HENDI Water Softener Instruction Manual

You should read this user manual carefully before using the appliance.

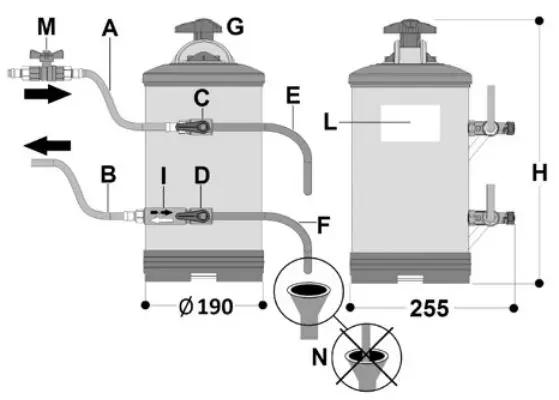

EQUIPMENT ILLUSTRATION

LEGEND (fig. 1):

- A. WATER INLET PIPE

- B. WATER OUTLET PIPE

- C. WATER INLET TAP

- D. WATER OUTLET TAP

- E. DEPRESSURIZATION PIPE

- F. REGENERATION PIPE

- G. TANK LID

- I. CHECK VALVE

- L. LABEL

- M. STANDARD TAP

- N. FLOOR SINK

RINSING AND ACTIVATION

SERVICE MODE

DEPRESSURIZATION AND SALT-REFILLING MODE

CLEANING

RINSING MODE

WARNINGS FOR THE USER

– This equipment must not be used by children or by people with physical, mental or sensory impairments, or by people lacking experience, unless they be supervised by someone responsible for their safety, or they received instructions regarding the correct and safe way to use the equipment and were warned of the risks.

– Never try to repair the equipment by yourself: you may cause damage. Ask your seller for assistance.

– Never touch or use the water softener with wet or damp hands or feet, or barefoot.

1. INTRODUCTION AND GENERAL INFORMATION

1.1 OBJECTIVE OF THE MANUAL

This instruction manual is addressed to qualified personnel who must have knowledge of the health and safety norms of the place of installation. The objective of this manual is to give useful information and warnings, both to the installer and the user, regarding:

HOW TO STORAGE AND KEEP THE EQUIPMENT BEFORE USE:

- Place and room conditions

- Expiry date

FOR THE INSTALLER - Precautions for hygienic safety

- Equipment description and characteristics

- Place and mode of installation

- Activation

- Procedures to follow after a period of inactivity of the equipment

- Equipment disposal

- Solutions to some problems

FOR THE USER - Instructions for the periodic rinsing of the resins

- Instructions for the care and cleaning of the equipment

- Health and hygiene warnings concerning the water produced by the equipment

The manual also gives you the guidelines to avoid an improper use of the equipment and it specifies the installer and the user’s responsibilities, therefore we suggest reading through this manual before installing or using the water softener. If the dispositions are not followed, the manufacturer will decline responsibility for any damage caused to people, things or animals, and will consider the guarantee null and void.

1.2 KEEPING THE MANUAL

This manual is an integral part of the product. It must be kept with care by the user and it must accompany the equipment, even in case of a propriety transfer.

1.3 EQUIPMENT IDENTIFICATION

The equipment is identified by the numbers written in bold on the bottom left side of the label (fig. 1, L) on the softener’s tank, on the package and on the back of this manual.

1.4 DECLARATION OF COMPLIANCE

This product complies with the Community Regulations and national laws applicable at the moment of its entrance on the market. The declaration of compliance signed by the manufacturer is available on request and online.

1.5 HYGIENIC SAFETY NORMS AND ICIM TESTING

This equipment has been tested by the ICIM Institute of Italian

Instruction Manual Water Softener Certificated for the Mechanic, licensed credited labor-tory , certificated to the compliance with:

• Reg. n.1935/2004/CE products and components contact with elements according to the dispositions MOCA.

• D.M. n.174/2004 products and components utilized in contact with feed water.

It is NECESSARY to use original replacements for repairs and maintenance, to guarantee hygienic safety. To preserve hygienic safety, we commend removing the equipment from the package only at the moment of installation.

1.6 RECOMMENDATIONS AND WARNINGS

FOR THE STORAGE:

- Storage the water softener in a dry place

- The temperature in the storage must be between 0 – 35 °C

- We recommend using the equipment within 24 months

FOR THE INSTALLER We suggest installing the equipment after carefully reading the instruction manual. Should complications arise, we suggest asking your seller for assistance. The seller’s information is written on the last page of this manual.

