HENDI Heavy Duty Planetary Mixer

You should read this user manual carefully before using the appliance.

Dear Customer,

Thank you for purchasing this Hendi appliance. Before using the appliance for the first time, please read this manual carefully, paying particular attention to the safety regulations outlined below.

Safety regulations

- This appliance is not intended for household use.

- The appliance must only be used for the purpose for which it was intended and designed. The manufacturer is not liable for any damage caused by incorrect operation and improper use.

- Keep the appliance and electrical plug away from water and any other liquids. In the event that the appliance should fall into water, immediately remove plug from the socket and do not use until the appliance has been checked by a certified technician. Failure to follow these instructions could cause a risk to lives.

- Never attempt to open the casing of the appliance yourself.

- Do not insert any objects in the casing of the appliance.

- Do not touch the plug with wet or damp hands.

- Danger of electric shock! Do not attempt to repair the appliance yourself. In case of malfunctions, repairs are to be conducted by qualified personnel only.

- Never use a damaged appliance! Disconnect the appliance from the electrical outlet and contact the retailer if it is damaged

- Warning! Do not immerse the electrical parts of the appliance in water or other liquids. Never hold the appliance under running water.

- Regularly check the power plug and cord for any damage. If the power plug or power cord is damaged, it must be replaced by a service agent or similarly qualified persons in order to avoid danger or injury.

- Make sure the cord does not come in contact with sharp or hot objects and keep it away from open fire. To pull the plug out of the socket, always pull on the plug and not on the cord.

- Ensure that the cord (or extension cord) is positioned so that it will not cause a trip hazard.

- Always keep an eye on the appliance when in use.

- Warning! As long as the plug is in the socket the appliance is connected to the power source.

- Turn off the appliance before pulling the plug out of the socket.

- Never carry the appliance by the cord.

- Do not use any extra devices that are not supplied along with the appliance.

- Only connect the appliance to an electrical outlet with the voltage and frequency mentioned on the appliance label.

- Connect the power plug to an easily accessible electrical outlet so that in case of emergency the appliance can be unplugged immediately. To completely switch off the appliance pull the power plug out of the electrical outlet.

- Always turn the appliance off before disconnecting the plug.

- Never use accessories other than those recommended by the manufacturer. Failure to do so could pose a safety risk to the user and could damage the appliance. Only use original parts and accessories.

- This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge.

- This appliance must not be used by children under any circumstances.

- Keep the appliance and its cord out of reach of children.

- Always disconnect the appliance from the mains if it is left unattended or is not in use, and before assembly, disassembly or cleaning.

- Never leave the appliance unattended during use.

Special Safety Regulations

- Use the machine only as described in this manual.

- This machine should be operated and installed by specialized trained personnel in the kitchen of the food industry such as catering, bakery, pizza, pastry, etc.

- All maintenance, installation and repair works should be performed by specialized trained authorized technicians.

- An equipotential bonding terminal is provided at the rear side of the appliance to allow cross bonding with other equipment.

- Do not place the machine on a heating object (gasoline, electric, charcoal cooker, etc.) Keep the appliance away from any hot surfaces and open flames. Always operate the machine on a level, stable, clean, heat-resistant and dry surface.

- Do not use the machine near explosive or flammable materials, credit cards, magnetic discs or radios.

- Wear protective clothing, mask, or protective glasses if necessary during operation.

- This machine is not intended to be operated by means of an external timer or separate remote-control system.

- Never bypass any safety interlocks on the machine.

- WARNING: Keep all ventilation openings in the appliance clear of obstruction.

- WARNING: ALWAYS switch off the machine and unplug from electrical power supply before cleaning, maintenance or changing attachments.

- Allow at least 30 cm spacing around the appliance for ventilation purpose during use.

- Caution! Securely route the power cord if necessary in order to prevent unintentional pulling or contact with the heating surface.

- WARNING! ALWAYS keep hands, long hair and loose clothing away from the moving parts.

- Do not put hands into the guarded area and mixing bowl when the machine is in operation.

- Do not load too much ingredients in order to prevent overflow of the food products. Maxi-mum capacity of the bowl is 10 liters for 222836, 222966 and 20 liters for 222843, 222973.

- Do not wash the machine with water or a waterjet. Washing with water can cause leakage and increase the risk of electric shock. No parts are dishwasher safe.

- Do not clean or store the machine unless it is completely cooled down.

- Special care should be taken when moving or transporting the machine as it is too heavy. With at least 2 people or using a trolley for assistance. Move the machine slowly, carefully and never be inclined over 45°C.

