CPS 1 HP Commercial Refrigerant Recovery System

SPECIFICATIONS

| Models | CR700/CR700JUK* | CR700E | CR700J | CR700S | |||||||

| Compressor Type | 1 HP Oil-less Reciprocating Compressor | ||||||||||

| Dimensions | 20cm (8”) wide x 37cm (14.5”) long x 30.5cm (12”) high | ||||||||||

| Weight | 15.3 kg (34 lbs.) | ||||||||||

| Operating Temperature Range | 0°C (32°F) to 49°C (120°) | ||||||||||

| Power Source | 115 V 50/60Hz 1 Ph | 220-240 V 50/60 Hz 1 Ph | 100 V 50/60 Hz 1 Ph | 230 V 50/60 Hz 1 Ph | |||||||

| Power Consumption | 850 W | ||||||||||

| Suction Pressure Gauge | -30” hg to 350 psig -76 cm hg to 35 kg/cm | -1 to 34.5 bar -100 kPa to 3450 kPa | -.1 to 3.5 MPa | -30” hg to 350 psig -76 cm hg to 35 kg/cm | |||||||

| Discharge Pressure Gauge | 0 to 800 psig 0 to 55 kg/cm |

0 to 55 bar 0 to 5500 kPa |

0 to 5.5 MPa | 0 to 800 psig 0 to 55 kg/cm |

|||||||

| Filtration | Cleanable 100-mesh screen integrated into Suction Port | ||||||||||

| Shut-Off Valves | Both Suction and Discharge piston manifold valves | ||||||||||

| Construction | Heavy gauge aluminum chassis with High Density Polyethylene Case | ||||||||||

| Overload Protection | 15 amp | 8 amp | 15 amp | 8 amp | |||||||

| High Pressure Shut-Off | 38 bar (550 psig) | ||||||||||

| Refrigerants | R-12, R-134a, R-401C, R-406A, R-500, R-401A R-409A, R-401B, R-412A, R-411A, R-407D, R-22 R-411B, R-502, R-407C, R-402B, R408A, R-509 R-407A, R-404A, R-402A, R-507, R-407B, R-410A |

||||||||||

| Flow Rate (at 60hz, reduce 15% for 50hz) Direct Vapor Direct Liquid Push-Pull Liquid |

Up to 43 kg/hr Up to 1.6 lb/min Up to 271 kg/hr Up to 10 lb/min Up to 542 kg/hr Up to 20 lb/min |

||||||||||

INTRODUCTION

Thank you for purchasing the CPS PROSET CR700 series unit. CPS is dedicated to give you the fastest and most reliable equipment to meet all your commercial refrigerant recovery requirements. In doing this CPS has integrated its latest technology and incorporated state of the art features while improving reliability and speed. The CR700 incorporates an Exclusive CPS Designed Patent Pending compressor that maximizes speed in both direct liquid and direct vapor recovery. The unit is equipped with a high airflow and high efficiency condensing system to maximize vapor recovery speed. The CR700 also incorporates an automatic Low

Pressure shut off switch.

The CR700 is designed for servicing commercial and residential refrigeration systems. Simply follow the quick start guide and turn it on. Once the recovery is complete, simply turn the center valve to the SELFCLEARING position. Now the unit is ready for the next type of refrigerant.

The PROSET CR700 series utilizes a 1 hp (0.85kW) patent pending oil-less compressor, non-restrictive piston manifold valves, and high capacity condensing system.

The following are additional features:

- “On the Run” SELF-CLEARING valve. No need to turn off the unit when switching from recovery to self-clearing.

- On board SUCTION and DISCHARGE gauges.

- 0 to 55 bar (800-psig) discharge gauge to handle R-410A.

- Small physical size.

- Automatic Low Pressure cutout switch.

- Integrated easy to use carrying handle and Safety bar.

- 550 psig High Pressure cutout switch

- Easy and secure filter accesses. No dangling filters to be damaged.

- Replaceable or cleanable filter cartridge.

- The Suction and Discharge shut-off valves. Easy to service if replacement required.

- Heavy-duty powder coated aluminum chassis surrounded by a tough High-Density Polyethylene case.

- Maintenance free Oil-less compressor

- Optional tank overfill sensor cord kit.

- patent pending

Low Pressure override switch to allow for continuous operation. To help you get a good start, please continue to carefully read the balance of this manual. This manual contains important information on the proper procedures for operating this equipment. Please pay close attention to the safety information, WARNING and CAUTIONS provided throughout this manual. Always remember “SAFETY FIRST”.

GENERAL SAFETY INSTRUCTIONS

Only qualified service personnel should operate this unit. Most states, countries, etc… may require the user to be licensed. Please check with your local government agency.