FOR THE USER

- Never try to repair the equipment by yourself: you may cause damage. Ask your seller for assistance.

- For manual regeneration and regular salt refilling’s, read the

“ACTIVATION AND INSTRUCTIONS FOR REGENERATION”. - Cleaning the water softener is part of the user’s duties.

The manufacturers are not responsible for any damage or harm that may derive by not following these precautions.

2. ABOUT THE EQUIPMENT

2.1 HOW DOES IT WORK?

The cationic resins in the softener’s tank transform calcium carbonate in sodium carbonate, which is water-soluble at the working temperatures of both coffee makers and ice makers machines. The transfer of sodium ions between the resins and water is imperative to soften drinking water, but this process tends to decline in proportion to the flow rate and the consumption of water. For this reason, it is necessary to regenerate the exhausted resins by making water and salt flow through them, therefore returning them to their active state. The resins gradually lose their cationic function, and consequently their efficiency, with each regeneration. We recommend replacing them after seven years of use.

2.2 EQUIPMENT DESCRIPTION

(fig. 1) The main components of the water softener are:

- 1 tank containing the resins for water softening

- 2 three-way taps (fig. 1, C-D)

- 1 tank lid (fig. 1, G)

2.3 THE PACKAGING CONTAINS

- 1 complete water softener

- 1 instruction manual

- 2 drain pipes (fig. 1, E-F)

2.4 TECHNICAL FEATURES

Pressure of feed water:. . . . . . . . 0,1 ÷ 0,8 MPa (1 ÷ 8 bar)

Nominal flow rate at 4 bar: . . . . . 1000 l/h

Room temperature: . . . . . . . . . . 4°C – 35°C

Joints for the connection to the water system:3/8″G; 3/4″G (fig. 3)

2.5 CHARACTERISTICS OF FEED WATER

Feed water must be:

- Drinkable and clean (SDI 1)

- Temperature must be between 6° and 25°C

- Hardness must be below 900 ppm CaCO3 (90°f)

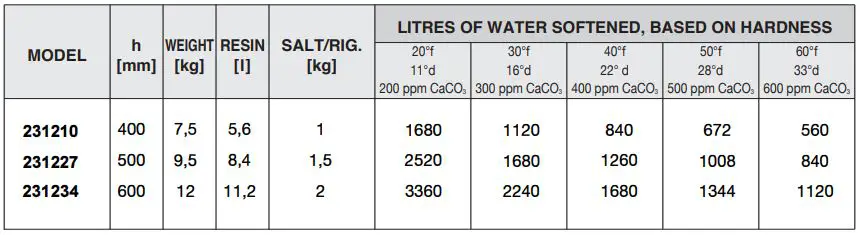

2.6 EQUIPMENT PERFORMANCE BASED ON WATER HARDNESS

3. INSTALLATION

3.1 PACKAGING

- Before the installation, check that the equipment was not damaged by the transport and does not show any anomaly. If in doubt, ask your seller, whose information is written on the back of this manual.

- Don’t throw the package away for some time, being careful to keep any dangerous or small parts of the package away from children.

3.2 CHOOSING THE PLACE OF INSTALLATION

- Ensure that any other water treatment machine is not present upline of the place of installation.

- Ensure that feed water comes from a drinking water pipe.

We recommend checking the chemical and physical parameters of the drinking water as well as its hardness before installation. - Install the equipment near a floor sink, to dispose of the waste water produced by the regeneration.

- Install the equipment in a dry place that can be easily accessible to maintain, regenerate and clean the equipment. Do not install the equipment in dirty and unhygienic places, or in any place difficult to clean.

- Ensure that room temperature in the place of installation is between 4°C and 35°C.

- Keep away from corrosive or acid products.

- Do not install in places where electric safety norms or personal safety norms are openly disregarded.

- Hydric pressure must not be under 0.1 Mpa (1 bar) or over 0.8 Mpa (8 bar). (We recommend at least 3 or 4 bar)

- If hydric pressure is over 8 bar, it is necessary to install a pressure adaptor.

- Salt packages or boxes must not be kept in humid places or in direct contact with the floor: keep it, for example, on a wooden pallet.