Intended use

- The appliance is intended for professional use and can be operated only by qualified personnel.

- The appliance is designed for mixing, kneading and emulsifying/whipping food products (e.g. flour, sugar, oils, fat, eggs and other ingredients) operated in the food industry and shops (e.g. catering, bakery, pizza, pastry and confectionary industry). Any other use may lead to damage to the appliance or personal injury.

- Operating the appliance for any other purpose shall be deemed as a misuse of the device. The user shall be solely liable for improper use of the device.

Grounding installation

This appliance is classified as protection class I appliance and must be connected to a protective ground. Grounding reduces the risk of electric shock by providing an escape wire for the electric current. This appliance is equipped with a cord having a grounding wire with a grounding plug. The plug must be plugged into an outlet that is properly installed and grounded.

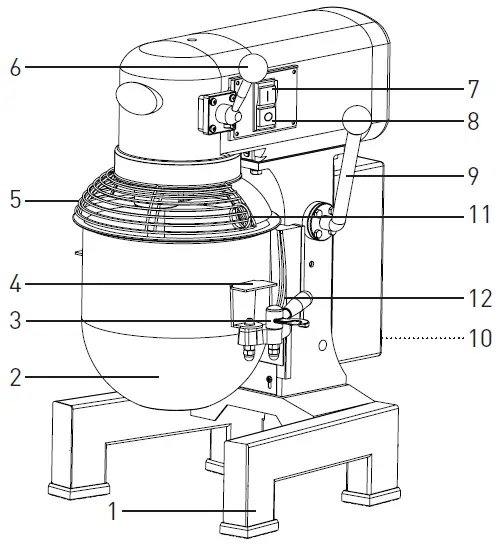

Main parts of the machine

- Rigid stand support

- Bowl

- Bowl clamp (x2)

- Bowl handles (x2)

- Bowl guard

- Speed control lever (3 settings for 3 attachments)

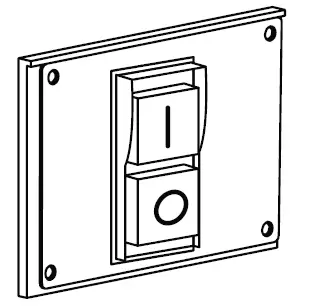

- ON button (GREEN, I)

- STOP button (RED, O)

- Bowl lift / lower handle

- RESET button (at the rear)

- Bowl guard handle

- Bowl cradle

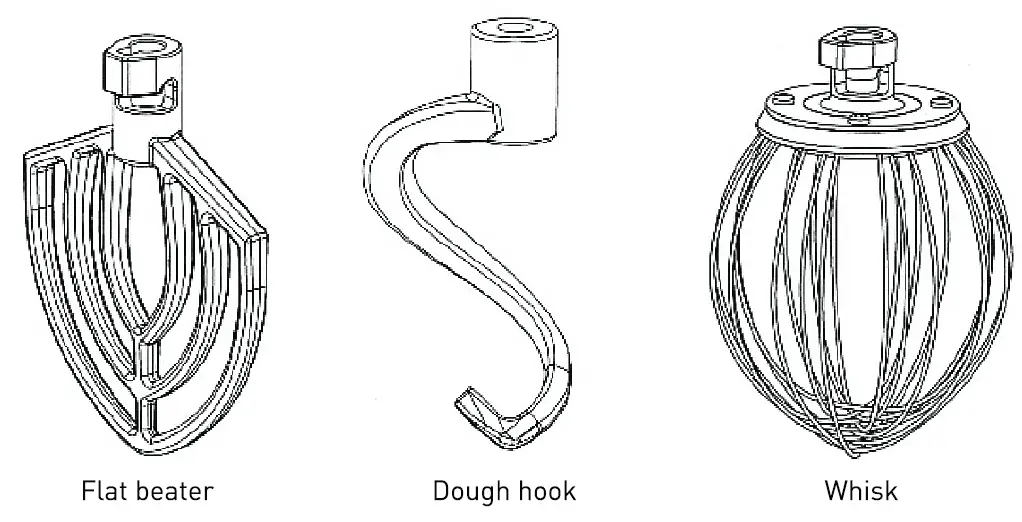

Attachments

Preparations before installation

- Carefully unbolt the machine from the skid using wrench if necessary.

- Remove all protective packaging and wrapping.

- Check the machine for completeness and trans-port damages. In case of incomplete delivery (e.g. Whisk, flat beater and dough hook) or damage, contact supplier immediately. DO NOT use the machine. (See ==> Warranty).