DANGER- the recovery tank used with this contains liquid refrigerant. Overfilling of the recovery tank may cause a violent explosion resulting in severe injury or even death. As a minimum, please use a scale to continuously monitor the recovery tank weight.

DANGER- Avoid breathing refrigerant vapors and lubricant vapor or mist. Breathing high concentration levels may cause heart arrhythmia, loss of consciousness, or even cause suffocation.

DANGER- ELECTRICAL SHOCK HAZARD-Always disconnect power source when servicing this equipment.

DANGER- EXPLOSION RISK. Do not recovery flammable refrigerants

CAUTION- all hoses may contain liquid refrigerant under pressure. Contact with refrigerant may cause frostbite or other related injuries. Wear proper personal protective equipment such as safety goggles and gloves. When disconnecting any hose, please use extreme caution.

CAUTION- avoid breathing refrigerant vapors and/or lubricant mist. Exposure may irritate eyes, nose, throat, and skin. Please read the manufacturers Material Safety Data Sheet for further safety information on refrigerants and lubricants.

CAUTION- to reduce the risk of fire, avoid the use of extension cords thinner than NO. 14 awg. (1,5mm) to prevent the overheating of this cord please keep length to a minimum.

CAUTION- do not use this equipment in the vicinity of spilled or open containers of gasoline or other flammable substances. Make certain that all safety devices are functioning properly before operating the equipment.

This equipment is intended for use of one refrigerant at a time until the Self Clearing feature is used. Mixing of different refrigerants will cause your recovered supply of refrigerant to become contaminated.

Note: It is very expensive to destroy mixed or damaged refrigerants

DIRECT LIQUID OR VAPOR OPERATION

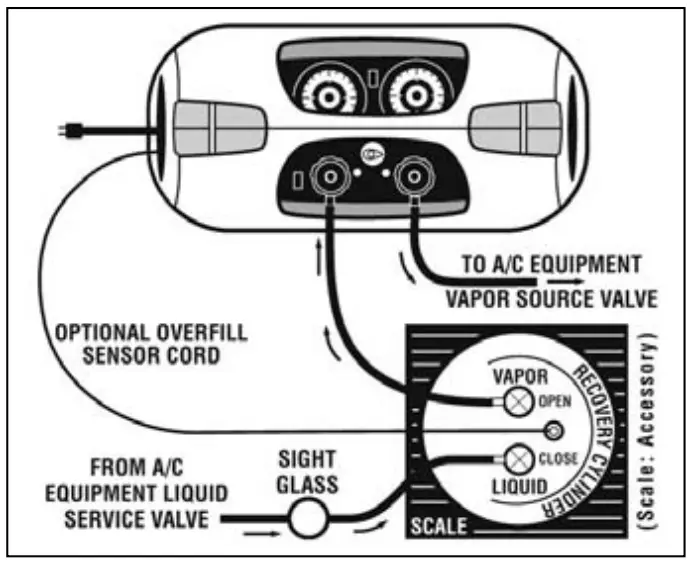

- Connect the unit as shown in Diagram 1.

Note: The recovery tank must be rated for 38 bar. - Open the vapor valve on the Recovery Tank.

- Open DISCHARGE valve on CR700.

Note: The Suction valve should be closed at this time. - Rotate the center valve to the “RECOVERY” position.

- Push the Main Power Switch “ON”.

Note: If the unit fails to start, make sure there is no suction pressure on the suction side of the unit. The compressor is designed to start against high differential pressures. Pressure on the suction side will reduce this differential. Reset Circuit Breaker if tripped. Push the LP Override Switch to the “ON” position. - Once unit has started, open the SUCTION valve on the CR700 to start the refrigerant flow.

- The CR700 is designed to directly recover large amounts of liquid refrigerant. If during liquid recovery the compressor begins to make a slugging or hammering noise, meter the incoming liquid by closing the suction valve until the noise subsides.

- The CR700 will automatically shut off* when a 10”hg vacuum is achieved. If the pressure rises (due to boiling liquid refrigerant) the CR700 will resume operation.

- After the CR700 has shut off, rotate the center valve to the SELF CLEARING position. The CR700 will resume operation automatically. The CR700 is now clearing out the condenser. The CR700 will automatically shut off* when a 10”hg vacuum is achieved.

Note: If the LP override switch is set to “ON” position the unit will run continuously.