3.3 CONNECTION TO THE WATER SYSTEM (fig.1)

The connection of the equipment to the water system must be done according to all applicable norms, following the instructions of the manufacturer and qualified personnel. During the installation use pipes, hoses, valves and components which comply with the applicable Italian norm on hygienic safety, the Ministerial Decree 174/2004. They must be kept in their sealed package until the moment of installation to preserve their hygienic safety. It is forbidden to use components that are not suitable for drinking water contact, or components which hygienic safety was compromised, as they could corrupt the quality of treated water and the equipment itself. Connect the water inlet (fig. 1, A) and outlet (fig.1, B) to the connection joints (fig.3) of the water softener, tightening them safely

Ensure that:

- The water inlet and outlet pipes (fig. 1, A and B) comply with the norms on drinking water pipes.

- The water inlet pipe (fig 1, A) has an internal diameter of at least 7 mm.

- A standard tap (fig. 1, M) must be installed by the user between the water system and the water softener, to ensure that water flow can be interrupted in case of necessity.

- Install on the water outlet a check valve (fig. 1, I) (DVGW, DIN 1988 T2) to protect the water softener from a reverse flow of hot water that could cause damage.

- Install a tap to take a sample of the outlet water, to test its hardness. All pipes must be free, not crushed or constricted.

3.4 CONNECTION TO THE DRAIN SYSTEM

Waste water resulting from the regeneration is funneled into the floor sink by the flexible pipe (fig.1, F) included in the package.

Warning: keep the drain pipe suspended over and not immersed in the water of the sink (fig. 1, N).

At the end of the installation, before opening the water inlet and outlet taps (fig. 1, C-D), rinse the resins as explained in the chapter “Activation and instructions for the regeneration”.

4. ACTIVATION AND INSTRUCTIONS FOR THE REGENERATION

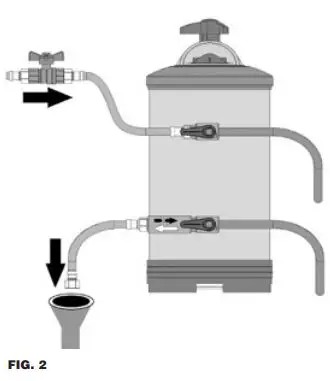

4.1 RINSING THE RESINS (fig. 2)

Put the water outlet pipe in the floor sink. Turn the tap levers on the left and open the standard tap to let the water in. Let the water flow until it is clear, then close the standard tap (fig.1, M) and connect the water outlet pipe to the machine of your choice.

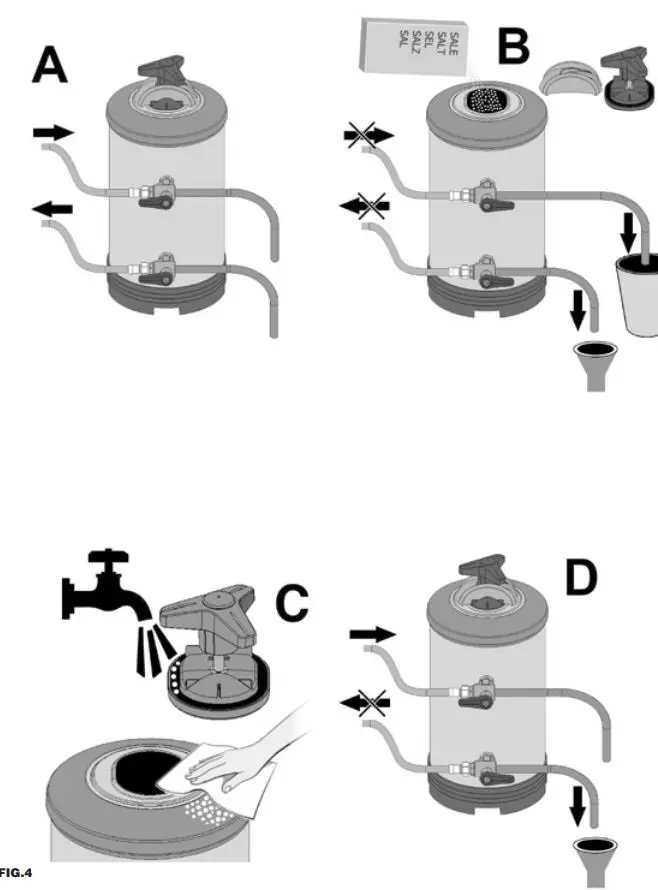

4.2 PERIODIC REGENERATION (fig. 4)

• Position B (DEPRESSURIZATION MODE)

1) Put the depressurization pipe in a bucket (fig. 1, E and fig. 4, position B)

2) Turn the tap levers on the right and wait until depressurization.