- Clean the machine and attachments before use (See ==> Cleaning and Maintenance).

- Make sure the appliance is completely dry.

Installation

- Read this manual thoroughly and carefully before installation and operation.

- Ensure the machine is placed in a dry area that have sufficient strength surface to support with no any obstruction during operation nearby.

- Ensure that the electrical power supply corresponds with the rating label on the machine.

- There should have adequate space around the machine for the operator to operate. It should be clean and free from obstructions, e.g. Nothing placed on or around the machine, such as scrap-ers, knives etc.

- Do not wear loose fitting clothing such as scarf, etc and long hair should be tied up and keep away from the moving parts.

CAUTION! Never bypass any safety switch.

Transportation and handling

- Do not move the machine while it is under operation.

- Unplug the machine, remove the bowl (2) and all attachments (whisk, flat beater or dough hook) when moving the machine.

- Hold the base of the machine (1) when moving to have better support.

- With at least 2 people or using trolley for assistance to move the machine due to heavy weight.

Special safety features

Attention: This machine has the following 3 safety switches. The machine only be started with all the safety switches are at the proper positions.

- Bowl position safety switch: The machine can be started up once the bowl is positioned at the correct position.

- Bowl guard (5) safety switch: The machine can only be started up once the bowl guard (5) is in the closed position.

- Bowl lift up handle (9) safety switch: The machine can only be started up once the bowl lift up han-dle (9) is located in the upwards position.

- Do not wear loose fitting clothing such as scarf, etc and long hair should be tied up and keep away from the moving parts

Operation

To avoid serious personal injury:

- DO NOT operate the machine without reading the instruction manual.

- ALWAYS STOP the machine by pressing RED “O” button (8) and unplug from electrical power supply before cleaning, maintenance, repair or changing any attachments.

- ALWAYS keep hands, hair and loose clothing away from the moving parts.

a) About the bowl guard

Note: When bowl guard (5) is open or not properly closed in lock position, the machine will not operate.

- To open the bowl guard (5), hold the bowl guard handle (11) and rotate it clockwise. To close the bowl guard (5), hold the bowl guard handle (11) and rotate it anti-clockwise.

- When the bowl guard handle (11) is lined up at the right side of the machine, the bowl guard (5) is in the is in the rocked position and ready for operation.

b) Install the bowl (2) to the machine

Note: Install the bowl (2) BEFORE fixing the attachments. Use the supplied bowl (2) only.

- Lower the bowl by pulling the bowl lift-up lever (9) downwards until it stops. So that the bowl cradle (12) is in a lower position.

- Place the bowl (2) carefully and slowly using the bowl handles (4) at 2 sides and

- With the locking pin into the hole at the middle of the bowl cradle (12) and

- Secure the bowl (2) by pull each bowl clamp (3) forward until the bowl (2) is locked tight.

c) Install different attachments (Flat beater, Dough hook or Whisk) to the machine

Note: It is more convenient and easier to install the attachments prior to adding the ingredients into the bowl (2).

- Rotate the bowl guard (5) clockwise gently with the bowl guard handle (6), so that it is in the open position.

- CAUTION! Use excessive force to open or close the bowl guard (5) may damage the safety lock micro switch. Be careful when open or close the bowl guard (5).

- Slide the attachments (Flat beater, Dough hook or Whisk) slowly upwards onto the planetary shaft fitting the shaft pin through the slot in the attachments.

- Rotate the attachments to secure it onto the planetary shaft.

d) Pouring and mixing ingredients

Note: Follow the “Mixing ingredients capacity” table in this manual. Overloading will lead to overflow or damage to the machine. IMPORTANT: Make sure the speed control lever (6) is set at the “dough hook” position.

- Add all the appropriate ingredients into the bowl (2).

- Lift upwards the bowl lift lever (9) until the bowl (2) locks into the position.

- Rotate the bowl guard (5) anti-clockwise and locks into the position.

e) Set the speed, attachment & start up the machine

- Select the appropriate speed by lifting or lowering the speed control lever (6). Three fixed speeds are available for different attachments

- After that, press the GREEN “I” button (7) to switch ON the machine. Press RED “O” button (8) to STOP the machine.

The machine will rotate in clockwise direction for item 222843 whereas and anti-clockwise direction for 222836. - CAUTION! ALWAYS STOP the machine BEFORE changing speeds. Failure to do so may damage the internal gear construction.

- To change the speed during the operation:

- Press the RED “O” button (8) to STOP the ma-chine.