RECOVERY AND SELF-CLEARING ARE COMPLETE

LIQUID PUSH-PULL OPERATION

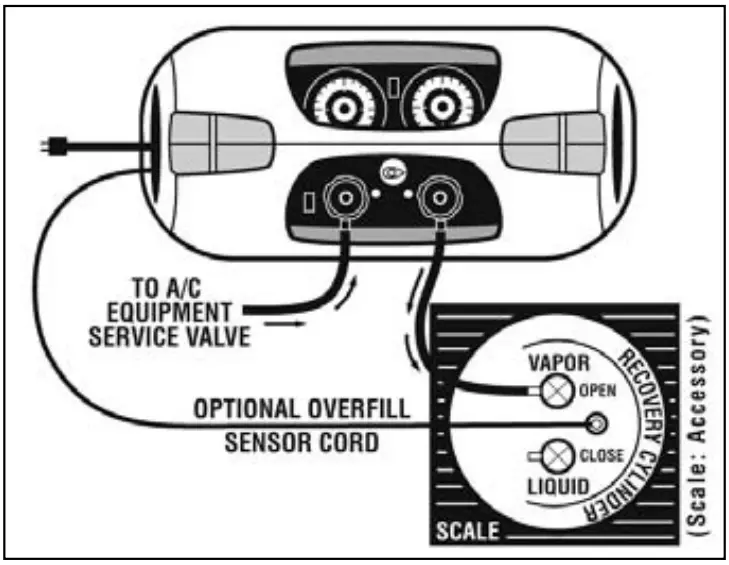

- Connect the unit as shown in Diagram 2.

Note: The recovery tank must be rated for 38 bar. - Open the liquid and vapor valve on the Recovery Tank.

Note: The Suction valve should be closed at this time. - Open the DISCHARGE valve on CR700.

- Rotate the center valve to the “SELF-CLEARING” position.

- Push the Main Power Switch “ON”

Note: If the unit fails to start, make sure there is no suction pressure on the suction side of the unit. The compressor is designed to start against high differential pressures. Pressure on the section side will reduce this differential. Reset Circuit Breaker if tripped. Push the LP Override Switch to the “ON” position. - Once unit has started, open the SUCTION valve on the CR700 to start the vapor refrigerant flow.

- Monitor the optional inline sight glass for liquid refrigerant movement.

- Once the liquid refrigerant is no longer present, close SUCTION valve. The CR700 will automatically shut off* when a 10”hg vacuum is achieved.

- Proceed to Direct Vapor Recovery Operation. (prior page)

Note: If the LP override switch is set to “ON” position the unit will run continuously.

ROUTINE MAINTENANCE

Filter Maintenance- the CR700 is equipped with a 100-mesh screen filter. This filter should be checked periodically. A partially clogged filter will slow down the recovery rate of this unit.

Check the filter cartridge as follows:

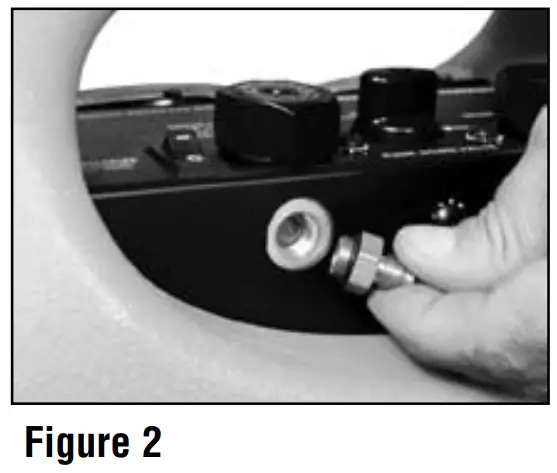

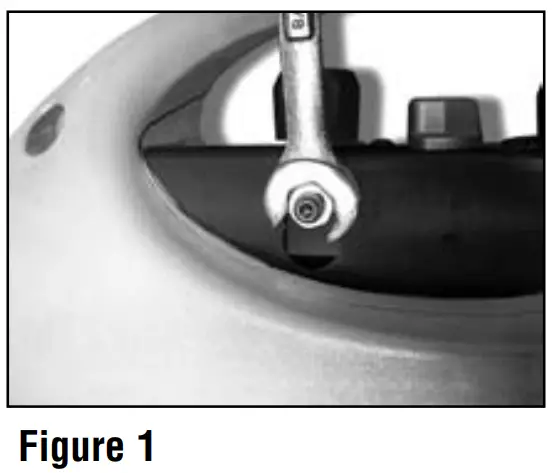

- Use a 5/8” socket or boxed end wrench to loosen the suction port as shown in Figure 1.

- Once loose, remove the suction port- filter cartridge as shown in Figure 2.

- Either clean the current cartridge or replace with new cartridge.

- Inspect O-ring. Re-lubricate with compressor oil or equivalent.

- Place filter cartridge back into suction port fitting.

- Hand tighten this assembly back onto the CR700.

- Use a 5/8” socket or boxed end wrench to tighten 1/8 of a turn.

Do not over tighten, damage to the O-ring may occur. - Check the connection for leaks.