3) Remove the lid (fig. 1, G) and add the required quantity of Instruction Manual Water Softener salt according to the model (see the table at paragraph 2.6)

• Position C (CLEANING)

Clean the lid and the seal (fig. 4, C) from any salt residue. Clean the upper part of the water softener from any salt residue and clean the tank and under the cover of the weld joint of any leaked salt water.

The manufacturer does not take responsibility for the corrosion of the tank caused by the failure to follow these instructions.

4) Put the lid back on and tighten it.

• Position D (RINSING MODE)

5) Turn the water inlet tap lever (fig. 1, C) on the left

6) Let the salt water come out from the drain pipe until the water is fresh (around 40 minutes)

• Position A (SERVICE MODE)

7) Put the water softener back in service mode by turning the water outlet tap lever back on the left (fig.1, D)

WARNING: during the regeneration, the machine connected to the water softener does not receive drinking water.

5. MAINTENANCE FOR THE INSTALLER:

5.1 CHANGING THE RESINS

The resins’ softening capacity ends after 5-7 years. This period can change based on the characteristic of the feed water and the quantity of softened water. After this period of time, the user needs to decide if it is enough to change the resins or if it is better to change the water softener itself. To change the resins it is necessary to disconnect the water softener and bring it to an appropriate place. To disconnect the water softener:

- 1) Close the main water inlet tap (fig. 1, M)

- 2) Put the depressurization pipe in a bucket (fig. 1, E and fig. 4, Position B).

- 3) Turn the tap levers on the right, as in fig. 4, Position B.

- 4) Wait a few seconds until depressurization.

- 5) When water stops coming out of the depressurization pipe (fig. 1, E) it is possible to unscrew the inlet and outlet pipes (fig. 1, A and B) from the joints (fig. 3).

- 6) Open the lid (fig. 1, G) and change the resins. Clean the interior of the tank before inserting the new resins.

Do not throw the exhausted resins in the sewers. The resins are not biodegradable and must be considered a non-hazardous waste (EU code CER 190905). After changing the resins, clean the lid seal and the upper part of the softener from any resin residue. - 7) Close the lid (fig. 1, G) and bring the softener back to its installation place.

- 8) Connect the water inlet and outlet pipes to the joints (fig. 3) and tighten them.

- 9) Rinse the resins as explained in paragraph 4.1.

5.2 RESIN PRESERVATION AND ACTIVATION AFTER A LONG PERIOD OF INACTIVITY

If the water softener is not to be used for more than 30 days, it is necessary to do a double regeneration first and then leave the water softener with the lid (fig. 1, G) closed. We suggest avoiding a period of inactivity longer than 12 months. It is forbidden to reactivate the system after this period of inactivity. If the period of inactivity is shorter than 12 months, it is necessary to rinse the resins and do a manual regeneration (paragraph 4.1 and 4.2) before reactivating the equipment.

6. IMPROPER USE OF THE EQUIPMENT

This equipment has been created to soften drinking water for domestic and technological use. The equipment must not be used for any other purpose and it must not be modified or tampered with in any way. Any other use than the one specified in this manual is improper and therefore dangerous. The manufacturer cannot be considered responsible for any damage caused by improper, mistaken or illogical use of the equipment.

- It is forbidden to feed the equipment with any liquid other than drinking water.

- It is forbidden to introduce in the tank any products other than salt (NaCl)