- Unplug the machine and change the attachment. [See ==> part c)].

- Change the speed by raising or lowering the speed control lever (6) with the correct attachment.

- Press the GREEN “I” button (7) to restart the machine.

RESET the Hi-limiter (thermal cut-out)

Please note that the RESET button (10) is located at the rear of the machine in order to prevent overheated.

- Unplug the machine from the electrical power outlet first.

- Let the machine to cool down completely.

- Press the RESET button (10) of the Hi-limiter (thermal cut-out)

- Then, plug into the electrical power outlet and start up the machine again.

Mixing ingredients capacity

Below table is just a reference about the maximum quantity for making the different food. There are many factors affecting such as the type of the flour, temperature of water, etc.

| Product | Attachment | Max. quantity | |||

| 222836 | 222966 | 222843 | 222973 | ||

| Egg white | Whisk | 1,0 kg | 1,5 kg | ||

| Mashed potato | Flat beater | 2,0 kg | 2,5 kg | ||

| Meringue (Qty of water) | Whisk | 1,5 litre | 2,0 litre | ||

| Waffle or pancake batter | Flat beater | 2,5 litres | 3,0 litre | ||

| Whipped cream | Whisk | 3,5 litres | 4,0 litre | ||

| Pizza dough (Medium, 50% water) | Dough hook | 2,0 kg | 2,5 kg | ||

| Pizza dough (Thick, 60% water) | Dough hook | 2,5 kg | 3,0 kg | ||

| Sponge cake | Whisk | 1,5 kg | 2,0 kg | ||

| Pie Dough | Flat beater | 2,0 kg | 2,5 kg | ||

| Bread or Roll Dough (Light/ Medium, 60% water) | Dough hook | Water 1,5 kg/ Flour 2,5 kg | Water 3,0 kg/ Flour 5,0kg | ||

Cleaning and Maintenance

Attention: Always unplug the appliance from the electrical power outlet and let it cool down completely before cleaning, maintenance, repair & storage.

Cleaning

- Always remove all the attachments before easy cleaning, otherwise it will become stuck on the shaft and difficult to remove later.

- Clean the machine and its attachments thoroughly after each use and ensure all food residues are removed.

- Never immerse the appliance in water or other liquids.

- Clean the surface with a slightly damp cloth or sponge with some mild soap solution.

- Never use abrasive sponges, detergents, steel wool or metallic utensils to clean the interior or exterior parts of the appliance.

- DO NOT wash the appliance with water or water-jet. Washing with water can cause leakage and increase the risk of electric shock.

- No any parts or attachments are dishwasher safe.

Recommended cleaning procedure:

| Parts | How to clean | Frequency |

| Bowl | Using a sponge or damp cloth with mild soap and water, rinse, sanitize and dry thoroughly. | Clean after each use |

| Attachments (Dough hook, beater and whisk) | Hand wash using mild soap and wa- ter, rinse, sanitize and dry thoroughly. | Clean after each use |

| Bowl guard | Hand wash using a sponge or damp cloth with mild soap and water, rinse, sanitize and dry thoroughly. | Clean after each use |

| Outer surface | Wipe with a clean damp cloth using soap and water, rinse, sanitize and dry. Do not use water jet. | Twice a week |

| Planetary Shaft | Wipe with a clean damp cloth using soap and water, rinse, sanitize and dry. | Clean after each use |

Storage

- Before storage, always make sure the appliance has already been disconnected from the electrical outlet and cooled down completely.

- Store the appliance in a cool, clean and dry place.

Troubleshooting

If the machine does not function properly, please check the below table for the solution. If you are still unable to solve the problem, please contact the supplier/service provider. DO NOT repair yourself.

| Problems | Possible causes | Possible solution |

| Machine do not start running | Bowl guard (5) is not in properly closed position. | Rotate the bowl guard (5) to the right until ful- ly closed properly. |

| Bowl (2) is not raised to the proper location. | Raise the bowl (2) to the correct position by using the level (9). | |

| The power plug is not connected properly. | Check to make sure the power plug is con- nected properly. | |

| Machine stops during operation | Internal overload activates to prevent overheat. | Press RED, “O” button (8), unplug the ma- chine, leave for cook down completely, press RESET button (10) at the back. |

| Damage or broken transmission belt | Check with the supplier | |

| Machine sound too noisy | Machine is not placed on a horizontal surface. | Adjust the surface or move to another horizontal surface. |

