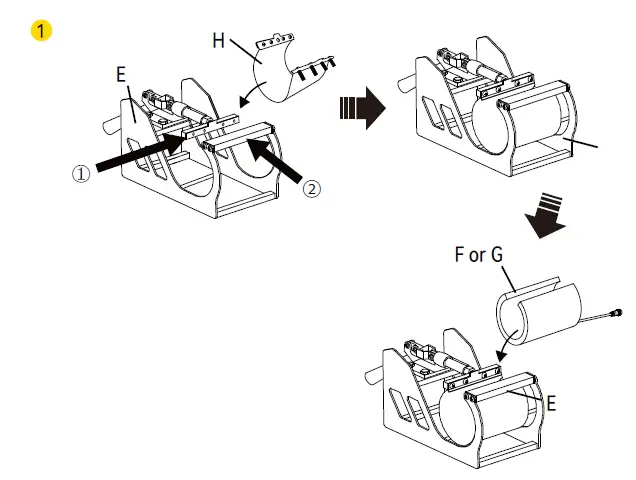

Replace Baking Coaster

- Install H to Part E. (Tighten the screws on both sides. We suggest to tighten the screws on the side ① first, and then tighten the screws on the side ② )

- Select the appropriate size baking coaster ( Part F or G ). Put the cup in Part E.

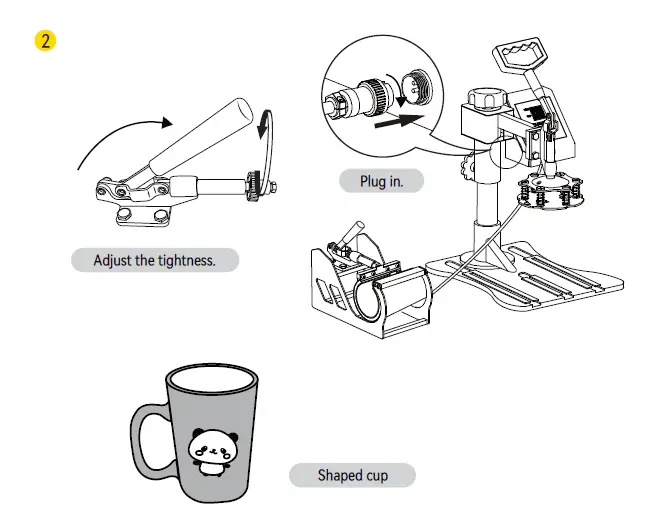

Replace Baking Coaster

- And install I or J to Part E. (Tighten the screws on both sides. We suggest to tighten the screws on the side ① first, and then tighten the screws on the side ② )

Printing methods

Adjust pressure to your requirement (Neither too tight nor too loose), Plug in the power cord and turn the power switch ON. The temperature starts to rise.Set the Initial temperature, Highest Temperature a pressing time. Once the temperature rise to the Initial temperature,the buzzer will send out a shot “BEEF” sound. Press the button once. Then Place the object (i.e. T shirt) on press bed. Pull down the handle to press the object. Wait for the time ends up with a long buzzer sound.(Note: There will be about 5s time for long buzzer to notify you it has finished,and after that will appear 5s for the short buzzer to notify you whether you still go on the next work,if not the temperature will fall down to the Initial temperature ) Work finish and take out the object. Turn off the power switch.

Troubleshooting for transfer quality

- Pale Color:The temperature is too low/the pressure is not correct/or not pressed long enough. Blurring Pattern: Too much transfer time causes proliferation.

- Part Blurring of Pattern: Heat was not distributed correctly through the heat plate. Allow more time between press operations.Pressure distribution can also be the cause,which can be set on the four plate surface adjusters.Please note that it has been factory set and there should be no need to adjust them.

- Dull Surface of Pattern:The pressure is too lager or the temperature is too high.

- Scarred Pattern:Transfer time is too long.

- Different Pattern Color:The pressure is not correct or the transfer paper is poor quality.

- Adhesive Paper:the temperature is too high or poor printing ink.

CAUTION

- CHECK the correct voltage before using the machine.Be SURE to operate with reliable grounded protection connections.

- TURN OFF the machine,and then DISCONNECT the power supply before replacing the heat units.DO NOT forget to wearing insulated gloves if the unit is still under high temperature.

- AVOID prolonged burning of the heating parts. If not turning the power off, please place a hot stamping replacement ( it could be a scrap and can be used repeatedly ).AVOID damaging the heating units with sharp parts of the stamping object.

- AVOID touching the heating units and the compression spring without protection in case of potential damage,of the body during use.

- If it’s hard to push the grasp, please adjust the rotation lock screw in order to reduce the pressure of the compression spring.Or, it will damage to the strength of the machine.

- Before lifting the machine, please lock the machine head by a rotation lock screw and loosen the handle(don’t screw the rotation lock screw too tight). Besides, do not put down the machine beyond the limit. When meeting the falling limit, you can feel an obvious pressure on the swiveling pressure adjustment wheel.

- Keep children away from the machine!!!

- DO NOT attempt to press products that are not intended for normal heat transfer. Baking pads should be avoided of empty burning.