7. EQUIPMENT DISPOSAL

EQUIPMENT FOR DOMESTIC TREATMENT OF DRINKING WATER

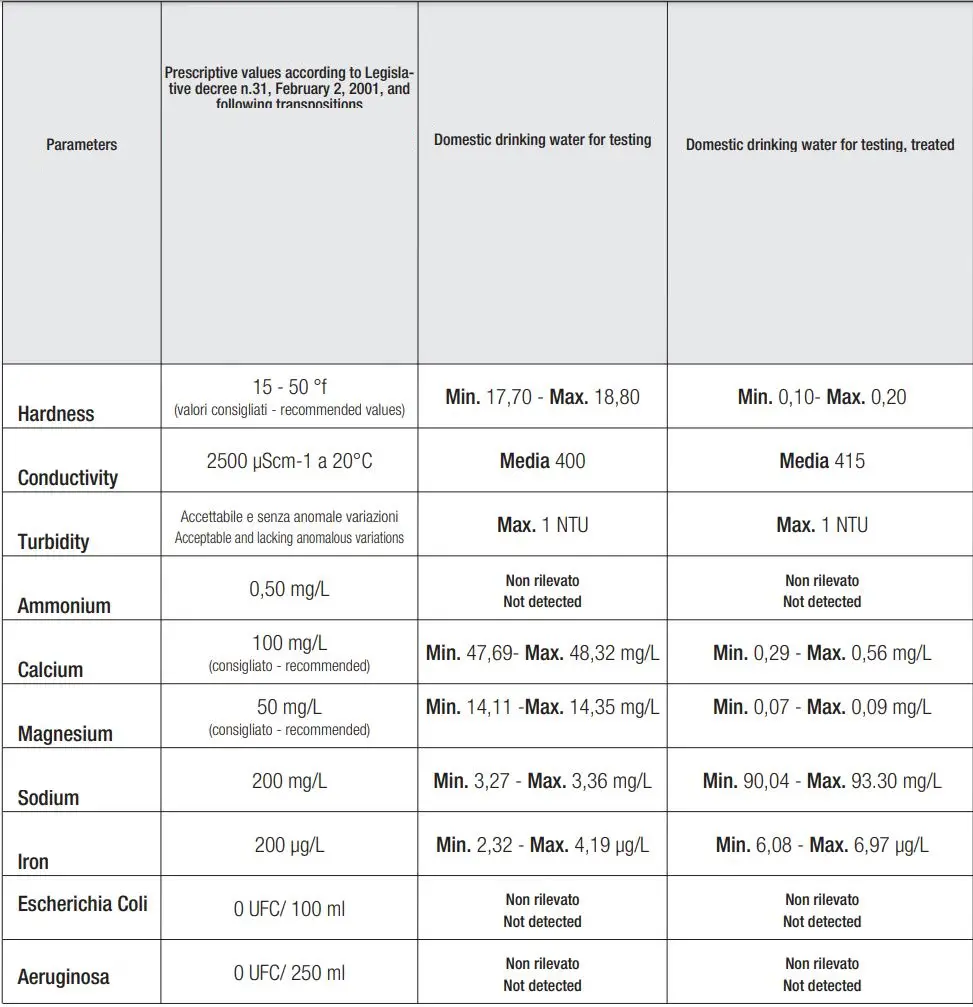

This equipment is a water softener for domestic use, to be connected exclusively with the water system. The following values refer to a test on 2540 liters, with domestic drinking water and 1 cycle of manual regeneration, in compliance with ICIM internal regulations on testing. The parameters comply with the values indicated by the Italian norms on the subject, the Legislative decree n.31, February 2, 2001, and following transpositions.

The drinking water-contact materials of the water softener comply with the parameters requested by the Italian laws (D.M. 6 Aprille 2004, n.174).

WARNING: this equipment needs periodic maintenance to guarantee the treated drinking water requirements and to maintain the features declared by the manufacturer.

THE EQUIPMENT MUST BE USED FOLLOWING THE RULES IN THE MANUAL

Hendi B.V.

Steenoven 21 3911 TX Rhenen, The Netherlands

Tel: +31 (0)317 681 040

Email: [email protected]

Hendi Polska Sp. z o.o.

ul. Magazynowa 5 62-023 Gdki, Poland

Tel: +48 61 6587000

Email: [email protected]

Hendi Food Service Equipment GmbH

Gewerbegebiet Ehring 15 5112 Lamprechtshausen, Austria

Tel: +43 (0) 6274 200 10 0

Email: [email protected]

Hendi UK Ltd.

Central Barn, Hornby Road Lancaster, LA2 9JX, United Kingdom

Tel: +44 (0)333 0143200

Email: [email protected]

Hendi Food Service Equipment Romania Srl

Str. 13 decembrie 94A, Hala 14 Braov, 500164, Romania

Tel: +40 268 320330

Email: [email protected]

PKS Hendi South East Europe SA

5 Metsovou Str. 18346 Moschato, Athens, Greece

Tel: +30 210 4839700

Email: [email protected]

Hendi HK Ltd.

1208, 12/F Exchange Tower 33 Wang Chiu Road,

Kowloon Bay, Hong Kong

Tel: +852 2154 2618

Email: [email protected]

Find Hendi on internet:

www.hendi.eu

www.facebook.com/HendiFoodServiceEquipment

www.linkedin.com/company/hendi-food-service-equipment-b.v.

www.youtube.com/HendiEquipment

– Changes, printing and typesetting errors reserved.