| Bowl (2) is not placed correctly. | Make sure the bowl (2) is placed into the bowl cradle (12) correctly with the guided pins (3). | |

| Attachments not fitted properly. | Remove and install the attachments into po- sition again. | |

| Bowl is overloaded. | Reduce ingredients capacity. | |

| Damaged or worn transmission belt. | Check with the supplier. | |

| Planetary gear needs lack of lubricant. | ||

| Attachments cannot install onto the planetary shaft easily | Lack of lubricant and / or cleaning of the plane- tary shaft required. | Wipe planetary shaft with a clean damp cloth and lubricate the shaft with mineral oil or grease. |

| Bowl lift / lower handle (9) not operation easily | Lack of lubricant on the bowl slides. | Lubricate bowl slides with mineral oil or grease. |

Technical specification

| Item no. | 222836 | 222966 | 222843 | 222973 | |

| Operating voltage and frequency | 220 – 240 V~ 50/60Hz | ||||

| Rated input power | 600W | 1100W | |||

| Net weight (approx.) | 53kg | 78kg | |||

| Protection class | Class I | ||||

| Waterproof protection class | IP23 | ||||

|

Rotation speed (r.p.m.) |

Dough hook | 148 | 197 | ||

| Flat beater | 244 | 317 | |||

| Whisk | 480 | 462 | |||

| Maximum bowl capacity | 10L | 20L | |||

| Maximum amount flour mixing | 2,5 kg | 5,0 kg | |||

| Max noise level | < 70 dB (A) | ||||

| Outer dimension | 480 x 400 x (H) 630mm | 560 x 500 x (H) 880mm | |||

Remark: Technical specification is subjected to change without prior notification

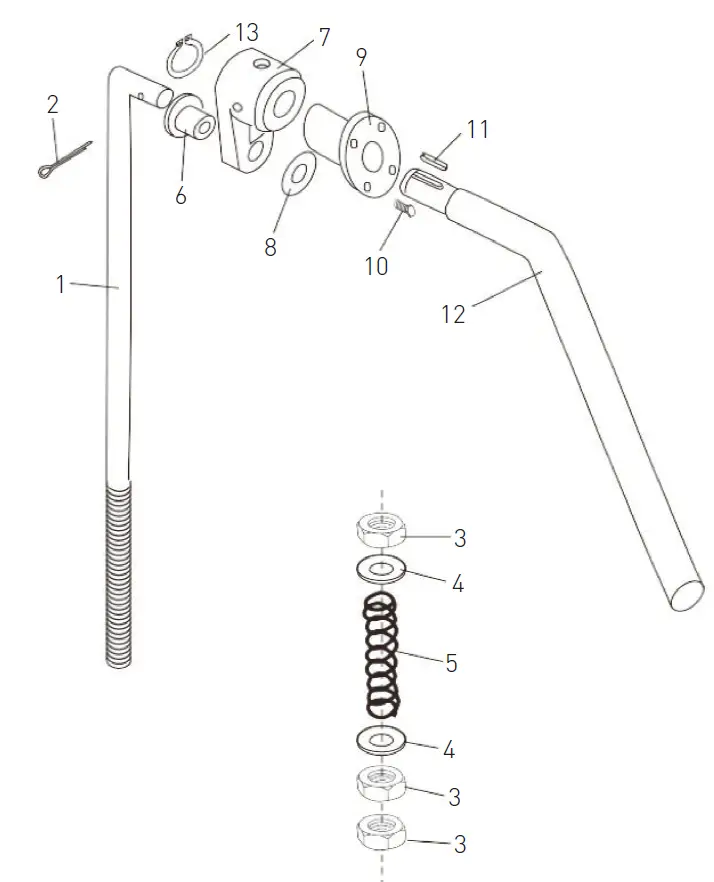

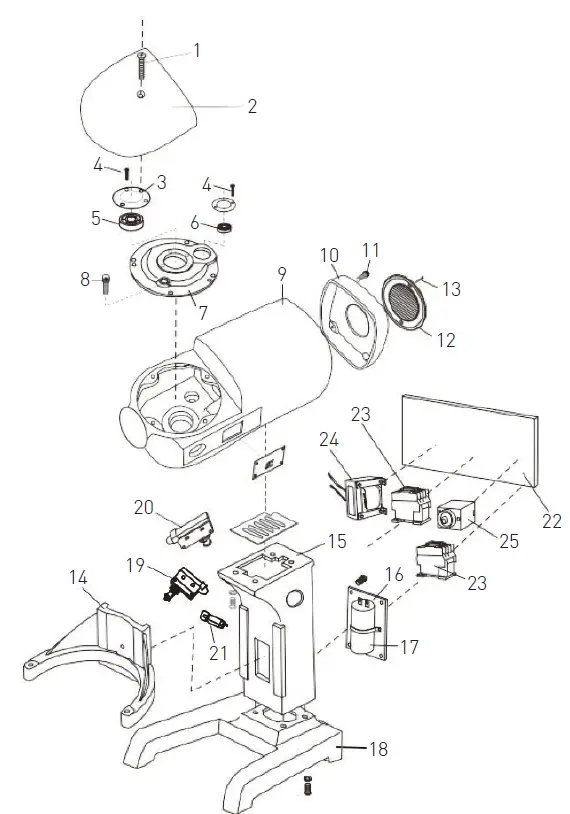

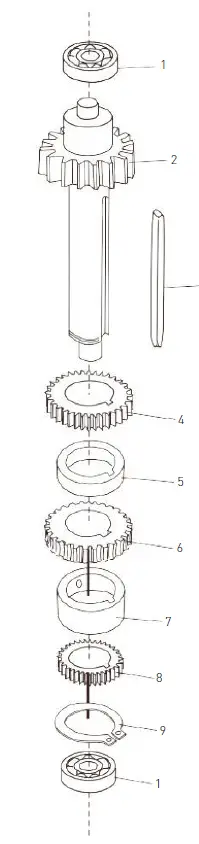

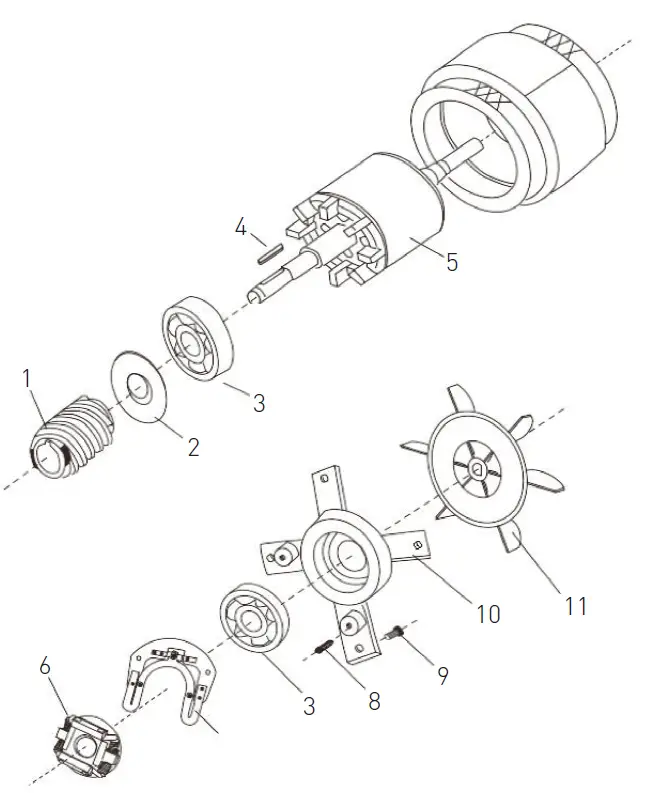

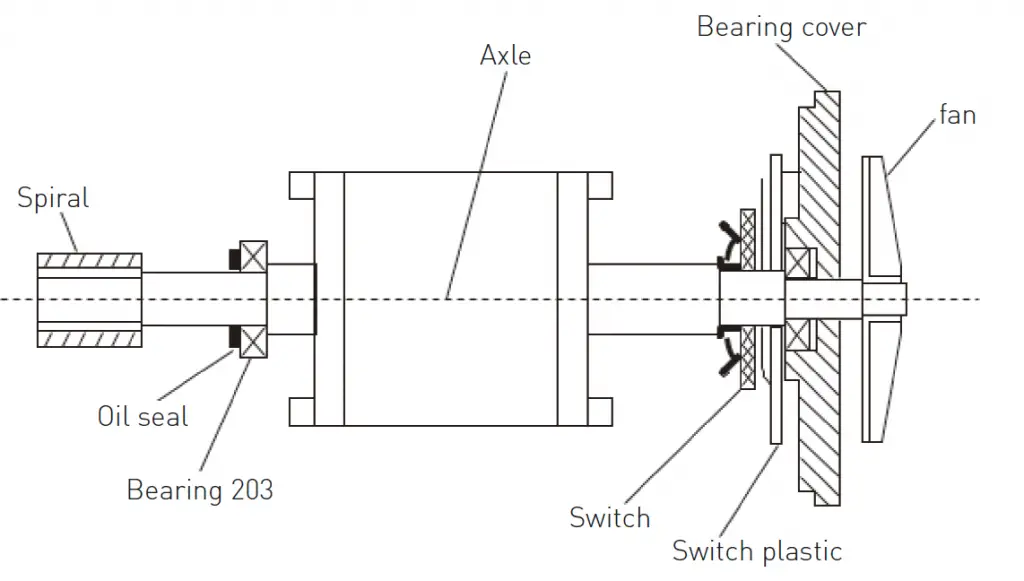

Exploded drawing and part list

Attention: The exploded drawing and part list consists of below parts:

- Transmission gear system at the top, bowl cradle and stand (Figure 1);

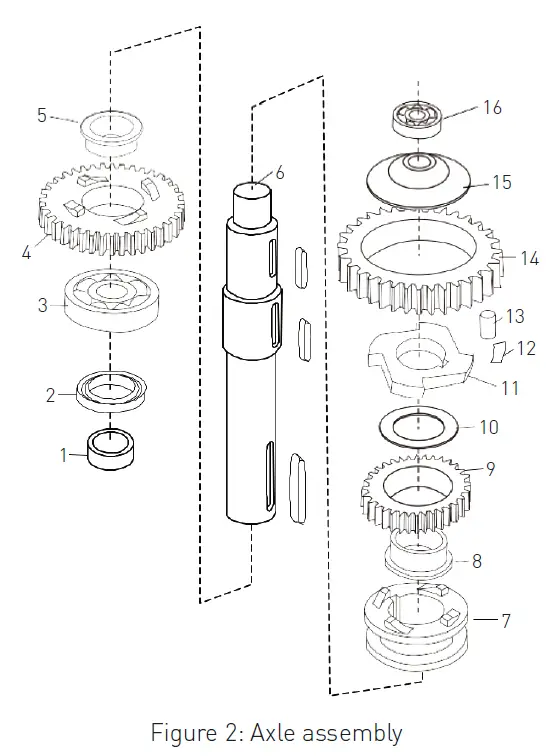

- Axle assembly (Figure 2);

- Gear axle assembly (Figure 3);

- Motor assembly (Figure 4);

- Bowl lift up assembly (Figure 5);

- Bowl guard turning plate and mixing axle (Figure 6);

- Speed control assembly (Figure 7)

| Part no. | Part name | Quantity |

| 1 | Screw M5x35 | 1 |

| 2 | Top cover | 1 |

| 3 | Cover plate | 1 |

| 4 | Screw M5x12 | 5 |

| 5 | Bearing | 1 |

| 6 | Bearing | 1 |

| 7 | Bearing cover | 1 |

| 8 | Screw M5x20 | 4 |

| 9 | Main body part | 1 |

| 10 | Rear cover | 1 |

| 11 | Screw M6x55 | 4 |

| 12 | Ventilation cover | 1 |

| 13 | Screw M5x12 | 1 |

| 14 | Bowl cradle | 1 |

| 15 | Rigid stand | 1 |

| 16 | Capacitor board | 1 |

| 17 | Capacitor | 1 |

| 18 | Base | 1 |

| 19 | Safety covering switch | 1 |

| 20 | Fluctuate safety switch | 1 |

| 21 | Overload protection | 1 |

| 22 | PCB control board | 1 |

| 23 | AC contact devices | 2 |

| 24 | Reactor | 1 |

| 25 | Timer relay | 1 |

| Part no. | Part name | Quantity |

| 1 | Cover | 1 |

| 2 | Oil seal 25x40x10 | 1 |

| 3 | Bearing | 1 |

| 4 | Big joint gear | 1 |

| 5 | Bearing ring | 1 |

| 6 | Axle | 1 |

| 7 | Joint | 1 |

| 8 | Bearing ring | 1 |

| 9 | Joint gear | 1 |

| 10 | Washer | 1 |

| 11 | Engager | 1 |

| 12 | Spring | 8 |

| 13 | Roller | 4 |

| 14 | Ring gear | 1 |

| 15 | Ring plate | 1 |

| 16 | Bearing | 1 |

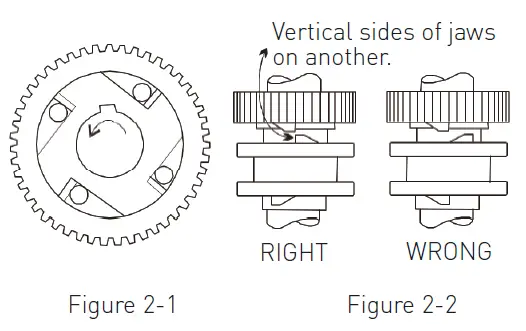

- Be sure to install correct position and lubricate all the pins in figure 2-1.

- Check if oil seal occur after reassembly.

| Part no. | Part name | Quantity |

| 1 | Bearing | 2 |

| 2 | Gear axle | 1 |

| 3 | Key 5×58 | 1 |

| 4 | Gear | 1 |

| 5 | Collar | 1 |

| 6 | Gear | 1 |

| 7 | Long collar | 1 |

| 8 | Gear | 1 |

| 9 | Ring | 1 |

Remark: Make sure the keys are all inserted to each gear.

| Part no. | Part name | Quantity |

| 1 | Spiral | 1 |

| 2 | Oil seal | 1 |

| 3 | Bearing | 2 |

| 4 | Key 4×22 | 1 |

| 5 | Axle | 1 |

| 6 | Switch | 1 |

| 7 | Plastic switch plate | 1 |

| 8 | Screws M4x8 | 2 |

| 9 | Screws M6x16 | 4 |

| 10 | Bearing cover | 1 |

| 11 | Fan | 1 |

| Part no. | Part name | Quantity |

| 1 | Lifting bar | 1 |

| 2 | Cotter pin 3×30 | 1 |

| 3 | Nut M10 | 3 |

| 4 | Flat washer | 2 |

| 5 | Spring | 1 |

| 6 | Knot cover | 1 |

| 7 | Lifting handle bracket | 1 |

| 8 | Flat washer | 1 |

| 9 | Flange cover | 1 |

| 10 | Screw M6x25 | 1 |

| 11 | Key 5×20 | 1 |

| 12 | Bowl lift handle | 1 |

| 13 | Screw washer | 1 |

| Part no. | Part name | Quantity |

| 1 | Mixing axle | 1 |

| 2 | Oil seal 20x40x10 | 1 |

| 3 | Bearing | 1 |

| 4 | Bowl guard | 1 |

| 5 | Planetary gear | 1 |

| 6 | Turning plate | 1 |

| 7 | Inner gear | 1 |

| 8 | Cover | 1 |

| 9 | Bearing | 1 |

| 10 | Screw M8x20 | 1 |

| 11 | Spring washer | 1 |

| 12 | Back cover of bowl guard | 1 |

| Part no. | Part name | Quantity | |

| A | 1 | Rod | 1 |

| 2 | Nut | 1 | |

| 3 | Spring | 1 | |

| 4 | Shaft | 1 | |

| 5 | Fork | 1 | |

| B | 6 | Pin 3×20 | 1 |

| 7 | Knot | 1 | |

| 8 | Steel ball bearing | 3 | |

| 9 | Spring | 3 | |

| 10 | Block cover | 1 | |

| 11 | Screw M5x10 | 1 | |

| 12 | Shaft | 1 | |

| 13 | Lever | 1 | |

Circuit diagram

Warranty

Any defect affecting the functionality of the appliance which becomes apparent within one year after purchase will be repaired by free repair or re-placement provided the appliance has been used and maintained in accordance with the instructions and has not been abused or misused in any way. Your statutory rights are not affected. If the appliance is claimed under warranty, state where and when it was purchased and include proof of purchase (e.g. receipt).

In line with our policy of continuous product development we reserve the right to change the product, packaging and documentation specifications with-out notice.

Discarding & Environment

When decommissioning the appliance, the product must not be disposed of with other household waste. Instead, it is your responsibility to dispose to your waste equipment by handing it over to a designated collection point. Failure to follow this rule may be penalized in accordance with applicable regulations on waste disposal. The separate col-lection and recycling of your waste equipment at the time of disposal will help conserve natural resources and ensure that it is recycled in a manner that protects human health and the environment. For more information about where you can drop off your waste for recycling, please contact your local waste collection company. The manufacturers and importers do not take responsibility for recycling, treatment and ecological disposal, either directly or through a public system.

Important notice to UK users

This appliance is fitted with a UK approved mains plug and a 13A fuse. Should the fuse need to be re-placed, an ASTA or BSI approved BS1362 fuse, rated at 13A must be used. The plug can be replaced by qualified electrician if it is damaged, and ensure that the fuse is removed beforehand. Always dis-pose of defunct plugs and fuses immediately.